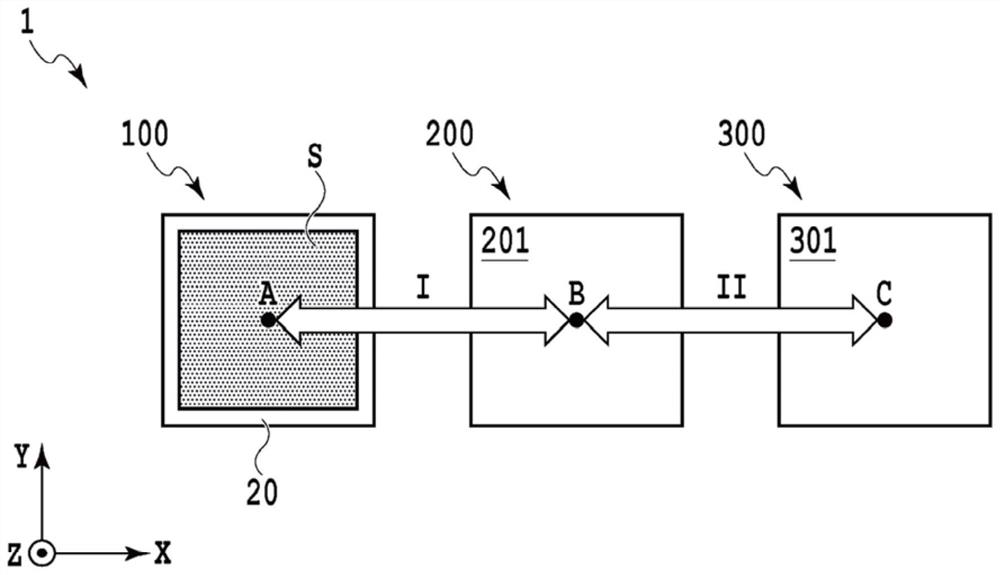

Stripping mechanism and laminating device using same

A technology of peeling mechanism and peeling starting point, applied in the directions of lamination, layered products, lamination auxiliary operation, etc., can solve the problems of peeling film, difficult to form peeling starting point, etc., and achieve the effect of smooth peeling action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

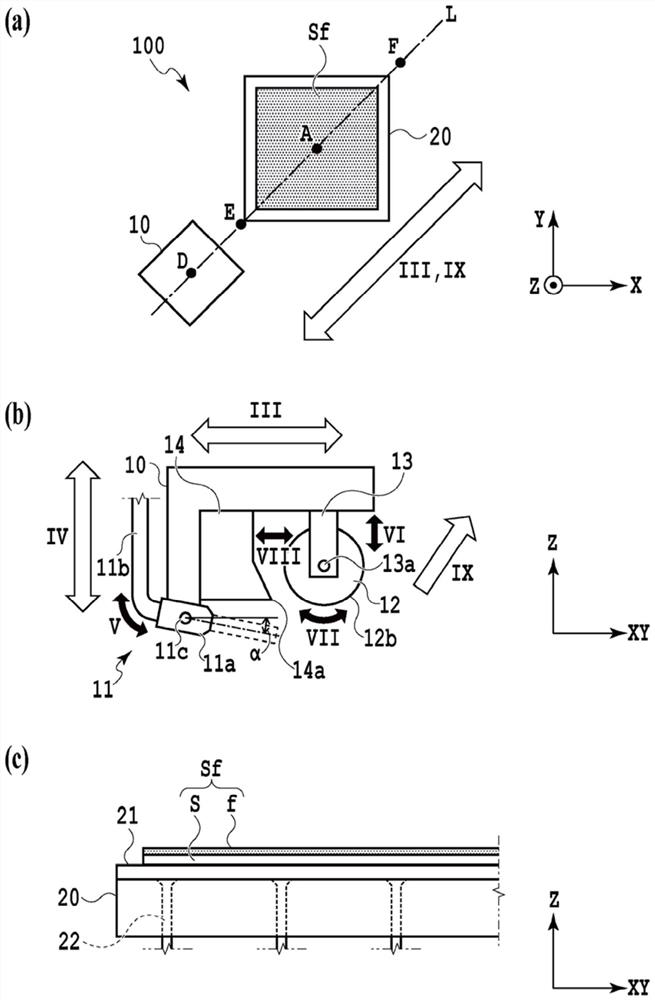

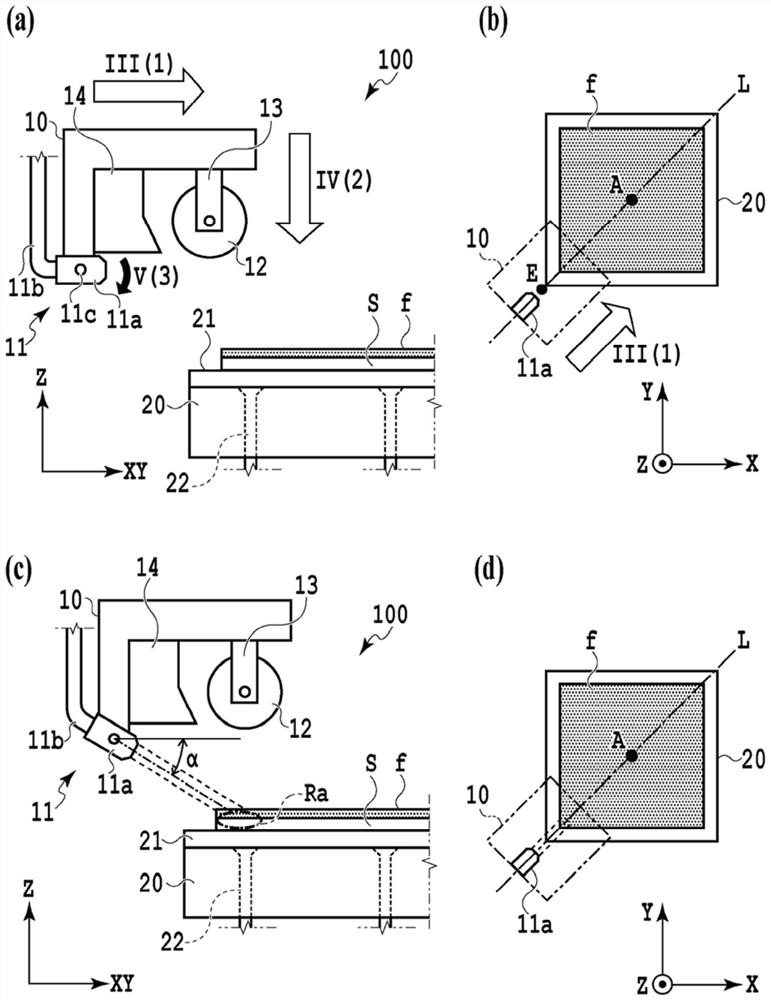

[0125] The first embodiment of the present invention is a peeling mechanism 100 including a peeling stage 20 for placing a sheet Sf with a film in a fixed state, and a peeling head 10 for peeling the film f from the sheet S placed on the peeling stage 20 and a cooling device 11, which cools a part of the outer peripheral portion of the sheet Sf with a thin film to form a peeling starting point Ra; the peeling head 10 includes a film holding device 12, 14 that holds the peeling starting point Ra In the state of the film f, the film f is peeled off from the sheet S by the relative movement of the peeling head 10 and the peeling stage 20 .

[0126] As described above, by cooling a part of the outer peripheral portion of the sheet Sf with a thin film to form the peeling starting point portion Ra, the rigidity of each of the thin film f and the sheet S can be increased, and the integration of the thin film f and the sheet S can be suppressed. It is possible to solve the problem (di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com