Water-based lithium-sodium ion battery and preparation method and application thereof

A sodium-ion battery, water-based technology, applied in batteries, secondary batteries, battery electrodes, etc., can solve the problems of electrode active material shedding, battery cycle life attenuation, narrow electrochemical stability window, etc., to reduce battery self-discharge, prevent Overcharging phenomenon, simple and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Preparation of an aqueous lithium-sodium ion battery

[0061] 1) Preparation of negative electrode active material-carbon-coated sodium titanium phosphate spherical particles

[0062] Dissolve 2000 g of sodium dihydrogen phosphate, 2000 g of titanium dioxide, and 2000 mL of phosphoric acid in 2000 mL of water, ball mill for 30 minutes, transfer to a 100-liter reactor at 150°C for 6 h, filter with suction, water, ethanol, water, and ethanol in sequence Wash, filter with suction for half an hour, transfer to a 50-degree oven, and dry overnight to obtain a precursor, disperse 100 g of glucose in 2000 g of water, spray-dry at 150°C, heat up to 700°C at 5°C / min and calcinate for 2 h in a nitrogen atmosphere , naturally cooled to room temperature to obtain carbon-coated sodium titanium phosphate spherical particles.

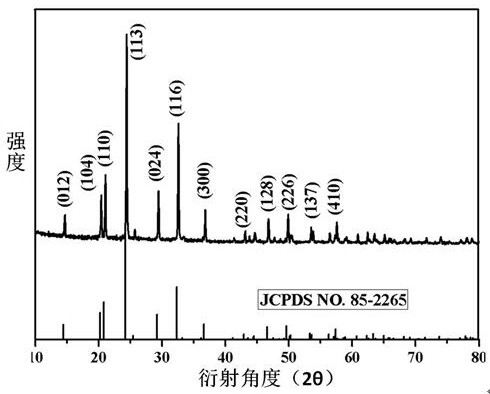

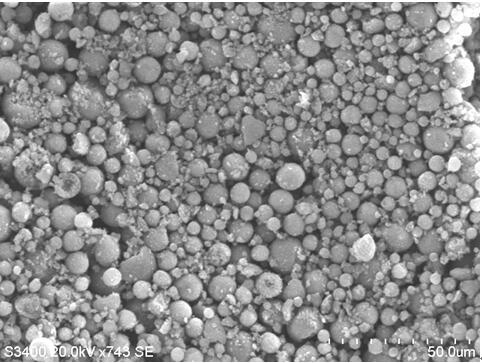

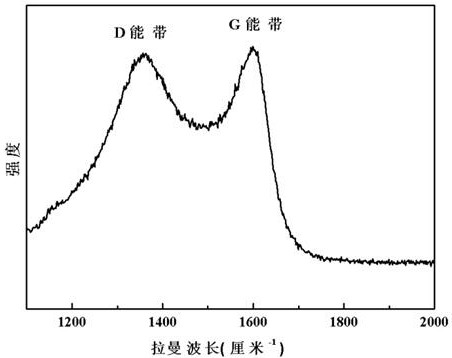

[0063] X-ray diffraction analysis was carried out by X-ray powder diffractometer, figure 1 It is the X-ray diffraction spectrum of the carbon-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com