Preparation method of high-nickel ternary material used for lithium ion battery

A high-nickel ternary material and lithium-ion battery technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of cycle performance, liquid absorption and retention capacity deviation, etc., to inhibit agglomeration, increase viscosity, and inhibit raw materials The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

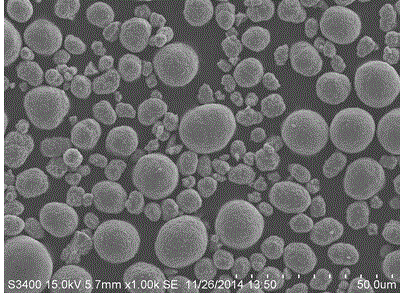

Image

Examples

Embodiment 1

[0014] A preparation method of high nickel ternary material used in lithium ion battery, said ternary material is Li(Ni 0.6 Co 0.2 Mn 0.2 )O 2 , Gram capacity ≥180mAh / g, 2000 cycle life retention rate ≥80%, including the following steps:

[0015] 1. Precursor solution preparation: Weigh 15.78g (0.06mol) NiSO 4 ·6H 2 O, 5.62 grams (0.02mol) C O SO4·7H 2 O, 3.96 grams (0.02mol) MnCl 2 ·4H 2 The O powder was then added to 5 g of polyvinylpyrrolidone and 70 g of double distilled water, and ultrasonically dispersed to obtain a mixed solution A. At the same time, at a temperature of 50 ℃, 8 grams (0.2 mol) of NaOH and 2000 mL of double distilled water were prepared into a 0.1 mol / L NaOH solution and poured into a four-necked flask, and 25.6 grams (0.1 mol) of sodium citrate, 3.5 grams (0.1 mol) ammonia, 4 grams of titanium oxide (0.05 mol) and 0.6 grams (0.05 mol) of activated carbon, stir well to obtain NaOH mixture B. Under uniform stirring, use a constant flow pump to add mixed solu...

Embodiment 2

[0018] A preparation method of a high nickel ternary material used in a lithium ion battery includes the following steps:

[0019] 1. Precursor solution preparation: Weigh 15.78g (0.06mol) NiSO 4 ·6H 2 O, 5.62 grams (0.02mol) C O SO4·7H 2 O, 3.96 grams (0.02mol) MnCl 2 ·4H 2 The O powder was then added to 2.5 g polyethylene glycol and 240 g double distilled water, and ultrasonically dispersed to obtain a mixed solution A. At the same time, at a temperature of 30 ℃, 4 grams (0.1mol) of NaOH and 1000mL of double distilled water were prepared into a 0.1mol / L NaOH solution and poured into a four-necked flask, and 3.7 grams (0.1mol) of ammonium fluoride, 3.5 grams (0.1 mol) ammonia water, 8 grams of titanium oxide (0.1 mol) and 1.2 grams (0.1 mol) of activated carbon, stir well to obtain NaOH mixture B. Under uniform stirring, use a constant flow pump to add mixed solution A to NaOH mixed solution B at a speed of 20 mL / min. After the dripping is complete, continue to stir uniformly fo...

Embodiment 3

[0022] 1. Precursor solution preparation: Weigh 15.78g (0.06mol) NiSO 4 ·6H 2 O, 5.62 grams (0.02mol) C O SO4·7H 2 O, 3.96 grams (0.02mol) MnCl 2 ·4H 2 The O powder was then added to 12 g of soluble starch and 37 g of double distilled water, and ultrasonically dispersed to obtain a mixed solution A. At the same time, at a temperature of 30 ℃, 4 grams (0.1mol) of NaOH and 1000mL of double distilled water were prepared into a 0.1mol / L NaOH solution and poured into a four-necked flask, and 3.7 grams (0.1mol) of ammonium fluoride, 3.5 grams (0.1 mol) ammonia water, 8 grams of titanium oxide (0.1 mol) and 1.2 grams (0.1 mol) of activated carbon, stir well to obtain NaOH mixture B. Under uniform stirring, use a constant flow pump to add mixed solution A to NaOH mixed solution B at a speed of 20 mL / min. After the dripping is complete, continue to stir uniformly for 20 minutes. The above process is completed under the protection of nitrogen. The mother liquor obtained is subjected to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com