Peeling device for garlic processing

A garlic and box technology, which is applied in the directions of application, separation of solids from solids by air flow, solids separation, etc., can solve the problems of garlic damage, low garlic peeling efficiency, and reduced garlic integrity, etc., to achieve convenient cleaning, The effect of expanding the chip removal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

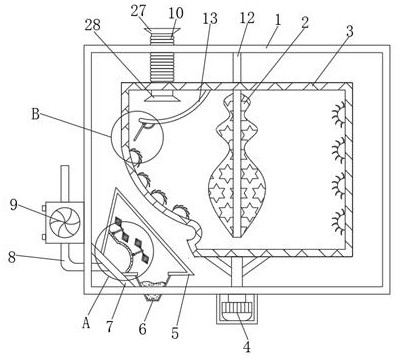

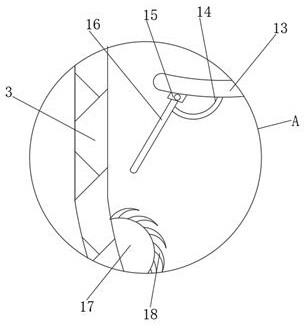

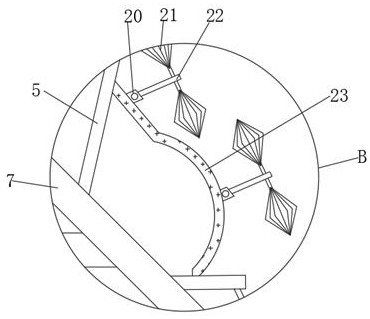

[0029] refer to Figure 1-4 , a peeling device for garlic processing, comprising a box body 1 and a net cage 3, the bottom outer wall of the box body 1 is connected with a motor 4 by bolts, and the outer wall of one end of the output shaft of the motor 4 forms a fixed connection with the bottom outer wall of the net cage 3 , the top inner wall of the box body 1 is connected with a fixed rod 12 by bolts, and the peripheral outer wall of the fixed rod 12 is wrapped with a friction block 2, the cross section of the friction block 2 is wavy, and the corrugation gradually increases from top to bottom, the box body The top outer wall of 1 has a through hole, and a bellows 10 is inserted in the through hole, and the inner walls at both ends of the bellows 10 are respectively inserted with a feed hopper 27 and a discharge hopper 28, and the bellows 10 is located above the cage 3 , one side inner wall of cage 3 is fixedly connected with fixed block 17 equidistantly distributed, and the...

Embodiment 2

[0033] refer to Figure 5-6 , a peeling device for garlic processing. Compared with Embodiment 1, the top outer wall of the material guide plate 13 is provided with installation grooves 24, and the installation grooves 24 are equidistantly distributed, and the inner walls on both sides of the installation grooves 24 are uniform. A rotating rod 26 is connected in rotation, and crushing teeth 25 are sleeved on the outer peripheral wall of the rotating rod 26 .

[0034] During use, when people need to peel the garlic, they can first add the garlic to the inside of the box body 1 through the feed hopper 27. When the garlic falls into the net cage through the material guide plate, the garlic will be in contact with the crushing teeth 25. , the garlic epidermis can be scratched through the crushing teeth 25, so that the follow-up peeling work of the garlic can be facilitated. The skin can be rotated during work, so the crushing tooth 25 can improve the peeling efficiency of garlic,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com