Modularization on-line digital post-printing tidying system

A digital printing and modular technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of inconvenient operation of multi-process tasks, waste of resources, and effort, and achieve low manual intervention time, save user funds, and facilitate upgrades The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

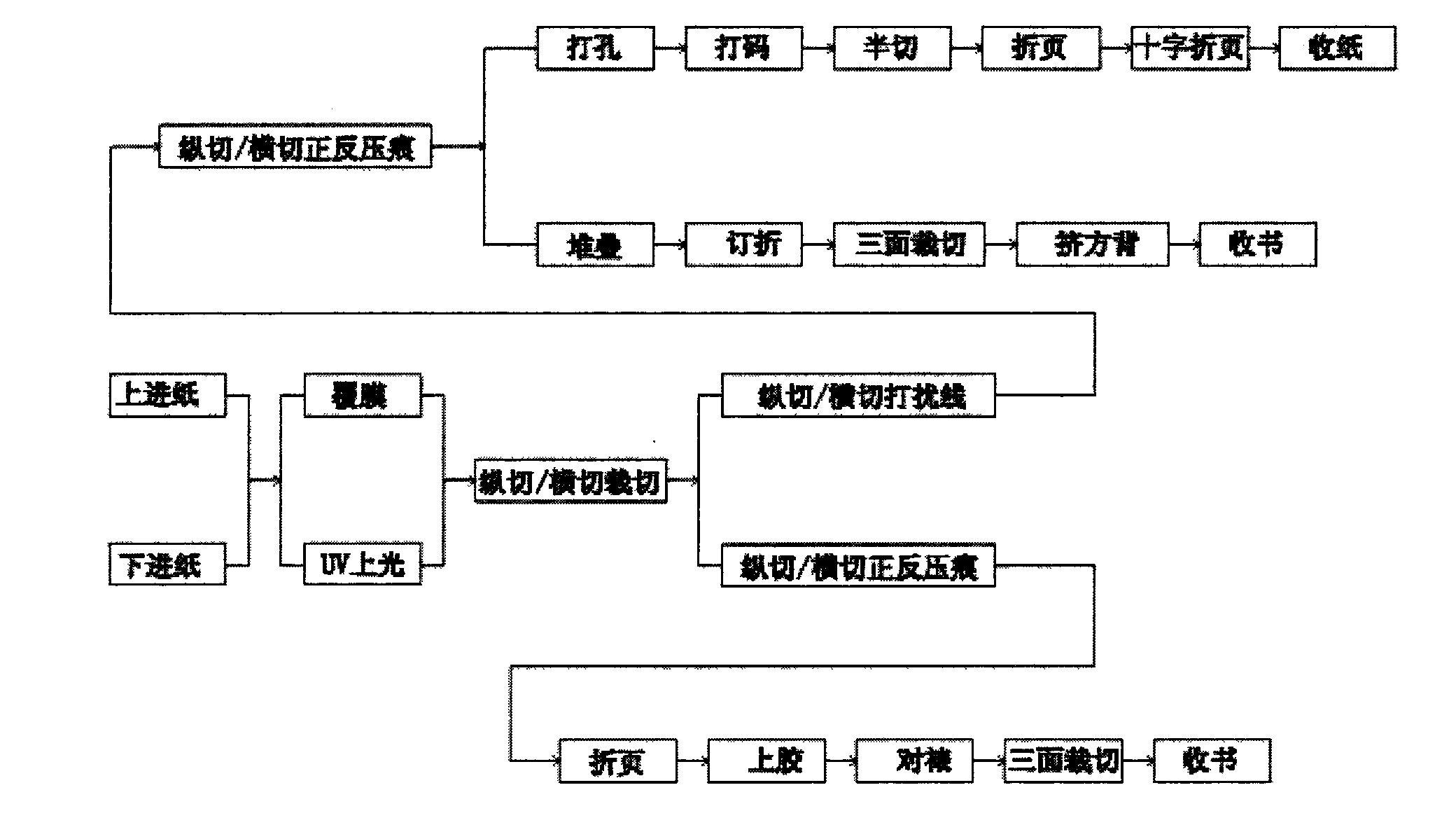

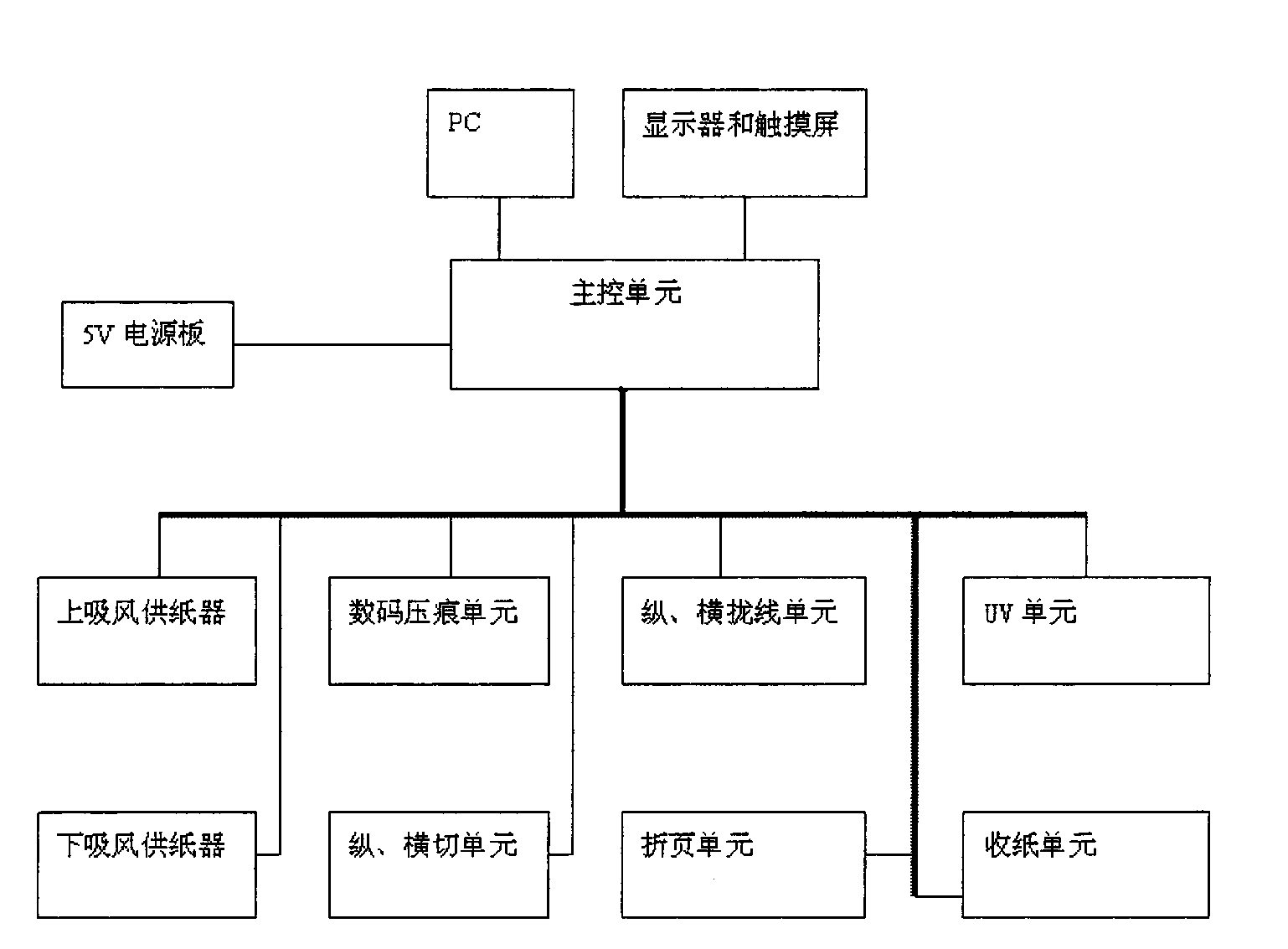

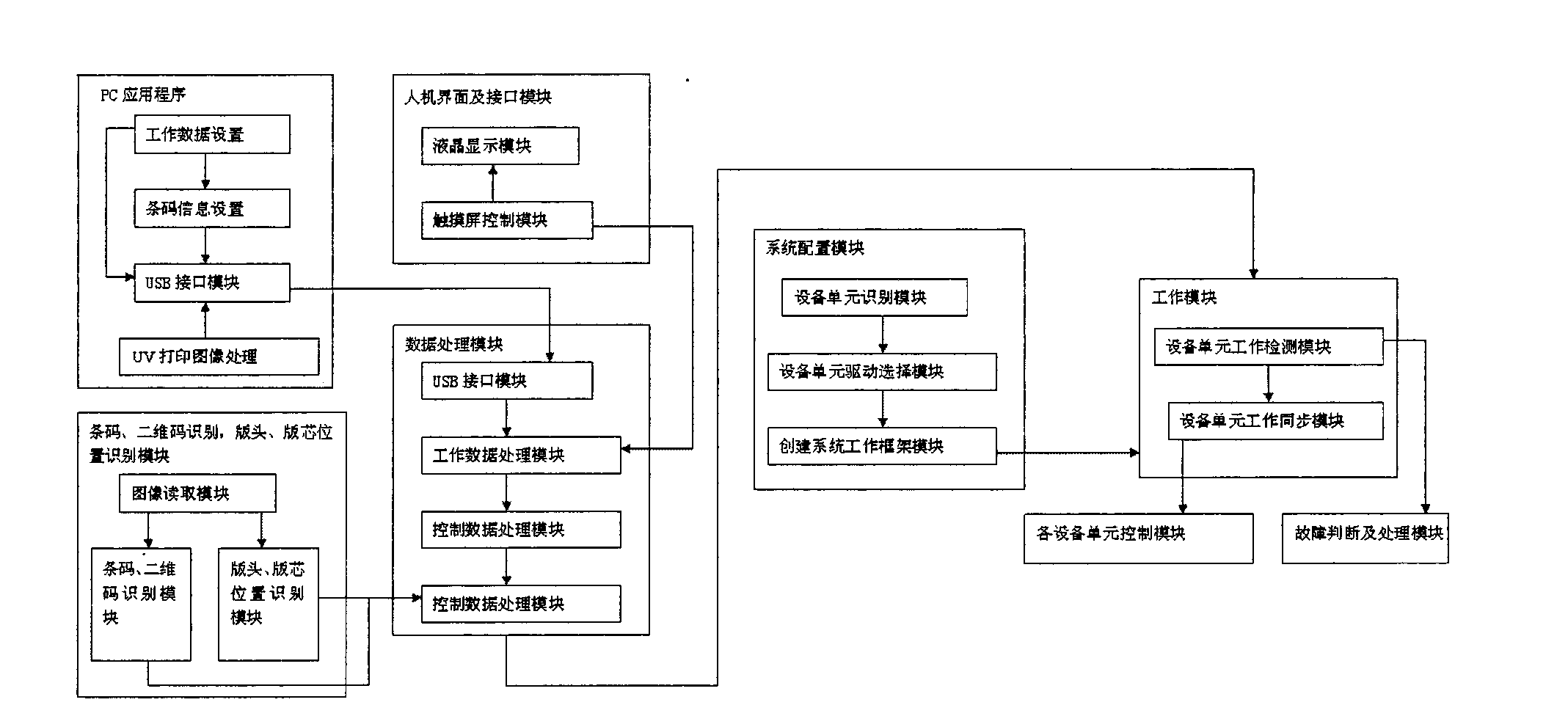

[0035] Such as figure 1 As shown, the modular online digital finishing system is used to process paper or other similar substrates in the form of sheets or rolls, and the final processed products are single-page, multi-page saddle-stitch booklets, and multi-page pair-to-mount binding Booklet and other three forms:

[0036] a), paper feeding-laminating (-UV)-longitudinal and horizontal cutting-longitudinal and horizontal folding lines-longitudinal and horizontal and positive and negative indentations-punching-coding-half cutting-folding-cross folding-receiving;

[0037] b), paper feeding-film (-UV)-vertical and horizontal cutting-vertical and horizontal folding lines-longitudinal and horizontal and positive and negative indentations-stacking-folding-three-sided cutting-squeezing square back-book collection (multi-page saddle stitch booklet);

[0038] c), paper feeding - film (-UV) - vertical and horizontal cutting - vertical and horizontal and front and back indentation - fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com