Carbon nano tube and carbon black composite dispersing liquid and preparation method thereof

A technology of carbon nanotubes and composite dispersion, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of inability to prepare high solid content dispersion liquid, high requirements for dispersion equipment, and large amount of dispersant, etc., to achieve high Filling properties, high liquid absorption and retention capacity, and the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

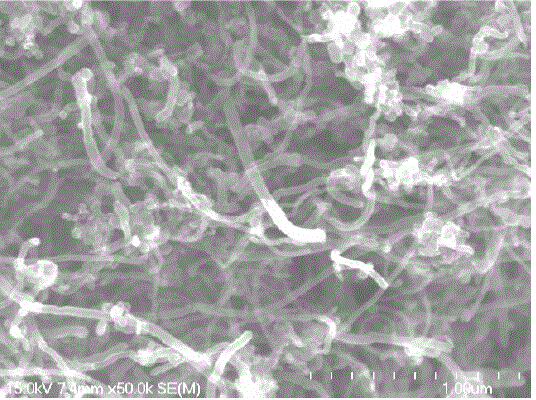

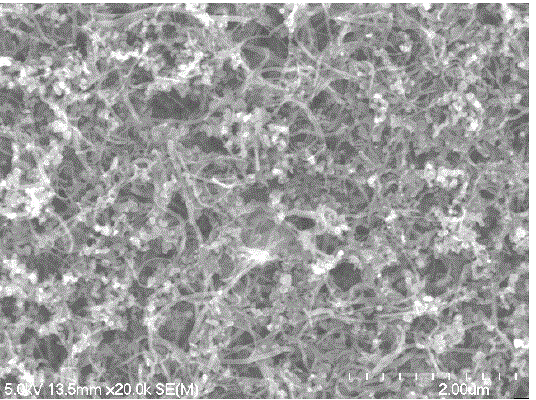

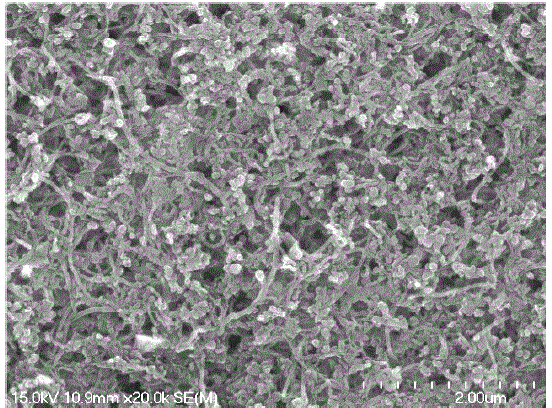

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments.

[0018] preferred embodiment

[0019] Step 1: Soak the acid-washed and purified carbon nanotubes in an aqueous solution, add a PVP (polyvinylpyrrolidone) solution and stir for at least 10 minutes. The carbon nanotubes are multi-walled carbon nanotubes with a diameter of 5nm-30nm.

[0020] Step 2: Dehydrating the carbon nanotubes soaked in the aqueous solution, and putting them into a drying furnace for drying treatment, so that the water content of the carbon nanotubes is below 0.5%.

[0021] Step 3: At a temperature lower than 30°C and a humidity lower than 30% R.Hs, pour 93.4% of the solvent and 0.6% of the dispersant into a high-speed dispersion tank for pretreatment, so that the dispersant is completely dissolved in in solvent. The dispersant adopts polyvinylpyrrolidone; the solvent adopts N-methylpyrrolidone, and water can also be used as the solvent.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com