Nonwoven fabric ceramic separator, and preparation method and application thereof

A technology of ceramic diaphragm and non-woven fabric, which is applied in the field of electrochemistry, and can solve the problems of powder dropping, affecting the performance of ceramic diaphragm, and poor powder coating uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

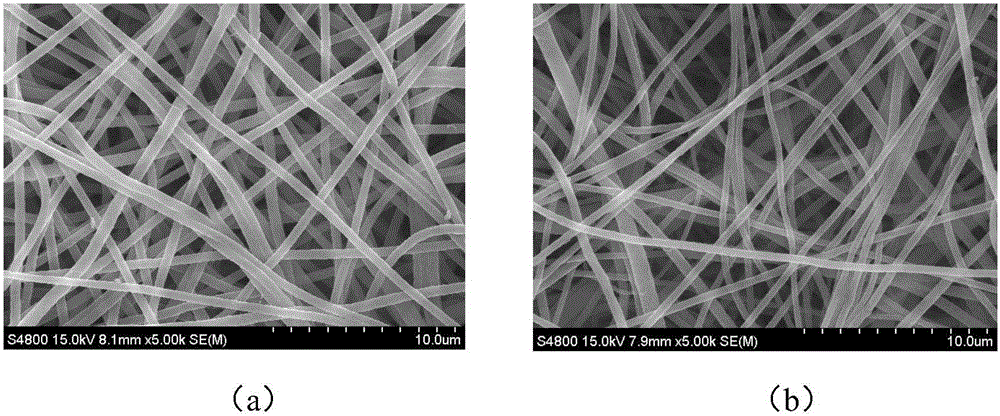

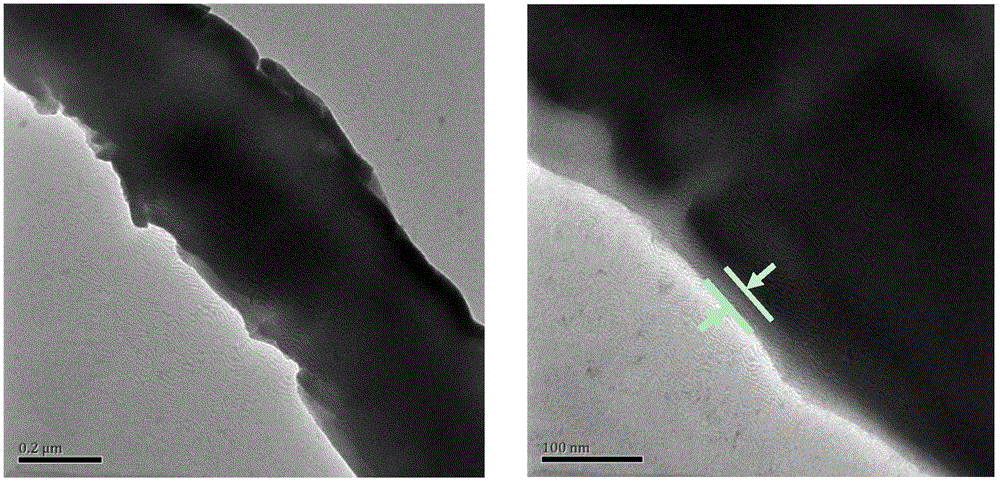

[0050] Take polyvinylidene fluoride-hexafluoropropylene, dissolve it in acetone / NMP solvent with a volume ratio of 1:1, prepare an electrospinning solution with a mass fraction of 17wt%, and perform high-voltage electrospinning with electrospinning equipment . The specific parameters are: positive pole voltage 12KV, negative pole grounded. The injection speed of the syringe pump is 300ul / h. The distance between the spinneret and the collecting plate is 15 cm. The non-woven fiber base film thus obtained is pretreated by RIE oxygen plasma activation (power 50W, treatment time 20s), then quickly transferred to the ALD reaction chamber, evacuated to below 20hPa, and heated to 70°C; Set up the program so that the precursor source and the high-purity water source are alternately pulsed and deposited, the precursor source is passed into the reaction chamber, and then the excess precursor is cleaned with nitrogen, and then water vapor is passed through to hydrolyze the precursor, an...

Embodiment 2

[0056] Take polyvinylidene fluoride, dissolve it in acetone / NMP solvent with a volume ratio of 1:1, prepare an electrospinning solution with a mass fraction of 17 wt%, and perform high-voltage electrospinning with electrospinning equipment. The specific parameters are: positive pole voltage 12KV, negative pole copper plate and grounded. The injection speed of the syringe pump is 300ul / h. The distance between the spinneret and the collecting plate is 15 cm. The non-woven fiber base film obtained in this way was pretreated by RIE oxygen plasma activation (power 50W, treatment time 20s), and then quickly transferred to the ALD reaction chamber, using titanium tetrachloride and high-purity water as the precursor source, Perform double-sided deposition of titanium dioxide with 150 pulse depositions on each side to obtain PVDF@TiO 2 Non-woven ceramic diaphragm.

Embodiment 3

[0058] Take a certain amount of polyvinyl alcohol (PVA), add it into deionized water, heat to 60° C., and keep stirring to prepare a high molecular polymer solution with a mass fraction of 8%. High-voltage electrospinning was performed using an electrospinning device. The specific parameters are: positive pole voltage 12KV, negative pole copper plate and grounded. The injection speed of the syringe pump is 300ul / h. The distance between the spinneret and the collecting plate is 15 cm. The PVA non-woven fiber base film thus obtained. After the above-mentioned non-woven fiber base film was pretreated by RIE oxygen plasma activation (power 50W, treatment time 20s), it was quickly transferred to the ALD reaction chamber, and titanium tetrachloride and high-purity water were used as precursor sources to carry out the oxidation of titanium dioxide. Double-sided deposition, 150 pulse depositions on each side, resulting in PVA@TiO 2 Non-woven ceramic diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com