Combined enhanced treatment process for low-turbidity high-alga raw water

A process and raw water technology, which is applied in the field of combined enhanced treatment of low-turbidity and high-algae raw water, can solve the problems of filter layer penetration, filter material surface clogging, algae entering clean water reservoirs and pipe networks, etc., to make full use of geothermal resources and simplify The effect of saving production management and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

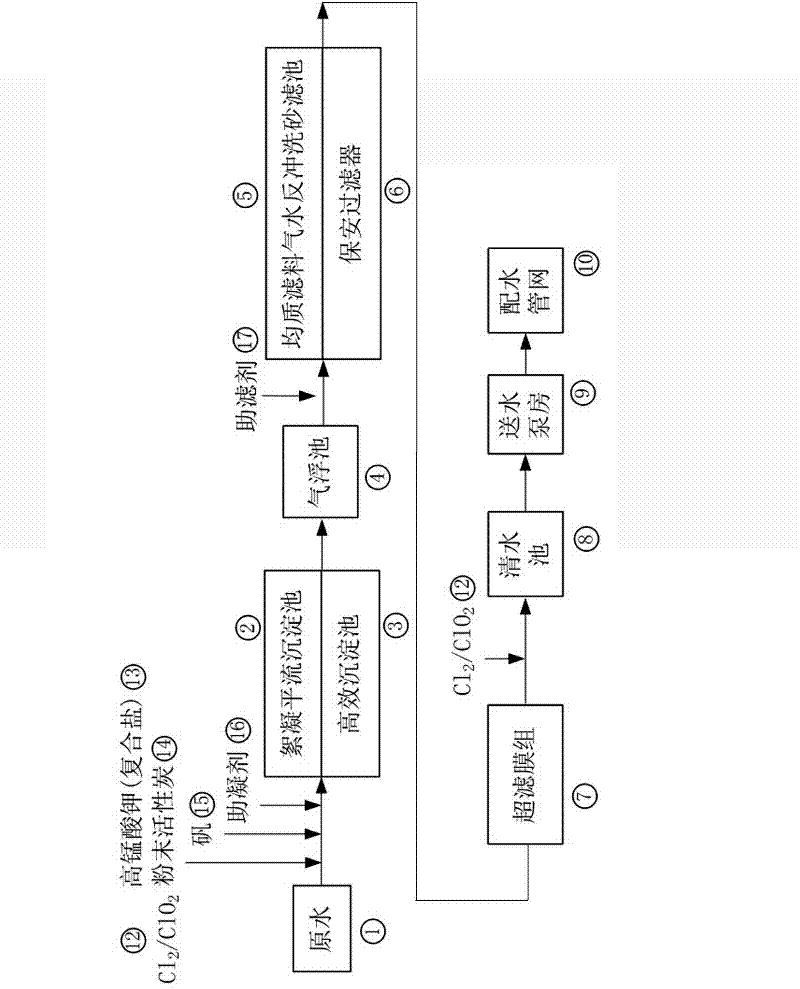

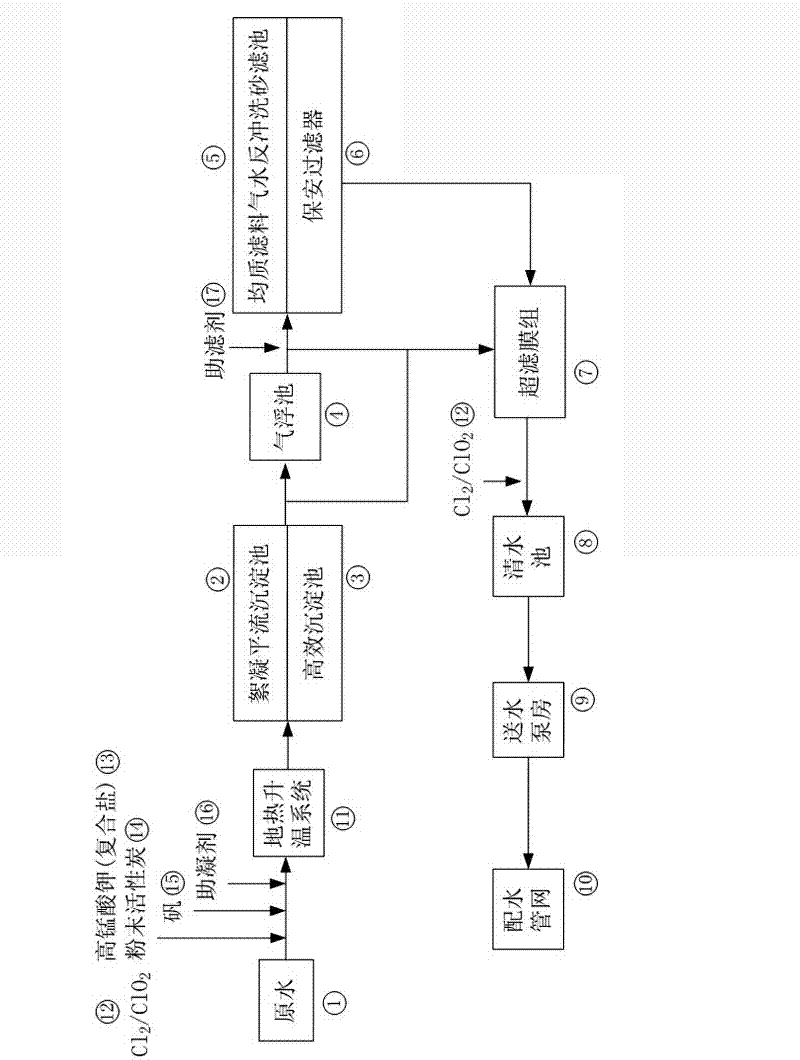

[0011] The invention is a combined enhanced treatment process for low-turbidity and high-algae raw water. Under normal conditions, the raw water 1 is first settled in the flocculation advection sedimentation tank 2 or the high-efficiency sedimentation tank 3, and then the air flotation tank 4 is used to remove algae. After being stored, it is sent to the water distribution pipe network 10 by the water delivery pump house 9 . When the turbidity of the raw water is high or the effect of sedimentation water is poor, after the algae removal by air flotation in the air flotation tank 4, it can be filtered by the homogeneous filter material air-water backwashing sand filter 5 or the security filter 6, and then filtered by the ultrafiltration membrane Group 7 further removes turbidity and algae, and the effluent is sent to the water distribution pipe network 10 by the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com