Wave-shaped applying structure

A wave-shaped, coating technology, applied in the direction of coating non-metallic protective layers, printed circuits, instruments, etc., can solve the problems of TAB/COF lead short circuit, etc., to achieve the effect of avoiding lead short circuit, increasing the flow space and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

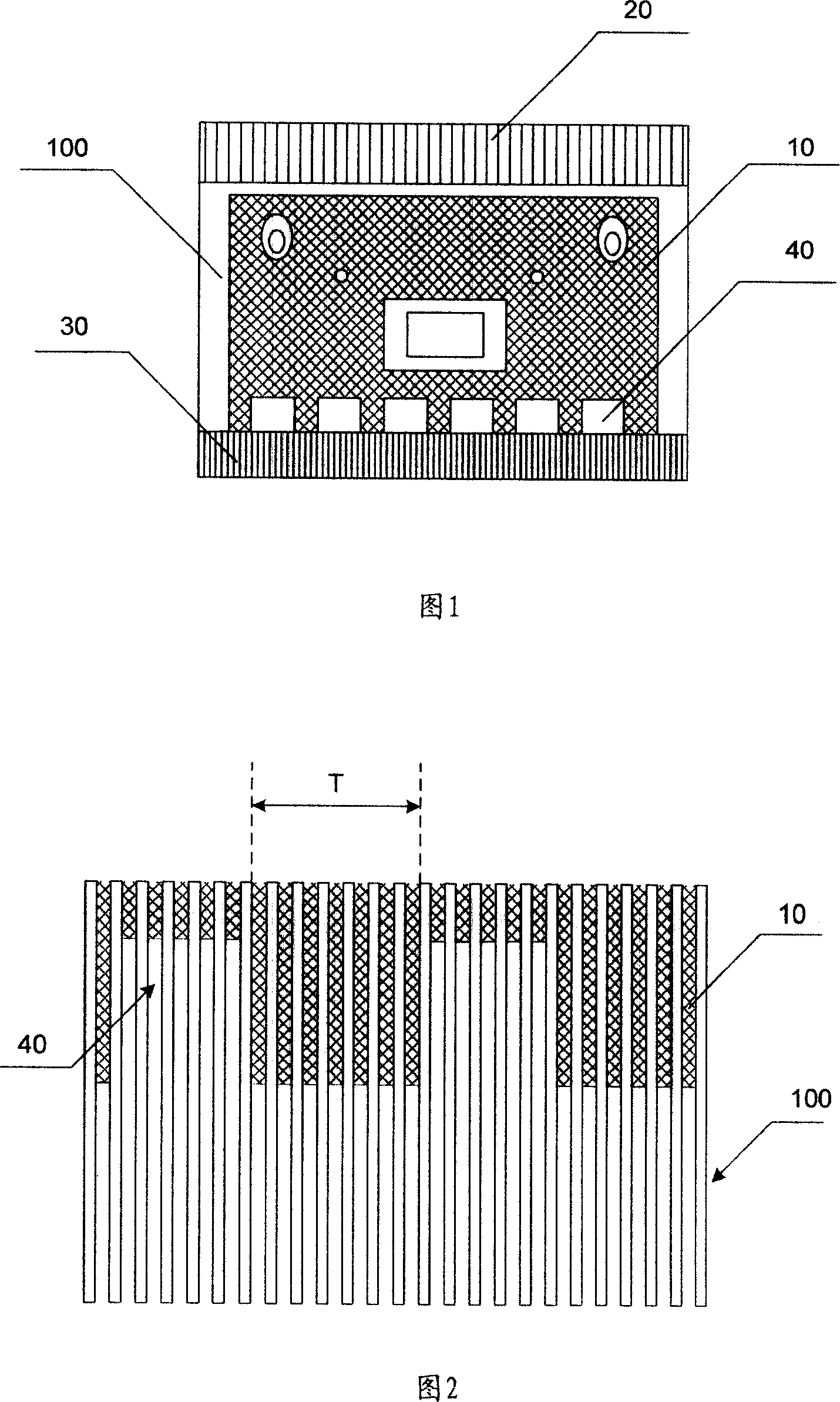

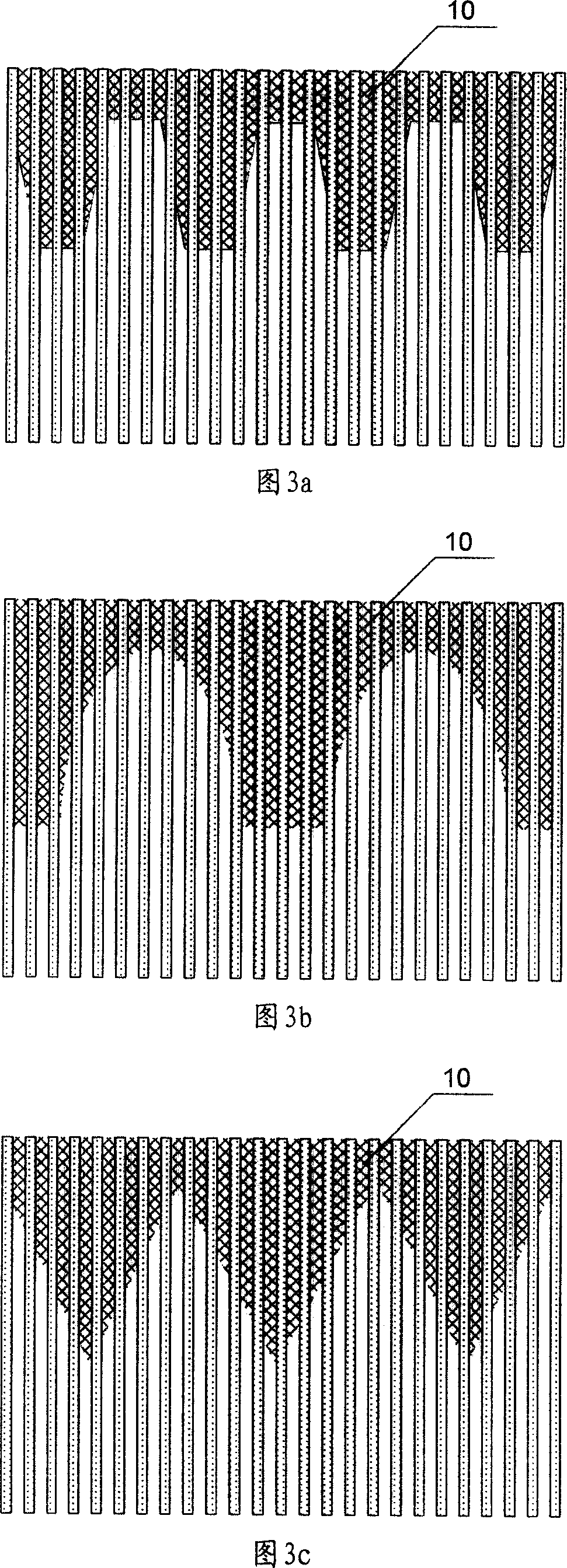

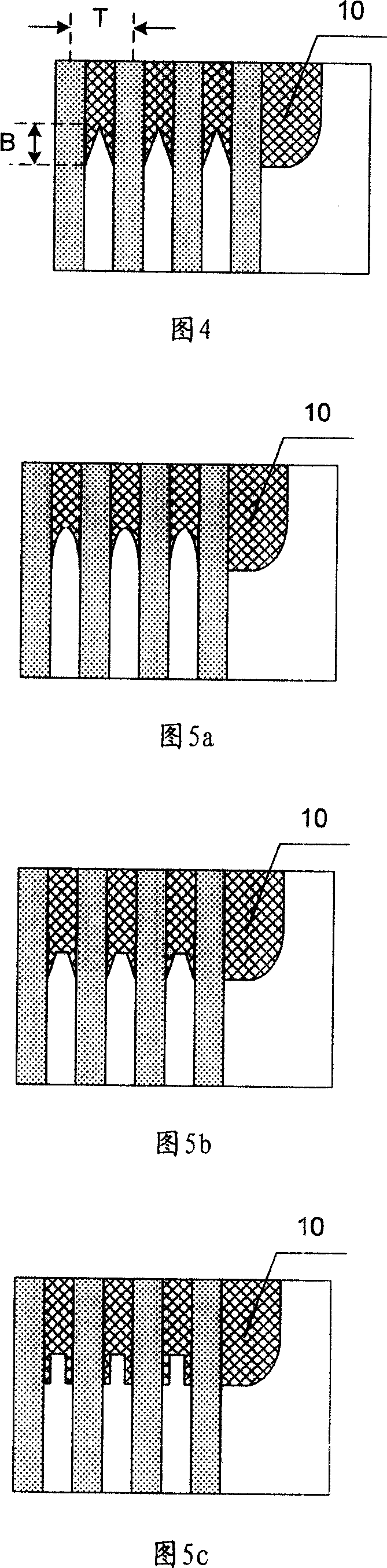

[0021] Fig. 1 is a schematic diagram of the wavy coating structure of the present invention. As shown in FIG. 1 , the S / R coating layer 10 is coated on the TAB / COF 100 , and the overall shape is still rectangular. The upper part of the TAB / COF is a printed circuit board and TAB / COF bonding (Bonding PCB) area 20 , and the lower part is a glass substrate and TAB / COF bonding (Bonding Cell) area 30 . The distance between the printed circuit board and the leads in the TAB / COF crimping area 20 is relatively large, about 400 μm, and there will be no accumulation of ACF particles. The distance between the glass substrate and the lead wires in the TAB / COF crimping area 30 is relatively small, about 60 μm, and ACF particles are likely to accumulate and cause short circuit of the TAB / COF lead wires. In the present invention, several recesses 40 are arranged on the edge of the S / R coating layer 10 in the area where the glass substrate and the TAB / COF are crimped, so that the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com