Building thermostatic agent and preparation method thereof

A technology of constant temperature and construction, applied in chemical instruments and methods, heat exchange materials, coatings, etc., to achieve the effects of saving money for the people, social benefits, convenient construction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

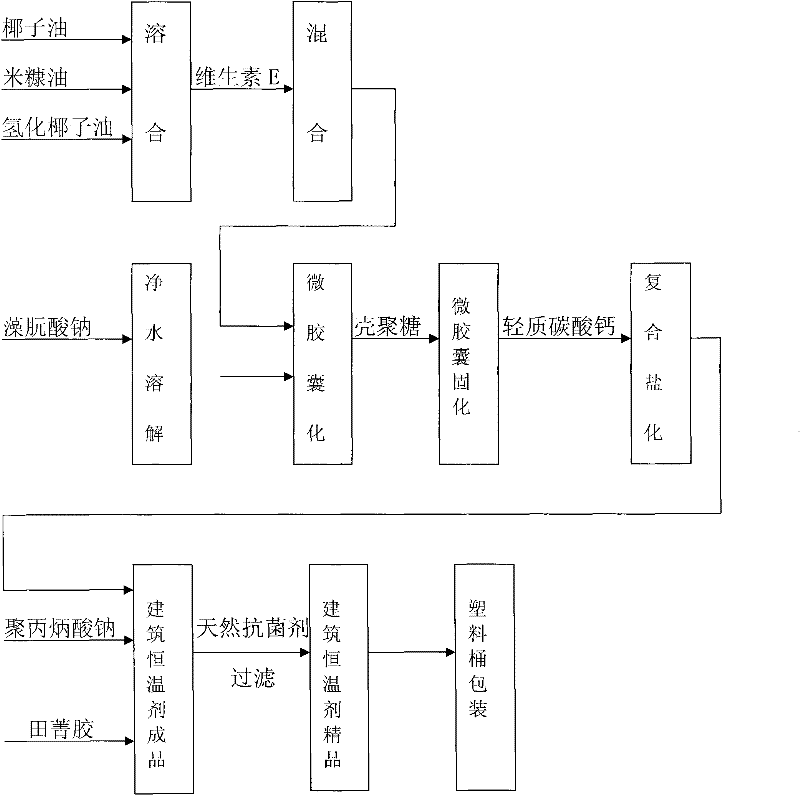

Method used

Image

Examples

Embodiment 1

[0041] A building thermostat, characterized in that: it is made by using the following ratio of raw and auxiliary materials and preparation method:

[0042] Weight ratio of raw and auxiliary materials:

[0043] 30% coconut oil with a melting point of 25°C-28°C and a fatty acid content of more than 90%

[0044] Melting point -5℃~-10℃, rice bran oil with fatty acid content above 80% 8%

[0045] 13% hydrogenated coconut oil with a melting point of 25°C-38.2°C and a fatty acid content of more than 95%

[0046] Vitamin E 0.1-0.5%

[0047] Sodium Alginate 1.0-3.0%

[0048] Vinegar-soluble chitosan 0.5-1.0%

[0049] Squat Gum 1.0-2.0%

[0050] Food grade light calcium carbonate 10-30%

[0051] Sodium polyacrylate 1.0-2.5%

[0052] Add water to 100%

[0053] The preparation method is:

[0054] 1) Add water to a stainless steel reaction tank with a heating interlayer, add the auxiliary material sodium alginate through the mesh screen at the mouth of the tank under stirring, st...

Embodiment 2

[0065] A building thermostat, characterized in that: it is made by using the following ratio of raw and auxiliary materials and preparation method:

[0066] Weight ratio of raw and auxiliary materials:

[0067] 35% coconut oil with a melting point of 25°C-28°C and a fatty acid content of more than 90%

[0068] Melting point -5℃~-10℃, rice bran oil with fatty acid content above 80% 10%

[0069] 15% hydrogenated coconut oil with a melting point of 25°C-38.2°C and a fatty acid content of more than 95%

[0070] Vitamin E 0.1-0.5%

[0071] Sodium Alginate 1.0-3.0%

[0072] Vinegar-soluble chitosan 0.5-1.0%

[0073] Squat Gum 1.0-2.0%

[0074] Food grade light calcium carbonate 10-30%

[0075] Sodium polyacrylate 1.0-2.5%

[0076] Add water to 100%

[0077] The preparation method is the same as in Example 1.

Embodiment 3

[0079] A building thermostat, characterized in that: it is made by using the following ratio of raw and auxiliary materials and preparation method:

[0080] Weight ratio of raw and auxiliary materials:

[0081] 30% coconut oil with a melting point of 25°C-28°C and a fatty acid content of more than 90%

[0082] Melting point -5℃~-10℃, rice bran oil with fatty acid content above 80% 8%

[0083] 13% hydrogenated coconut oil with a melting point of 25°C-38.2°C and a fatty acid content of more than 95%

[0084] Vitamin E 0.1-0.5%

[0085] Sodium Alginate 1.0-3.0%

[0086] Vinegar-soluble chitosan 0.5-1.0%

[0087] Squat Gum 1.0-2.0%

[0088] Food grade light calcium carbonate 10-30%

[0089] Sodium polyacrylate 1.0-2.5%

[0090] Add water to 100%

[0091] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com