Method and device for manufacturing optical display device

An optical film and detection device technology, applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve the problem of not exerting a peeling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

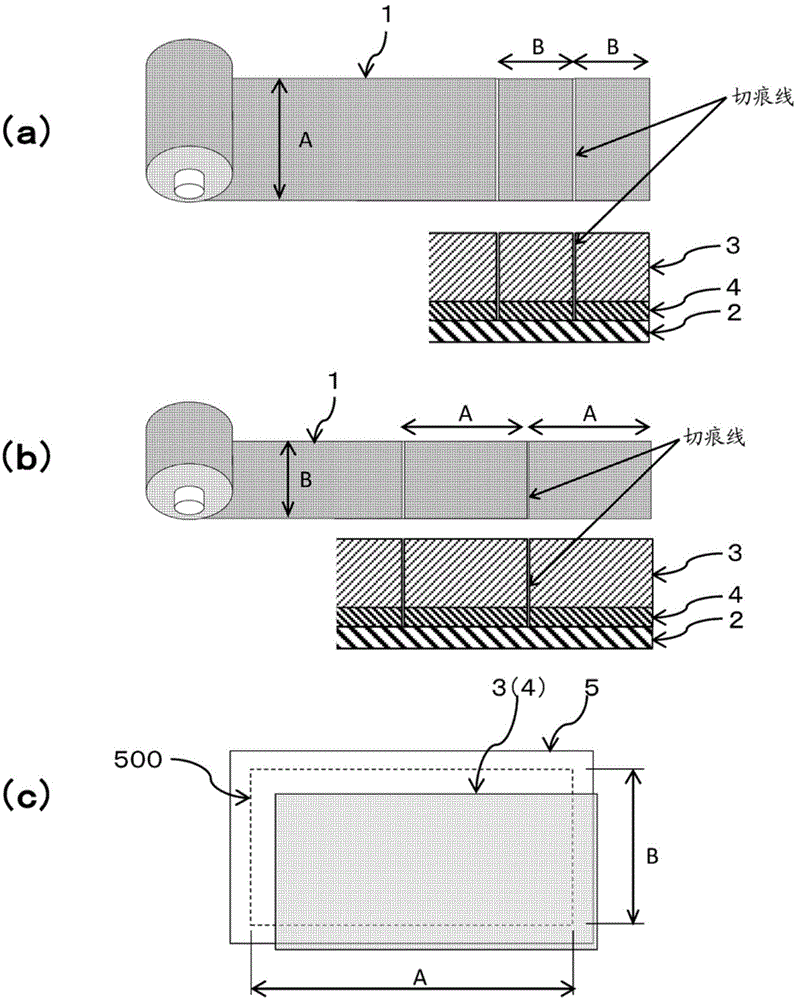

[0064]

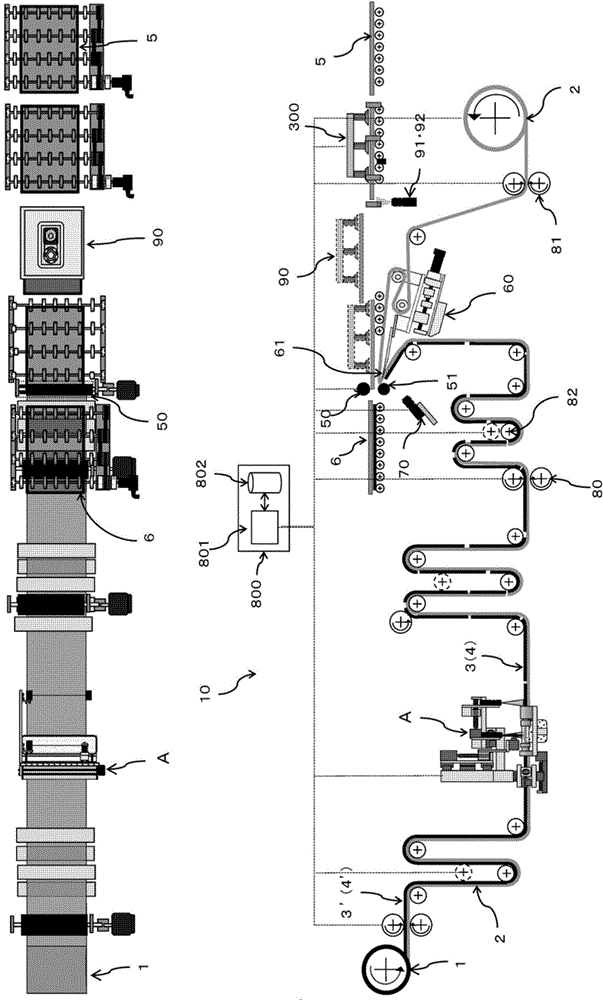

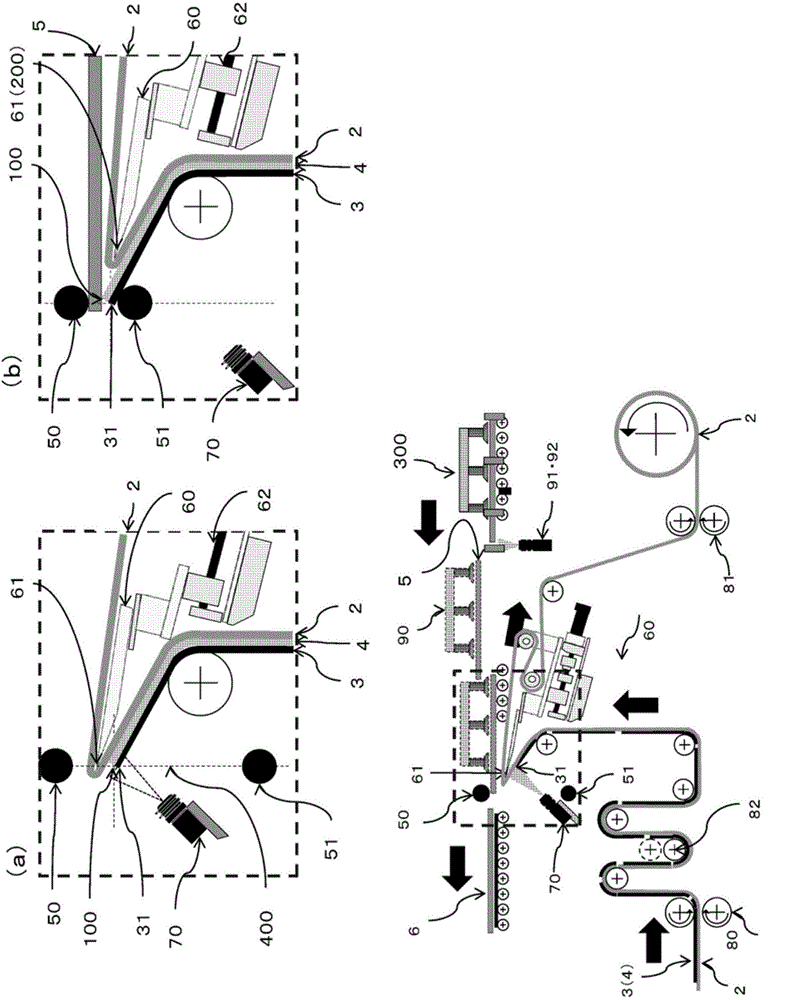

[0065] figure 2 It is a top view and a side view which show the whole apparatus 10 which manufactures the optical display device 6 by bonding the optical film sheet 3 and the panel member 5 at the predetermined attachment position 100. Among them, the laminating rollers 50, 51 configured to open and close in the up and down direction with respect to the conveying direction are arranged at the predetermined sticking position 100, and the movable peeling body 60 is arranged. The space 400 between the closing rolls 50 and 51 is movable between the space 400 and the work start position 200 .

[0066] Depend on image 3 It can be seen that the carrier film 2 supports the front end 31 of the optical film sheet 3 in a state wound on the movable peeling body 60, and the carrier film 2 is in a state where the back side is folded back inwardly at the top 61 constituting the front end portion of the movable peeling body 60. The state of being wound on the movable peeling bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com