Cold-rolled hot-galvanized duplex steel and manufacturing method thereof

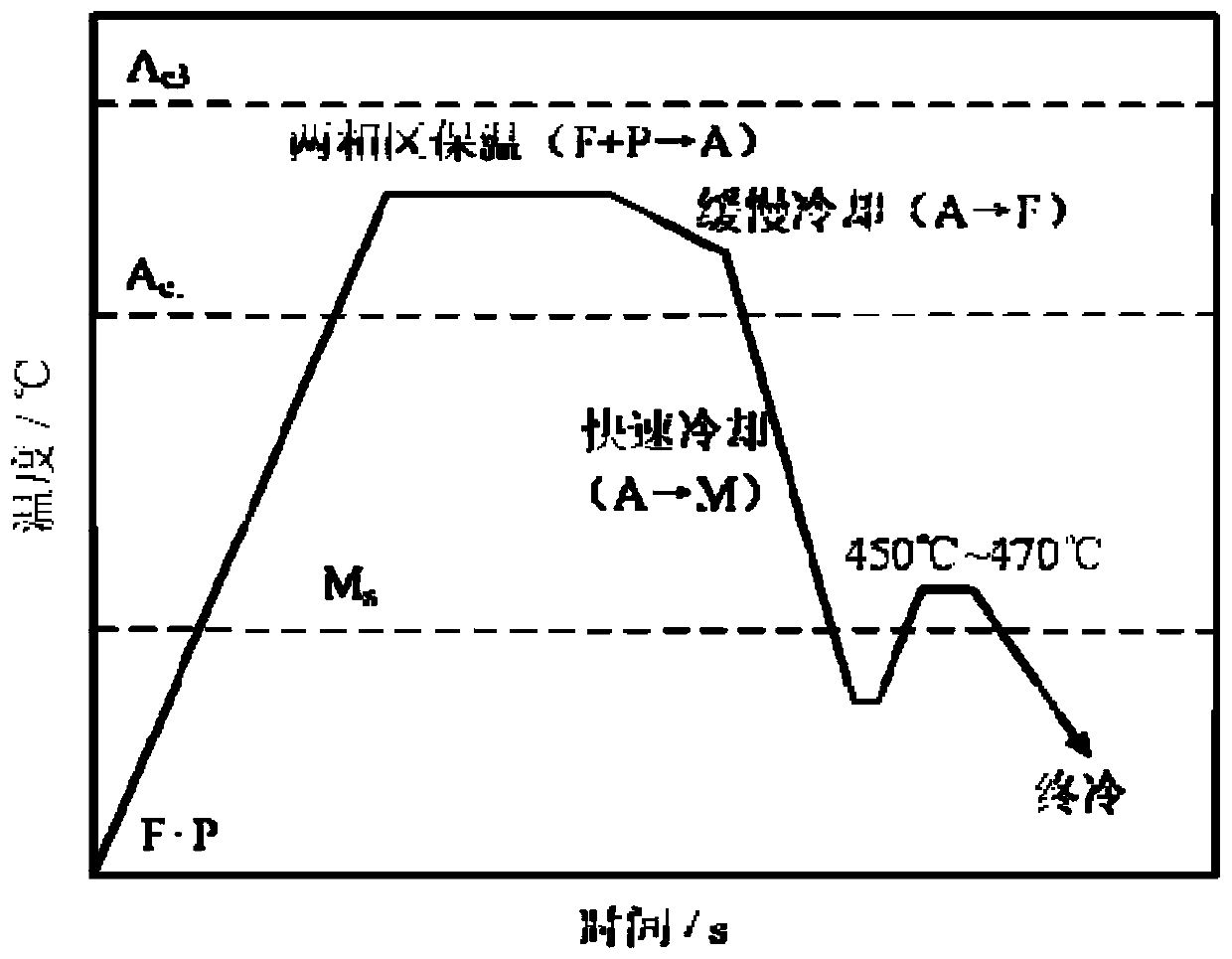

A manufacturing method, hot-dip galvanizing technology, applied in the direction of manufacturing tools, hot-dip galvanizing process, heat treatment furnace, etc., can solve the problems of increasing the content of alloy elements, affecting the welding performance of materials, and increasing the production cost of products, so as to reduce the content and improve the production cost. Product welding performance, the effect of simplifying production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Tensile strength 590MPa grade dual-phase steel chemical composition mass percentage (wt.%) is: C: 0.09%, Mn: 1.55%, S: 0.010%, P: 0.015%, Si: 0.35%, Als: 0.04%, Cr : 0.50%, N: 0.006%, and the balance is Fe and impurities.

[0041] The hot rolling process is as follows: the slab heating temperature is 1250°C, the finish rolling temperature is 1000°C, the final rolling temperature is 850°C, and the coiling temperature is 600°C.

[0042] The reduction rate of cold rolling is 60%, and the cold strip steel is obtained, which enters the subsequent continuous annealing process.

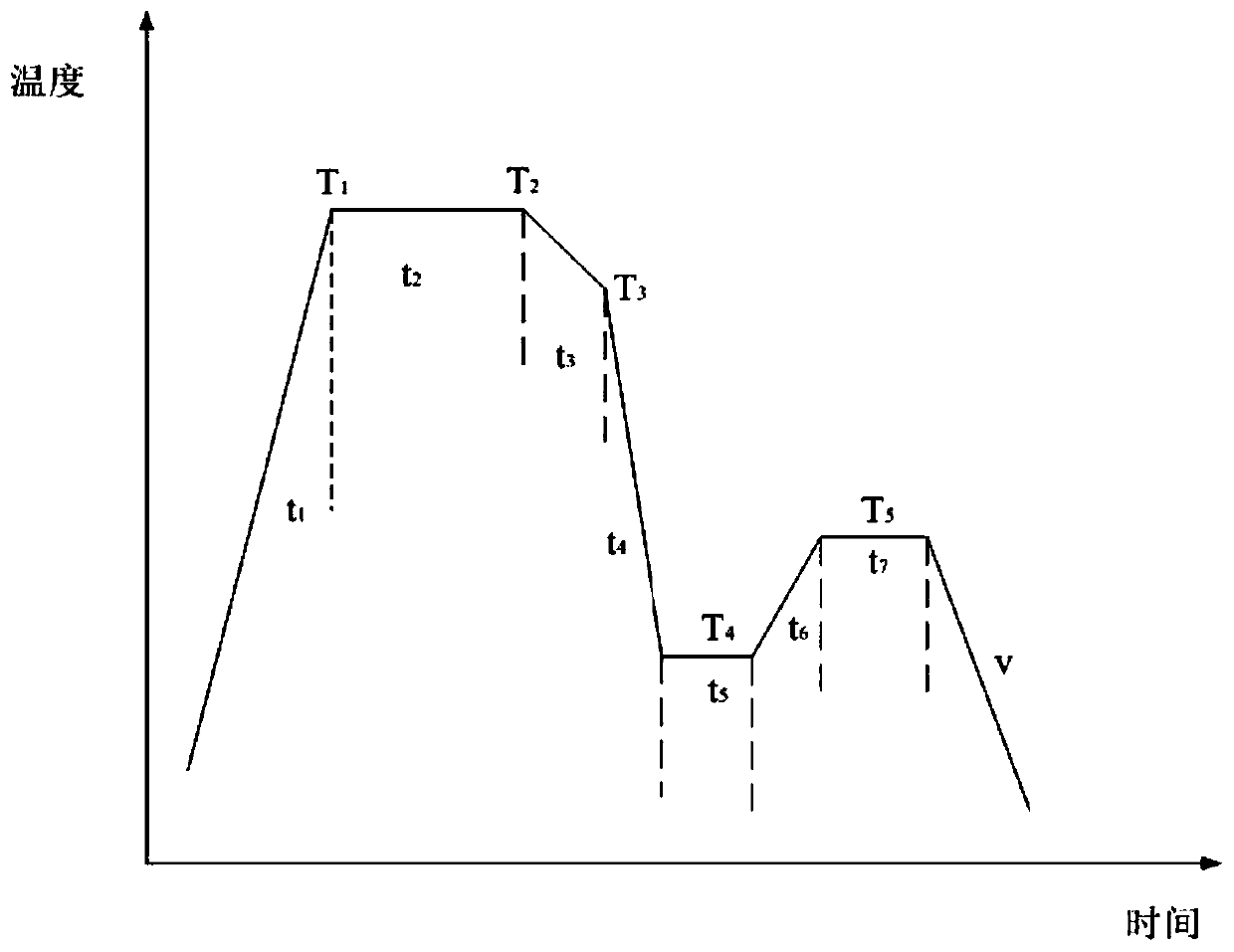

[0043] The continuous annealing process parameters are shown in Table 1.

[0044] Table 1

[0045]

[0046]

[0047] The mechanical properties of the above cold-rolled hot-dip galvanized dual-phase steel after continuous annealing are shown in Table 2.

[0048] Table 2

[0049]

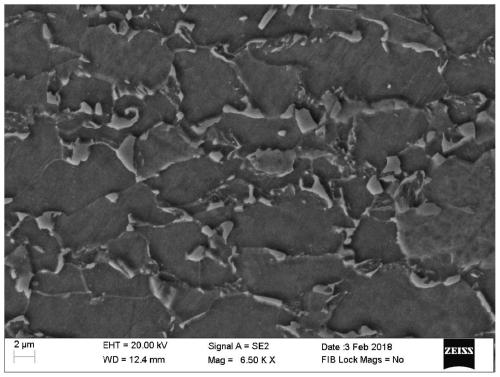

[0050] image 3 It shows the microstructure of the finished dual-phase steel with a tensile strength of 590MP...

Embodiment 2

[0052]Tensile strength 780MPa grade dual-phase steel chemical composition mass percentage (wt.%) is: C: 0.16%, Mn: 1.75%, S: 0.010%, P: 0.020%, Si: 0.35%, Als: 0.04%, Cr : 0.55%, N: 0.006%, Ti: 0.02%, and the balance is Fe and impurities.

[0053] The hot rolling process is as follows: the slab heating temperature is 1220°C, the finish rolling temperature is 1000°C, the final rolling temperature is 860°C, and the coiling temperature is 620°C.

[0054] The reduction ratio of cold rolling is 55%, and the cold strip steel is obtained, which enters the subsequent continuous annealing process.

[0055] The continuous annealing process parameters are shown in Table 3.

[0056] table 3

[0057]

[0058]

[0059] The mechanical properties of the cold-rolled hot-dip galvanized dual-phase steel after continuous annealing are shown in Table 4.

[0060] Table 4

[0061]

[0062] Figure 4 It shows the microstructure of the finished dual-phase steel with a tensile strength of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com