Corn cob skinning machine

A technology for peeling machines and corn cobs, which is applied to harvesters, agricultural machinery and implements, and threshing equipment. The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

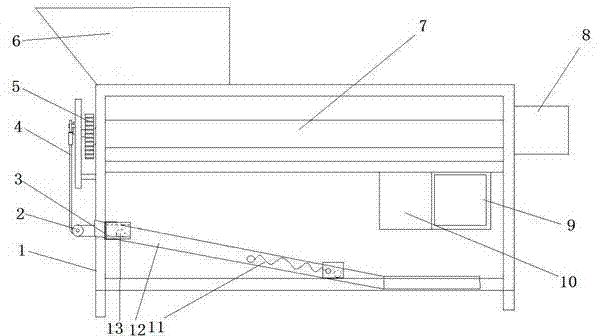

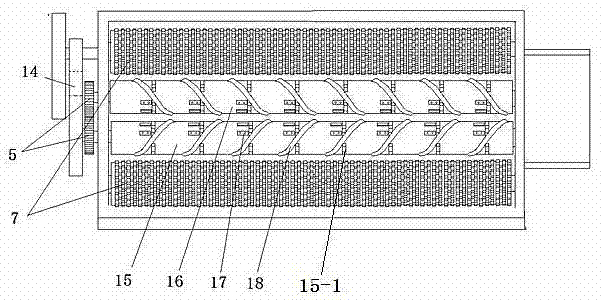

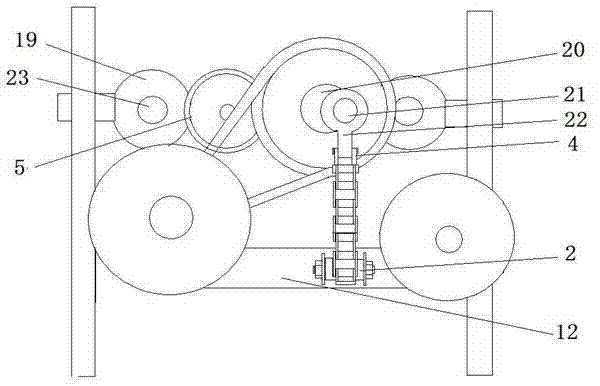

[0013] See Figure 1-5 , the concrete structure is as follows: two parallel rubber rubbing rollers 7 two ends are provided with rotating shaft 23, and rubber rubbing roller 7 is to superimpose suit rubber disc on the mandrel, and many breaches are evenly distributed on the circumference of rubber disc (see Figure 5 ), the gaps of adjacent rubber discs are staggered; the rotating shaft 23 of the rubber rubbing roller is rotated and assembled on the frame 1 through the bearing seat 19; two parallel rib rollers 15, 16. Spiral ribs 18 are arranged on the surface of the two rib rollers, and the spiral ribs 18 on the two rib rollers rotate in the opposite direction, and many rubber rubbing blocks 17 are fixed by screws on the surface of the two rib rollers at the same time; The raised ring 15-1 with a gap is integrally connected; the roller shafts of the two rib rollers are respectively connected to a transmission gear 5, and the two transmission gears 5 are meshed with each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com