Processing method of chilled meat

A processing method and technology for cooling meat, which are applied in the direction of preservation of meat/fish by freezing/cooling, preservation of meat/fish, food preservation, etc. Simple and effective to reduce the rate of juice flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

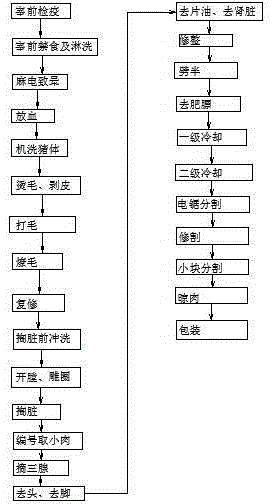

Image

Examples

Embodiment 1

[0036] A processing method for chilled meat, specifically comprising the following steps:

[0037] The first step is pre-slaughter quarantine. First, carry out group inspection or individual inspection on the pigs to be slaughtered. Only healthy pigs that pass the quarantine and quality inspection can enter the slaughterhouse for slaughter;

[0038] The second step, fasting and rinsing before slaughter, fast the healthy pigs that pass the above inspection for 15 hours; then drive the healthy pigs to the shower pen, rinse for 4 minutes, and wash the pigs at a temperature of 25°C clean;

[0039] Step 3: Stunning by electric shock, drive the above-mentioned pigs that have been showered into the electric shock station in batches for electric shock, the working voltage is 75V, the working current is 1A, and the electric shock time is 1 second;

[0040] The fourth step, bloodletting, the pig is assassinated and bloodletted within 25 seconds after the anesthesia, that is, the vein i...

Embodiment 2

[0064] A processing method for chilled meat, specifically comprising the following steps:

[0065]The first step is pre-slaughter quarantine. First, carry out group inspection or individual inspection on the pigs to be slaughtered. Only healthy pigs that pass the quarantine and quality inspection can enter the slaughterhouse for slaughter;

[0066] The second step, fasting and rinsing before slaughter, fast the healthy pigs that pass the above inspection for 18 hours; then drive the healthy pigs to the shower pen, rinse for 5 minutes, and wash the pigs at a water temperature of 28°C clean;

[0067] Step 3: Stunning by electric shock, drive the above-mentioned pigs that have been showered into the electric shock station in batches for electric shock, the working voltage is 80V, the working current is 1.2A, and the electric shock time is 2 seconds;

[0068] The fourth step, bloodletting, the pig is assassinated and bloodletted within 25 seconds after the anesthesia, that is, th...

Embodiment 3

[0093] A processing method for chilled meat, specifically comprising the following steps:

[0094] The first step is pre-slaughter quarantine. First, carry out group inspection or individual inspection on the pigs to be slaughtered. Only healthy pigs that pass the quarantine and quality inspection can enter the slaughterhouse for slaughter;

[0095] The second step, fasting and rinsing before slaughter, fast the healthy pigs that pass the above inspection for 20 hours; then drive the healthy pigs to the shower stall, rinse for 6 minutes, and wash the pigs at a temperature of 30°C clean;

[0096] Step 3: Stunning by electric shock, drive the above-mentioned pigs that have been showered into the electric shock station in batches for electric shock, the working voltage is 85V, the working current is 1.5A, and the electric shock time is 3 seconds;

[0097] The fourth step, bloodletting, the pig is assassinated and bloodletted within 25 seconds after the anesthesia, that is, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com