Preparation method and application of corn straw all-component membrane

A technology of corn stalks and full components, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of low utilization rate of deep processing, waste of feed resources, low value, etc., and achieve good UV resistance and dissolution process The effect of simplicity and short production process cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a full-component film of corn stalks, comprising the steps of:

[0040] 1) Pretreatment: Cut the corn stalks into 5 cm sections, after dedusting, cleaning and drying, pulverize with a pulverizer, and pass through a 90-mesh sieve to obtain corn stalk powder;

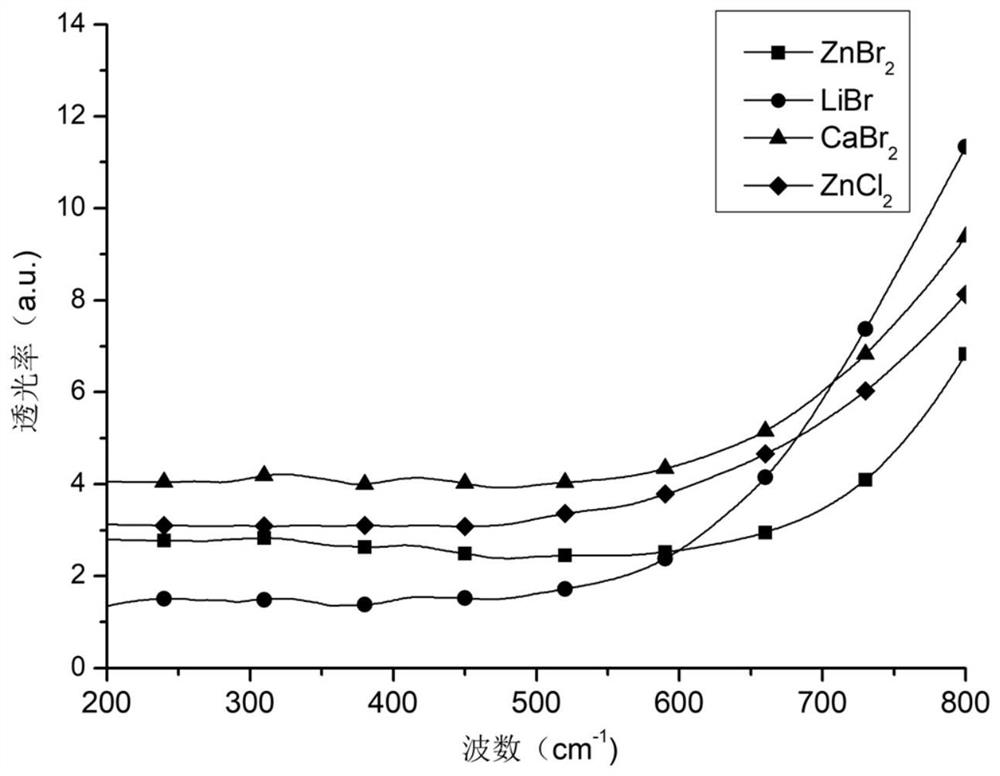

[0041] 2) Dissolving: put the corn stalk powder obtained in step 1) into a zinc bromide solution with a mass concentration of 75%, the mass ratio of the corn stalk powder to the zinc bromide solution is 1:25, and stir and dissolve at 80°C. The stirring and dissolving time was 45min to obtain a solution;

[0042] 3) Film making: Pour the solution obtained in step 2) into a glass plate to form a film, place it in a ventilated place for 1 hour, wash the film with a large amount of distilled water to remove residual solvent, and cover the cleaned film evenly with two glass plates Put them together in a vacuum drying oven at 60°C for 10 hours, and then peel off the film from the glass plate to ob...

Embodiment 2

[0044] A method for preparing a full-component film of corn stalks, comprising the steps of:

[0045] 1) Pretreatment: cut the corn stalks into 6 cm sections, after dedusting, cleaning and drying, pulverize with a pulverizer, and pass through an 80-mesh sieve to obtain corn stalk powder.

[0046] 2) Dissolution: put the corn stalk powder obtained in step 1) into a lithium bromide solution with a mass concentration of 65%, the mass ratio of the corn stalk powder to the lithium bromide solution is 1:25, and stir and dissolve at 120°C. The stirring and dissolving time is 60min, obtain lysate;

[0047] 3) Membrane production: Pour the solution obtained in step 2) into a glass plate to form a film, place it in a ventilated place for 1.5 hours, wash the film with a large amount of distilled water to remove residual solvent, and cover the cleaned film with two glass plates Evenly place them together in a vacuum drying oven at 50°C for 12 hours, and then peel off the film from the gl...

Embodiment 3

[0049] A method for preparing a full-component film of corn stalks, comprising the steps of:

[0050] 1) Pretreatment: Cut corn stalks into 10 cm sections, after dedusting, cleaning and drying, pulverize with a pulverizer, pass through a 100-mesh sieve to obtain corn stalk powder.

[0051] 2) Dissolving: Put the corn stalk powder obtained in step 1) into a calcium bromide solution with a mass concentration of 75%, the mass ratio of the corn stalk powder to the calcium bromide solution is 1:25, and stir and dissolve at 130°C. Stirring and dissolving time was 20min to obtain a solution;

[0052] 3) Film making: Pour the solution obtained in step 2) into a glass plate to form a film, place it in a ventilated place for 1 hour, wash the film with a large amount of distilled water to remove residual solvent, and cover the cleaned film evenly with two glass plates Put them together in a vacuum drying oven at 40°C for 12 hours and then peel off the film from the glass plate to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com