Intelligent laser cutting treatment method for filter capsule waste cigarettes

A technology of laser cutting and waste cigarettes, which is applied in the fields of tobacco, paper cigarettes, and applications. It can solve the problems of large labor demand, complex device structure, and high equipment failure rate, and achieve simple production management, simple machine structure, and paper scraps. The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

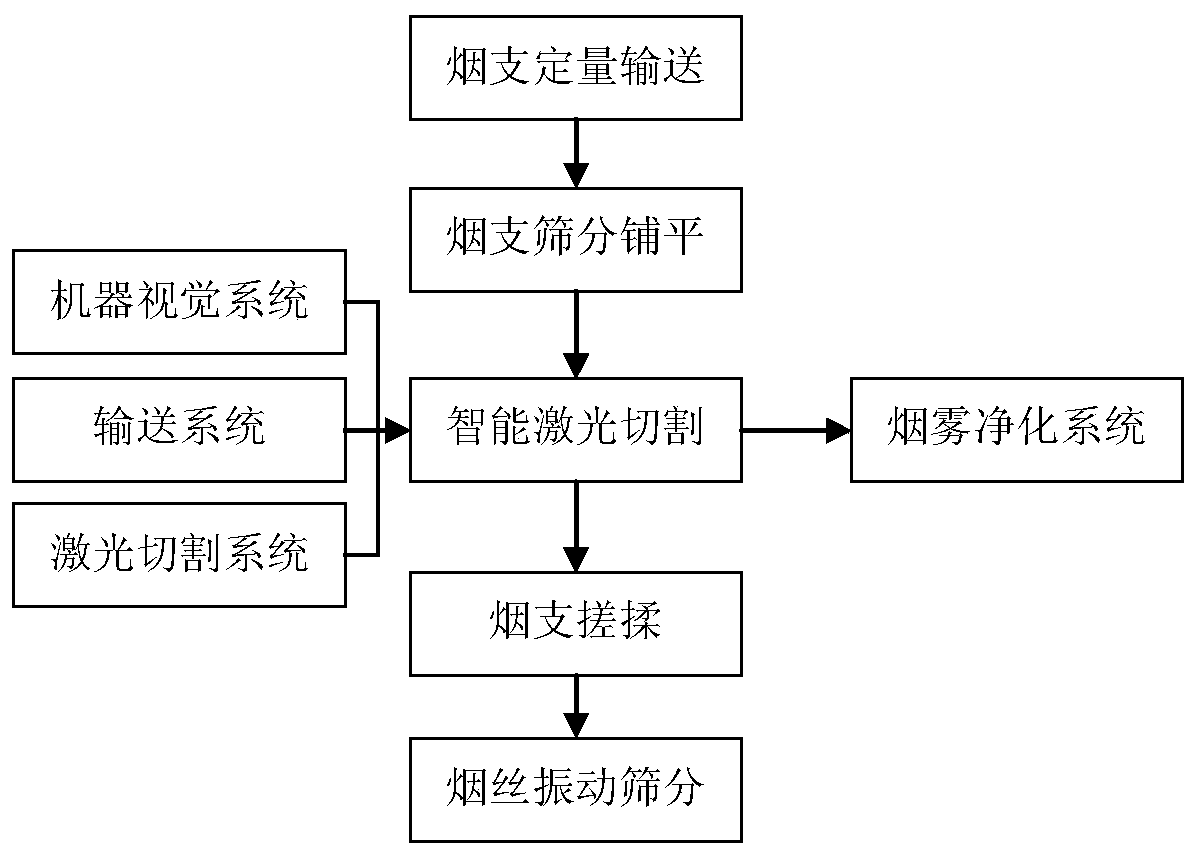

[0026] A method for intelligent laser cutting and processing of explosive bead waste cigarettes, including quantitative transportation of cigarettes, preliminary screening and flattening of cigarettes, intelligent laser cutting (including machine vision recognition device, stable and adjustable speed conveying system, laser cutting device , smoke purification system), cigarette rubbing, shredded tobacco vibration screening and other processes:

[0027] (1) Quantitative delivery of cigarettes. In this embodiment, a feeder with a silo is used to transport the waste cigarettes to the vibrating flattening device at a controllable speed.

[0028] (2) Preliminary screening and paving of cigarettes. The cigarettes are transported by the feeder to the vibrating screen of the vibrating paving device. The vibrating screen vibrates periodically along the direction of cigarette transportation, so that the cigarettes can pass through the vibration during the forward process. Try to lay it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com