Silica aerogel power manufacturing system and manufacturing method using the same

An airgel powder and manufacturing system technology, applied to chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve problems such as low productivity and unbalanced processing time, so as to save raw materials and solve uneven processes balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is capable of various modifications and may have various embodiments, and specific embodiments will be described in detail below with reference to the accompanying drawings.

[0047] In the following description, many specific matters such as specific components are shown, but these are provided to assist understanding of the present invention, and the present invention can be implemented without these specific matters. In addition, when describing the present invention, a detailed description is omitted when it is considered that a specific description of a related well-known function or configuration would obscure the gist of the present invention.

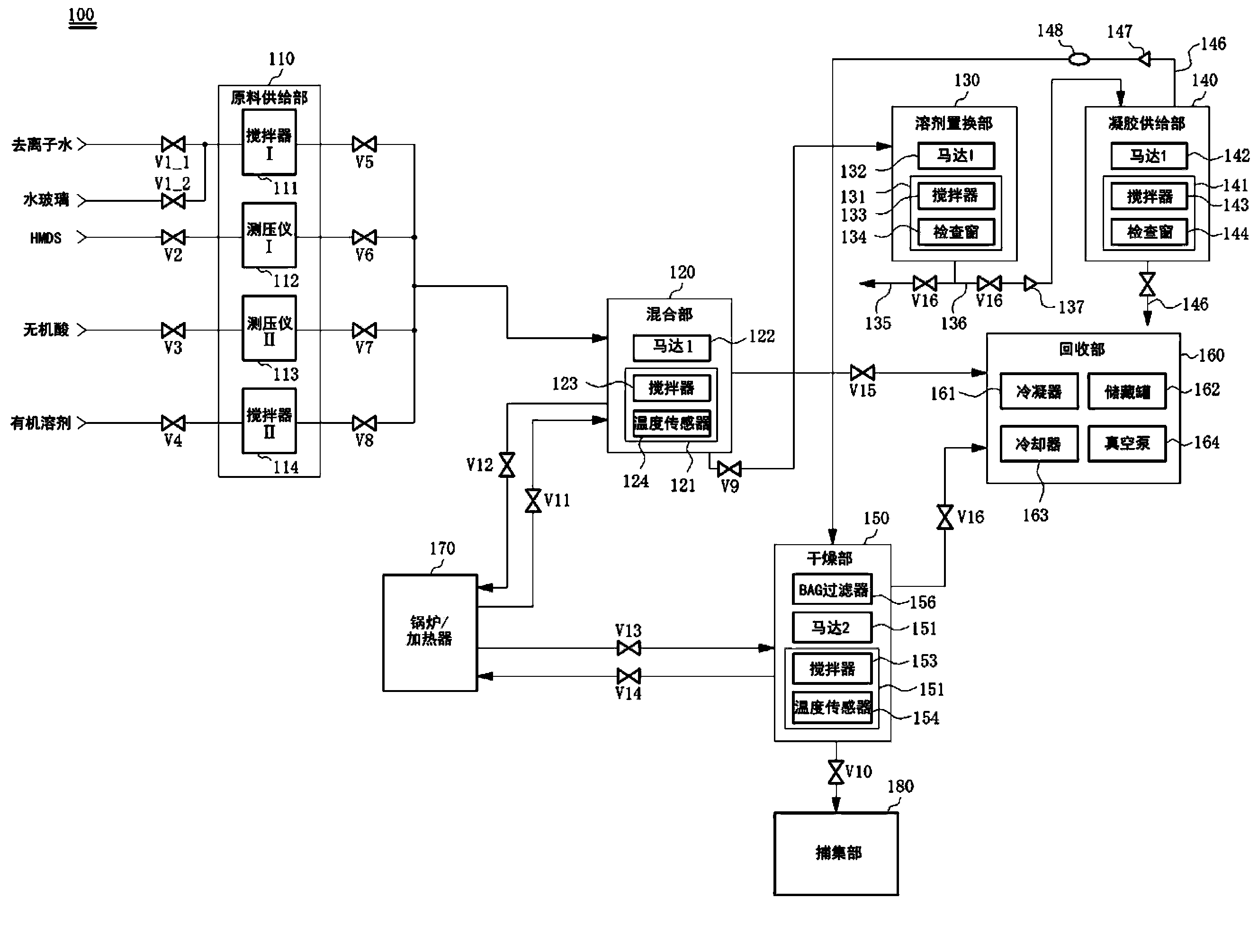

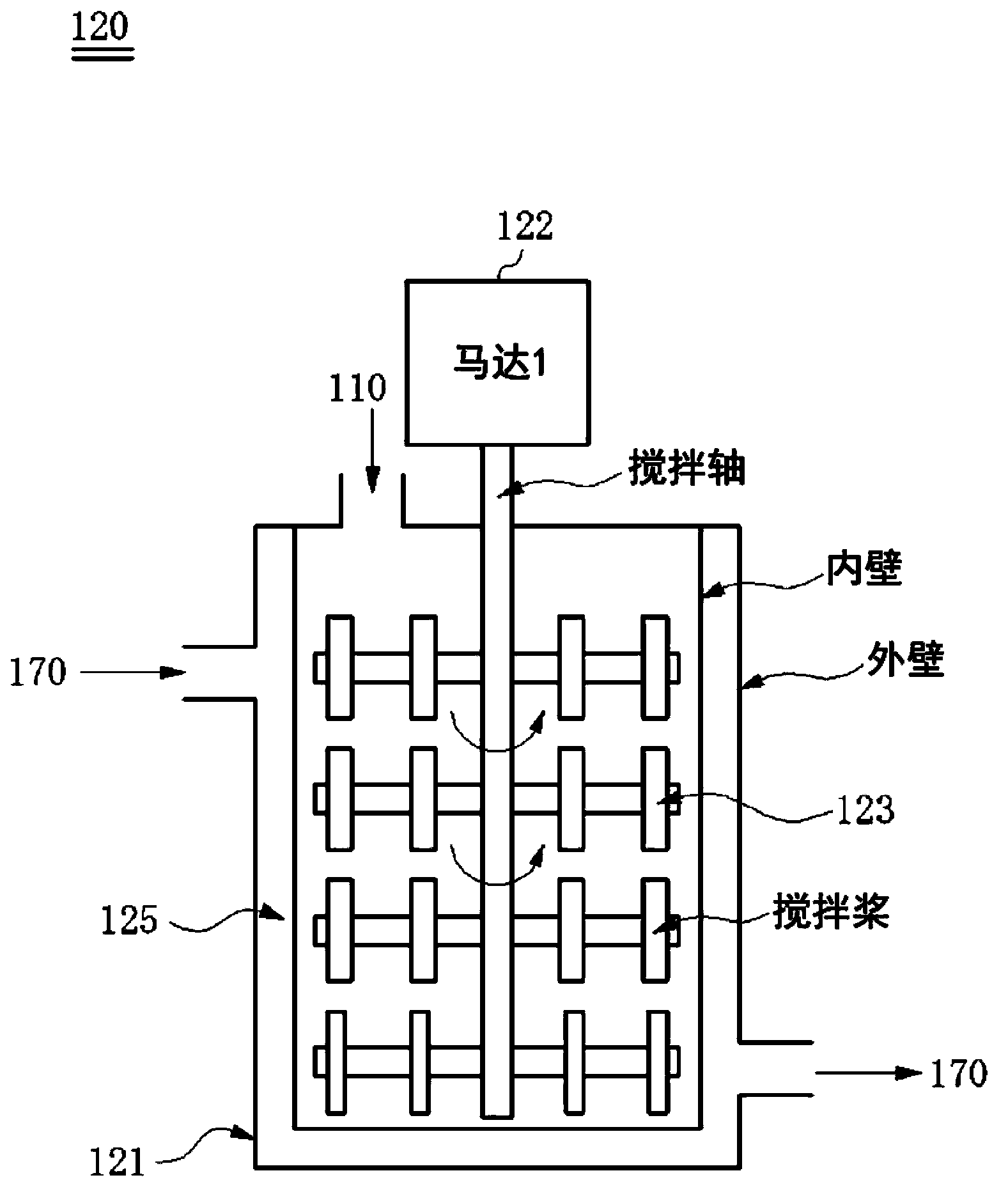

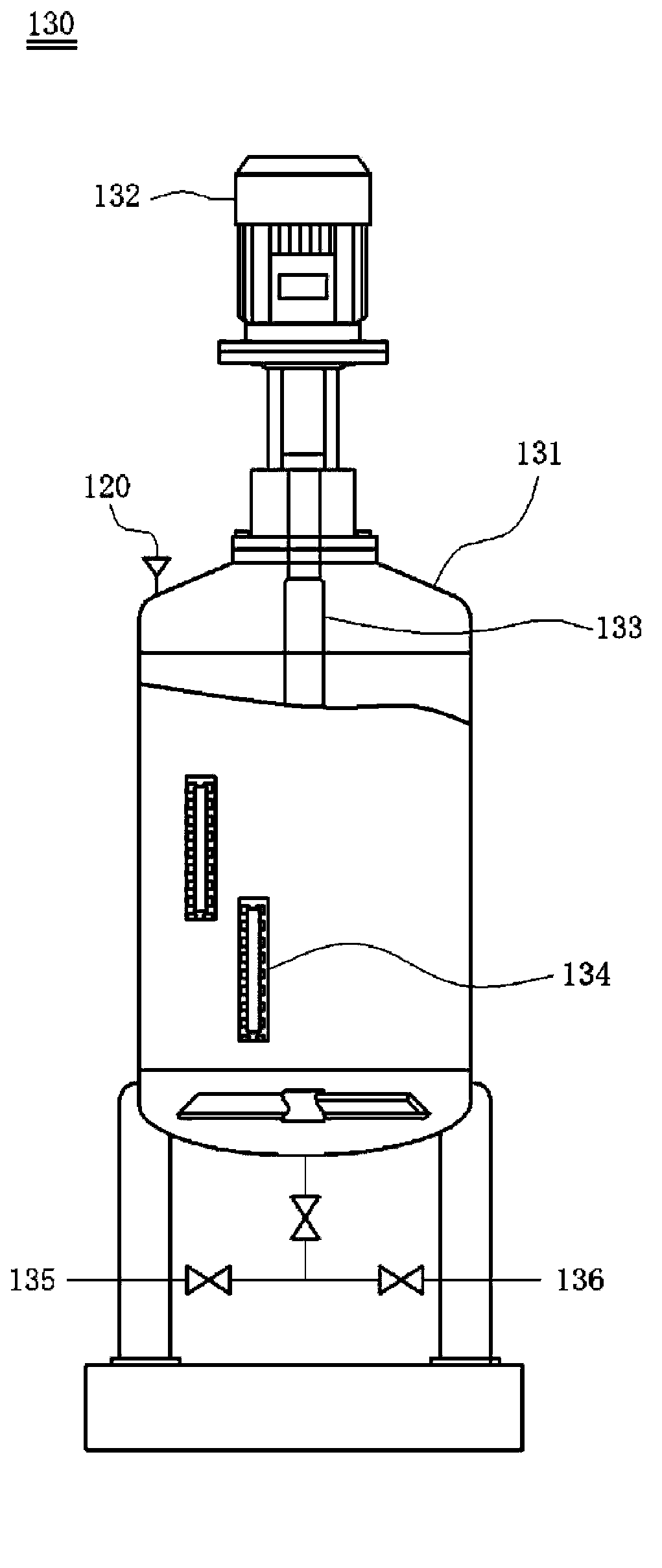

[0048] figure 1 It is a block diagram of the silica aerogel powder manufacturing system of the present invention. The silica aerogel powder manufacturing system includes a raw material supply unit 110, a mixing unit 120, a solvent replacement unit 130, a gel supply unit 140, a drying unit 150, a reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com