Lithium battery, silicon composite material for same and method for preparing silicon composite material

A technology of silicon composite materials and composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited performance improvement, low initial charge and discharge efficiency, poor cycle performance of lithium batteries, etc., achieve good cycle performance, improve Effects of initial efficiency, specific capacity, and good liquid absorption and retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

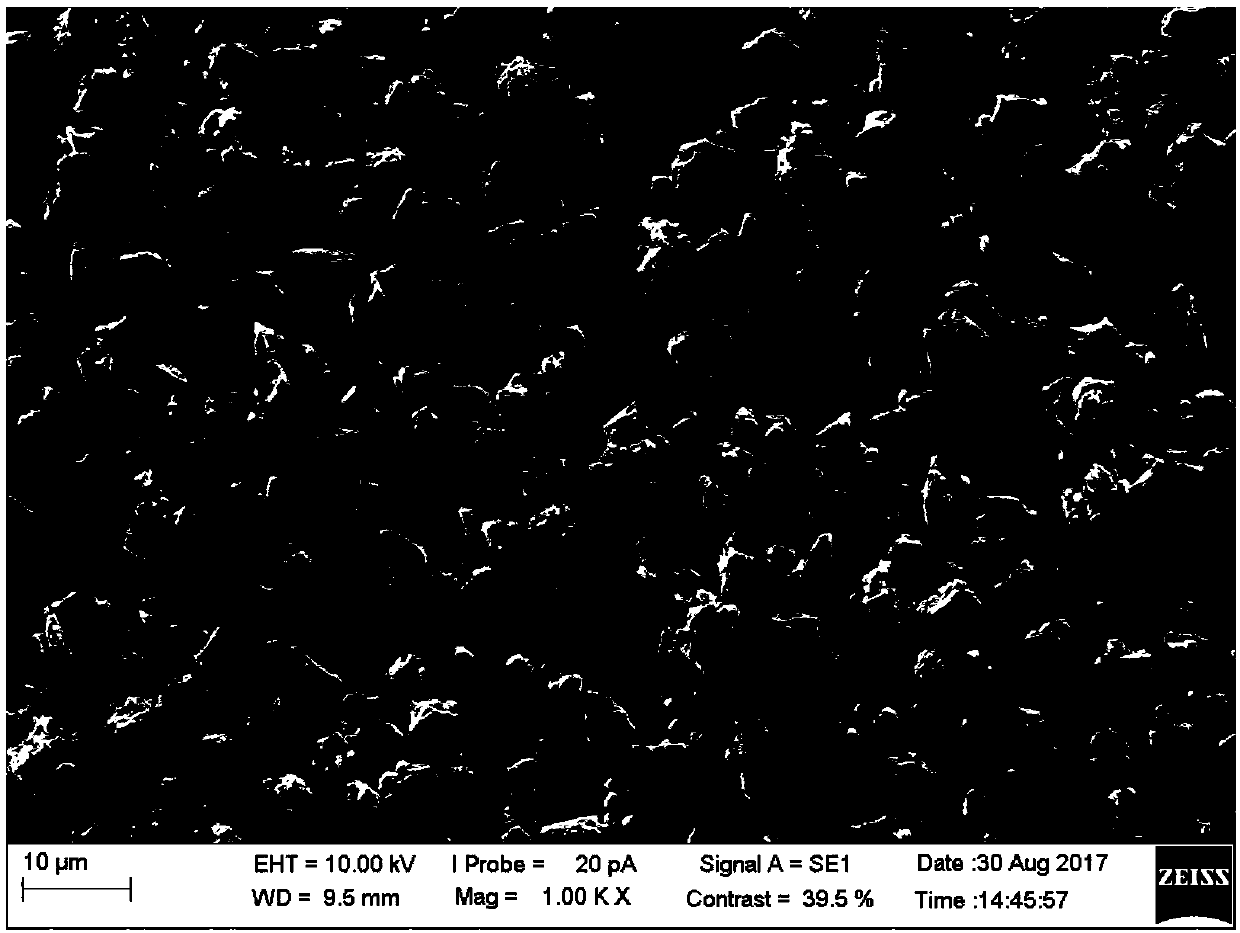

Image

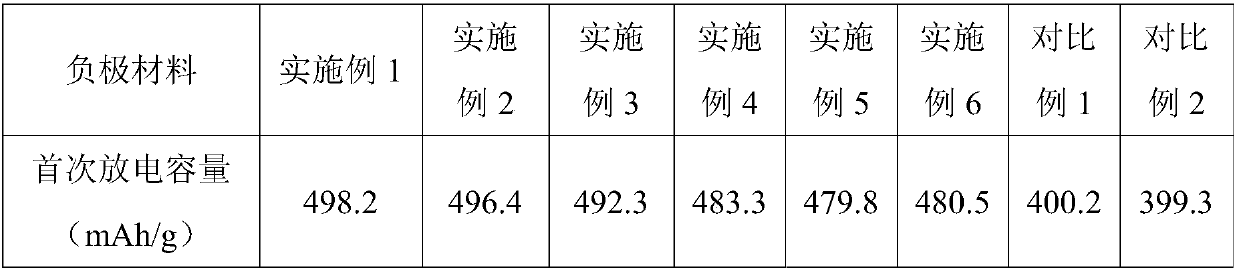

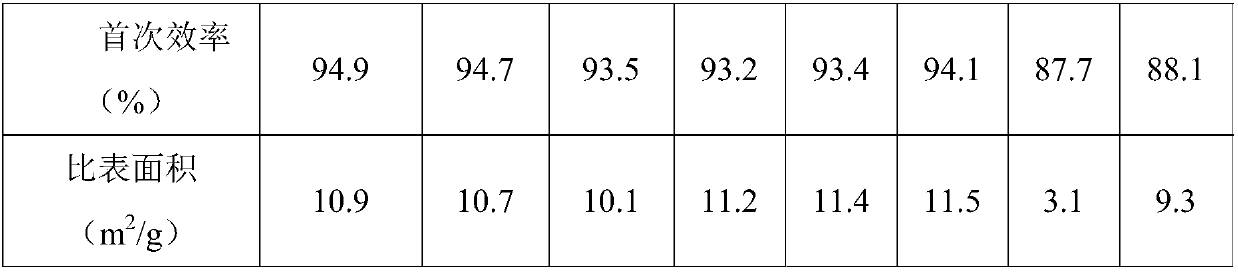

Examples

Embodiment 1

[0036] The silicon composite material for lithium batteries in this embodiment has a core-shell structure, the core of which is nano-silicon particles, and the shell includes two layers, one is the middle layer coated on the surface of the nano-silicon particles, and the other is the middle layer coated on the surface of the nano-silicon particles. The outer layer of the surface. The middle layer is a non-electron-conducting polymer material, and the outer layer includes an inorganic lithium compound and additives. In this embodiment, the non-electron-conducting polymer material is a silane-modified polyamide resin, and the inorganic lithium compound is LiBH 4 , the additive is biphenyl. Nano-silicon, non-electron-conductive polymer materials, LiBH 4 The mass ratio to biphenyl is 10:10:6:1. The thickness of the shell is 500nm, wherein the thickness ratio of the middle layer to the outer layer is 3:2.

[0037] The preparation method of the silicon composite material for lith...

Embodiment 2

[0042] The silicon composite material for lithium batteries in this embodiment has a core-shell structure, the core of which is nano-silicon particles, and the shell includes two layers, one is the middle layer coated on the surface of the nano-silicon particles, and the other is the middle layer coated on the surface of the nano-silicon particles. The outer layer of the surface. The middle layer is a non-electron-conductive polymer material, and the outer layer includes an inorganic lithium compound and an additive. In this embodiment, the non-electron-conductive polymer material is a silane-modified polyester resin, and the inorganic lithium compound is Li 3 N, the additive is biphenyl. Nano-silicon, non-electronic conductive polymer materials, Li 3 The mass ratio of N to biphenyl is 50:50:5:1. The thickness of the shell is 300nm, wherein the thickness ratio of the middle layer to the outer layer is 1:5.

[0043] The preparation method of the silicon composite material fo...

Embodiment 3

[0048] The silicon composite material for lithium batteries in this embodiment has a core-shell structure, the core of which is nano-silicon particles, and the shell includes two layers, one is the middle layer coated on the surface of the nano-silicon particles, and the other is the middle layer coated on the surface of the nano-silicon particles. The outer layer of the surface. The middle layer is a non-electron-conducting polymer material, and the outer layer includes inorganic lithium compounds and additives. In this embodiment, the non-electron-conducting polymer material is silane-modified polyphenol resin. The inorganic lithium compound is LiBNH 6 , the additive is cyclohexylbenzene. Nano-silicon, non-electronic conductive polymer materials, Li 3 The mass ratio of N to cyclohexylbenzene is 5:5:5:1. The thickness of the shell is 600nm, wherein the thickness ratio of the middle layer to the outer layer is 5:1.

[0049] The preparation method of the silicon composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com