Composite insulated sleeve

A composite insulation and bushing technology, which is applied in the direction of insulators, insulators, lead-in/through-type insulators, etc., can solve problems such as insufficient functional reliability, low anti-seepage reliability, and poor strength reliability, and achieve outstanding functional reliability. The effect of short processing time and low tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

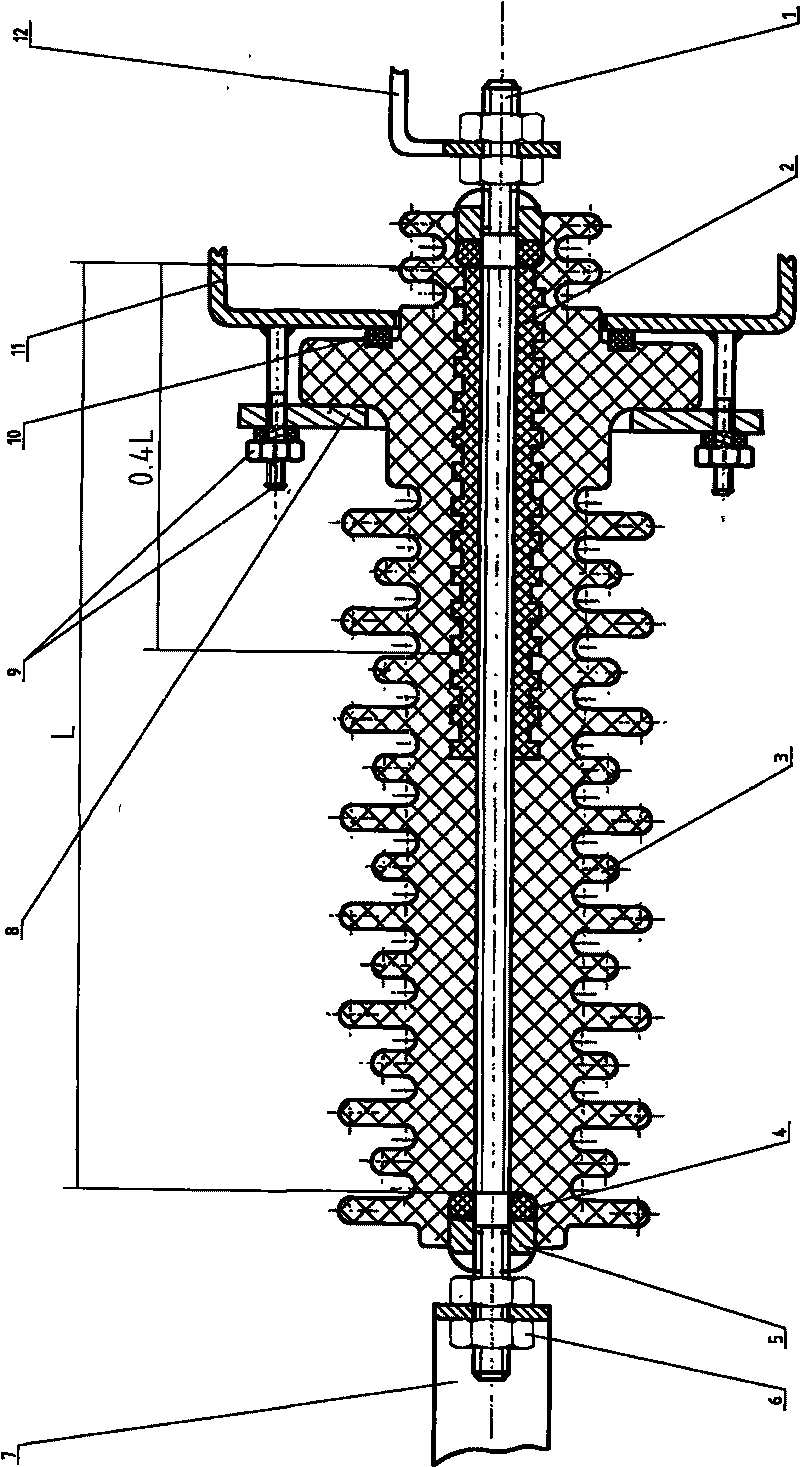

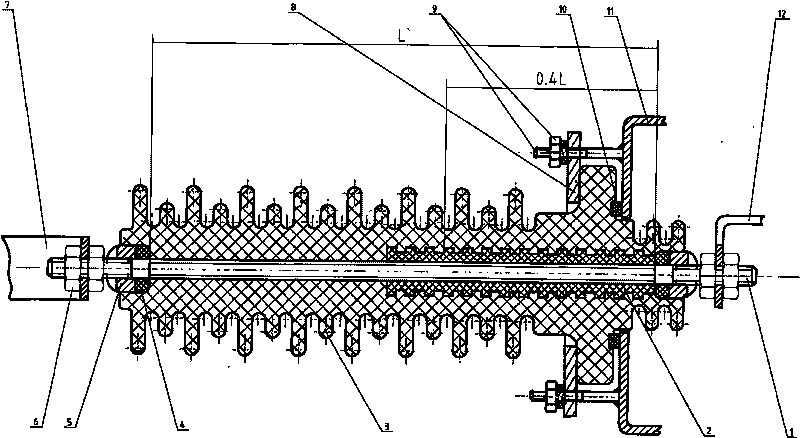

[0029] Further illustrate the embodiment of the present invention below in conjunction with accompanying drawing: please see accompanying drawing,

[0030] Serial numbers 1 to 6 show the components of the composite insulating bushing of the embodiment, and serial numbers 7 to 12 show the components related to this example. The composite insulating bushing of this example is suitable for use in American box-type transformers with a voltage level of 35KV.

[0031] The components of the embodiment are as follows: 1 is the conductive rod, which is located at the central axis of the structure and is connected to the outer cable and the inner coil of the transformer; 2 is the insulating core, which is hooped on the 0.4L long section of the conductive rod, which is its internal pressure resistance The first line of defense for insulation; 3 is the insulating umbrella, which is laminated on the outer layer of the composite member of the conductive rod and the insulating core, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com