A fully automatic stripping device

A stripping device and fully automatic technology, applied in lamination, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of high production process requirements, inconvenient replacement, and high manufacturing cost of coil materials, and achieve stripping accuracy High, improve work efficiency, reduce the effect of operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

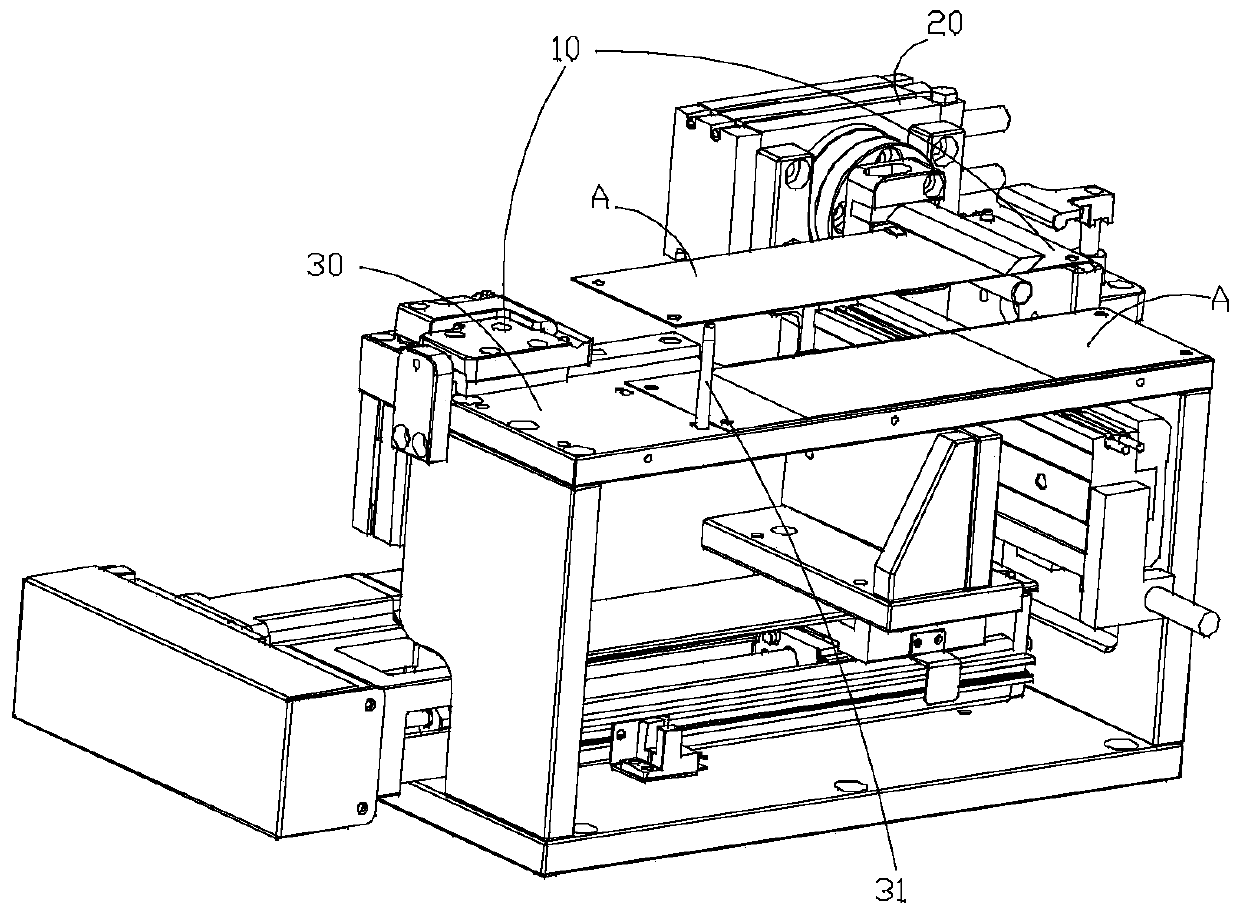

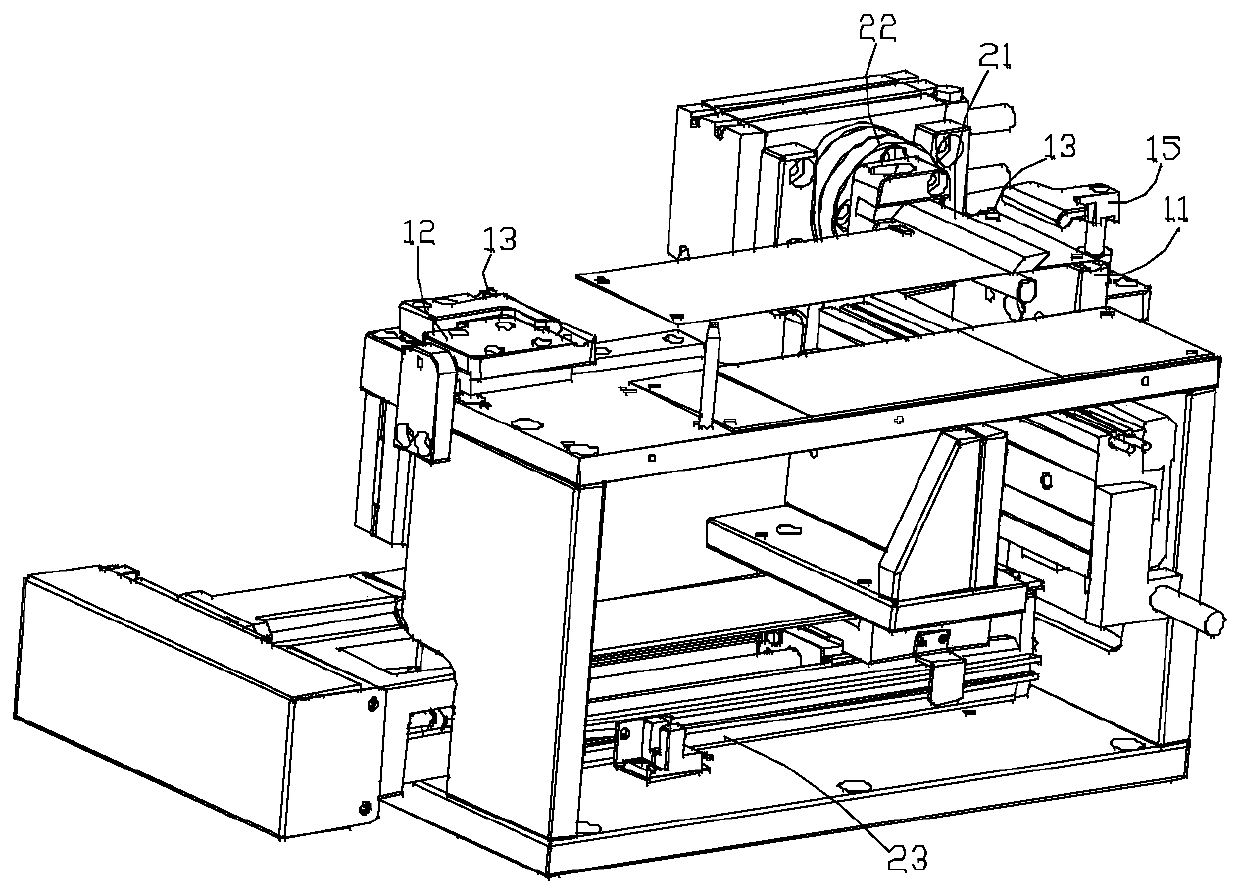

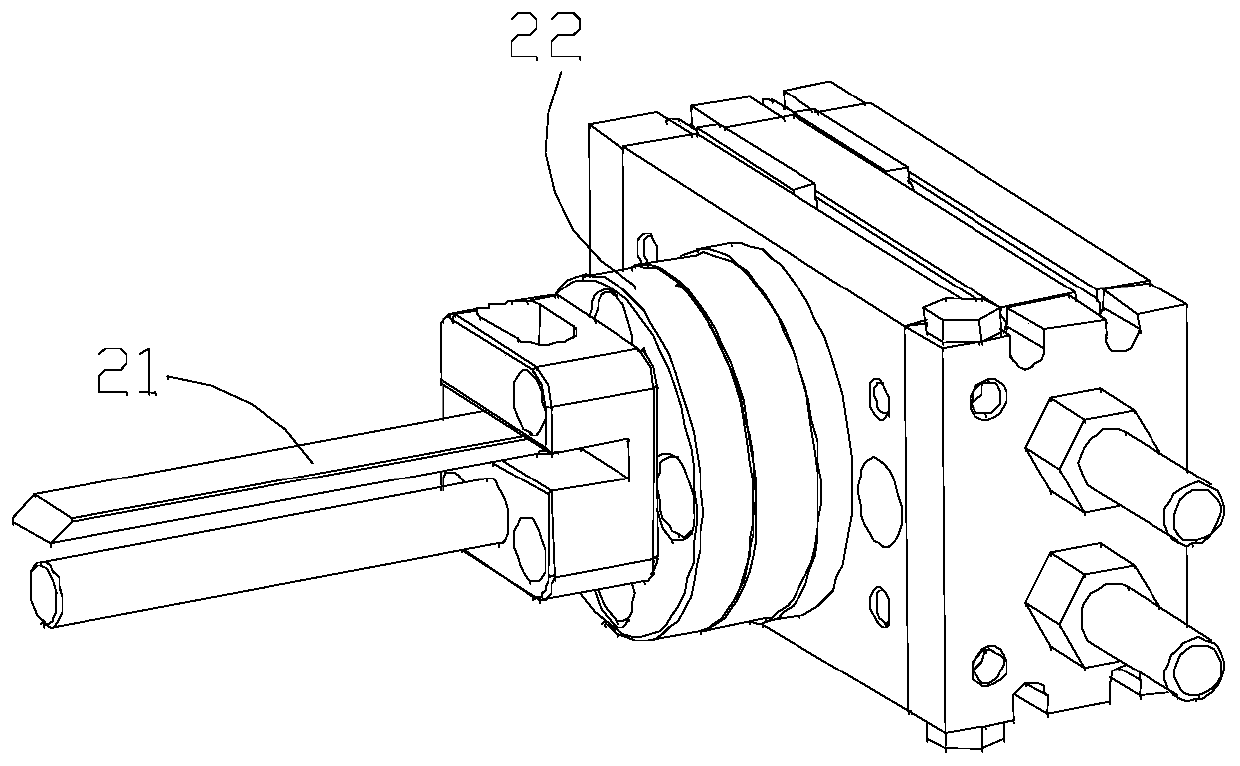

[0016] Such as Figures 1 to 4 As shown, a fully automatic stripping device includes a material placement unit 10 and a stripping unit 20. During specific work, the raw material is arranged on the material placement unit 10, and the raw material A is prepared by the material placement unit 10. Fixing is carried out, and then the stripping unit 20 operates to complete the stripping action of the raw material.

[0017] The raw material refers to the product of centrifuge paper or other patches pasted on the carrier.

[0018] The material placement unit 10 includes a fixed material holder 11 and a movable material holder 12, and stringers 13 are arranged on the fixed material holder 11 and the mobile material holder 12 respectively.

[0019] The raw material is hung between the fixed material rack 11 and the movable material rack 12, wherein one end of the raw material is threaded on the string head 13 of the fixed material frame 11, and the other end of the raw material is thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com