Method for manufacturing magnetic tiles with magnetic field lines diffusing in radiating mode

A production method and technology of magnetic lines of force, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem of inability to manufacture permanent magnet tiles, and achieve the effects of reasonable design, improved work efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

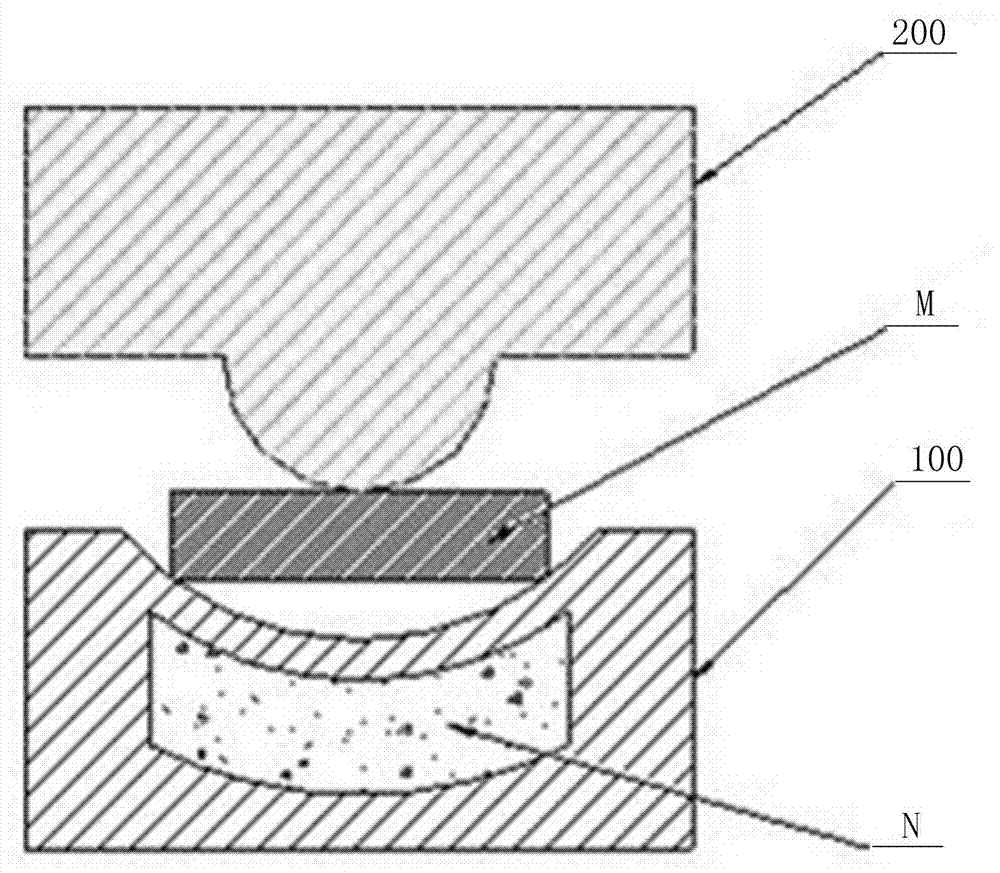

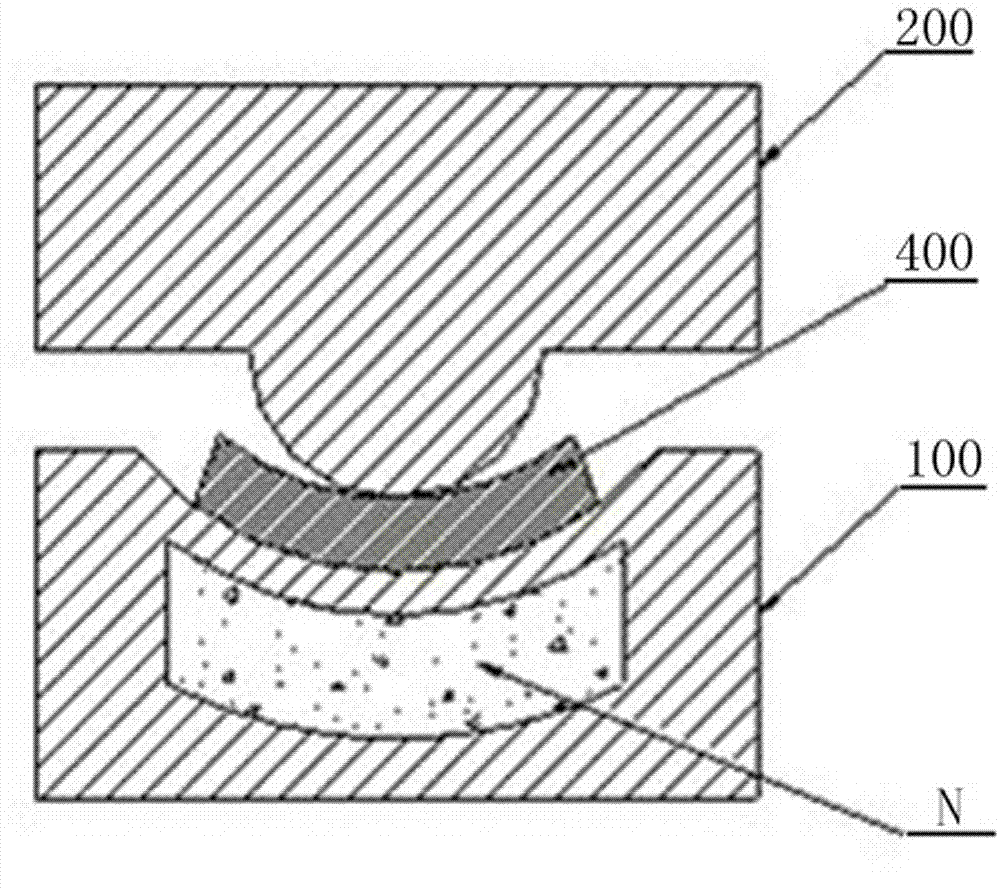

[0037] A method for manufacturing a magnetic tile with divergent radiation of magnetic force lines, comprising the following steps:

[0038] (1) Clean the surface of the magnetic block M with the parallel distribution of magnetic field lines β; it can be cleaned by surface air blasting first, and after cleaning, perform surface plasma cleaning in a heat treatment furnace, especially to remove oxides attached to the surface , so that it can achieve the purpose of cleaning and pollution-free.

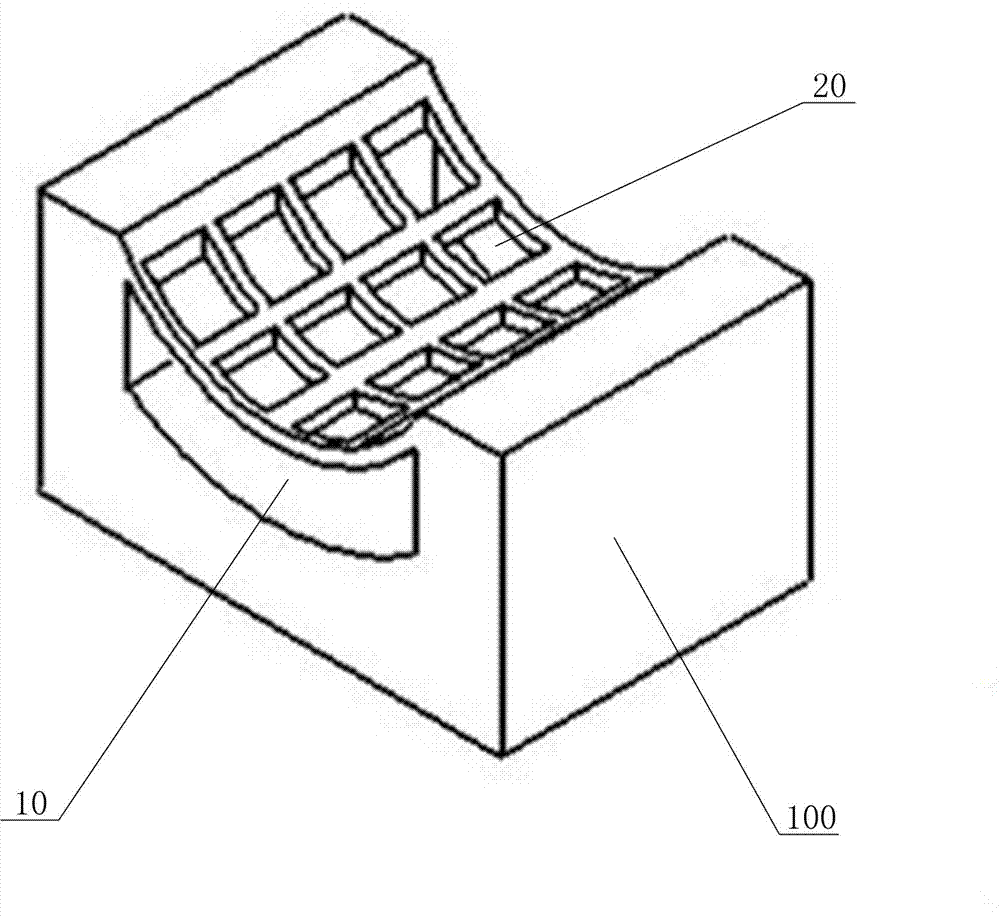

[0039] (2), such as image 3 , 4, 5, the base 100 is prepared from a material that does not react physically and chemically with the magnetic block M, the top of the base 100 has an arc surface 30, and the base 100 is located below the arc surface 30 to form a The arcuate surface 30 is an arcuate cavity 10 having the same radian. The arcuate surface 30 is provided with through holes 20 communicating with the arcuate cavity 10 and covering the arcuate surface 30 .

[0040] During specif...

Embodiment 2

[0051] A method for manufacturing a magnetic tile with divergent radiation of magnetic force lines, comprising the following steps:

[0052] (1) Clean the surface of the magnetic block M with the parallel distribution of magnetic field lines β; it can be cleaned by surface air blasting first, and after cleaning, perform surface plasma cleaning in a heat treatment furnace, especially to remove oxides attached to the surface , so that it can achieve the purpose of cleaning and pollution-free.

[0053] (2), such as image 3 , 4 , 5, the base 100 is prepared from a material that does not react physically and chemically with the magnetic block M, the top of the base 100 has an arc surface 30, and the base 100 is located below the arc surface 30 to form a The arcuate surface 30 is an arcuate cavity 10 having the same radian. The arcuate surface 30 is provided with through holes 20 communicating with the arcuate cavity 10 and covering the arcuate surface 30 .

[0054] During speci...

Embodiment 3

[0065] A method for manufacturing a magnetic tile with divergent radiation of magnetic force lines, comprising the following steps:

[0066] (1) Clean the surface of the magnetic block M with the parallel distribution of magnetic field lines β; it can be cleaned by surface air blasting first, and after cleaning, perform surface plasma cleaning in a heat treatment furnace, especially to remove oxides attached to the surface , so that it can achieve the purpose of cleaning and pollution-free.

[0067] (2), such as image 3 , 4 , 5, the base 100 is prepared from a material that does not react physically and chemically with the magnetic block M, the top of the base 100 has an arc surface 30, and the base 100 is located below the arc surface 30 to form a The arcuate surface 30 is an arcuate cavity 10 having the same radian. The arcuate surface 30 is provided with through holes 20 communicating with the arcuate cavity 10 and covering the arcuate surface 30 .

[0068] During speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com