Composite positive pole piece for lithium ion battery, preparation method of composite positive pole piece and lithium ion battery

A technology of lithium ion battery and positive pole piece, which is applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of low workshop humidity requirements, corrosion of stainless steel rollers and their knife edges, and increased cost, and achieves Improve the first efficiency and magnification, improve the liquid absorption and retention capacity, and overcome the effect of low tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

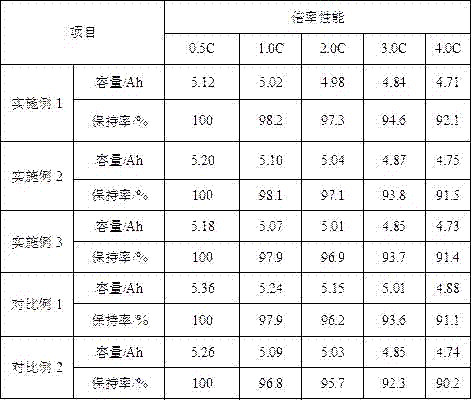

Embodiment 1

[0027] A lithium-ion battery cathode composite pole piece, which has a layered structure, including an inner layer, an intermediate layer and an outer layer, the inner layer is a mesh aluminum foil current collector, the middle layer is a positive electrode active material layer, and the material of the positive electrode active material is ternary Cathode material (Li(Ni 0.5 co 0.3 mn 0.2 )O 2 ), the outer layer is a sprayed layer, and the thickness ratio of the inner layer, the middle layer and the sprayed layer is 25:200:3.

[0028] The preparation method of the lithium-ion battery cathode composite pole piece specifically comprises the following steps:

[0029] S1. Preparation of spraying liquid: First, weigh 3g of polyvinylidene fluoride and add it to 200g of N-methylpyrrolidone, then add 3g of carbon nanotubes after even dispersion, and then add 94g of lithium hexafluoroaluminate , after high-speed dispersion and uniform spraying liquid with a viscosity of 1500mpa•S;...

Embodiment 2

[0034] A lithium-ion battery cathode composite pole piece, which has a layered structure, including an inner layer, an intermediate layer and an outer layer, the inner layer is a mesh aluminum foil current collector, the middle layer is a positive electrode active material layer, and the material of the positive electrode active material is ternary Cathode material (Li(Ni 0.5 co 0.3 mn 0.2 )O 2 ), the outer layer is a sprayed layer, and the thickness ratio of the inner layer, the middle layer and the sprayed layer is 15:100:1.

[0035] The preparation method of the lithium-ion battery cathode composite pole piece specifically comprises the following steps:

[0036] S1. Preparation of spraying liquid: First, weigh 5g of polyvinylidene fluoride and add it to 200g of N-methylpyrrolidone, then add 1g of carbon nanotubes after even dispersion, and then add 94g of lithium hexafluoroaluminate , after high-speed dispersion and uniform spraying liquid with a viscosity of 1000mpa•S; ...

Embodiment 3

[0041] A lithium-ion battery cathode composite pole piece, which has a layered structure, including an inner layer, an intermediate layer and an outer layer, the inner layer is a mesh aluminum foil current collector, the middle layer is a positive electrode active material layer, and the material of the positive electrode active material is ternary Cathode material (Li(Ni 0.5 co 0.3 mn 0.2 )O 2 ), the outer layer is a sprayed layer, and the thickness ratio of the inner layer, the middle layer and the sprayed layer is 30:250:5.

[0042] The preparation method of the lithium-ion battery cathode composite pole piece specifically comprises the following steps:

[0043] S1. Preparation of spraying liquid: First, weigh 1g of polyvinylidene fluoride and add it to 200g of N-methylpyrrolidone, then add 5g of carbon nanotubes after even dispersion, and then add 94g of lithium hexafluoroaluminate , after high-speed dispersion and uniform spraying liquid with a viscosity of 2000mpa•S;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com