A kind of method and graphene precursor of internal mixer exfoliation preparation graphene precursor

A technology of graphene and internal mixer, applied in the direction of graphene, nano-carbon, etc., can solve problems such as difficulty in realizing large-scale industrial production, lattice defects of graphene layer structure, and affecting the conductivity of graphene, etc., to achieve large-scale Industrial production, easy large-scale industrial production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

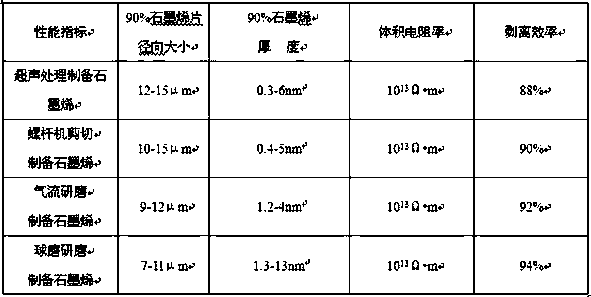

Image

Examples

Embodiment 1

[0031] (1) Using natural flake graphite powder as raw material, place natural flake graphite powder and excess acrylamide in deionized water containing sodium dodecyl sulfate, natural flake graphite powder and acrylamide, the The mass ratio of the deionized water of alkyl sodium sulfate three is 1:0.8:5, and the weight ratio of sodium lauryl sulfate and deionized water in the deionized water containing sodium lauryl sulfate is 1:100, Then the mixed solution was stirred, and the stirring speed was set to be 10rpm. After the mixed solution was stirred until the raw materials were evenly distributed, the mixed solution was ultrasonically treated, and the ultrasonic power was set to be 10KW, and the ultrasonic treatment was performed for 30 hours to obtain the infiltrated natural flake graphite powder dispersion;

[0032] (2) Centrifuge the soaked natural flake graphite powder dispersion, the centrifugation speed is 100rpm, and the separation time is 60 minutes, then filter to obta...

Embodiment 2

[0036](1) Using colloidal graphite as a raw material, place colloidal graphite powder and excess formamide in deionized water containing sodium lauryl sulfate, colloidal graphite powder and formamide, said sodium lauryl sulfate containing The mass ratio of the deionized water three is 1:1:10, and the weight ratio of sodium lauryl sulfate and deionized water in the deionized water containing sodium lauryl sulfate is 1:100, then the mixed solution Stir, set the stirring speed to be 50rpm, stir the mixed solution until the raw materials are evenly distributed, then carry out ultrasonic treatment to the mixed solution, set the ultrasonic power to 100KW, and perform ultrasonic treatment for 15 hours to obtain the infiltrated colloidal graphite powder dispersion;

[0037] (2) Centrifuge the infiltrated colloidal graphite powder dispersion, the centrifugation speed is 100rpm, and the separation time is 60 minutes, then filter to obtain wet colloidal graphite powder, stir and blend the...

Embodiment 3

[0041] (1) Using expandable graphite as raw material, place expandable graphite powder and excess formamide in deionized water containing sodium dodecyl sulfate, expandable graphite powder and formamide, the The mass ratio of the deionized water three of sodium sulfate is 1:1:10, and the weight ratio of sodium lauryl sulfate and deionized water in the deionized water containing sodium lauryl sulfate is 1:100, then to The mixed solution is stirred, and the stirring speed is set to be 50rpm. After the mixed solution is stirred until the raw materials are evenly distributed, the mixed solution is subjected to ultrasonic treatment, and the ultrasonic power is set to 100KW, and the ultrasonic treatment is performed for 15 hours to obtain the infiltrated colloidal graphite powder dispersion;

[0042] (2) Centrifuge the soaked expandable graphite powder dispersion at a speed of 100 rpm and a separation time of 60 minutes, then filter to obtain wet expandable graphite powder, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com