Preparation method of high-voltage ternary composition material

A technology of composite materials and ternary materials, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of poor coating effect, poor compatibility between materials and electrolyte, and achieve good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

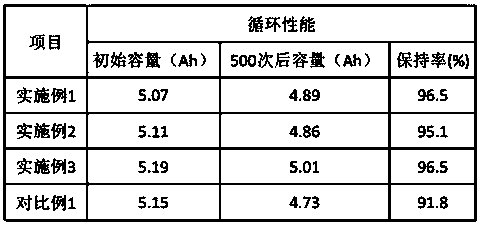

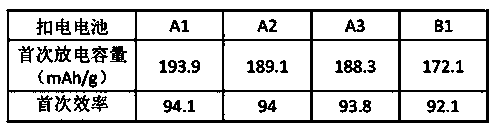

Embodiment 1

[0030] 1. Precursor preparation:

[0031] Using a high-speed mixer to mix 85g Ni 0.6 co 0.2 mn 0.2 (OH) 2 Ternary material precursor powder, 15g of lithium carbonate, 3g of manganese sulfate and 3g of VOSO 4 Mix evenly through a three-dimensional mixer, then place it in a bell furnace, heat up to 750°C at a rate of 8°C / min in an air atmosphere, and keep it at 750°C for 6 hours, then continue to heat up to 900°C for 6 hours, and then heat it up with the furnace Cool down to room temperature, and obtain high-voltage nickel-cobalt-manganese-lithium material A after crushing and sieving;

[0032] 2), coating:

[0033] Weigh 100g of trimethylhexylbis(trifluoromethylsulfonyl)imide, then add 50ml of graphene solution with a concentration of 3%, stir evenly, then add 20g of urea and stir evenly to obtain coating solution B; then Weigh 100g of material A and add it to 800ml of coating solution B, mix evenly, and after stirring evenly, prepare a ternary composite material by spray...

Embodiment 2

[0035] 1.) Precursor preparation:

[0036] Using a high-speed mixer to mix 80gNi 0.6 co 0.2 mn 0.2 (OH) 2Ternary material precursor powder, 10g lithium hydroxide, 1g manganese chloride and 1g (VO 2 ) 2 SO 4 Mix evenly by a three-dimensional mixer, then place it in a bell furnace, raise the temperature to 700°C at a rate of 5°C / min in an air atmosphere, and keep it at 700°C for 12 hours, then continue to heat it up to 850°C for 12 hours at a constant temperature, and then heat it up with the furnace Cool down to room temperature, and obtain high-voltage nickel-cobalt-manganese-lithium material A after crushing and sieving;

[0037] 2), coating:

[0038] Weigh 100g of N-methyl-N-propylpiperidine bis(trifluoromethylsulfonyl)imide (PP13TFSI), then add 20ml, the concentration is 5% graphene solution, after stirring evenly, add 10g Stir the urea evenly to obtain coating solution B; then weigh 100 parts of material A and add it to 500ml of coating solution B and mix evenly. ...

Embodiment 3

[0040] 1) Precursor preparation:

[0041] Using a high-speed mixer to mix 90gNi 0.6 co 0.2 mn 0.2 (OH) 2 Ternary material precursor powder, 20g of lithium carbonate powder, 5g of manganese nitrate and 5g of VCl 3 Mix evenly by a three-dimensional mixer, then place it in a bell furnace, raise the temperature to 800°C at a rate of 10°C / min in an air atmosphere, and keep it at 800°C for 2 hours, then continue to heat it up to 950°C for 2 hours, and then heat it up with the furnace Cool down to room temperature, and obtain high-voltage nickel-cobalt-manganese-lithium material A after crushing and sieving;

[0042] 2), coating:

[0043] Weigh 100g of trimethylhexylbis(trifluoromethylsulfonyl)imide, then add 100ml of graphene solution with a concentration of 1%, stir evenly, then add 30g of urea and stir evenly to obtain coating solution B; After that, 100 parts of material A were weighed and added to 1000 ml of coating liquid B, mixed evenly, and after stirring evenly, a tern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com