Method for producing poly aluminum chloride by using byproduct of diethyl methylphosphonate production

A technology of diethyl methyl phosphite and polyaluminum chloride, applied in aluminum chloride, aluminum halide, alkali metal chloride, etc., can solve the problems of pollution, high equipment requirements, excessive metal element content, etc. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

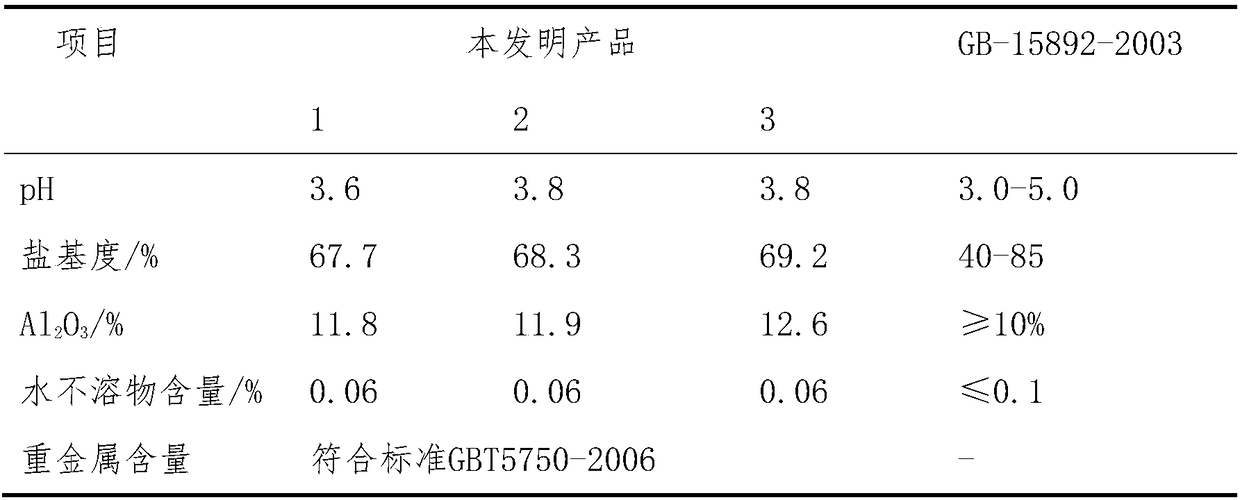

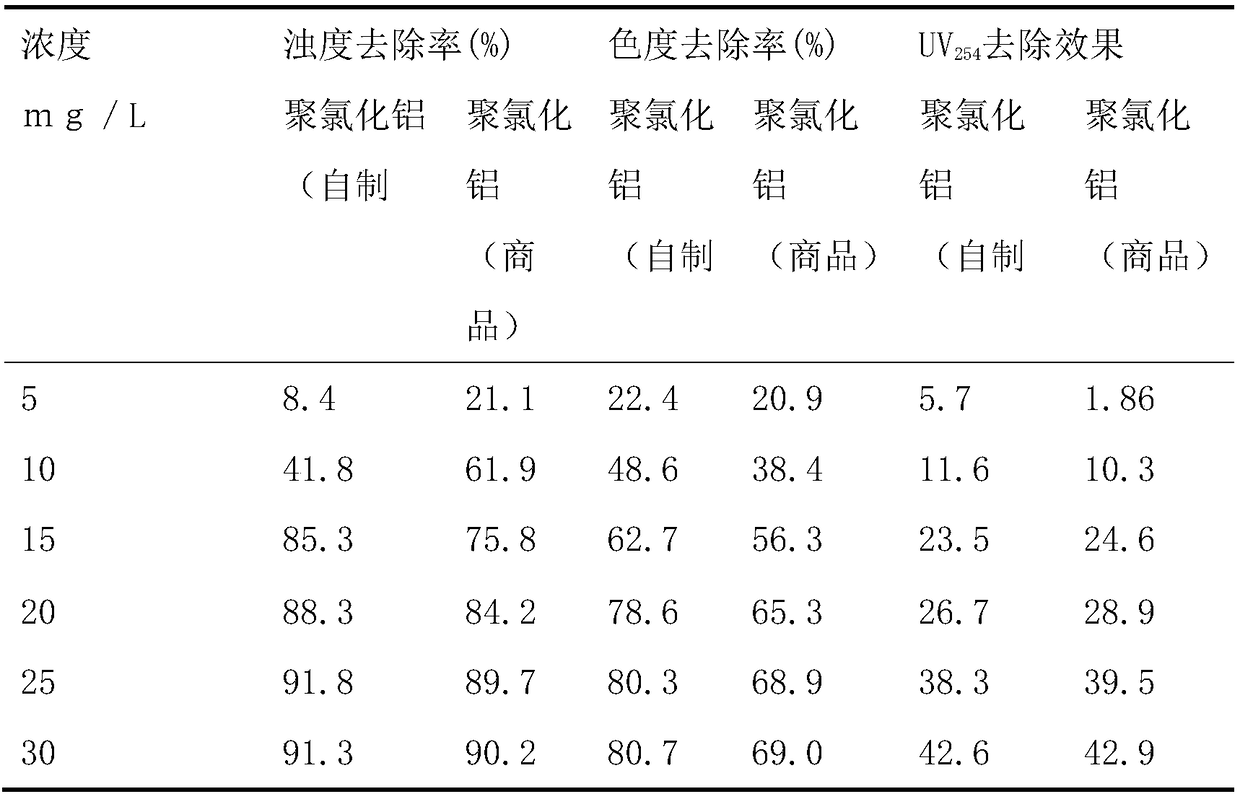

Embodiment 1

[0042] The present invention comprises the following steps:

[0043] (1), slowly put 7 parts of sodium tetrachloroaluminate, a by-product rich in sodium tetrachloroaluminate in the production process of diethyl methylphosphonite, into the dissolution kettle for dissolution, and then carry out solid-liquid separation, separation Sodium chloride crystallizes, and the solution is collected;

[0044] (2), the collected solution is added in the reactor, then add 0.2 part of ferric chloride and 1 part of hydrochloric acid, stir and mix for 15 minutes;

[0045] (3) Control the temperature of the reactor to be above 85°C; add 0.1 parts of aluminum hydroxide and 2 parts of calcium metaaluminate in order to carry out polymerization reaction;

[0046] (4) Control the temperature at 100°C and keep it warm for 75 minutes;

[0047] (5), separate after cooling, and the filtrate is the product of the present invention.

[0048] 0.01 part of industrial white oil was added as a defoamer befo...

Embodiment 2

[0052] The present invention comprises the following steps:

[0053] (1), slowly put 7 parts of sodium tetrachloroaluminate, a by-product rich in sodium tetrachloroaluminate in the production process of diethyl methylphosphonite, into the dissolution kettle for dissolution, and then carry out solid-liquid separation, separation Sodium chloride crystallizes, and the solution is collected;

[0054] (2), the collected solution is added in the reactor, then add 0.5 part of ferric chloride and 1 part of hydrochloric acid, stir and mix for 15 minutes;

[0055] (3) Control the temperature of the reactor to be above 85°C; add 1 part of aluminum hydroxide and 2 parts of calcium metaaluminate in order to carry out polymerization reaction;

[0056] (4) Control the temperature at 100°C and keep it warm for 75 minutes;

[0057] (5), separate after cooling, and the filtrate is the product of the present invention.

[0058] 0.02 part of silicone oil was added as a defoamer before the poly...

Embodiment 3

[0062] The present invention comprises the following steps:

[0063] (1), slowly put 7 parts of sodium tetrachloroaluminate, a by-product rich in sodium tetrachloroaluminate in the production process of diethyl methylphosphonite, into the dissolution kettle for dissolution, and then carry out solid-liquid separation, separation Sodium chloride crystallizes, and the solution is collected;

[0064] (2), the collected solution is added in the reactor, then add 0.5 part of ferric chloride and 1 part of hydrochloric acid, stir and mix for 15 minutes;

[0065] (3) Control the temperature of the reactor to be above 85°C; add 1 part of aluminum hydroxide and 2 parts of calcium metaaluminate in order to carry out polymerization reaction;

[0066] (4) Control the temperature at 100°C and keep it warm for 75 minutes;

[0067] (5), separate after cooling, and the filtrate is the product of the present invention.

[0068] 0.03 parts of industrial white oil was added as a defoamer before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com