Preparation method of reactive nitrogen-phosphorus flame retardant for aqueous polyurethane

A nitrogen-phosphorus flame retardant, water-based polyurethane technology, applied in the field of flame retardant modified polyurethane flame retardant, can solve the problems of reducing flame retardancy and being susceptible to heat precipitation, and achieves good flame retardant effect, high synthesis efficiency, and structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The steps of this embodiment are as follows:

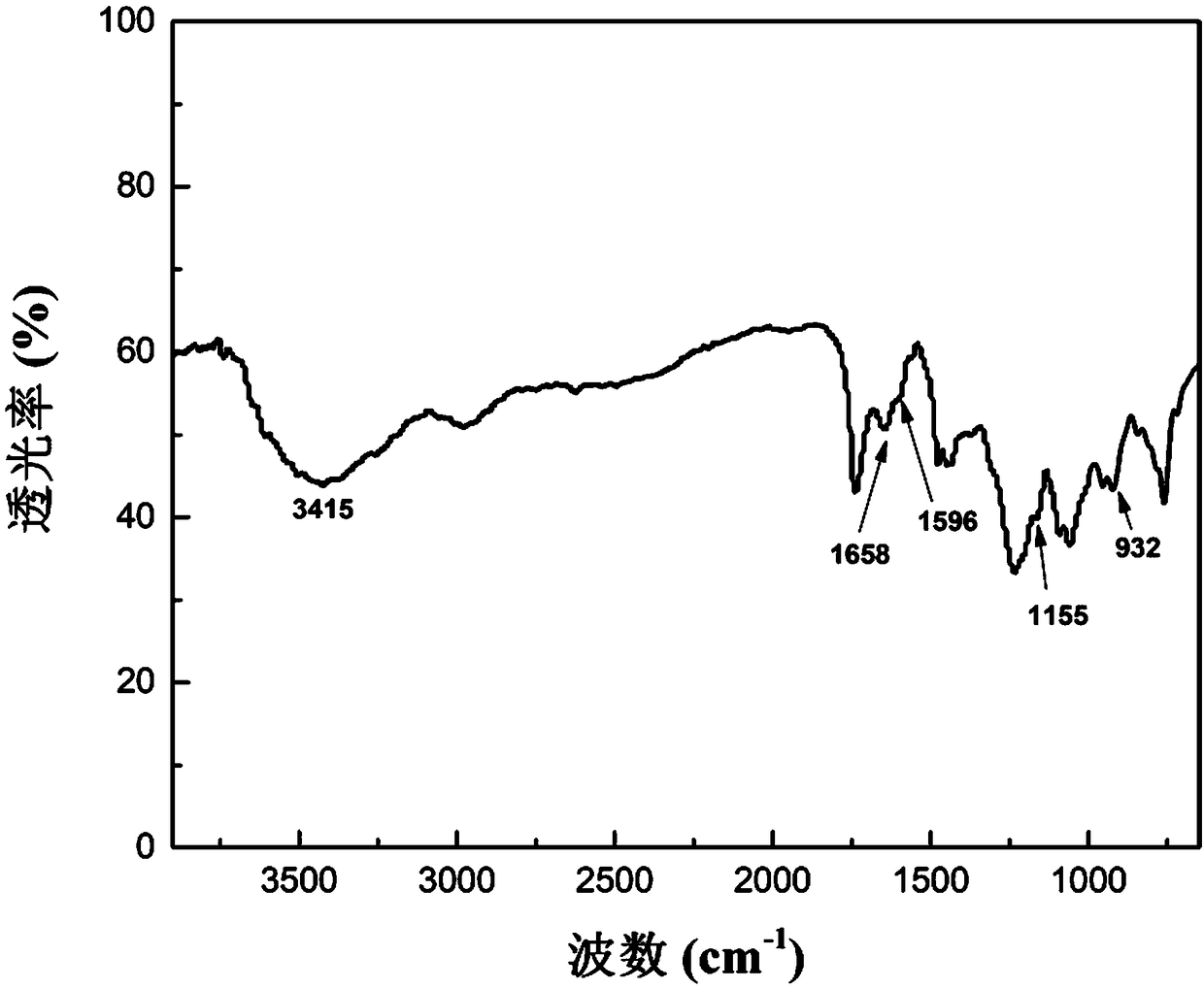

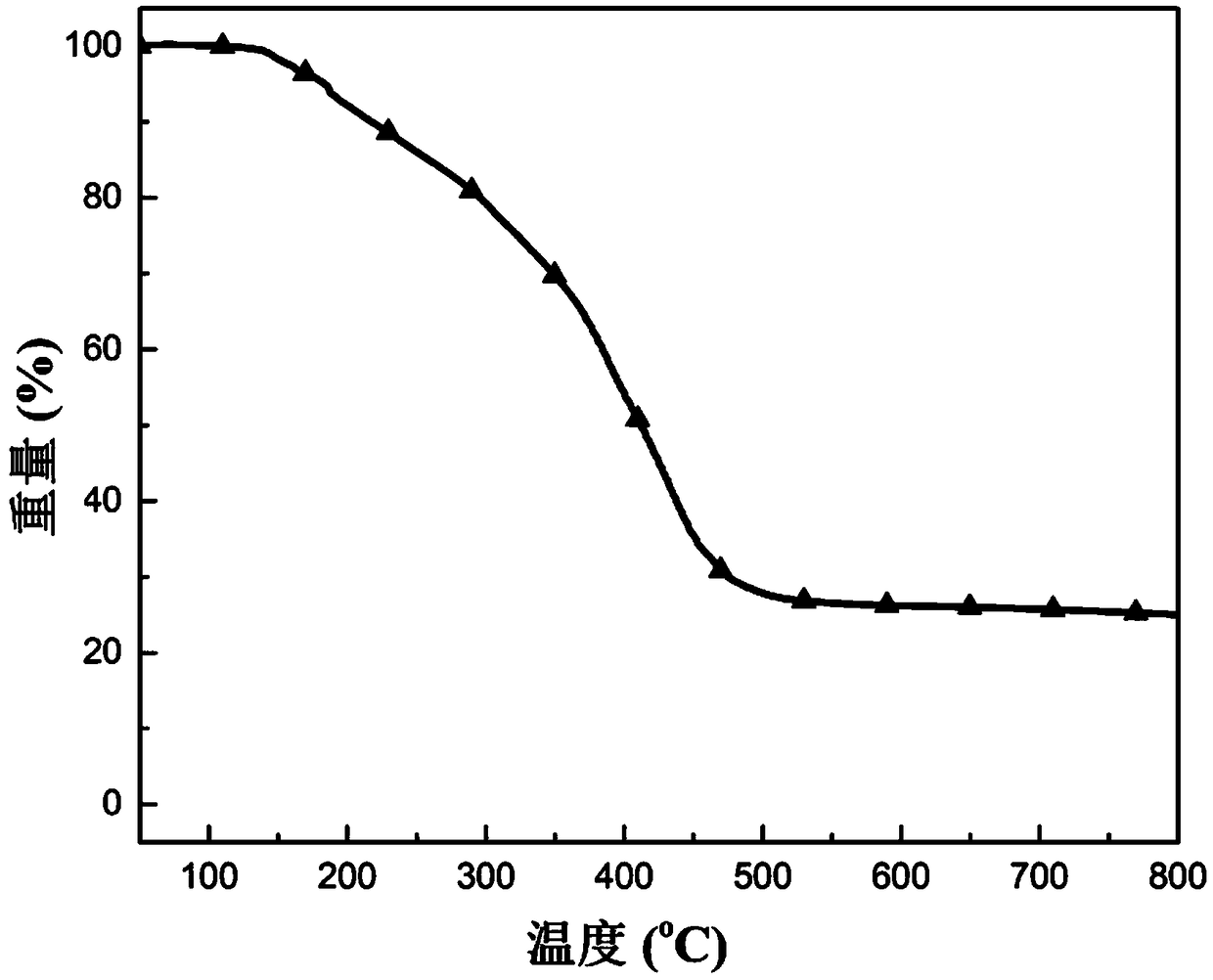

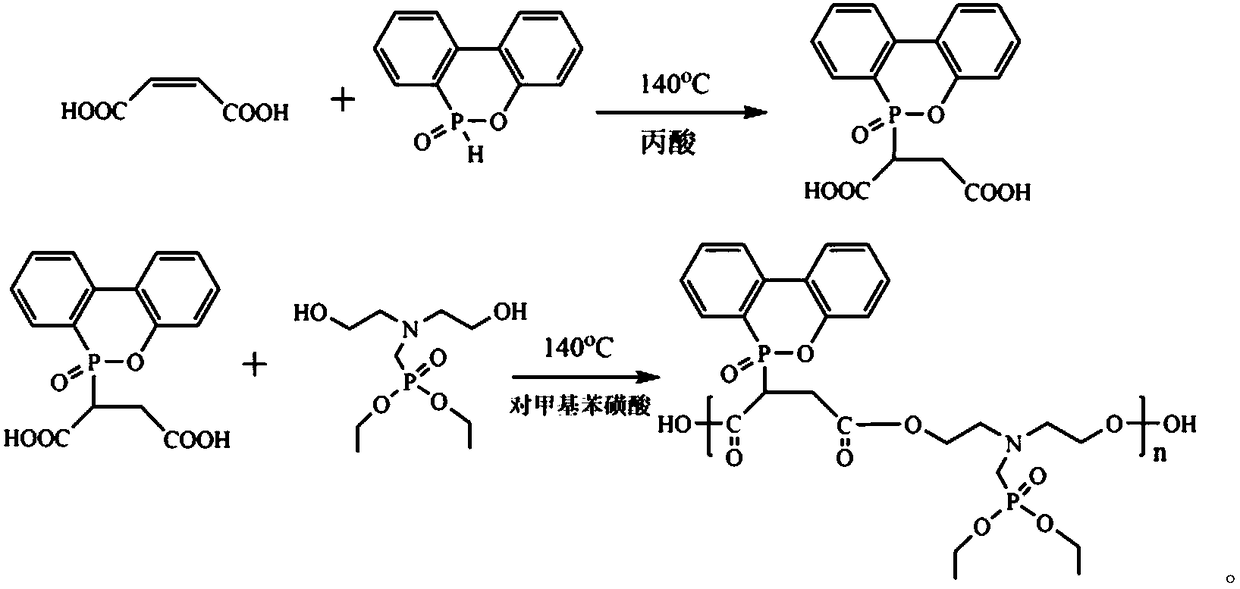

[0027] (1) Preparation of phosphorus-containing derivatives

[0028] Add 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide (DOPO), 2-butene-1,4-dioic acid and solvent propionic acid into the reaction vessel and mix well, Addition reaction was then carried out under stirring at 140°C for 12h. After the reaction time was up, the reaction mixture was vacuum-dried at a vacuum degree of 0.085MPa and a temperature of 40°C for 10h to obtain a phosphorus-containing derivative. The 9, The molar ratio of 10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide, 2-butene-1,4-dioic acid and propionic acid is 1:1:20;

[0029] (2) Preparation of reactive nitrogen and phosphorus flame retardants

[0030] The phosphorus-containing derivative obtained in step (1), N,N-bis(2-hydroxyethyl)aminomethylene phosphonic acid diethyl ester (FRC-6), water-carrying agent toluene and catalyst p-toluenesulfonic acid Add it into the reaction container and ...

Embodiment 2

[0040] The steps of this embodiment are as follows:

[0041] (1) Preparation of phosphorus-containing derivatives

[0042] Add 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide (DOPO), 2-propylene-1,2-dicarboxylic acid and solvent butanoic acid to the reaction vessel and mix uniform, and then add reaction at 180°C for 24 hours under stirring. After the reaction time is up, the reaction mixture is vacuum-dried at a vacuum degree of 0.095MPa and a temperature of 60°C for 24 hours to obtain a phosphorus-containing derivative. The molar ratio of 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide, 2-propylene-1,2-dicarboxylic acid and butyric acid is 1:3:100;

[0043] (2) Preparation of reactive nitrogen and phosphorus flame retardants

[0044] Add phosphorus-containing derivatives obtained in step (1), N,N-bis(2-hydroxyethyl)aminomethylenephosphonic acid diethyl ester (FRC-6), water-carrying agent xylene and catalyst thionyl chloride Mix evenly in the reaction container, and...

Embodiment 3

[0047] The steps of this embodiment are as follows:

[0048] (1) Preparation of phosphorus-containing derivatives

[0049] Add 9,10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide (DOPO), 2-methyl-2,5-furandione and solvent benzene into the reaction vessel and mix well, Addition reaction was then carried out under stirring at 160°C for 16h. After the reaction time was up, the reaction mixture was vacuum-dried for 20h at a vacuum degree of 0.090MPa and a temperature of 50°C to obtain a phosphorus-containing derivative. The 9, The molar ratio of 10-dihydro-9-oxa-10-phospha-phenanthrene-10-oxide, 2-methyl-2,5-furandione and benzene is 1:2:80;

[0050] (2) Preparation of reactive nitrogen and phosphorus flame retardants

[0051] With step (1) gained phosphorus-containing derivative, N,N-bis(2-hydroxyethyl)aminomethylene phosphonic acid diethyl ester (FRC-6), water-carrying agent ethylbenzene and catalyst concentrated hydrochloric acid (mass concentration greater than 20%) into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com