Lithium ion battery composite separation membrane and preparation method thereof

A lithium-ion battery and composite diaphragm technology, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of limited liquid absorption and liquid retention, limited application, poor electrolyte wetting ability, etc., and achieves a simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

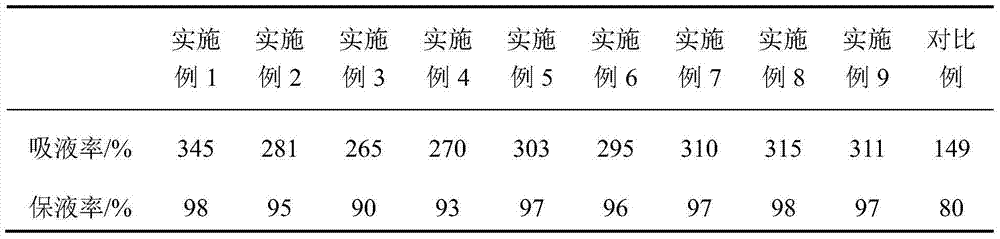

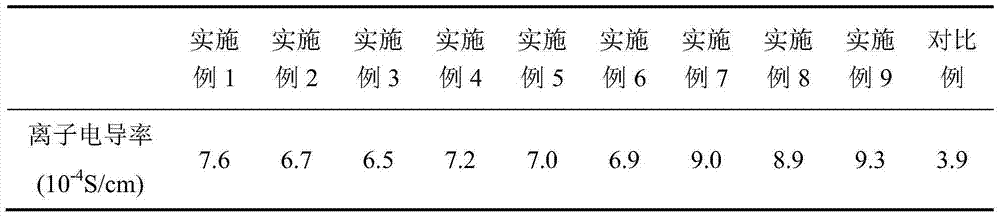

Examples

Embodiment 1

[0036] The preparation method of lithium-ion battery composite diaphragm in the present embodiment is:

[0037] (1) Preparation of modified natural rubber latex: in parts by weight, add 50 parts of water and 1 part of OP-10 to natural rubber latex containing 100 parts of dry rubber, and then add 0.2 parts of grafted monomer methyl methacrylate Ester, 0.005 part of potassium persulfate, 0.005 part of sodium bisulfite, 0.01 part of dodecyl mercaptan and 0.01 part of sodium dodecylsulfonate, heat up under the protection of nitrogen, when the temperature rises to 80 ° C, keep warm for 30 minutes , and then evenly drop 0.8 parts of the remaining grafted monomers, and control the dropwise addition within 2 hours, then continue to react at 80°C for 3 hours, and cool to room temperature to obtain;

[0038] (2) In parts by weight, 5 parts of water and 5 parts of dimethylformamide were added to 100 parts of modified natural rubber latex, mixed evenly, coated on a polyethylene diaphragm,...

Embodiment 2

[0040] The preparation method of lithium-ion battery composite diaphragm in the present embodiment is:

[0041](1) Preparation of modified natural rubber latex: in parts by weight, add 50 parts of water and 3 parts of OP-10 to natural rubber latex containing 100 parts of dry rubber, then add 7.5 parts of grafted monomer maleic anhydride, 0.4 part of potassium persulfate, 0.1 part of sodium bisulfite, 0.1 part of octadecyl mercaptan and 0.1 part of sodium dodecyl sulfonate are heated up under the protection of nitrogen. Evenly add 22.5 parts of the remaining grafted monomers dropwise, and control the dropwise addition within 2 hours, then continue the reaction at 80°C for 3 hours, and cool to room temperature to obtain the product;

[0042] (2) In parts by weight, add 10 parts of water and 30 parts of absolute ethanol to 100 parts of modified natural rubber latex, mix well, coat on a polyethylene diaphragm, cure at room temperature, and dry at 30°C.

Embodiment 3

[0044] The preparation method of lithium-ion battery composite diaphragm in the present embodiment is:

[0045] (1) Preparation of modified natural rubber latex: in parts by weight, add 50 parts of water and 7 parts of Pingpingjiao to natural rubber latex containing 100 parts of dry rubber, then add 20 parts of grafted monomer vinyl acetate, 1 1 part of dibenzoyl peroxide, 0.5 part of dodecyl mercaptan and 0.3 part of octylphenol polyoxyethylene ether, the temperature is raised under the protection of nitrogen, when the temperature rises to 80 ° C, keep warm for 30 minutes, and then evenly add 40 parts The remaining grafted monomers are controlled to be added dropwise within 2 hours, and then continue to react at 80°C for 3 hours, and then cooled to room temperature to obtain the product;

[0046] (2) In parts by weight, 20 parts of water and 100 parts of acetone are added to 100 parts of modified natural rubber latex, mixed evenly, coated on a polyethylene diaphragm, and drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com