Drilling and evaluating system for rectangular rubber material

An evaluation system, rubber technology, applied in general control systems, control/regulation systems, analysis materials, etc., can solve problems such as low drilling quality, inaccurate drilling and center drilling positions, etc., to improve production efficiency, reduce Production cost, the effect of simplifying production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention introduces an embodiment of a drilling evaluation system for rectangular rubber materials. The rectangular rubber material to be processed is a vulcanized rubber with a length of 50 mm, a width of 40 mm, a height of 40 mm, and a density of 1.1 g / cm3. The diameter of the central drilling hole is 10 mm, and the weighing qualified mass range is 83.78 grams to 83.58 grams.

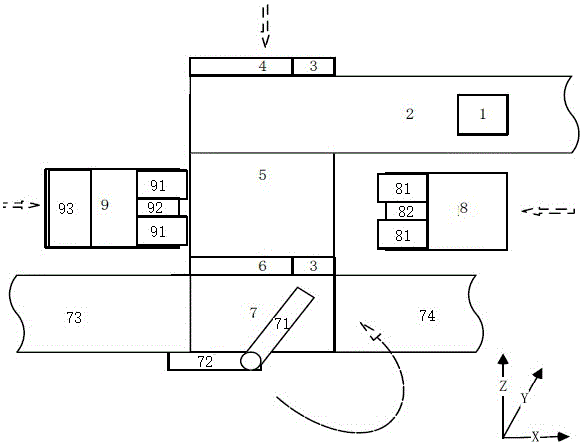

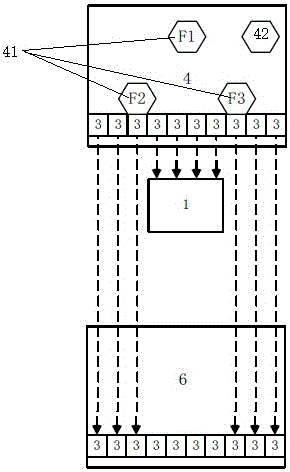

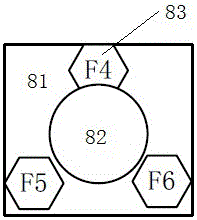

[0037] like figure 1 As shown, the rectangular rubber material drilling evaluation system disclosed in the present invention includes a feeding conveyor belt 2 for conveying a rectangular rubber material 1, and the left and right sides of the feeding conveyor belt 2 are respectively provided with corresponding first push plates 4 and drilling holes. Platform 5, a first baffle plate 6 is provided on the outside of the drilling platform 5, and a weighing platform 7 is also provided on the outside of the first baffle plate 6; the left and right sides of the drilling platform 5 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com