Wire buckle intermediate peeling machine and its use method

A stripping machine and wire technology, applied in the direction of line/collector parts, electrical components, connections, etc., can solve the problems of operator health impact, wire injury, and many operators, so as to reduce labor intensity of workers and improve production efficiency , the effect of reducing the operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be described in further detail below in conjunction with the accompanying drawings.

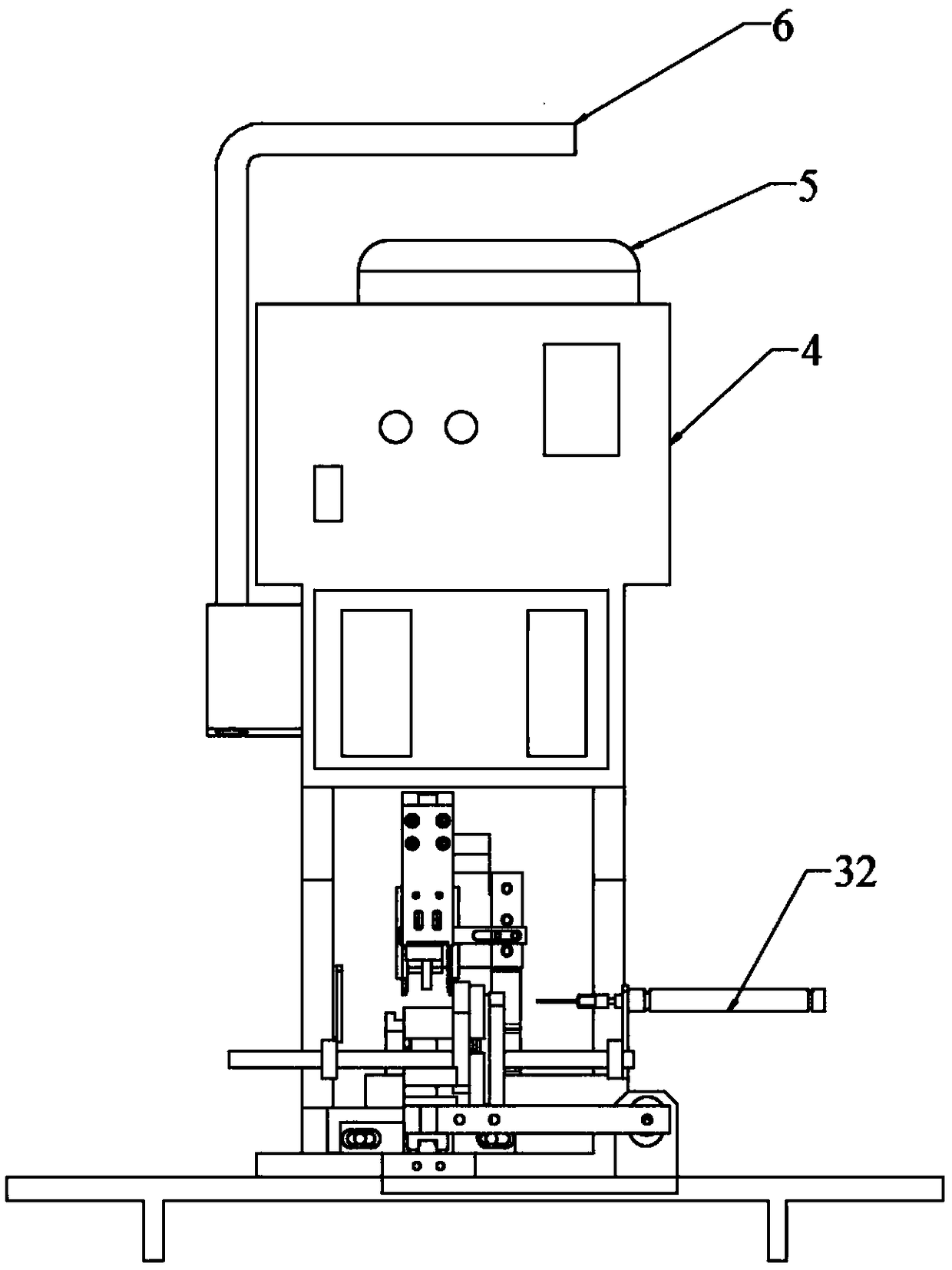

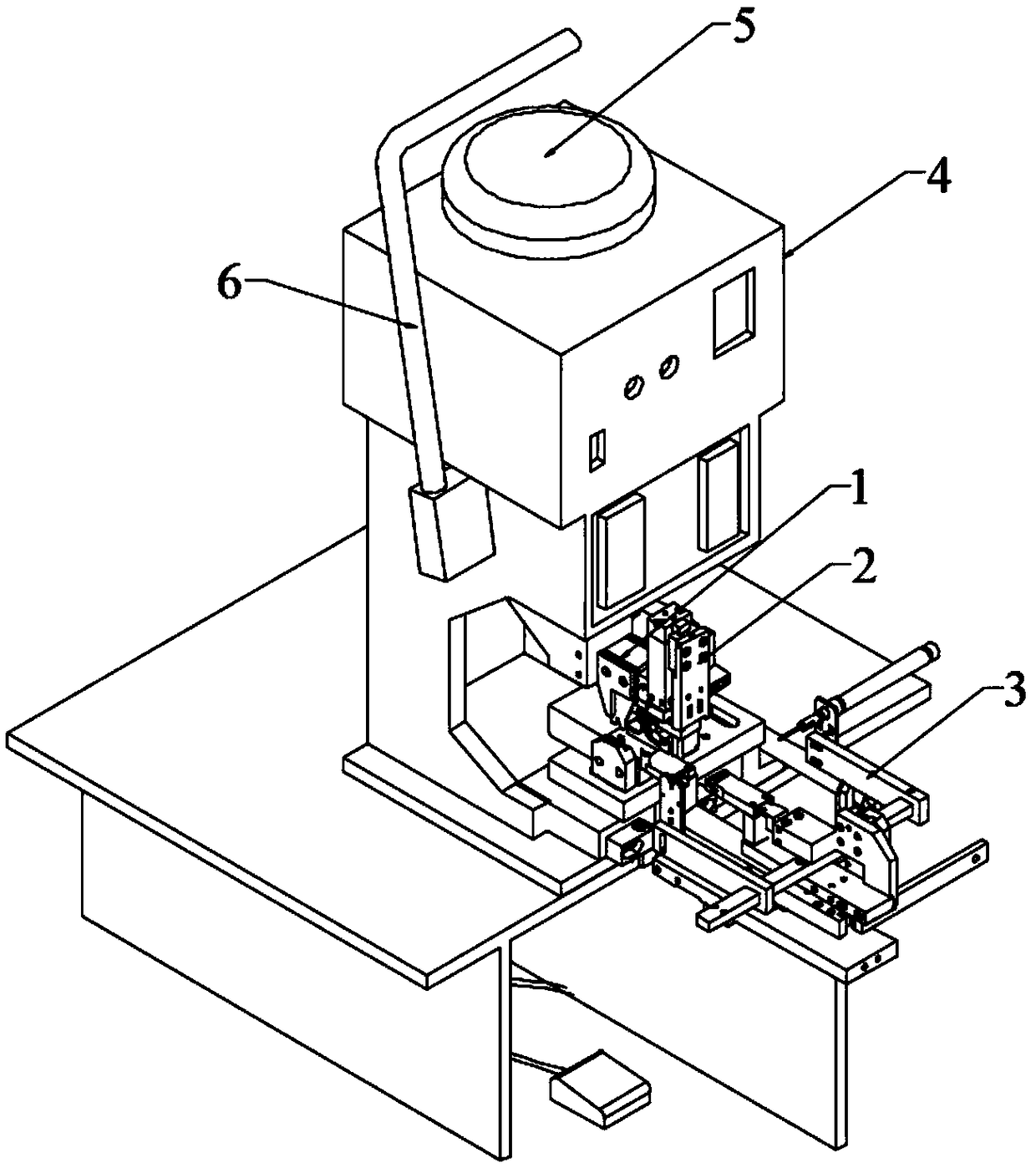

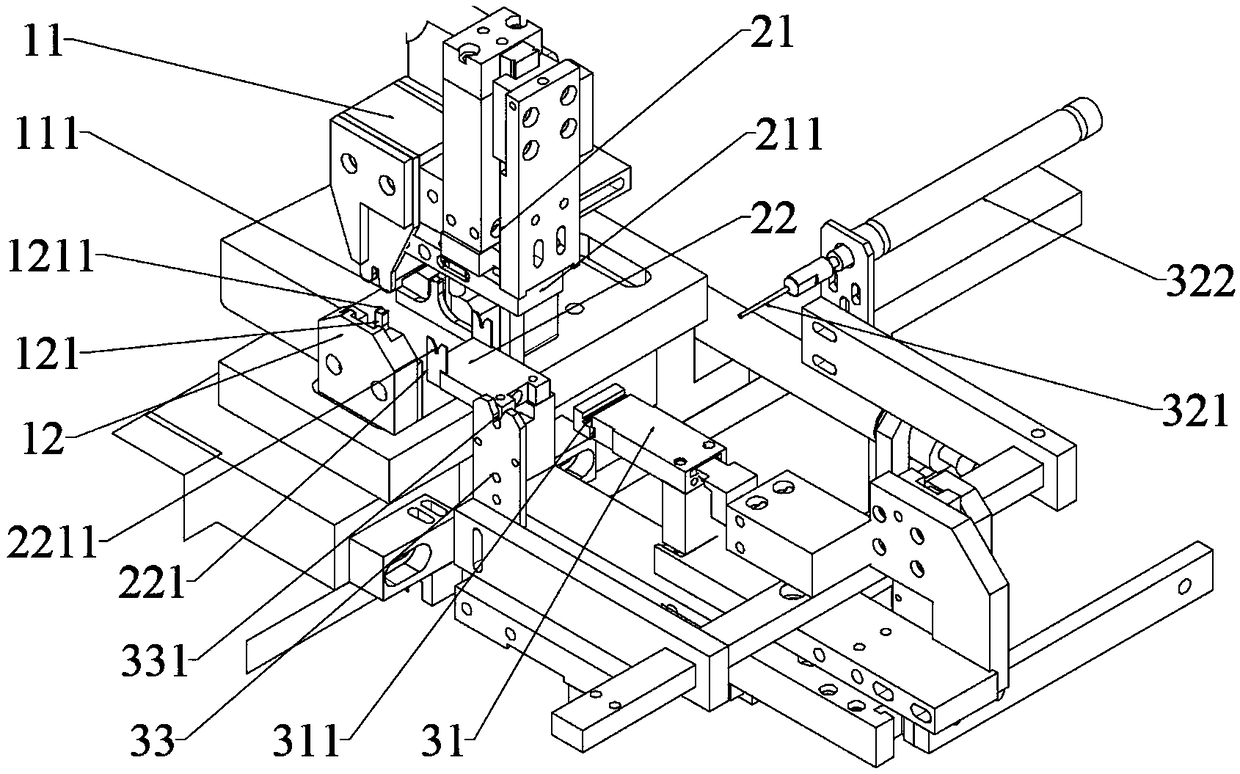

[0032] Figure 1 to Figure 4 A wire buckle intermediate stripper according to an embodiment of the present invention is schematically shown. like Figure 1 to Figure 4 As shown, the wire buckle intermediate peeling machine includes a buckle die 1 , a skin cutting die 2 , a peeling fixture 3 , a control device 4 , a first driving device 5 and a second driving device 7 .

[0033] Wherein the buckle die 1 is located under the control device 4, and the buckle die 1 includes a buckle upper die 11 and a buckle lower die 12. The end of the buckle upper die 11 close to the buckle lower die 12 is provided with a punch 111 arranged oppositely. When the upper buckling die 11 moves toward the lower buckling die 12 , the punch 111 firmly punches the wires and fasteners loaded on the lower buckling die 12 together. The lower punching die 12 may be provided with oppositely arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com