Carbon nano tube dispersion liquid and preparation method thereof

A carbon nanotube and dispersion technology, which is applied in the field of carbon nanotube dispersion and its preparation, can solve problems such as the difficulty of large-scale mass production of carbon nanotube dispersion, achieve suitable mass production, improve battery performance, and reduce dispersion costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

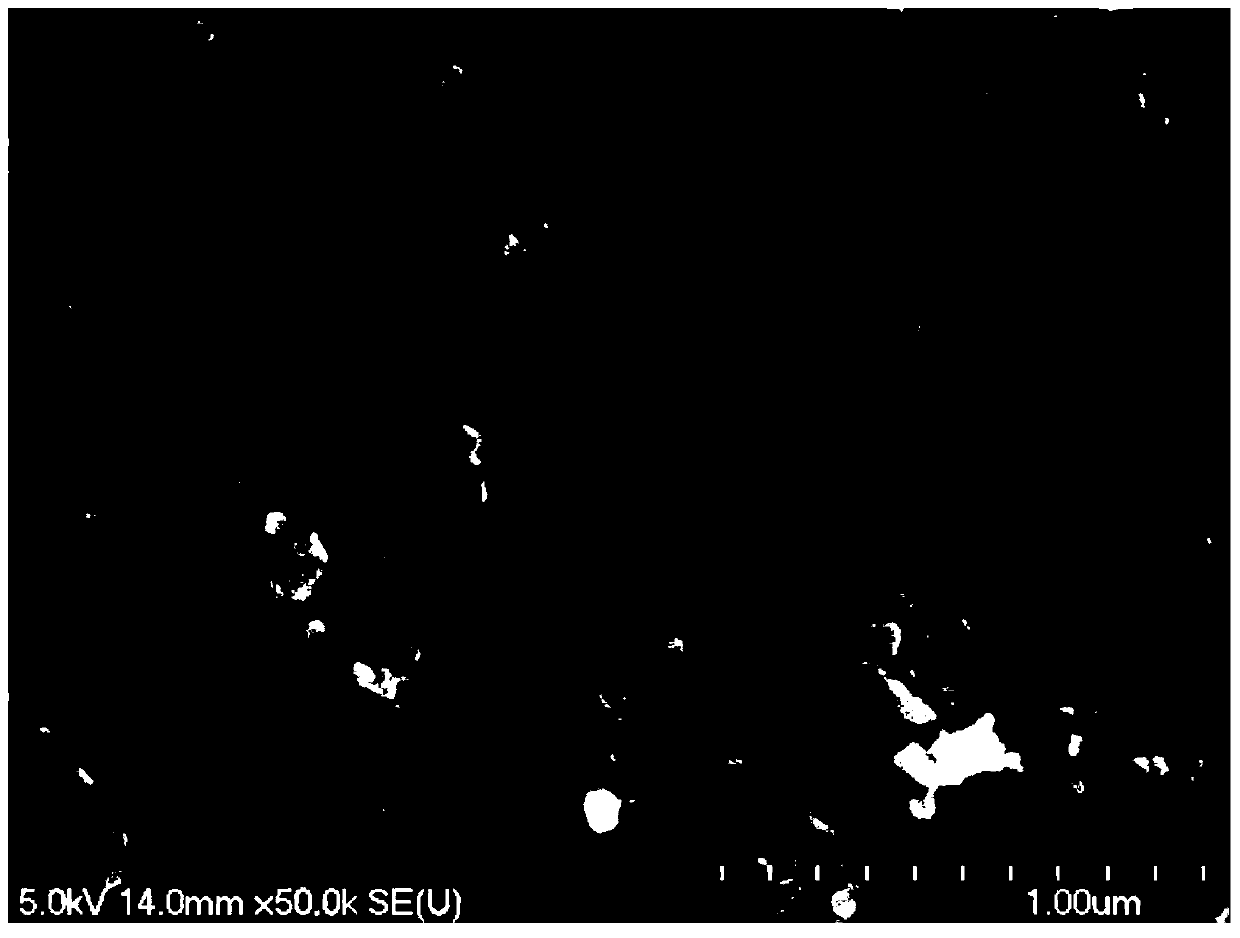

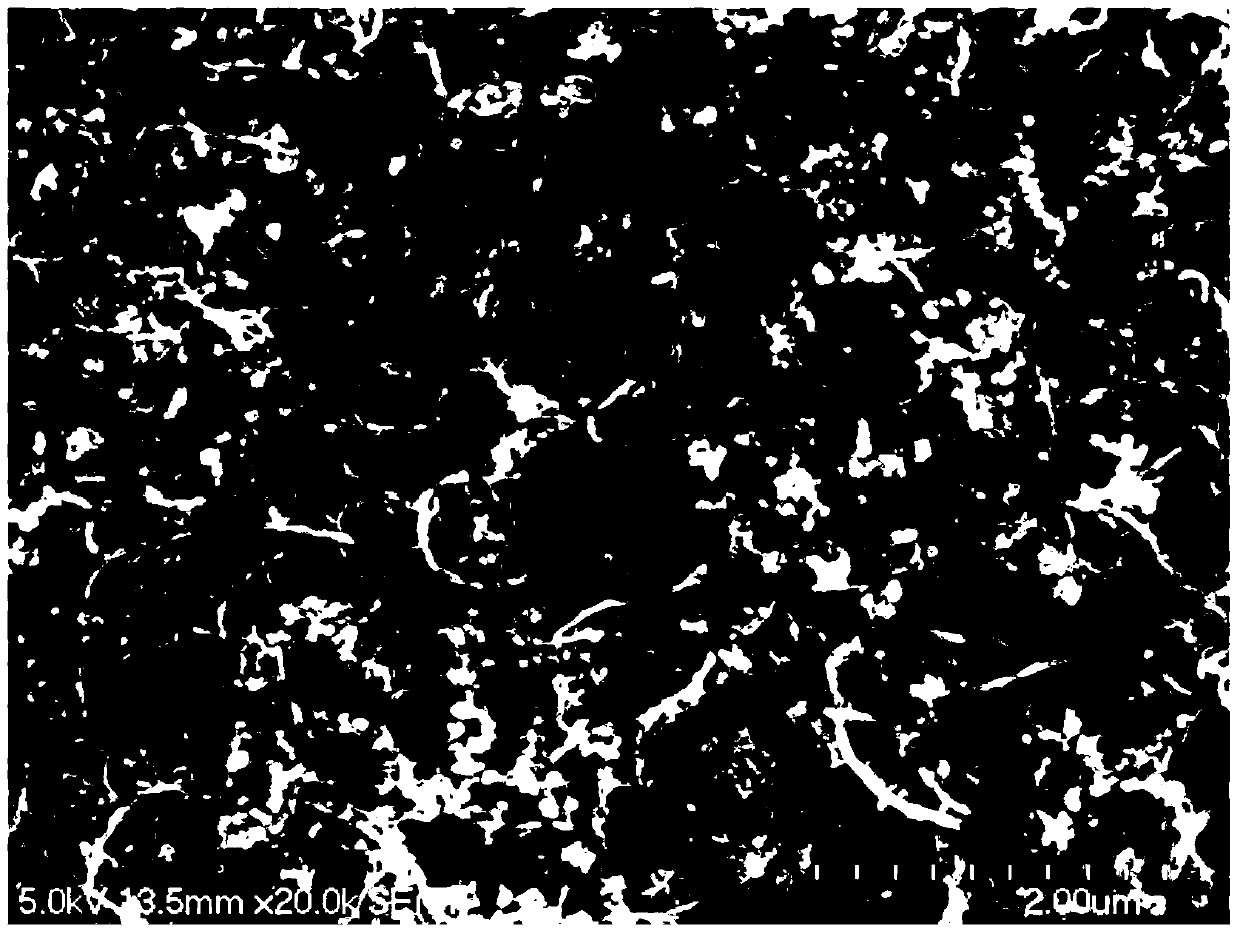

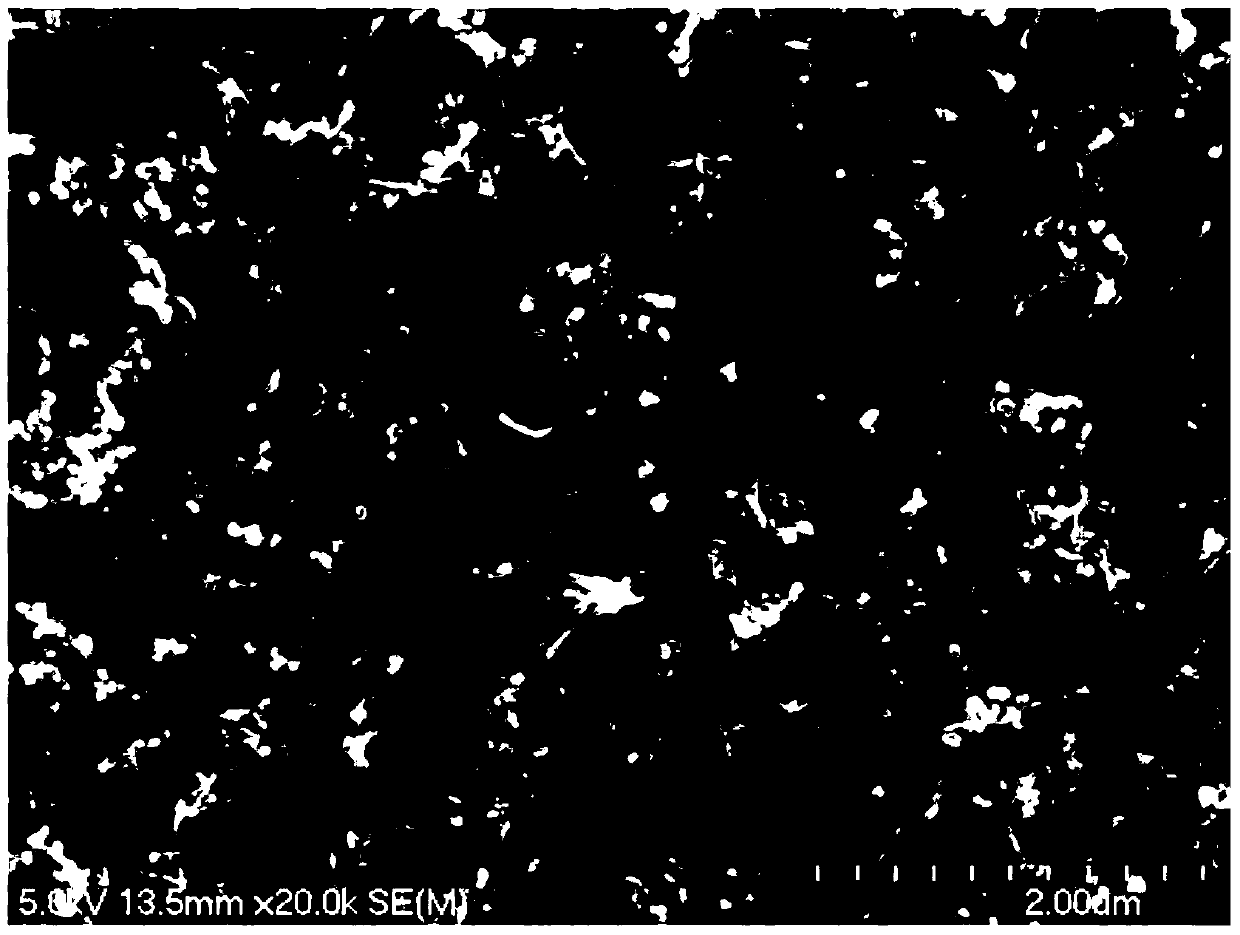

Image

Examples

preparation example Construction

[0021] The invention also provides a method for preparing a carbon nanotube dispersion, the steps of which include: dispersing carbon nanotubes, high-conductivity carbon black and a dispersant in a solvent, and grinding to obtain a carbon nanotube dispersion.

[0022] Wherein, the sequence of adding carbon nanotubes, high-conductivity carbon black and dispersant to the solvent can be added in the manner of solvent, carbon nanotubes, dispersant and high-conductivity carbon black in the present invention, and can also be adjusted according to actual conditions.

[0023] Preferably, the grinding temperature is 20° C. to 60° C., so as to further improve the performance of the carbon nanotube dispersion and avoid re-agglomeration of the dispersed carbon nanotubes caused by high temperature.

[0024] Preferably, the steps include: S1. In an environment with a humidity lower than 30% R.Hs, put part of the solvent N-methylpyrrolidone into a basket sand mill, then add carbon nanotubes, ...

Embodiment 1-4

[0040] (1): In a dehumidified environment at room temperature (humidity lower than 30% R.Hs), pour the solvent N-methylpyrrolidone into the basket sand mill, and reserve enough solvent for dissolving the dispersant polyvinylpyrrolidone . Slowly pour the dispersant polyvinylpyrrolidone into the reserved solvent and keep stirring at a low speed to form a solution. After standing still, the dispersant solution becomes clear and slightly light yellow.

[0041] (2): Turn on the cooling circulating water at 20°C, so that the slurry temperature is between 20°C and 60°C during the sanding process, pour the carbon nanotubes into the solvent in the basket sand mill, and stir at a low frequency of 10Hz Accelerate the wetting of carbon nanotubes for 5-10 minutes, then lift the sanding basket to scrape the edge, then lower the sanding basket, and perform sanding at 35Hz for 0.5-1h.

[0042] (3): Pour the prepared dispersant solution into the basket sand mill, and perform sand milling at 3...

Embodiment 1

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com