Preparation method of lithium titanate/carbon nano tube composite cathode material

A carbon nanotube composite and negative electrode material technology, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of destroying the stable structure of lithium titanate, affecting battery cycle performance, and poor stability of negative electrode materials, so as to achieve high-rate discharge. ability, improve liquid absorption ability and cycle stability, and have good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

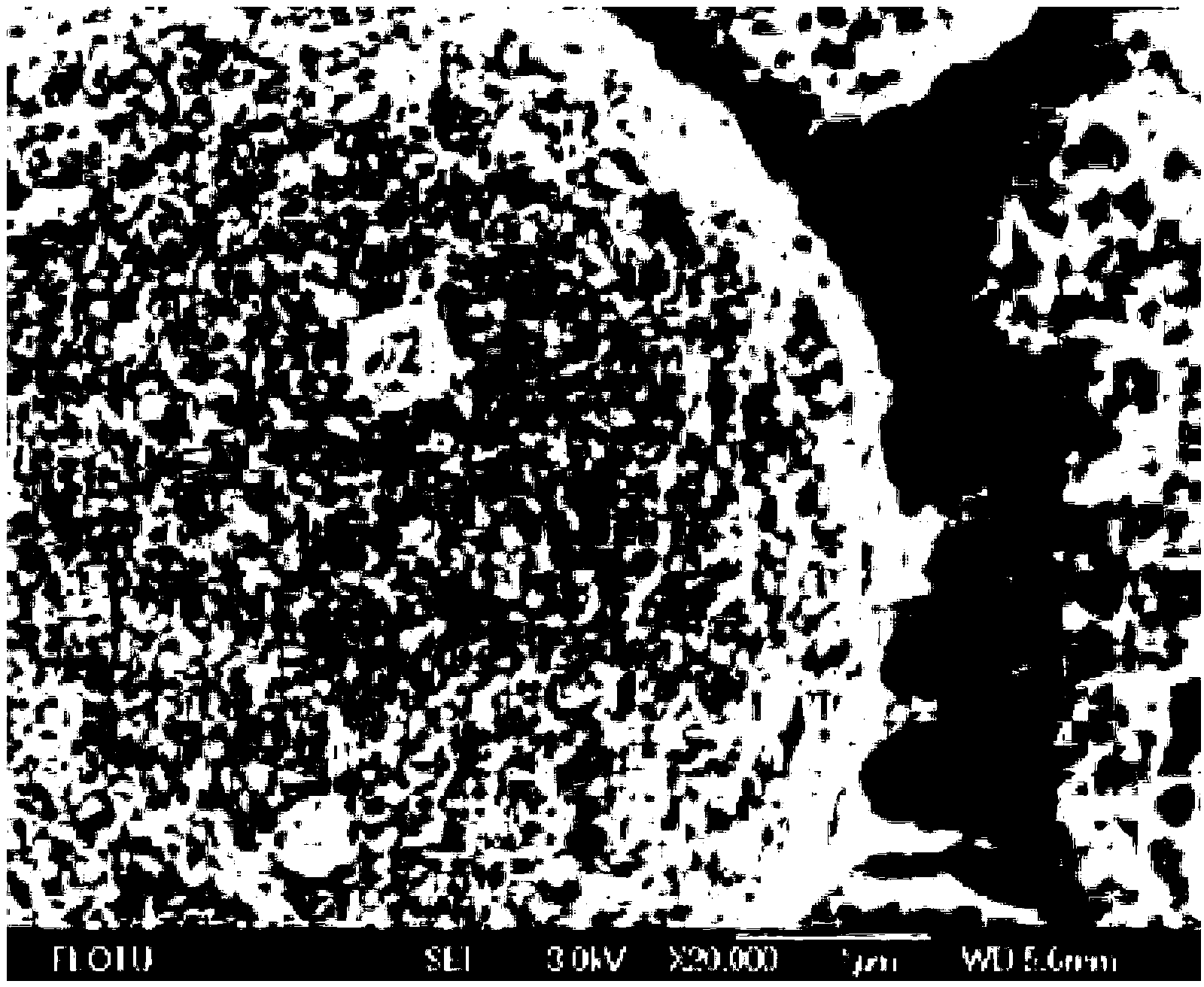

[0025] In this example, the lithium titanate / carbon nanotube composite negative electrode material is prepared by the following method, and the specific steps are:

[0026] (1) Preparation of lithium titanate powder: According to the molar ratio of lithium: titanium: dispersant = 1:1.2:5, take lithium carbonate, titanium dioxide and absolute ethanol, mix them evenly and add them to the planetary ball mill at a speed of 400 rpm / Wet ball milling for 48 hours to obtain a powder with a particle size of 2 μm. The powder was dried at a constant temperature of 100°C for 2 hours, and the dried powder was calcined at 800°C for 12 hours under the protection of argon, and the calcined powder was cooled. Take it out at 100°C, put it into an ultra-fine ball mill and mill it at a speed of 1000 rpm for 120 minutes to obtain lithium titanate powder with a particle size of 1 μm;

[0027] (2) Add an iron catalyst with a particle size of 50 nm to the lithium titanate powder with a particle size...

Embodiment 2

[0030] In this example, the lithium titanate / carbon nanotube composite negative electrode material is prepared by the following method, and the specific steps are:

[0031] (1) Preparation of lithium titanate powder: Take lithium nitrate, titanium dioxide and absolute ethanol according to the molar ratio of lithium: titanium: dispersant = 1:2:3, mix them evenly and add them to the planetary ball mill at a speed of 400 rpm / Wet ball milling at a rotating speed of 48 hours to obtain a powder with a particle size of 5 μm. The powder was dried at a constant temperature of 100 ° C for 3 hours, and the dried powder was calcined at 1000 ° C for 24 hours under the protection of nitrogen. The calcined powder was cooled to Take it out at 100°C, then put it into an ultra-fine ball mill and mill it at a speed of 2000 rpm for 300 minutes to obtain lithium titanate powder with a particle size of 3 μm;

[0032] (2) Add a cobalt catalyst with a particle size of 100 nm to the lithium titanate ...

Embodiment 3

[0035] In this example, the lithium titanate / carbon nanotube composite negative electrode material is prepared by the following method, and the specific steps are:

[0036](1) Preparation of lithium titanate powder: According to the molar ratio of lithium: titanium: dispersant = 1:2:8, take lithium acetate, titanium dioxide and absolute ethanol, mix them evenly and add them to the planetary ball mill at a speed of 400 rpm / Wet ball milling at a rotating speed of 48 hours to obtain a powder with a particle size of 0.5 μm. The powder was dried at a constant temperature of 100°C for 4 hours, and the dried powder was calcined at 600°C for 48 hours under the protection of helium. The calcined powder Cool to 100°C and take it out, then put it into an ultra-fine ball mill and mill at a speed of 1500 rpm for 200 minutes to obtain lithium titanate powder with a particle size of 0.3 μm;

[0037] (2) Add a nickel catalyst with a particle size of 30 nm to the lithium titanate powder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com