Patents

Literature

35results about How to "Reduce operators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

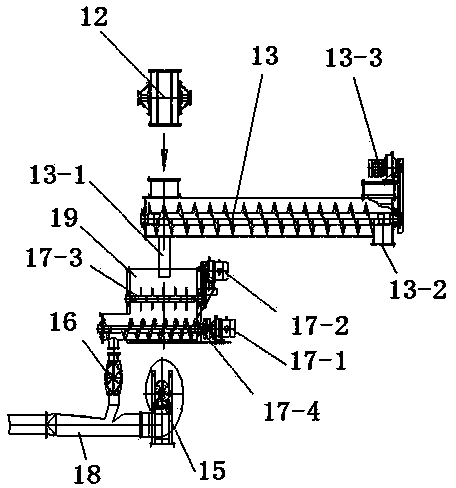

Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

InactiveCN103894260ADoes not destroy nutrientsKeep the scentGrain treatmentsProcess engineeringIndustrial engineering

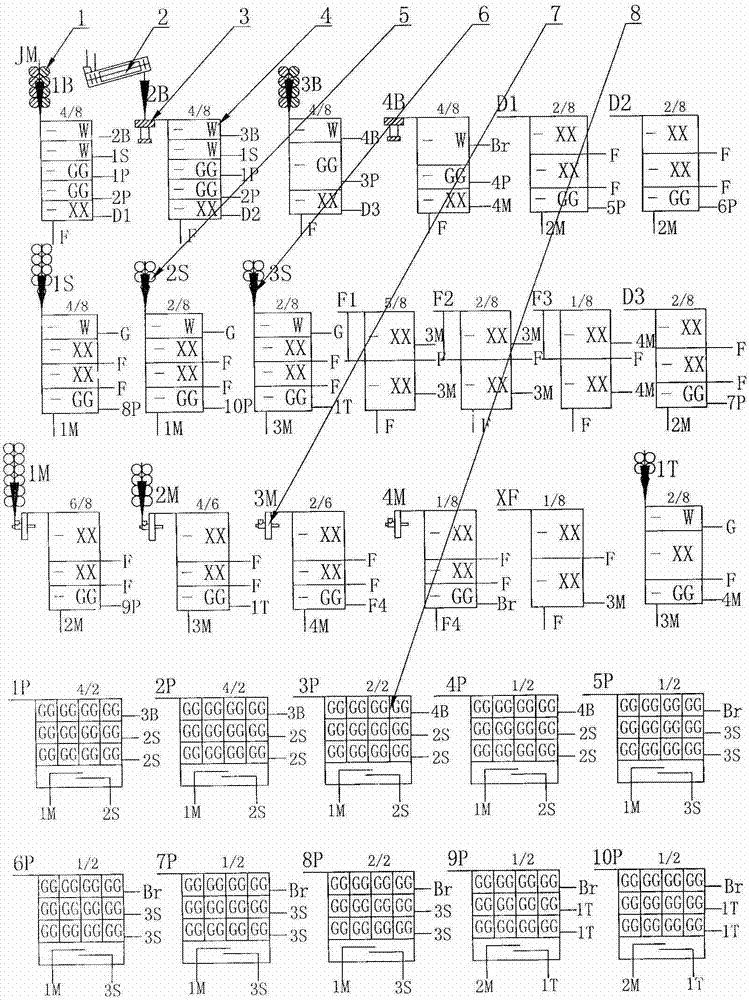

The invention relates to an efficient simplified wheat flour milling technology comprising the working procedures of shelling, residue grinding, core grinding, tailing grinding and flour clearing, and an efficient simplified wheat flour milling device. In the shelling working procedure, an extrusion cutting grinder with a superior stripping and scraping function is used for replacing the existing tooth roller flour mill and is taken as a main residue making device; in the core grinding working procedure, an efficient impact flour mill is used for replacing a smooth roll flour mill and is taken as a main flour making device, and the grinding function of the efficient impact flour mill is more than twice as high as that of the prior art; two wraps are wetted by water, residue grinding is carried out for three times, and germ extraction is carried out during residue grinding; after the core 1 and the core 2 are slightly ground by a roller mill, the aim of rapidly and efficiently producing the high-quality flour at low temperature with low consumption can be achieved by virtue of a strong impact method of a water cooling efficient impact grinder and the like. The wheat flour milling production line extrusion process designed by the invention is simple in process, low in civil engineering equipment investment, high in production efficiency, simple in operation and management and low in energy consumption; the produced high precision flour is large in proportion; the produced flour is good in edible quality and food production performance; the produced flour has the advantages that the original fragrance of the wheat is maintained by the flour, and the like.

Owner:王洪福

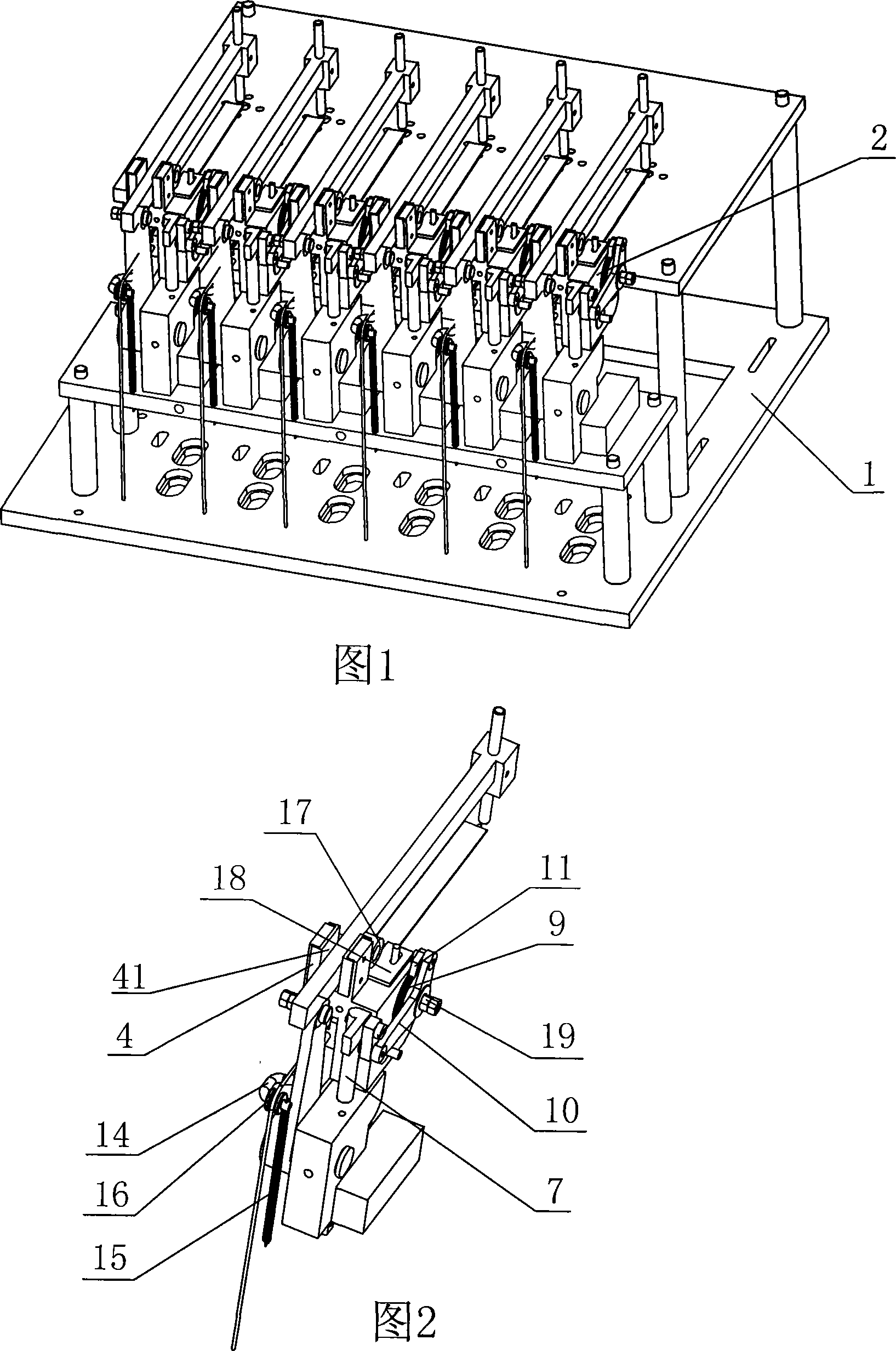

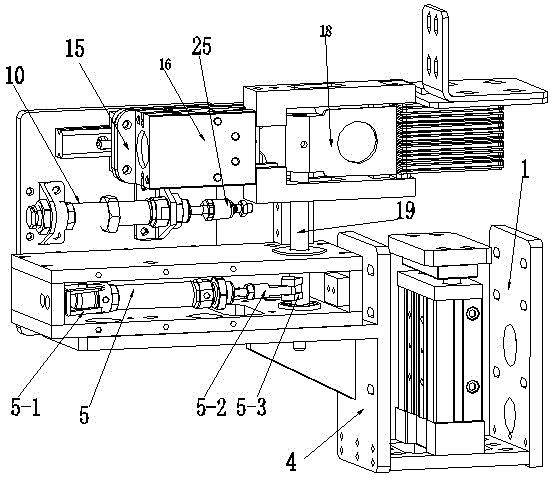

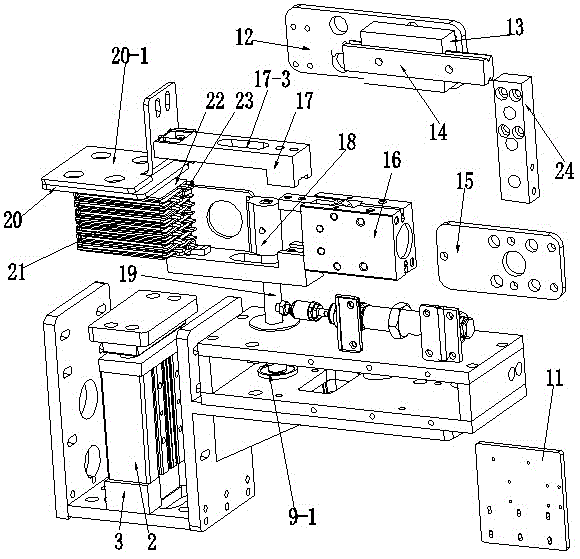

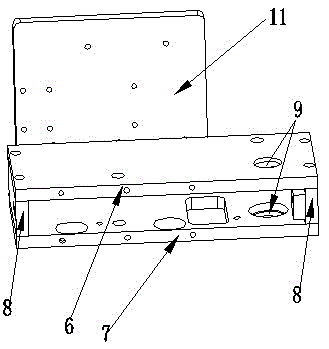

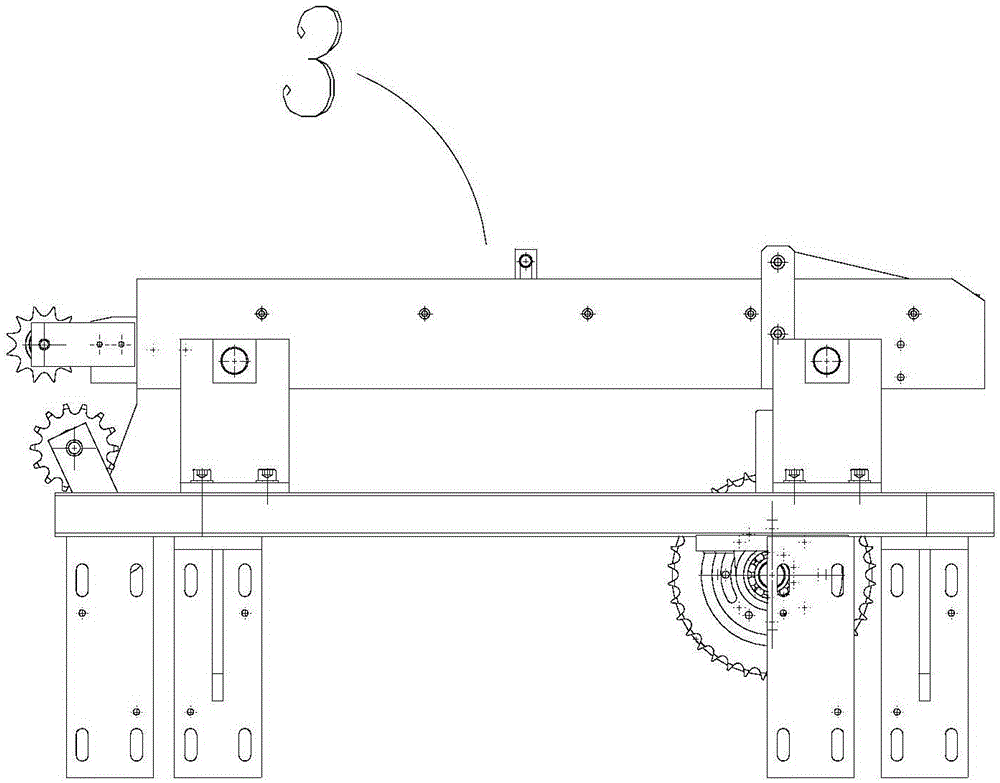

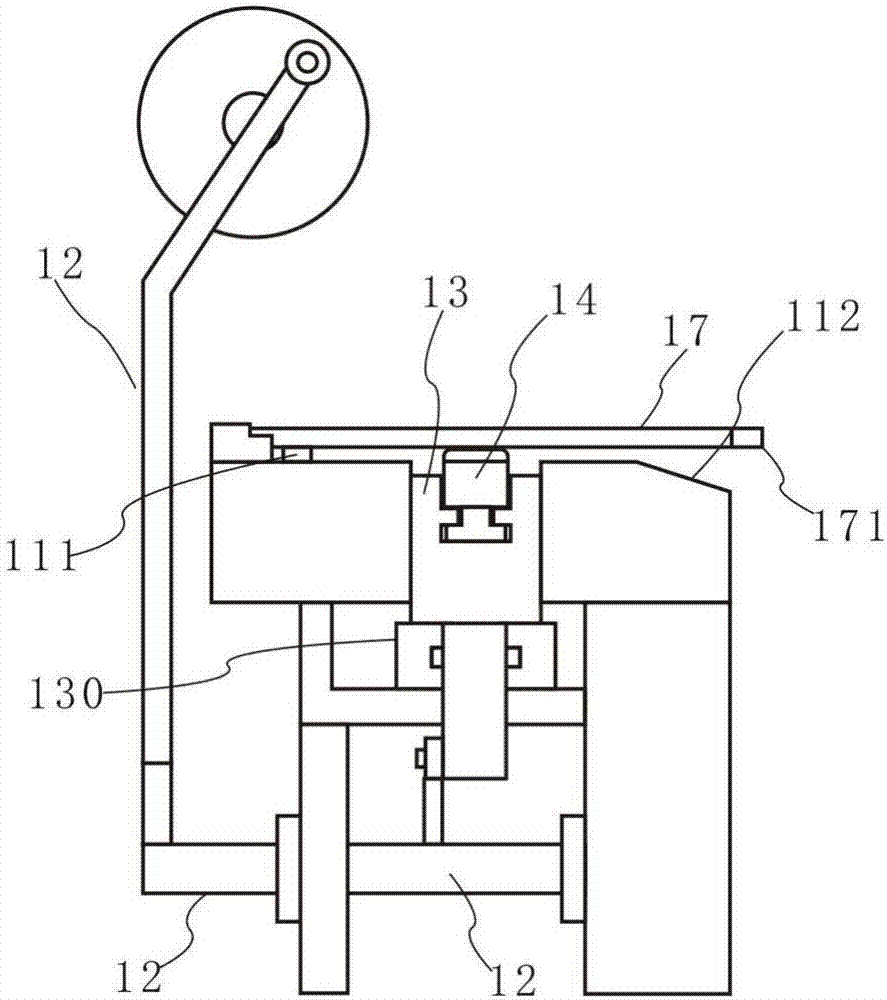

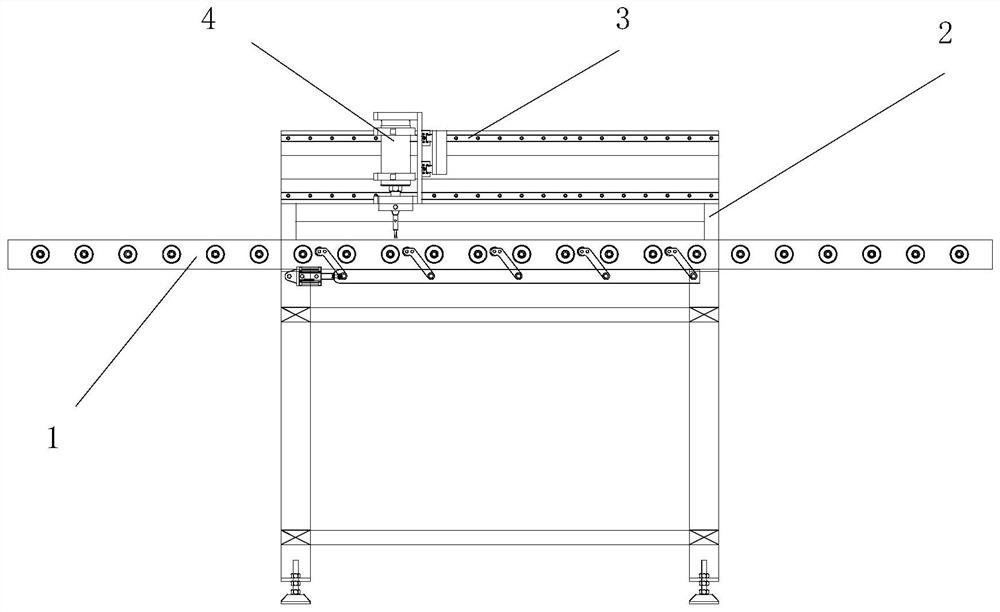

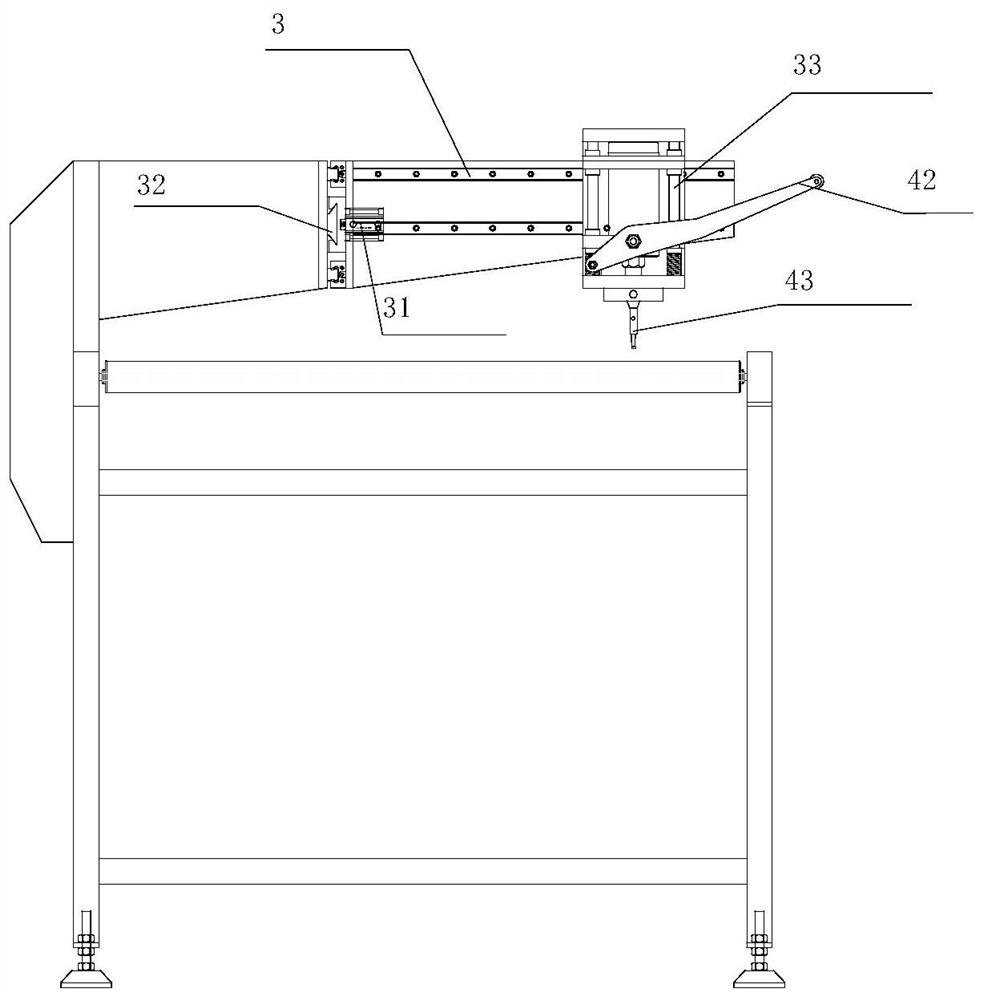

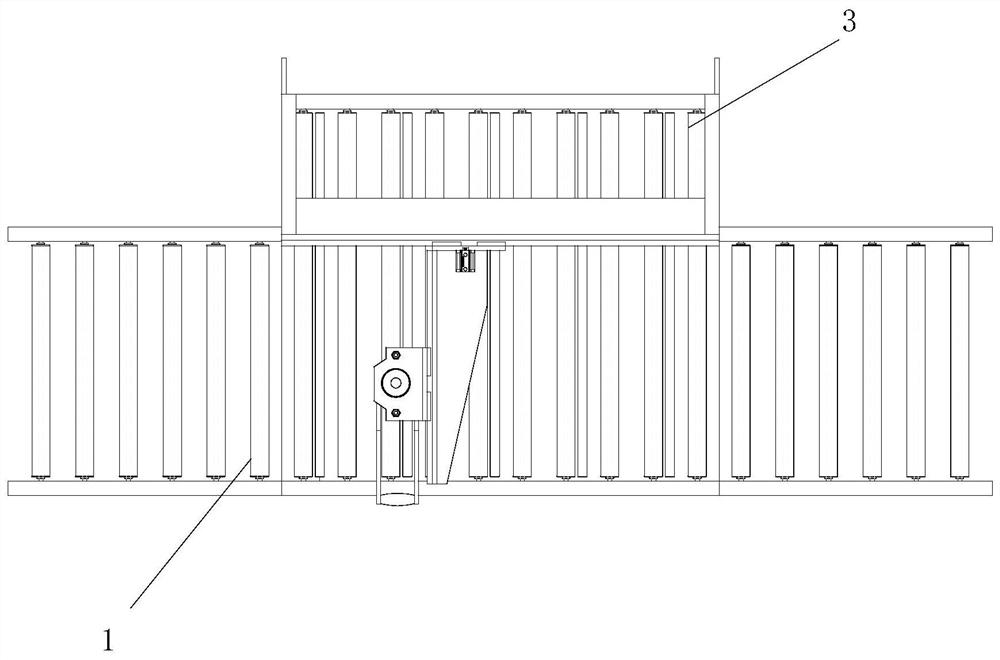

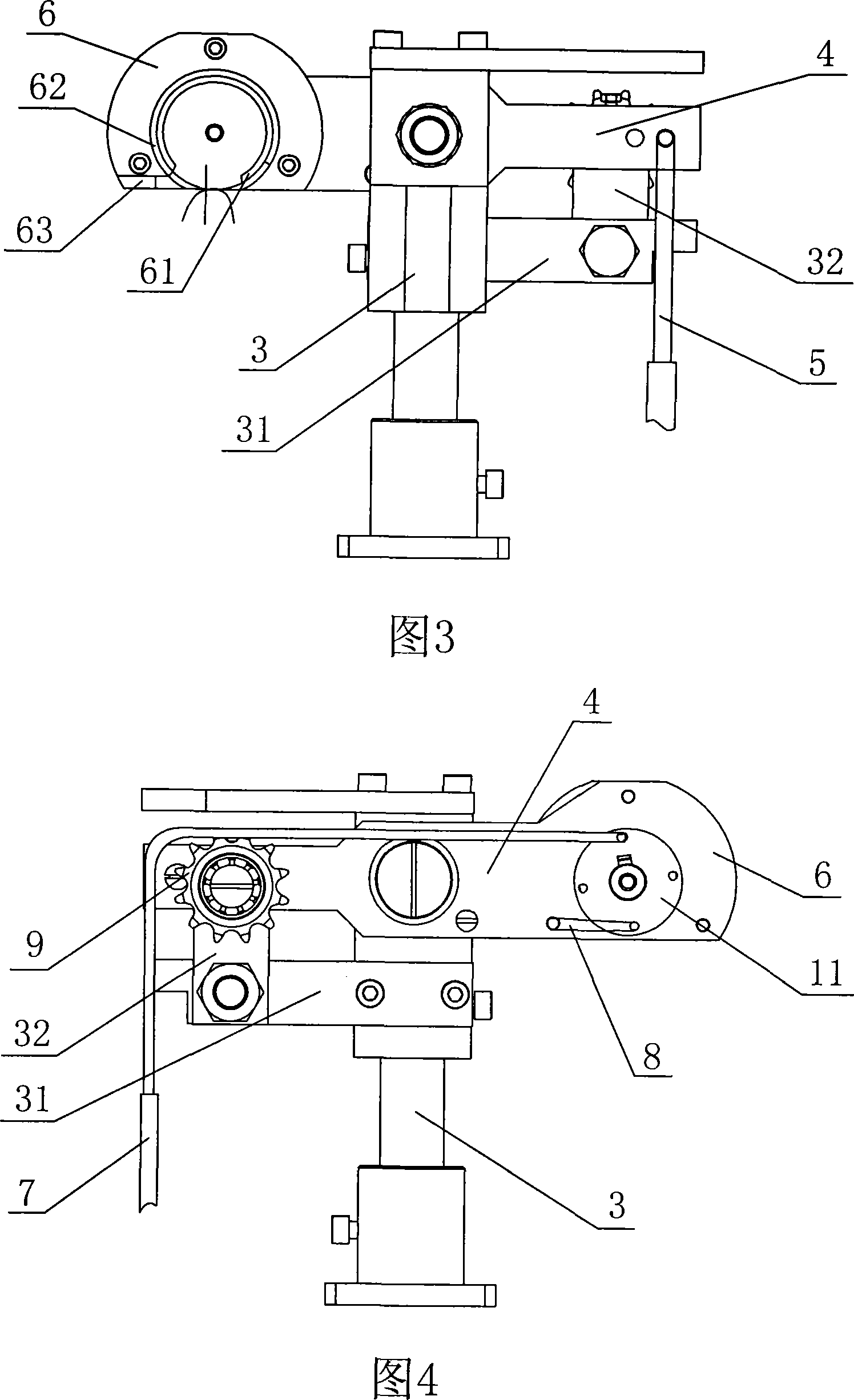

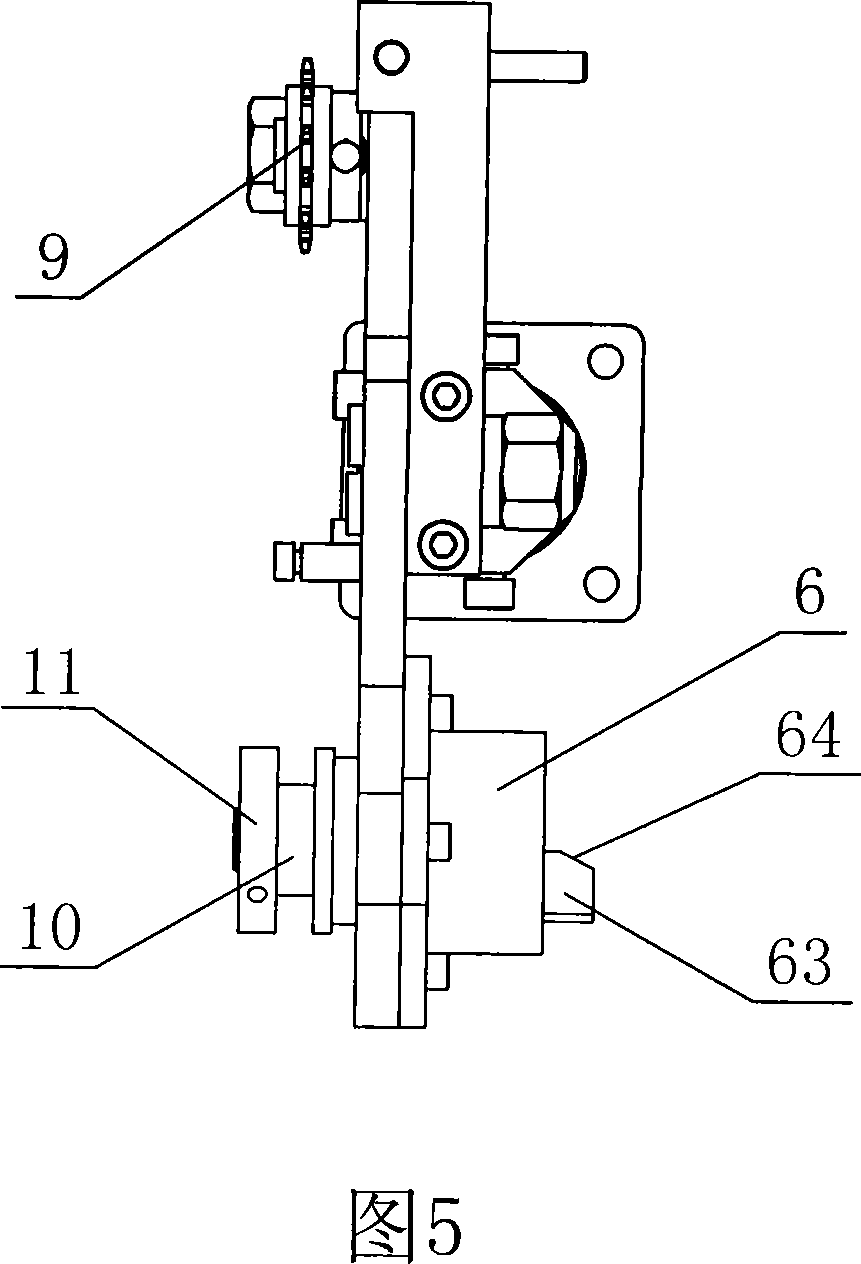

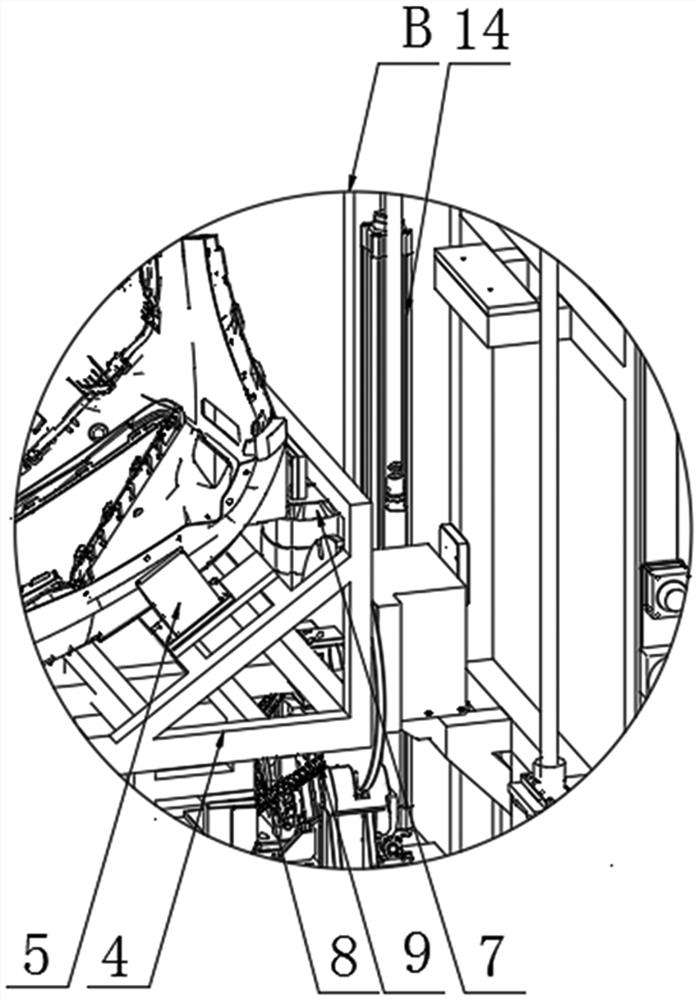

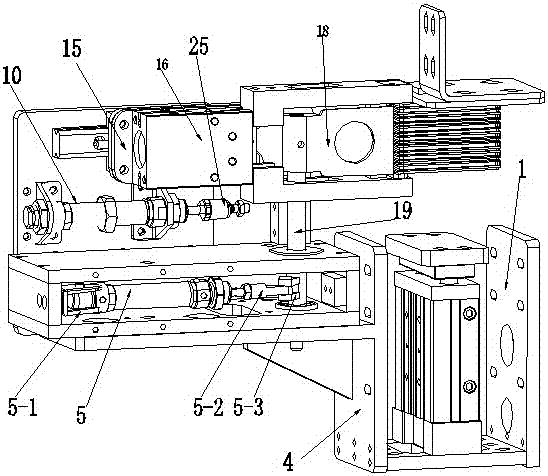

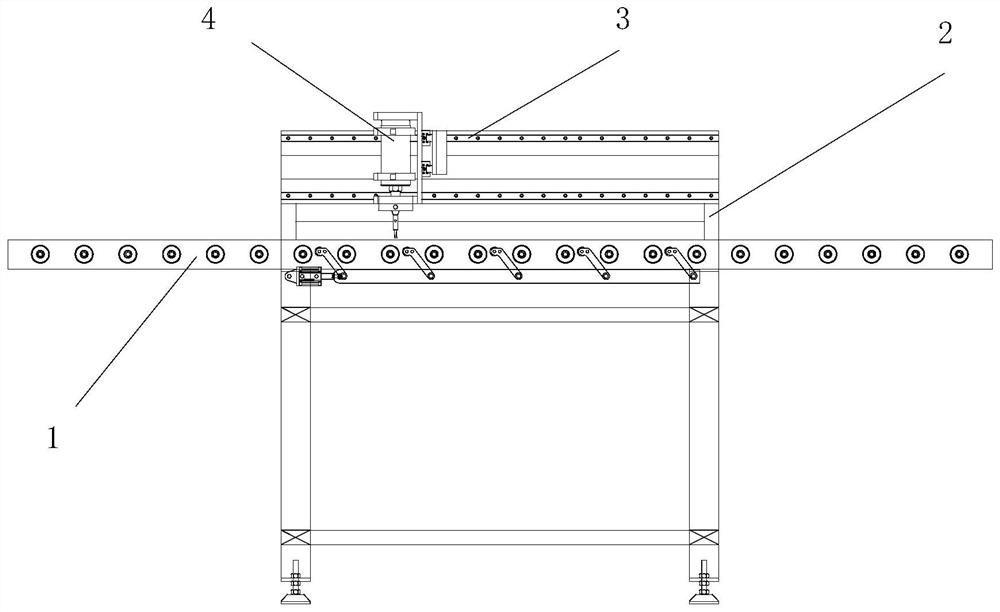

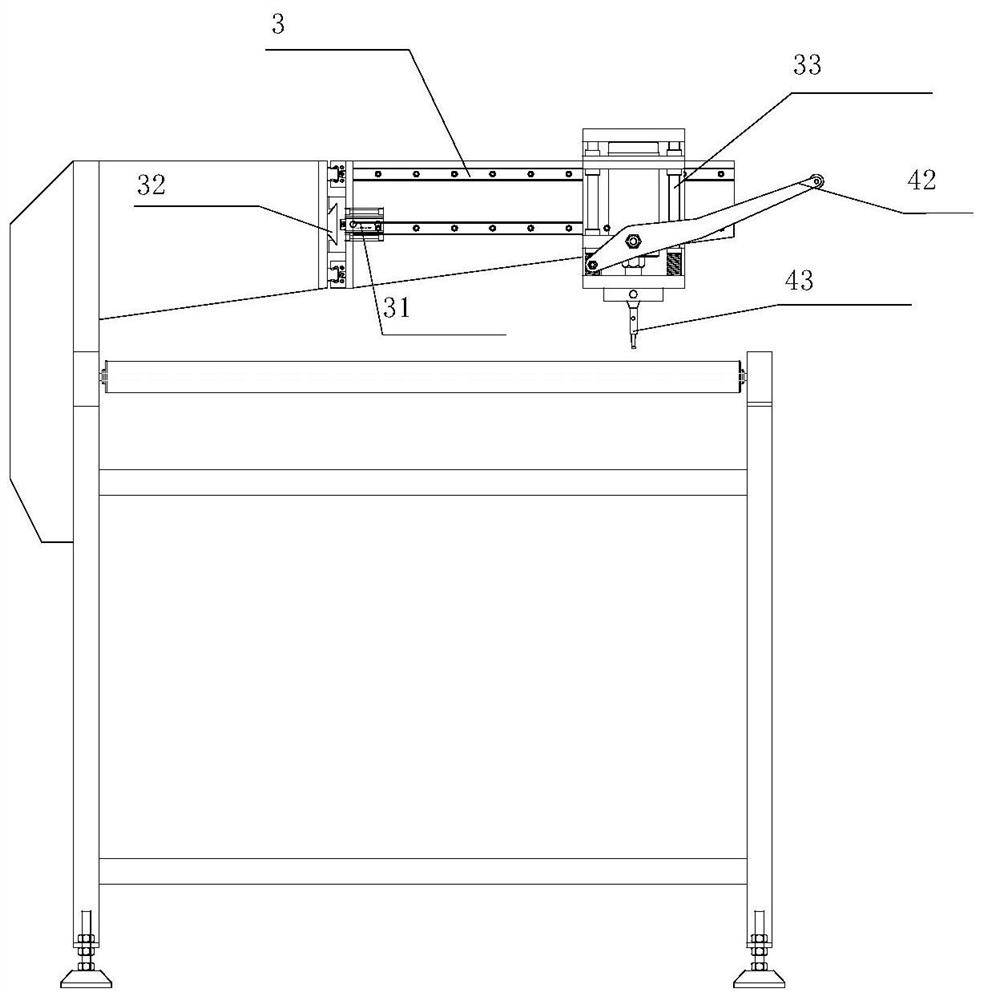

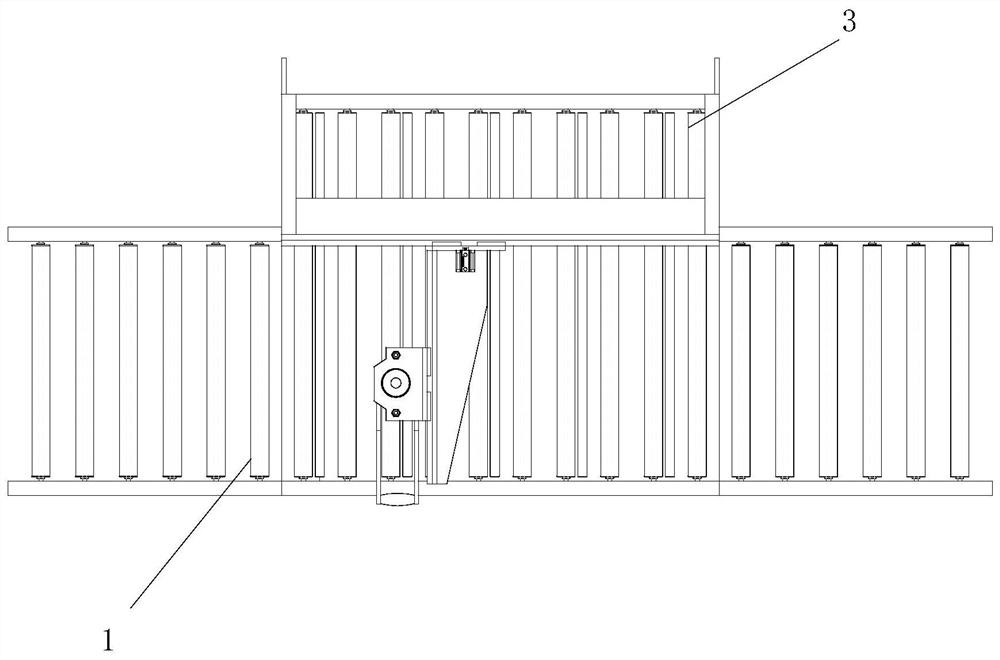

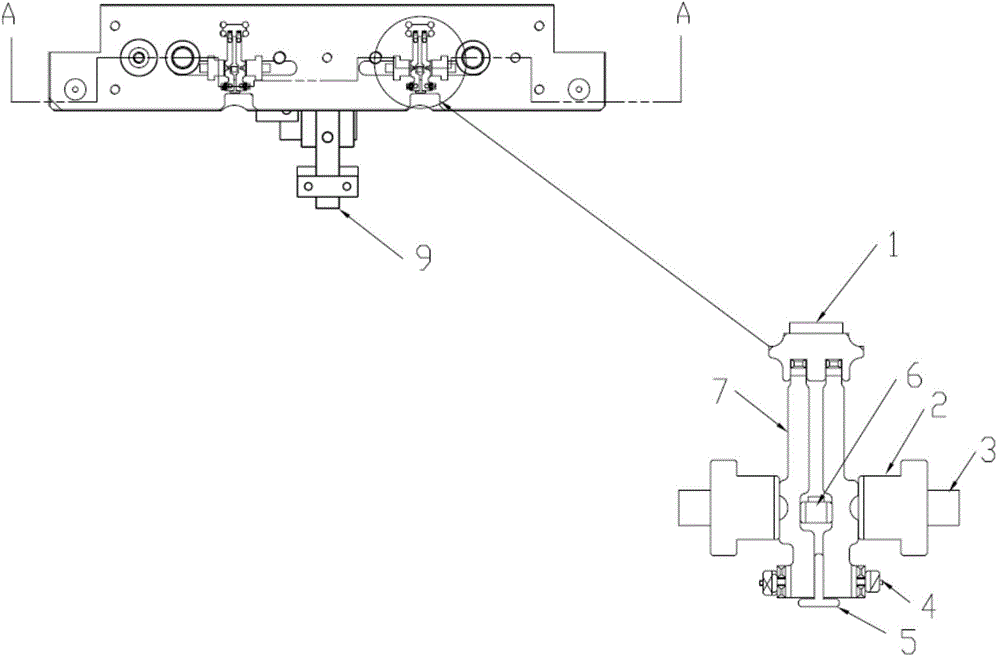

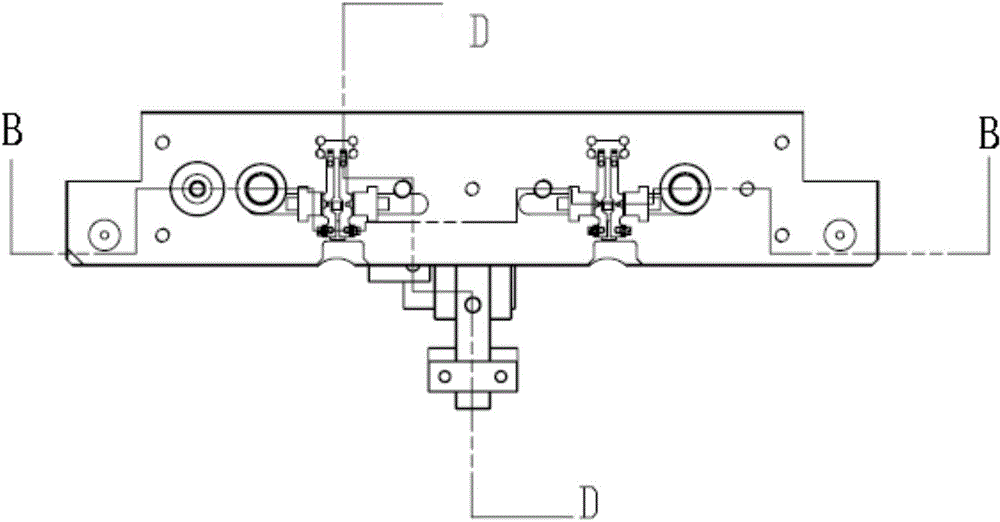

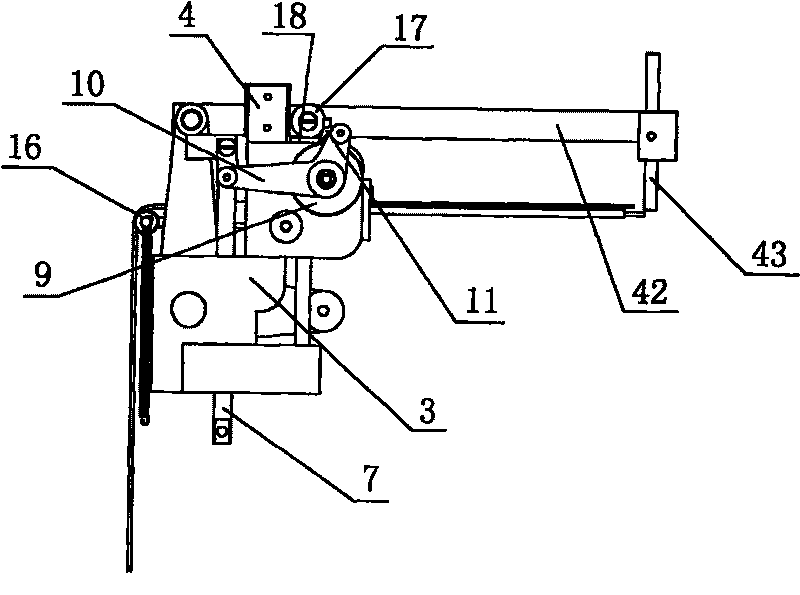

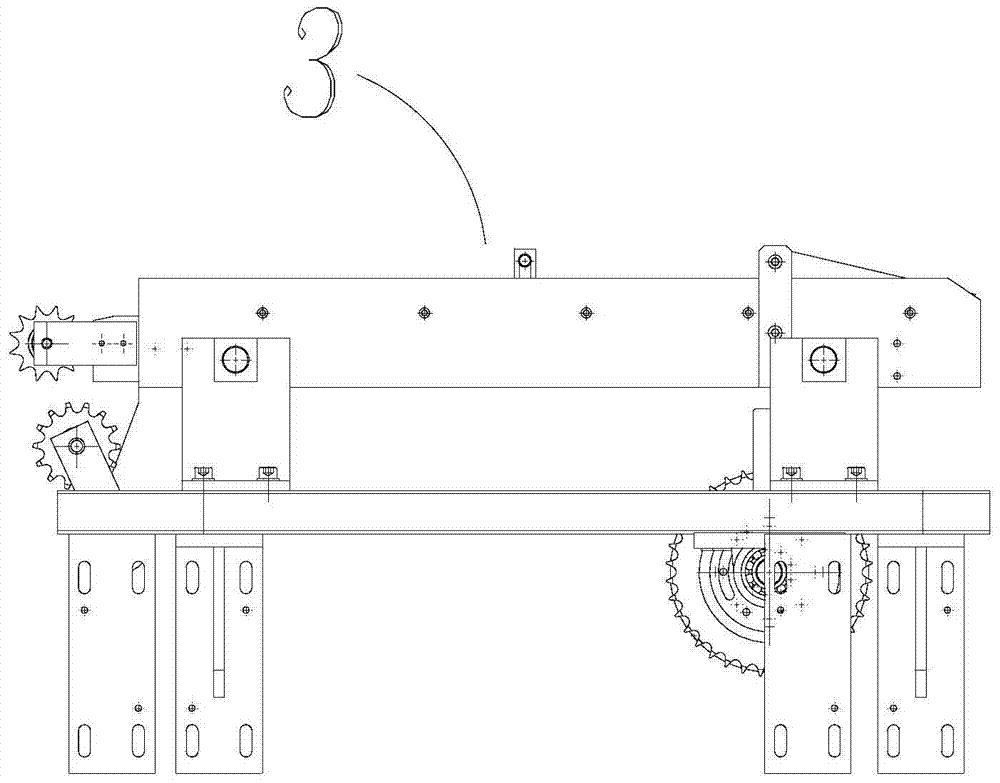

Automatic cutting device of multi-connected pipe fittings

InactiveCN105562817AImprove cutting productivityIncrease productivityMetal sawing devicesMetal sawing accessoriesPipe fittingEngineering

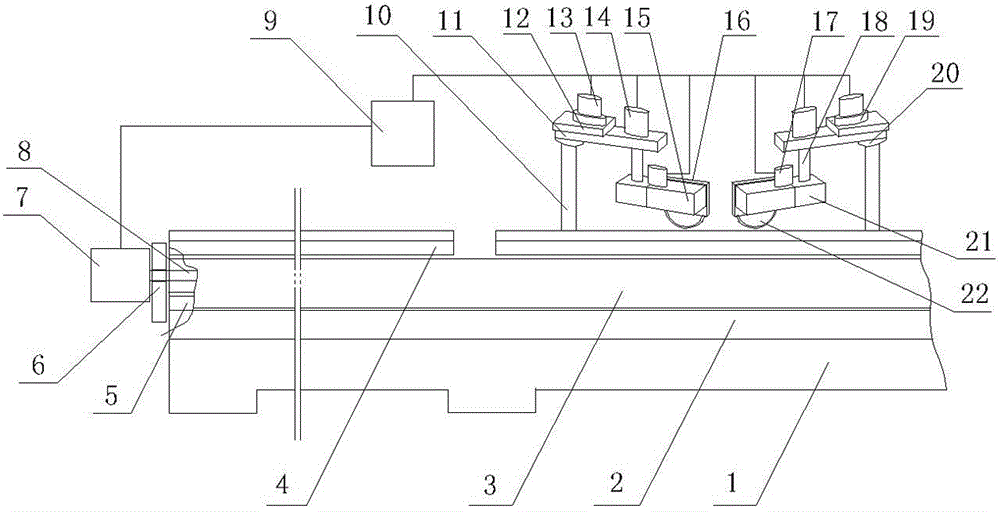

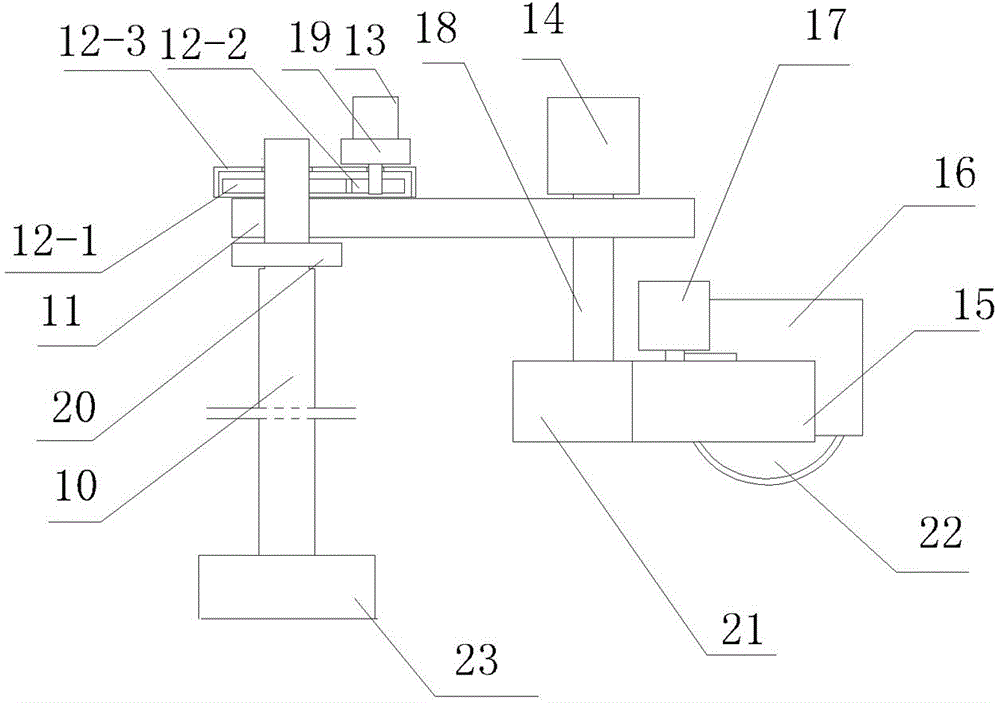

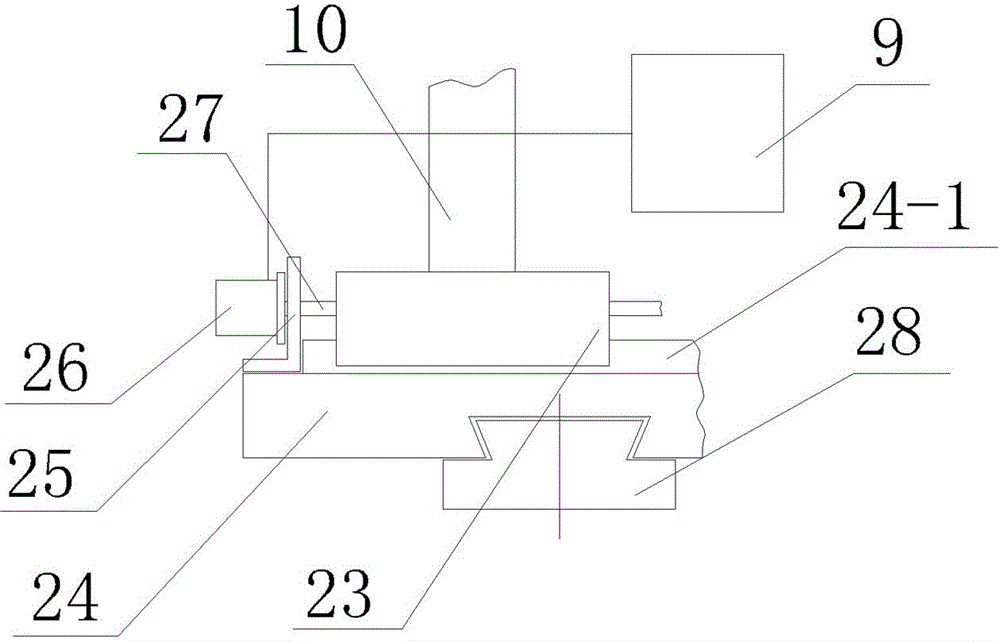

The invention discloses an automatic cutting device of multi-connected pipe fittings. The automatic cutting device comprises two saw blade cutters, multi-connected elbow cutting molds and a controller; a mold movement adjusting mechanism is arranged at the bottom of each multi-connected elbow cutting mold; the saw blade cutters and the mold movement adjusting mechanisms are in signal connection with the controller; and each multi-connected elbow cutting mold is provided with an automatic opening / closing and unloading mechanism. The cutting device can realize full-automatic cutting of the multi-connected elbow pipe fittings, greatly improves the cutting production efficiency, saves the manpower, reduces the equipment and building investment, and reduces the production cost.

Owner:王朝永

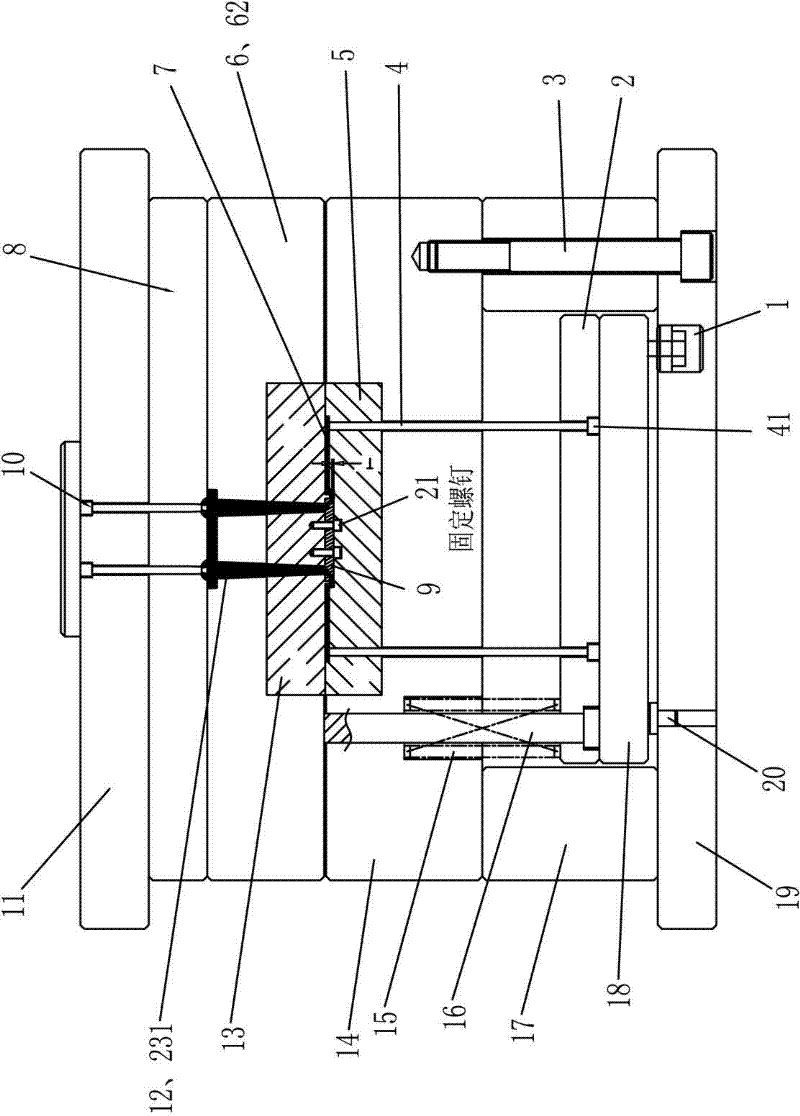

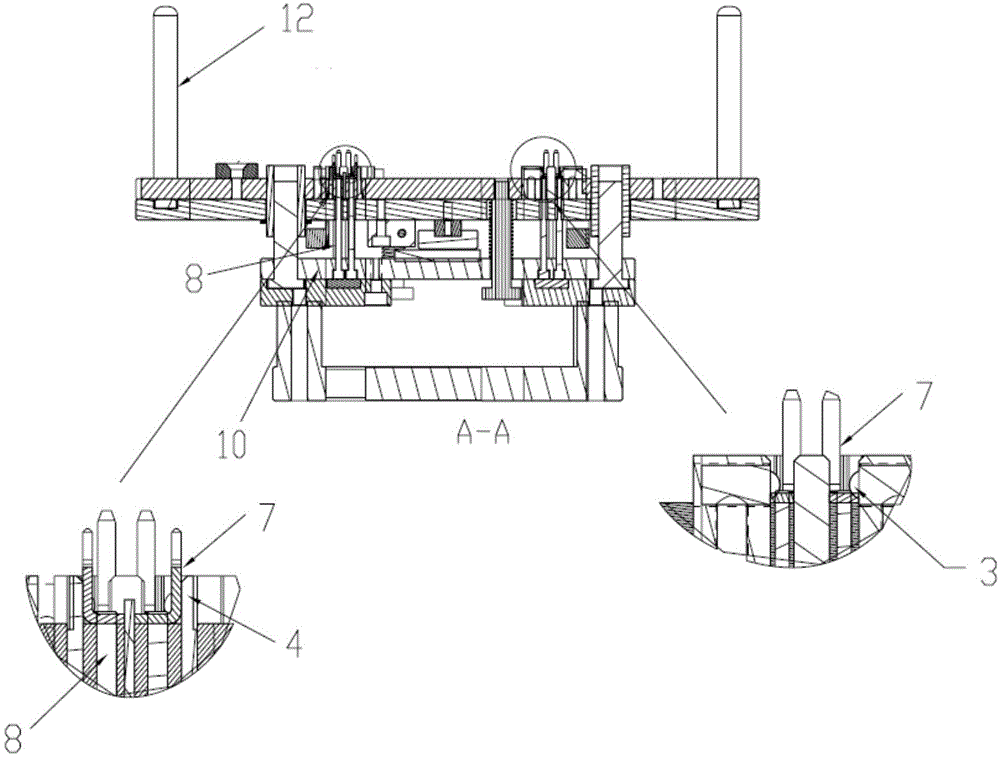

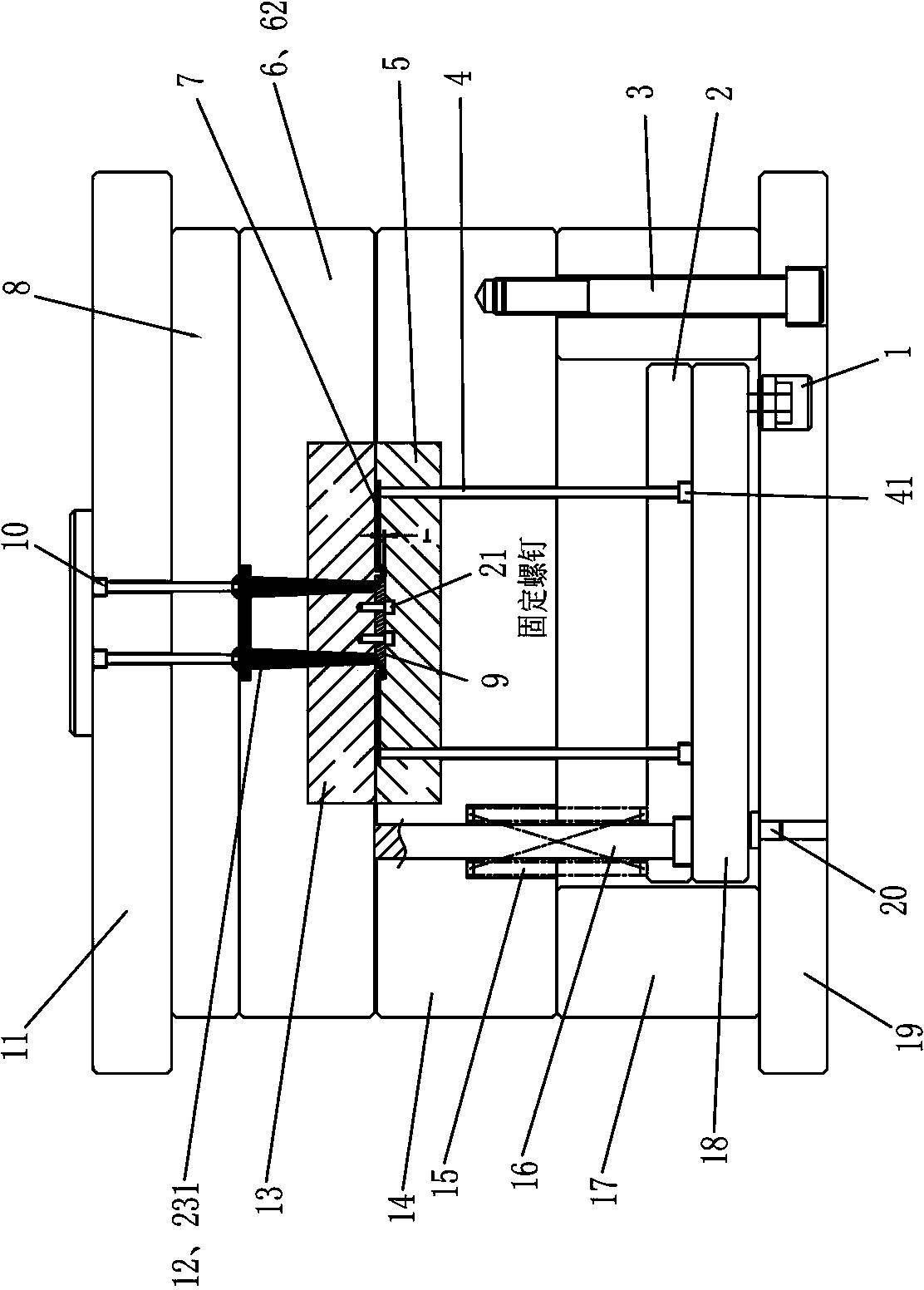

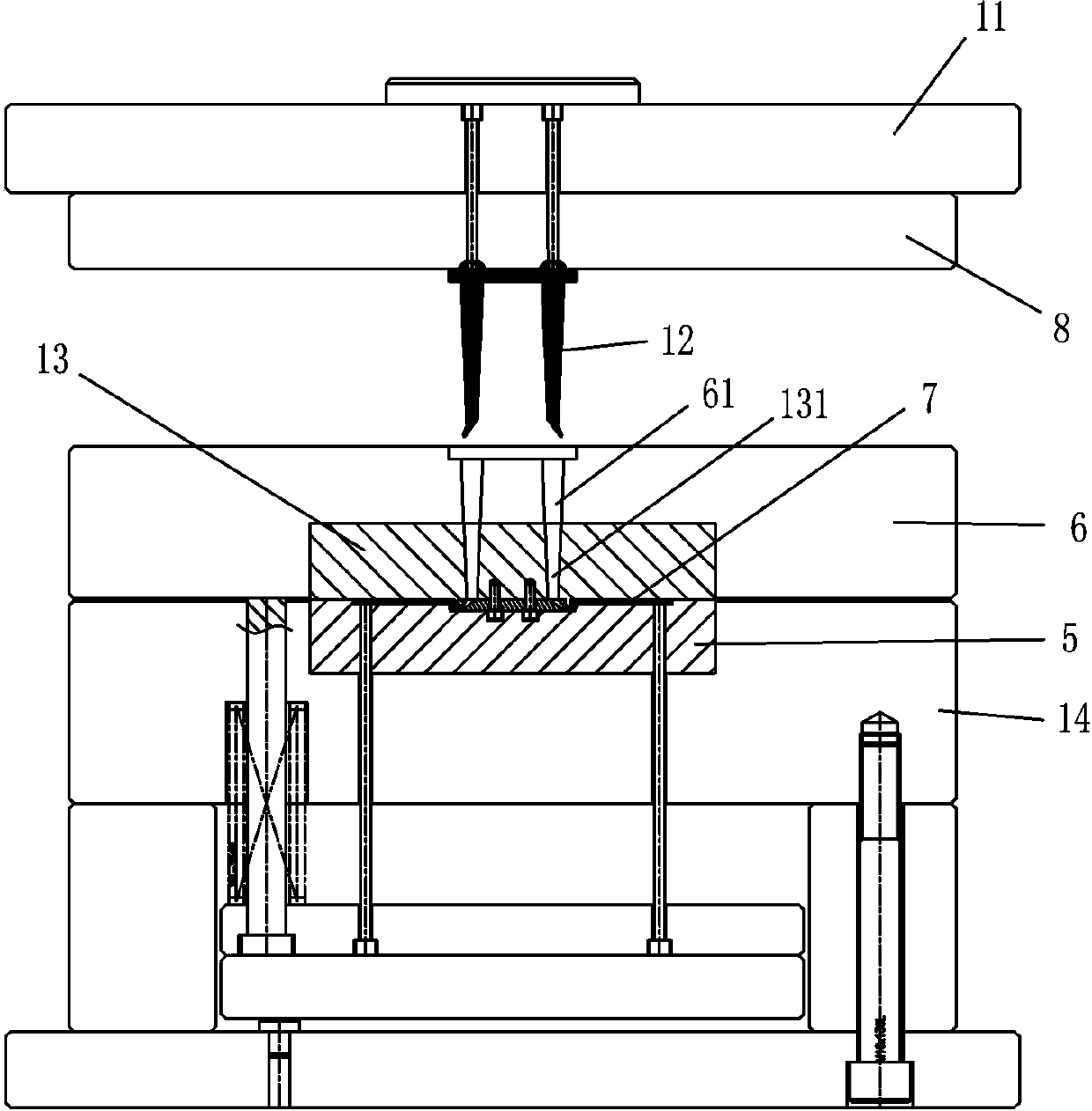

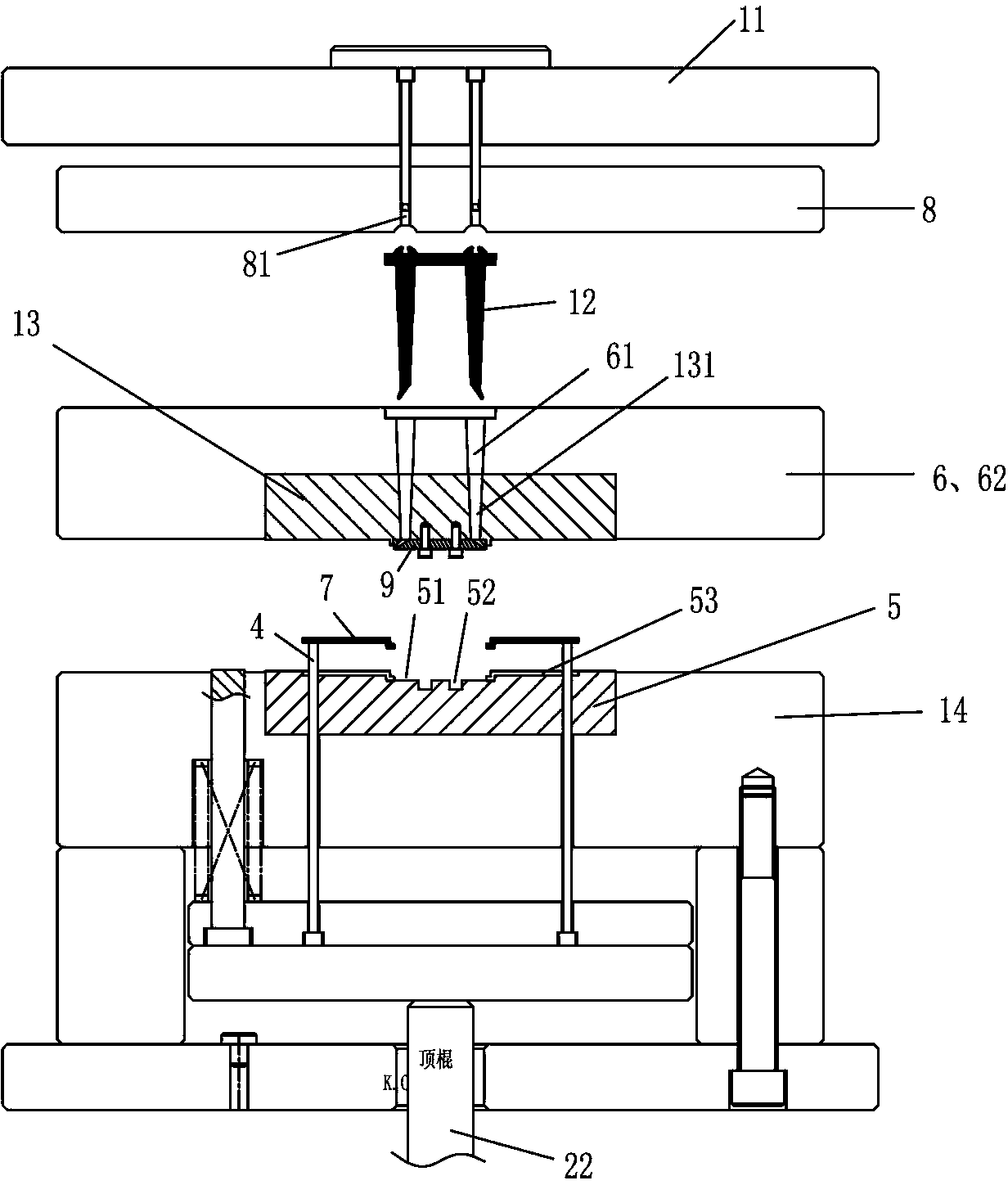

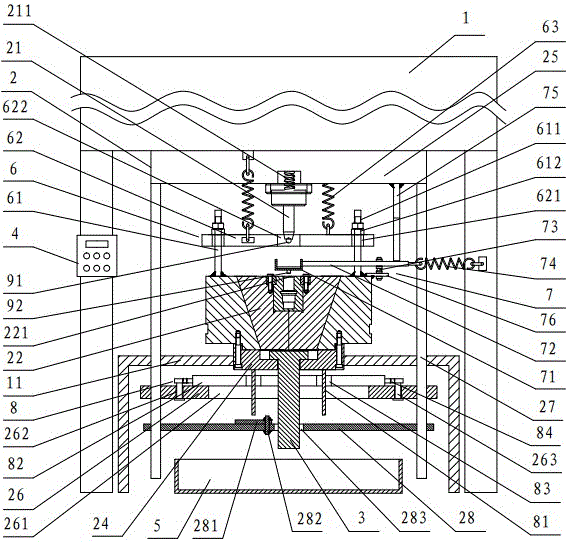

Mold for automatically cutting water port in mold of common injection molding machine through cold pulling

The invention relates to a mold for automatically cutting a water port in a mold of the common injection molding machine through cold pulling. The mold comprises a fixed mold seat, a fixed mold plate, a movable mold seat, a movable mold plate, a mold foot and an injection molding machine top rod. The mold has four water port cutter structures, wherein 1, a water port cutter is arranged in a fixed mold core, and an underflow channel is formed in the water port cutter and is connected with a large water port main flow channel and a product cavity; 2, a water port cutter is arranged in a fixed mold core and comprises a cutter body and a cutter head, the cutter body is provided with a large water port main flow channel, and an underflow channel is formed on the cutter head and is connected with a product cavity; 3, a water port cutter is also arranged in a movable mold core, and an underflow channel is formed at the front end of a cutter body and is connected with a product cavity; and 4, a movable mold core is provided with a movable mold core boss and a large water port sub flow channel, the large water port sub flow channel is connected with a large water port main flow channel and a product cavity, and a glue inlet mode is a large water port bottom lapping glue inlet mode. The mold automatically cuts the water port in the mold in a mode of separating a product from a large water port sprue through cold pulling and cutting.

Owner:阳恒

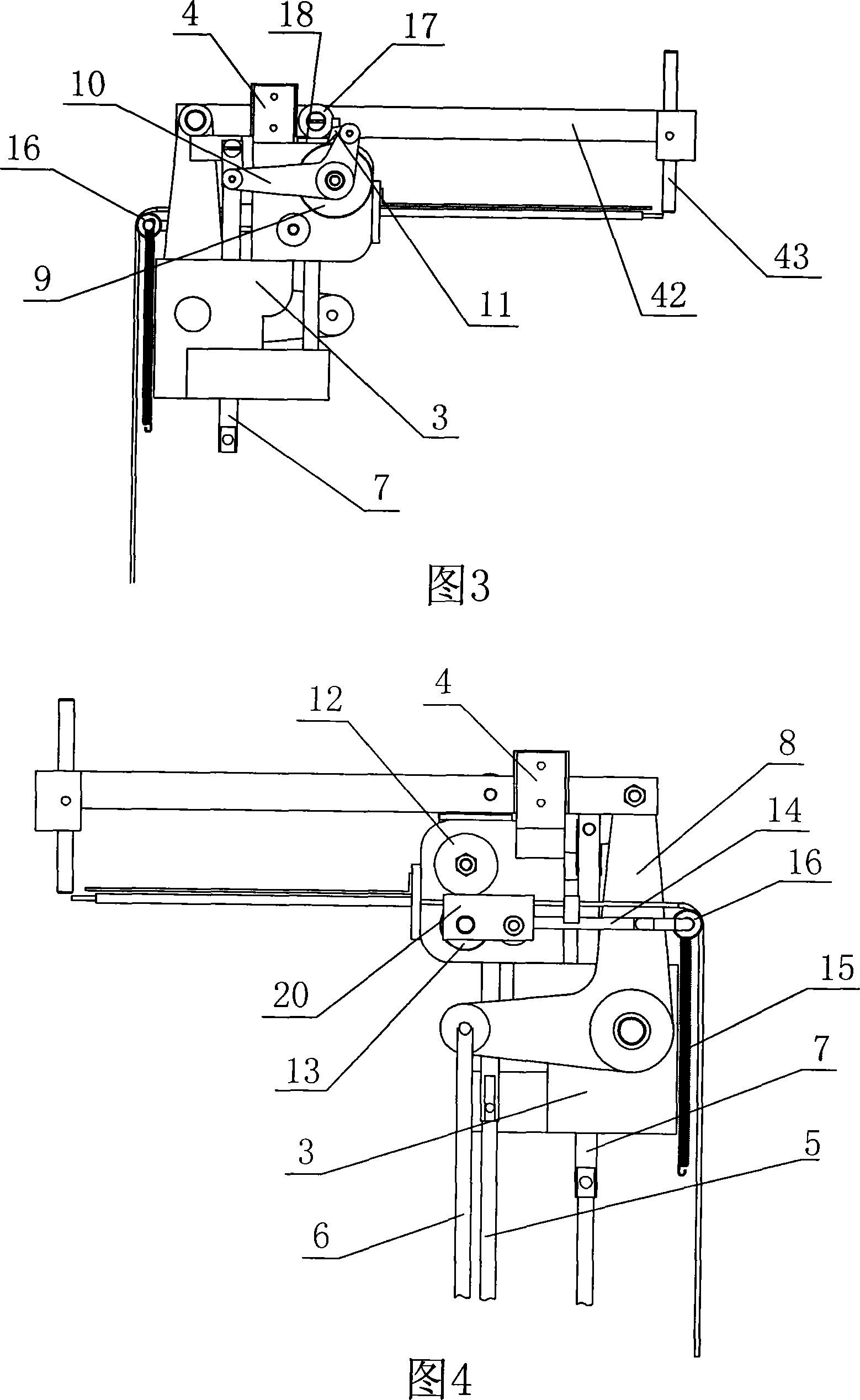

Wire lead solder device for screw energy conserving lamp assembling production

InactiveCN101219496ANo wasteHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesEdison screwOxidation resistant

The invention discloses a lead solder device applied to assembly production of edison screw energy saving lamps, which is characterized in that the invention comprises at least one soldering tin mechanism arranged on a work station platform. The soldering tin mechanism comprises a base and a first cylinder ejector pin. The base is coupled with a rocker arm; one end of the rocker arm is coupled with a second cylinder ejector pin and the other end with a cantilever. The end of the cantilever is vertically arranged with a welding head, the first cylinder ejector pin goes through the base and is apically grafted at the lower part of the cantilever and the base is provided with a solder wire delivery mechanism. The invention has the advantages that the welding head is made of oxidation-resistant and corrosion resistant pontil which does not need replacing frequently, the work station platform can be provided with a plurality of soldering tin mechanism parallel to meet different production demand, the structure of the whole device is simple, the working efficiency can be improved at least one time and operators can be reduced at least by half.

Owner:ANHUI SUNSHINE LIGHTING APPLIANCE CO LTD

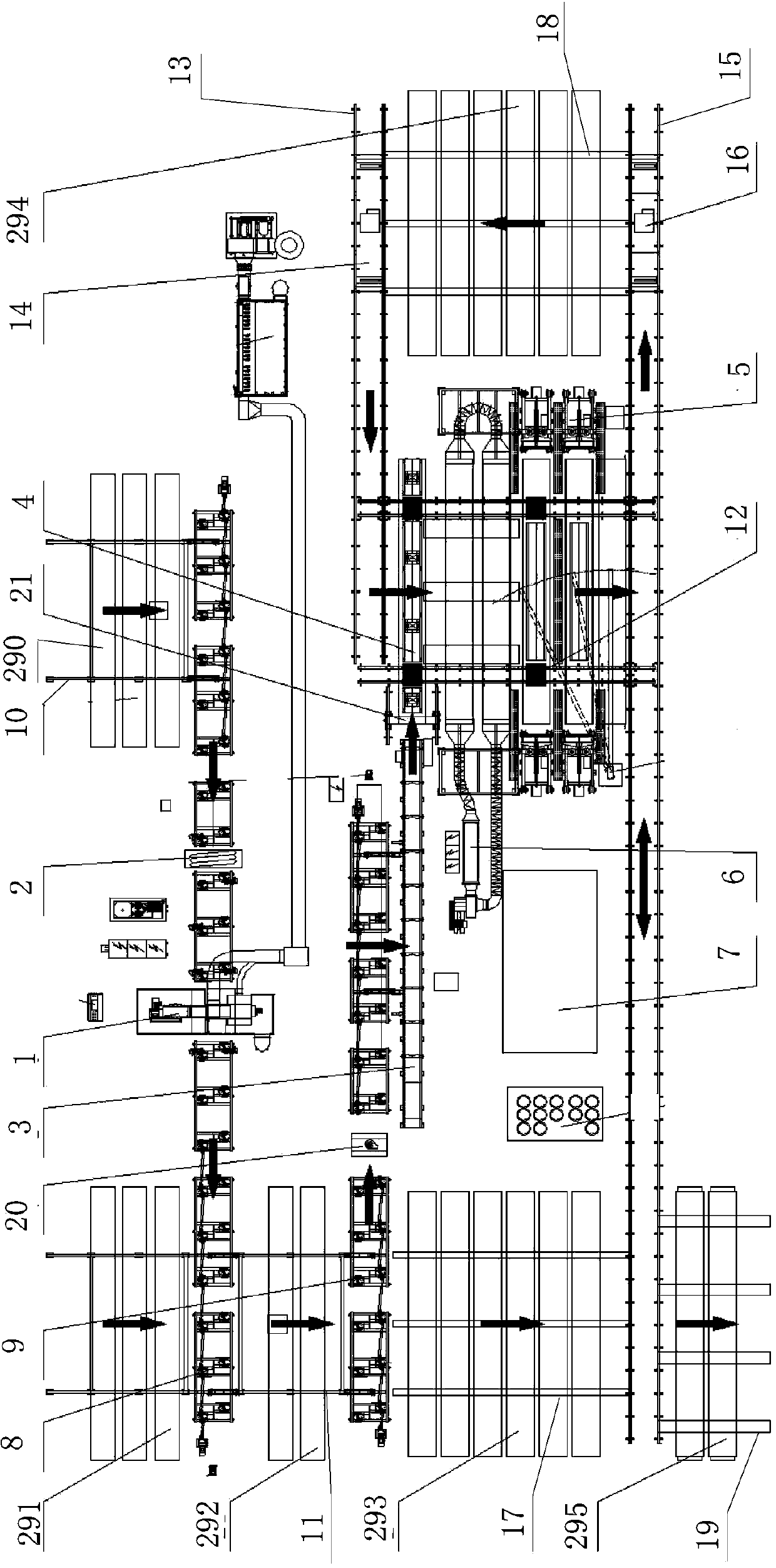

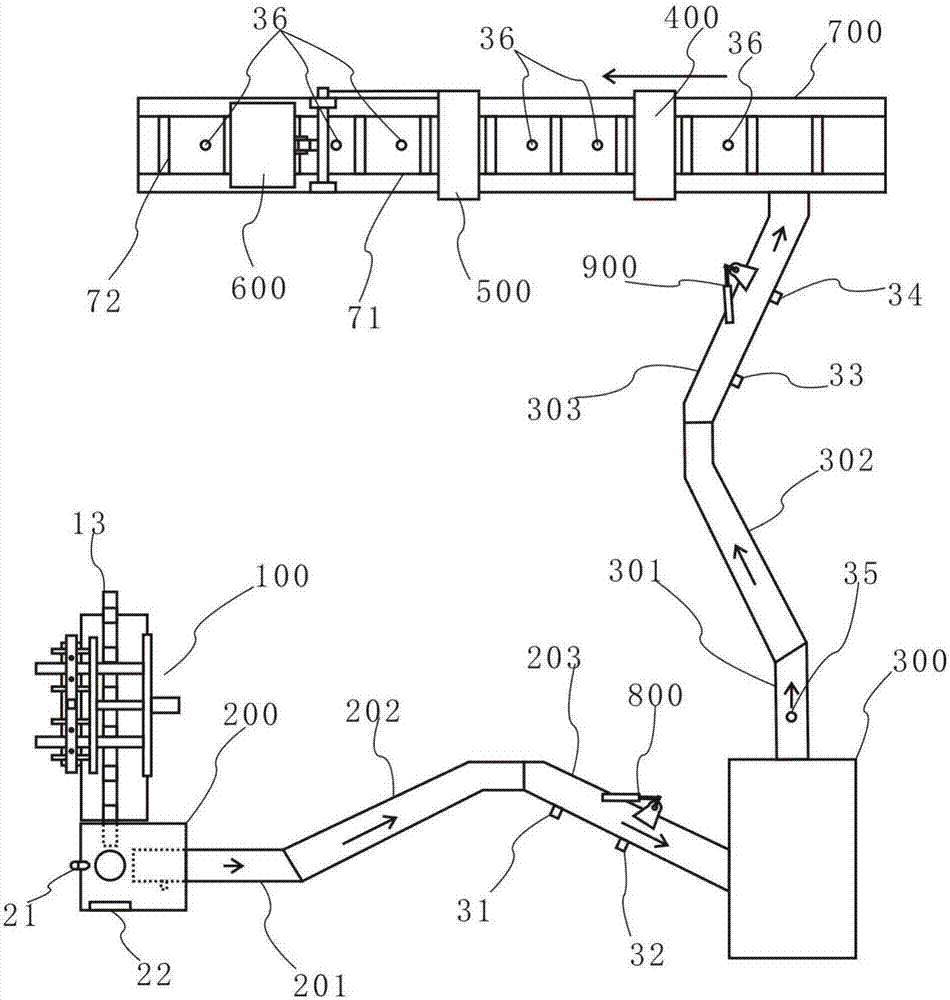

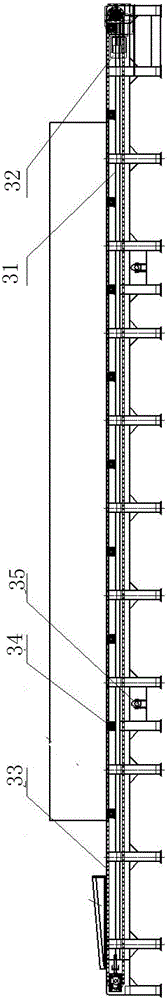

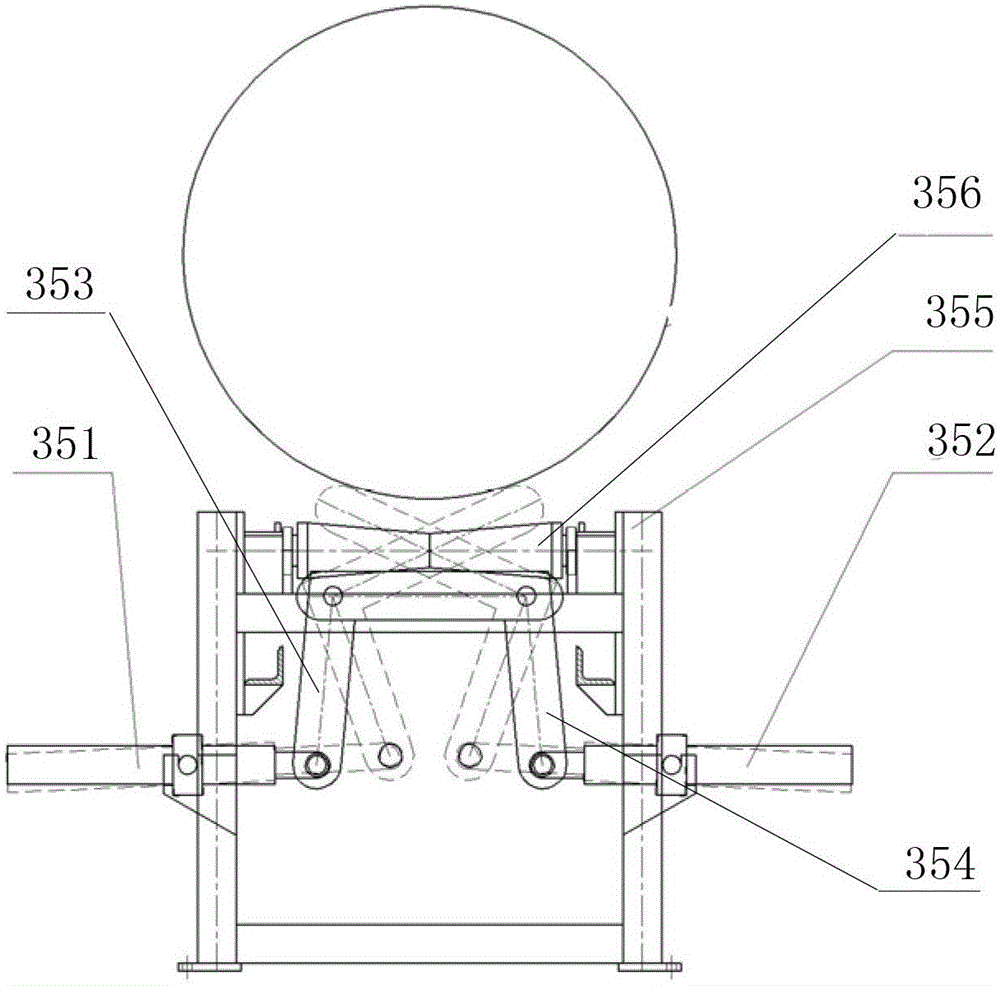

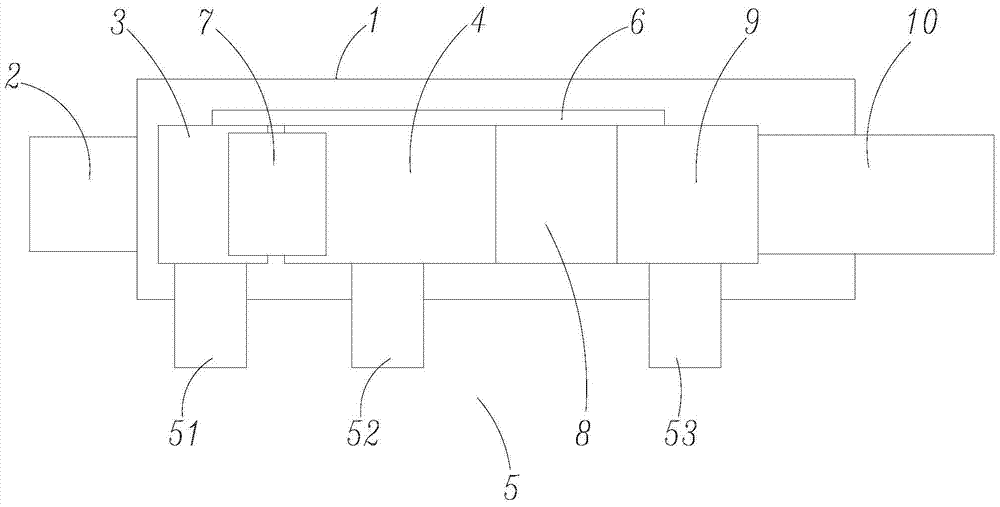

Digitalized two-step method filling operation assembly line for directly-buried polyurethane thermal insulation pipes

The invention relates to the technical field of medical auxiliary devices, in particular to a digitalized two-step method filling operation assembly line for directly-buried polyurethane thermal insulation pipes. The digitalized two-step method filling operation assembly line comprises a steel pipe transmission unit, a rust and dust removal system, a medium frequency heating device, a pipe penetrating machine, a lifting moving V-shaped box, an upper blocking machine, a preheating device before foaming and a polyurethane foaming unit, wherein the steel pipe transmission unit, the rust and dust removal system, the medium frequency heating device, the pipe penetrating machine, the lifting moving V-shaped box, the upper blocking machine, the preheating device before foaming and the polyurethane foaming unit are connected in sequence. By means of the digitalized two-step method filling operation assembly line for the directly-buried polyurethane thermal insulation pipes, potential safety hazards in production are reduced; through a continuous operation mode, namely, after the pipes (including steel pipes and PE pipes) enter a production line, the bottoms of the pipes never leave the production line, and the pipes move from one position to a next position through a series of actions such as hydraulic transmission and chain transmission till finished pipes move out of the production line; a hoisting tool is used in none of the steps, so that hidden dangers are reduced.

Owner:天津裕实工程技术有限公司

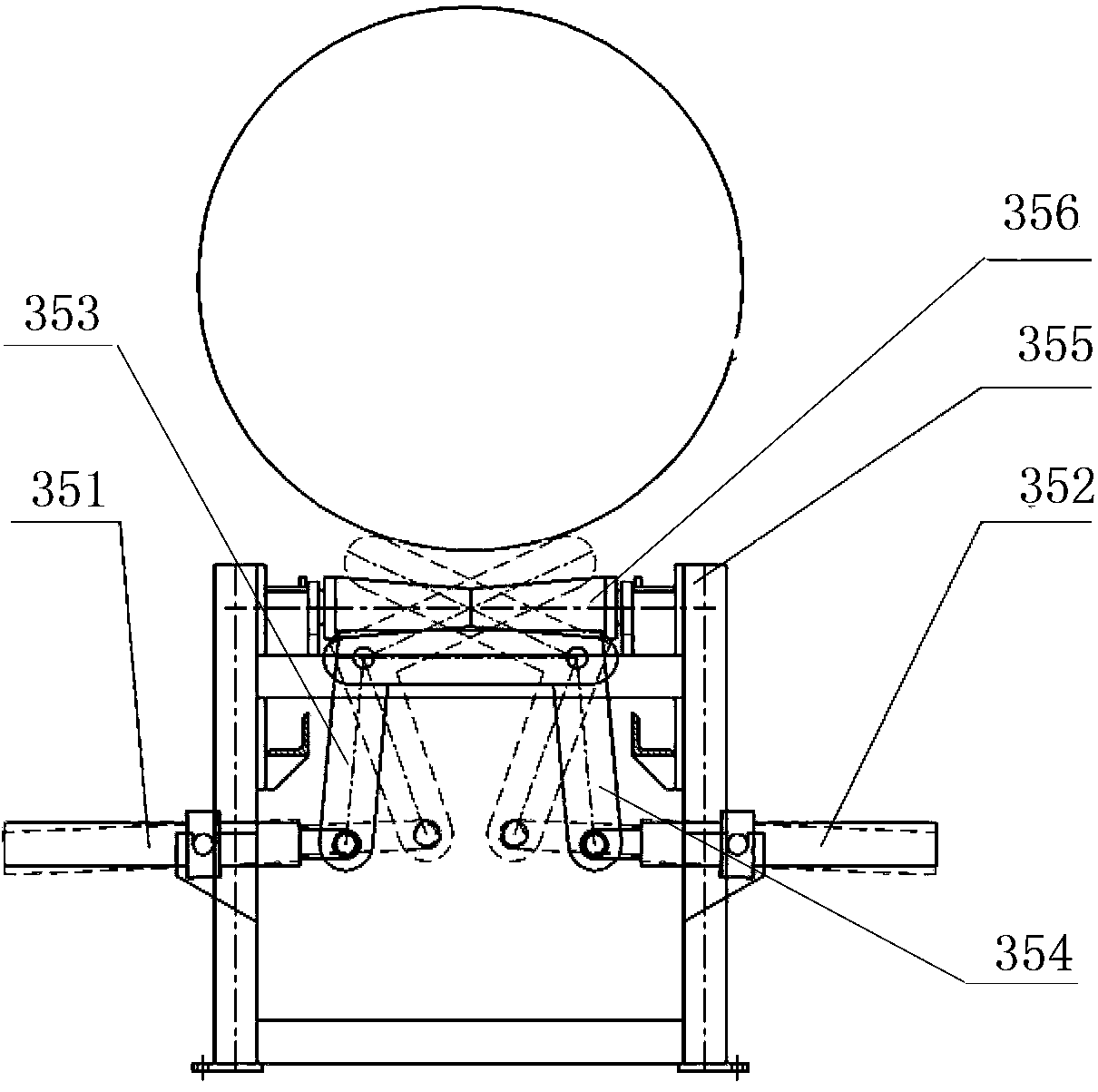

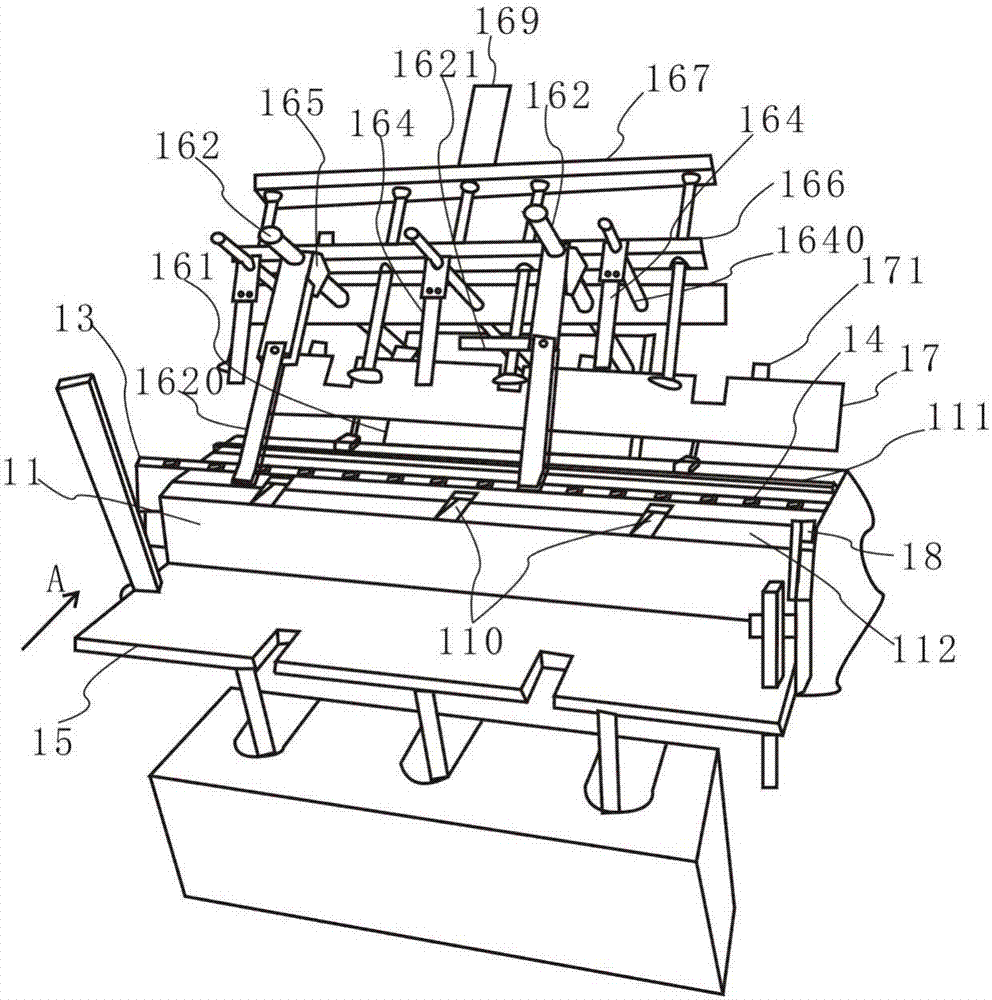

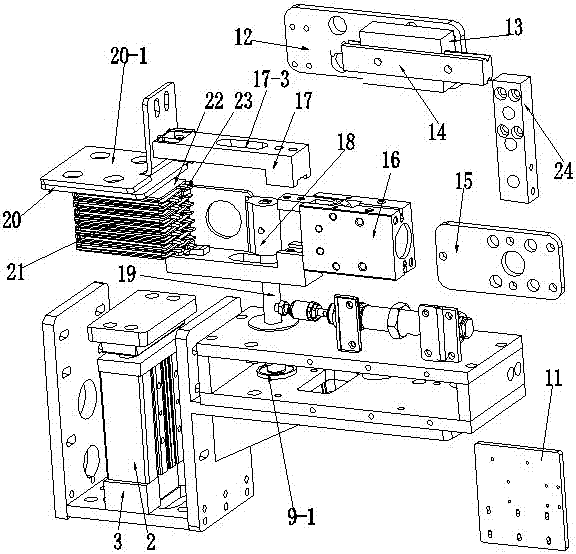

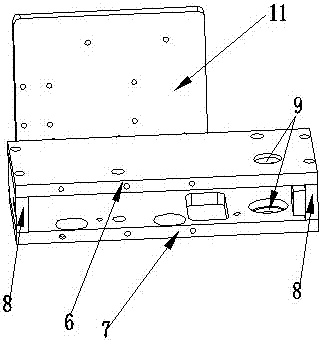

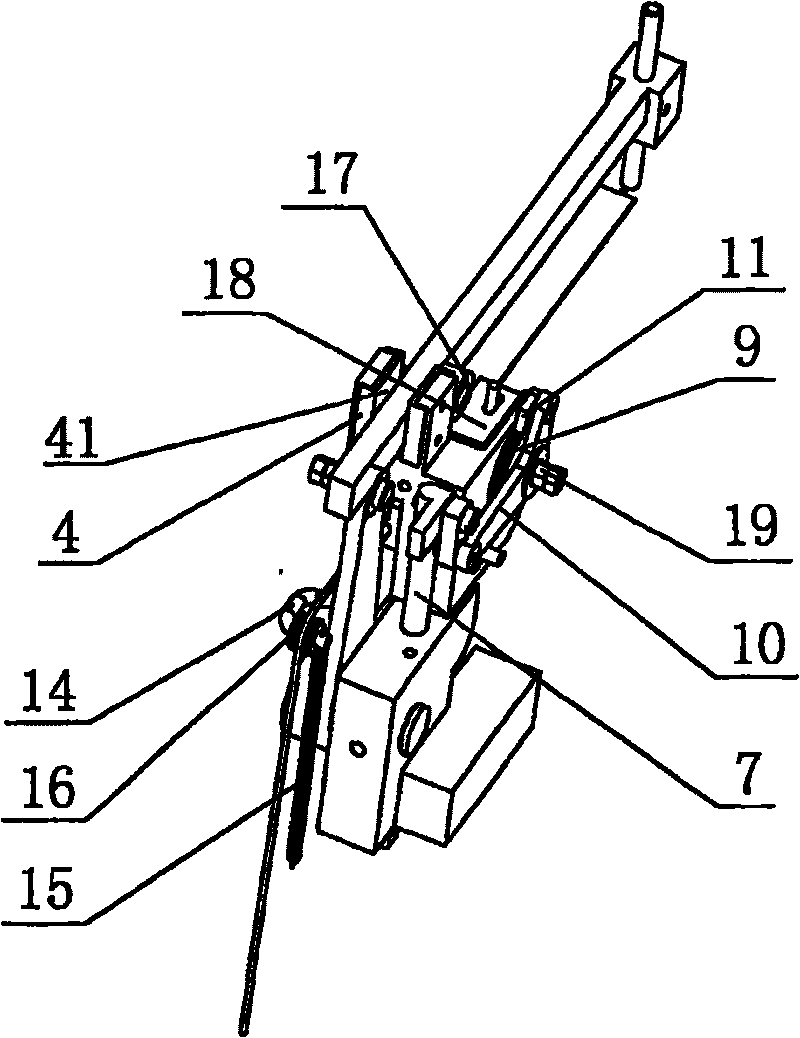

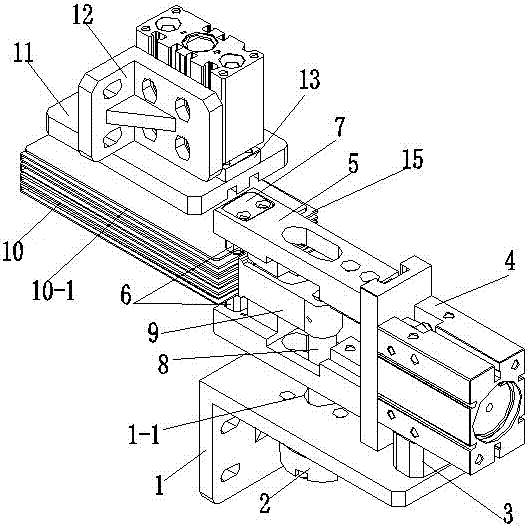

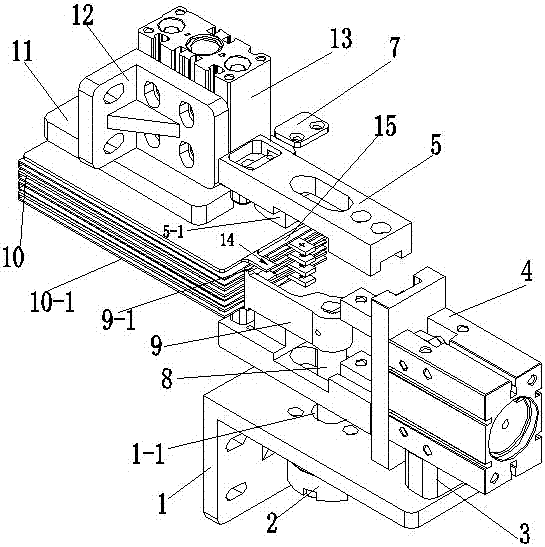

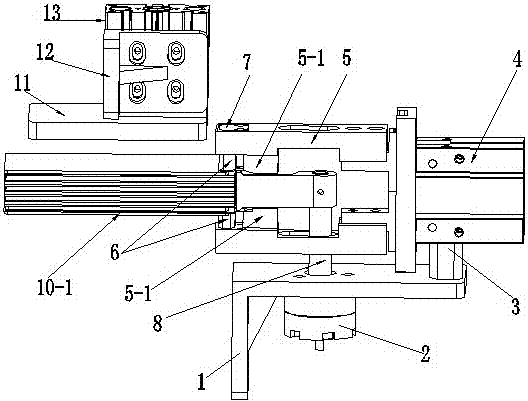

Automatic pole lug bending device for accumulator side plates

ActiveCN104475503AImprove efficiencySolve quality problems such as sheddingCell component detailsCushionEngineering

The invention discloses an automatic pole lug bending device for accumulator side plates. The automatic pole lug bending device is characterized in that the automatic pole lug bending device mainly comprises an L-shaped mounting base, a lifting air cylinder, an air cylinder cushion block, a T-shaped support plate, an air cylinder, a fixing base, a connecting rod, a sleeve clip, a screw, an upper plate, a lower plate, side plates, through holes, a sliding air cylinder, a mounting plate, a slider, a guide rail, a mounting plate B, a pneumatic finger, a press plate, a protrusion block, a waist-shaped hole, a shaft lever and a swing ejector. The cushion block is mounted on the L-shaped mounting base transversely, the lifting air cylinder is mounted on the cushion block, the T-shaped support plate is mounted on the lateral side of the L-shaped mounting base, the upper plate, the lower plate, the air cylinder and the shaft rod are arranged above the T-shaped support plate sequentially, the mounting plate is mounted in rear of the upper plate and the lower plate, the guide rail and the pneumatic finger are arranged on the mounting plate, and pole clusters are arranged between the lifting air cylinder and the press plate. Through the design of the press plate, the protrusion block and the swing ejector, bending dynamics and angles of pole lugs are uniform, damage to the side plates of the pole clusters are avoided, and product quality and production efficiency of accumulators are improved.

Owner:ZHUZHOU YINGDING AUTOMATION EQUIP TECH

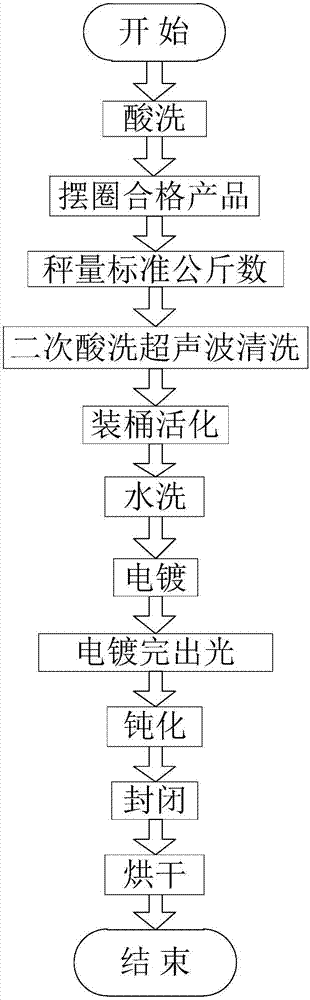

Manufacturing method for automatic galvanizing

InactiveCN106884200AAvoid mutual contaminationEnsure product quality consistencyCellsMagnetic materialsPower flowElectroplating

The invention discloses an automatic galvanizing production method. The automatic galvanizing production method includes the following steps: pickling, swinging qualified products, weighing standard kilograms, secondary pickling ultrasonic cleaning, barrel activation, water washing, electroplating, light emission after electroplating, passivation, sealing, and initial drying and out of the barrel for secondary drying; among them, the current control of the galvanizing production process, the pH detection and adjustment of the plating solution and passivation solution, the addition of supplementary solution, the replacement of the light-emitting solution, the control of electroplating and passivation time, and the passivation Quantity control is controlled by computer automation. Multiple control points of the automatic galvanizing production method are automatically controlled to ensure the consistency of product quality; the operator is reduced accordingly, and the labor cost is reduced; the mutual pollution of the solution in the operation process is solved, and the production process goes smoothly; the work site is neat and orderly .

Owner:SINO MAGNETICS TECH

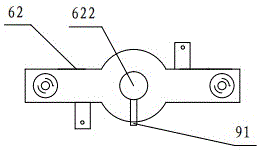

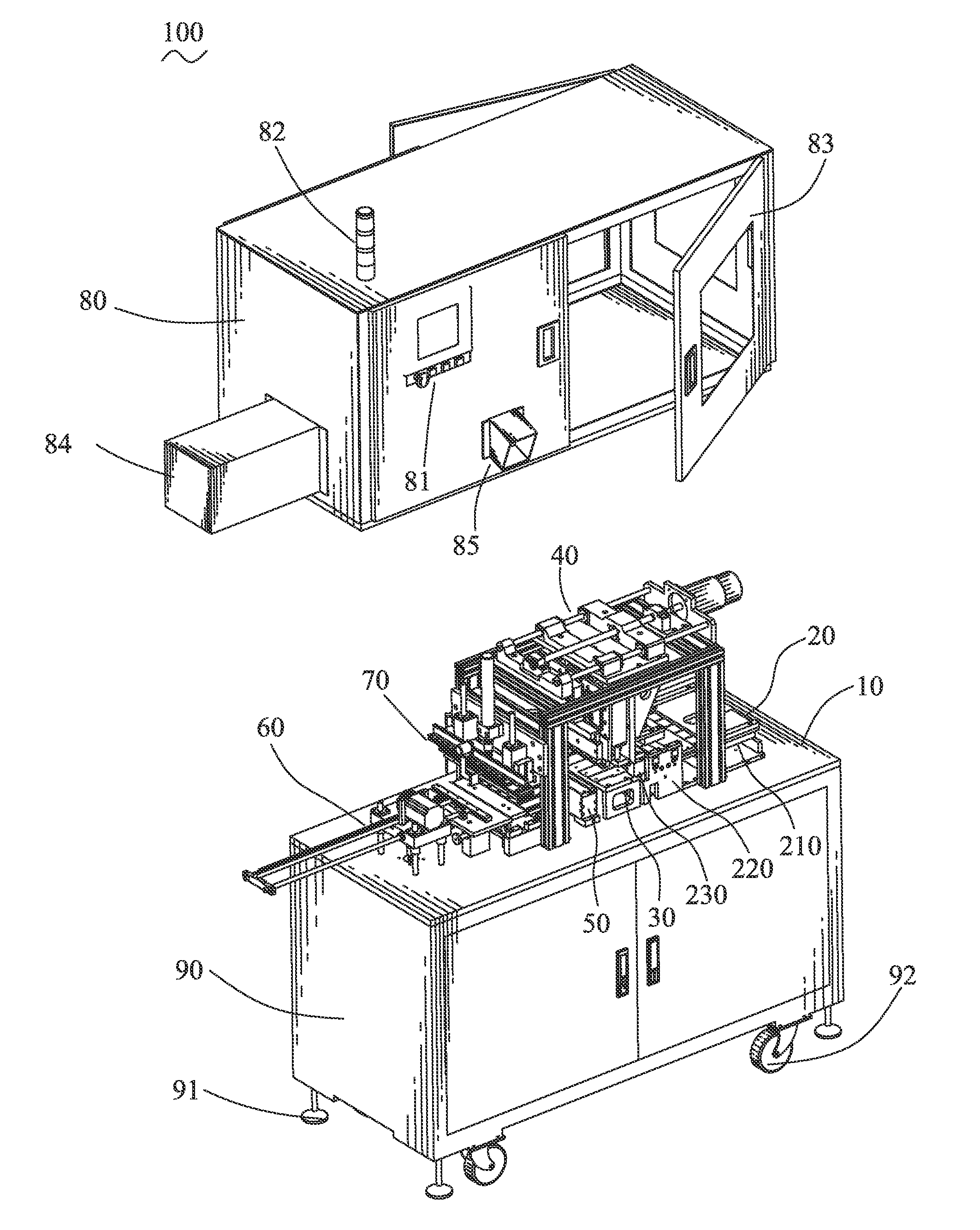

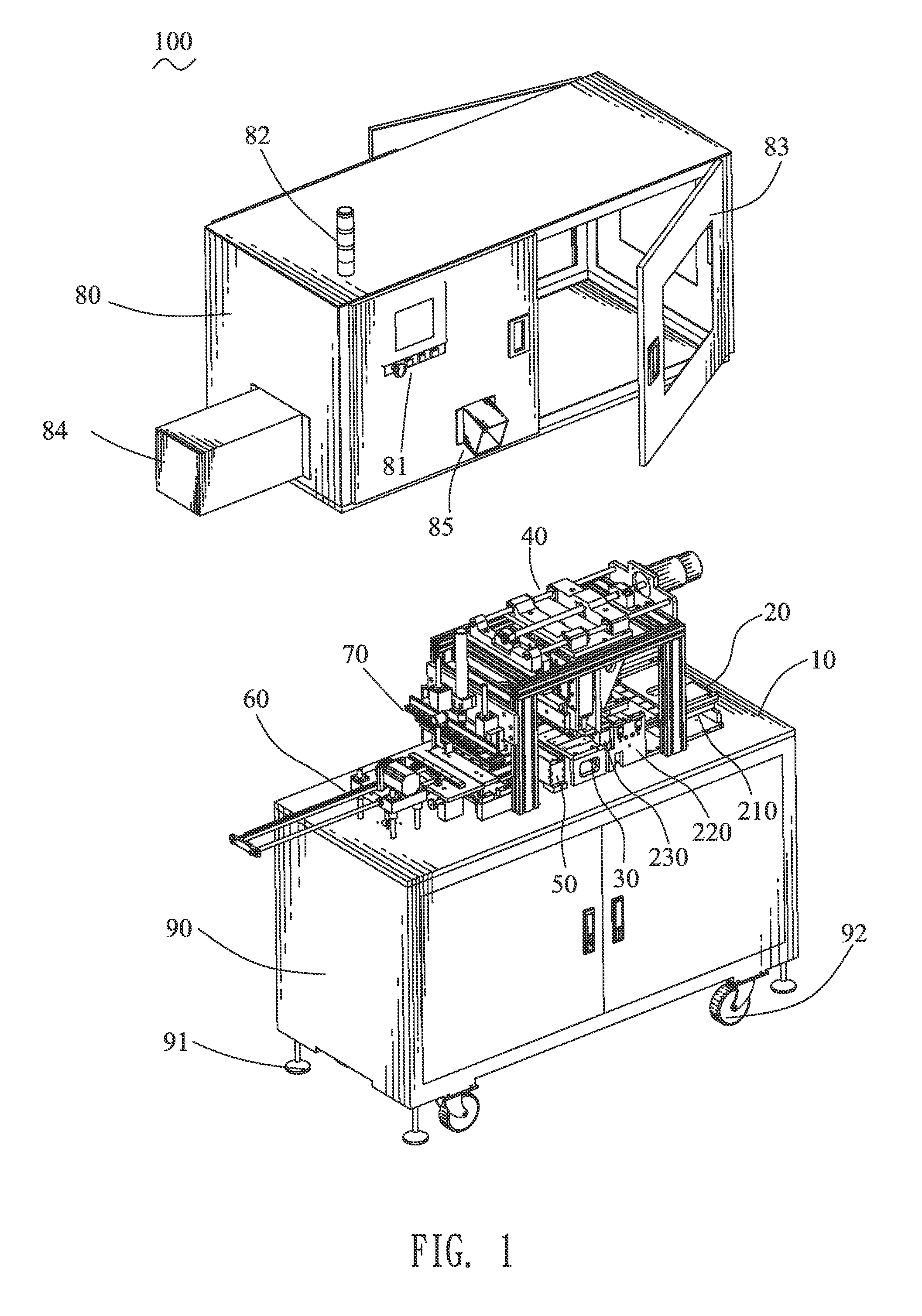

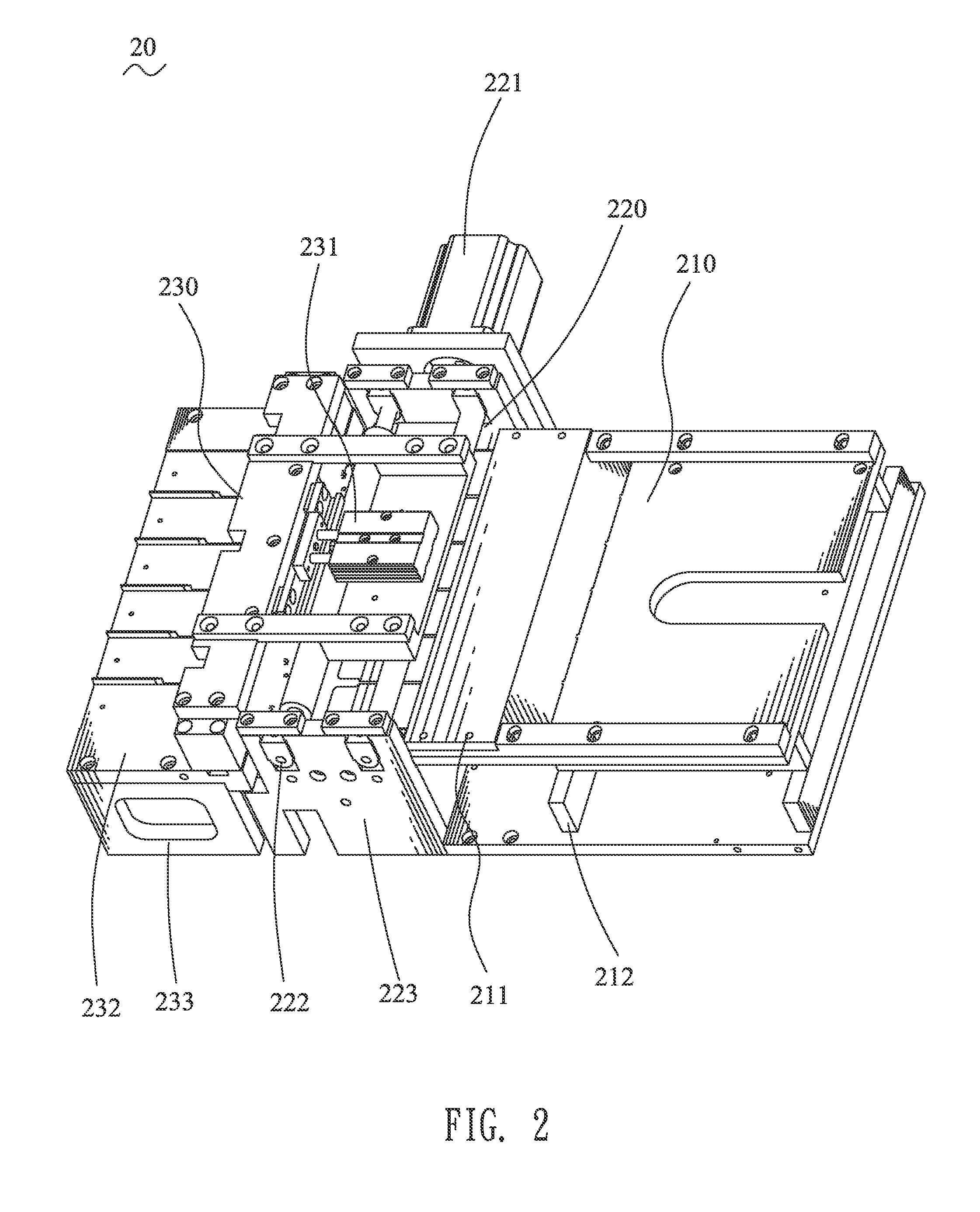

Automatic circle forming apparatus

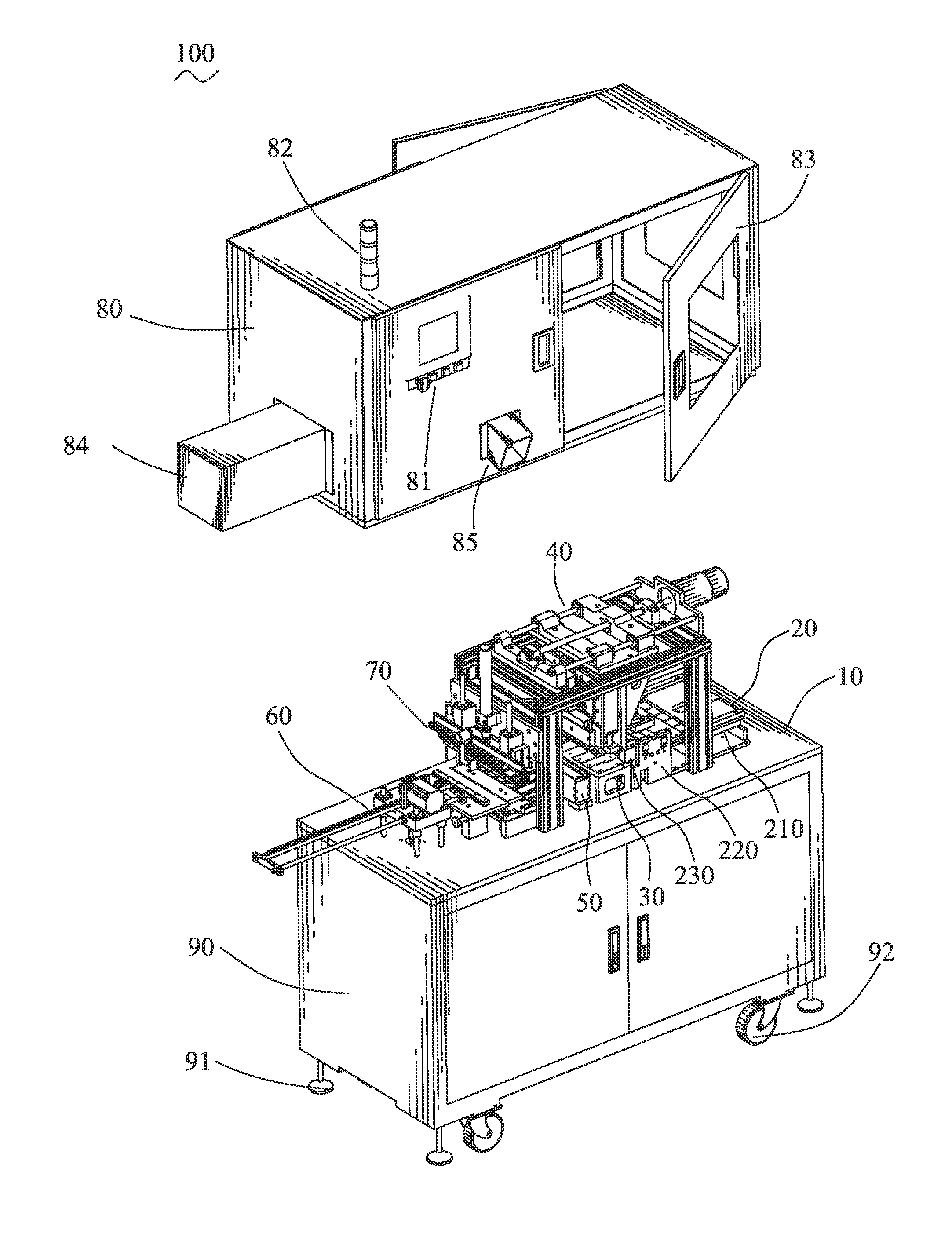

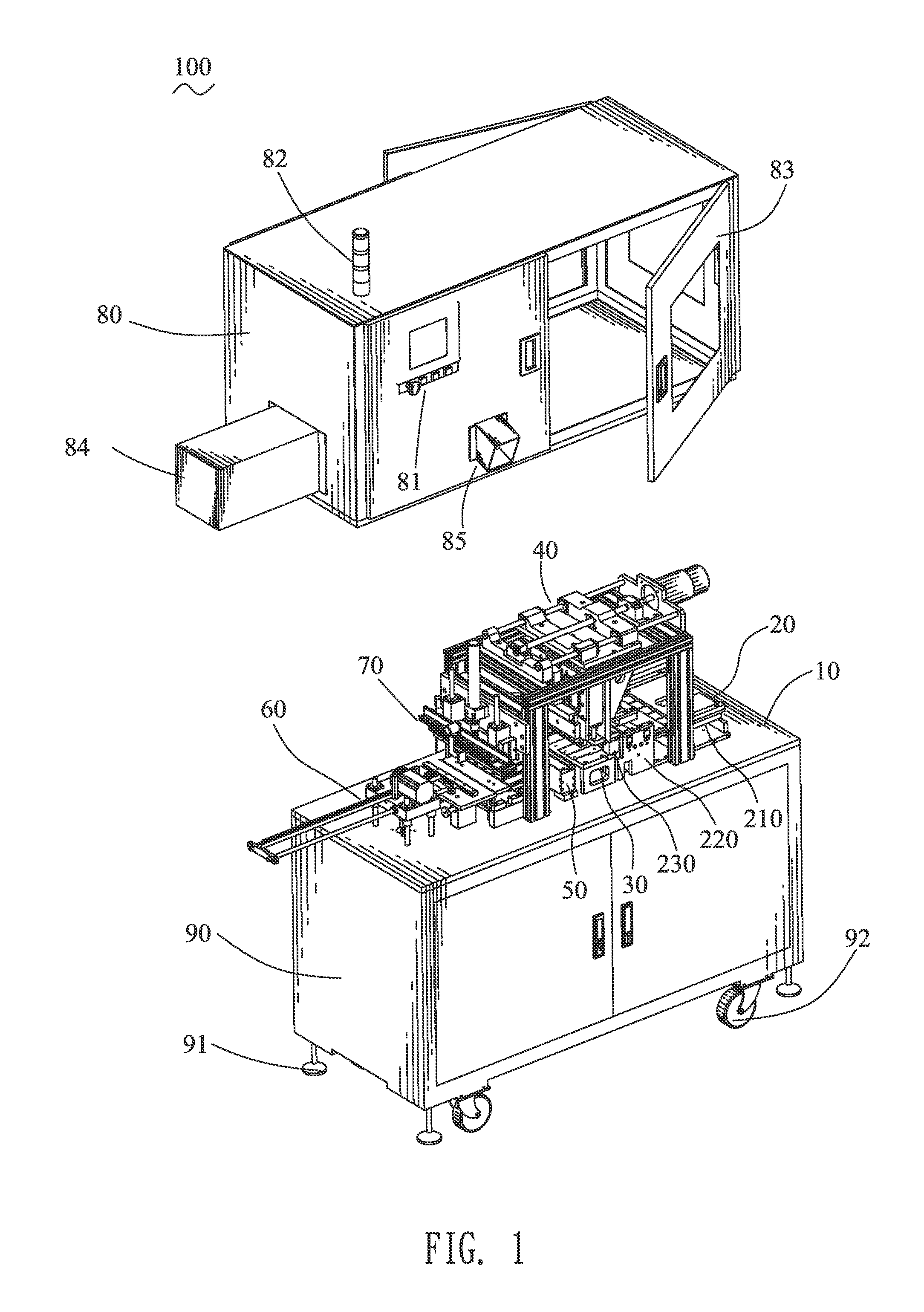

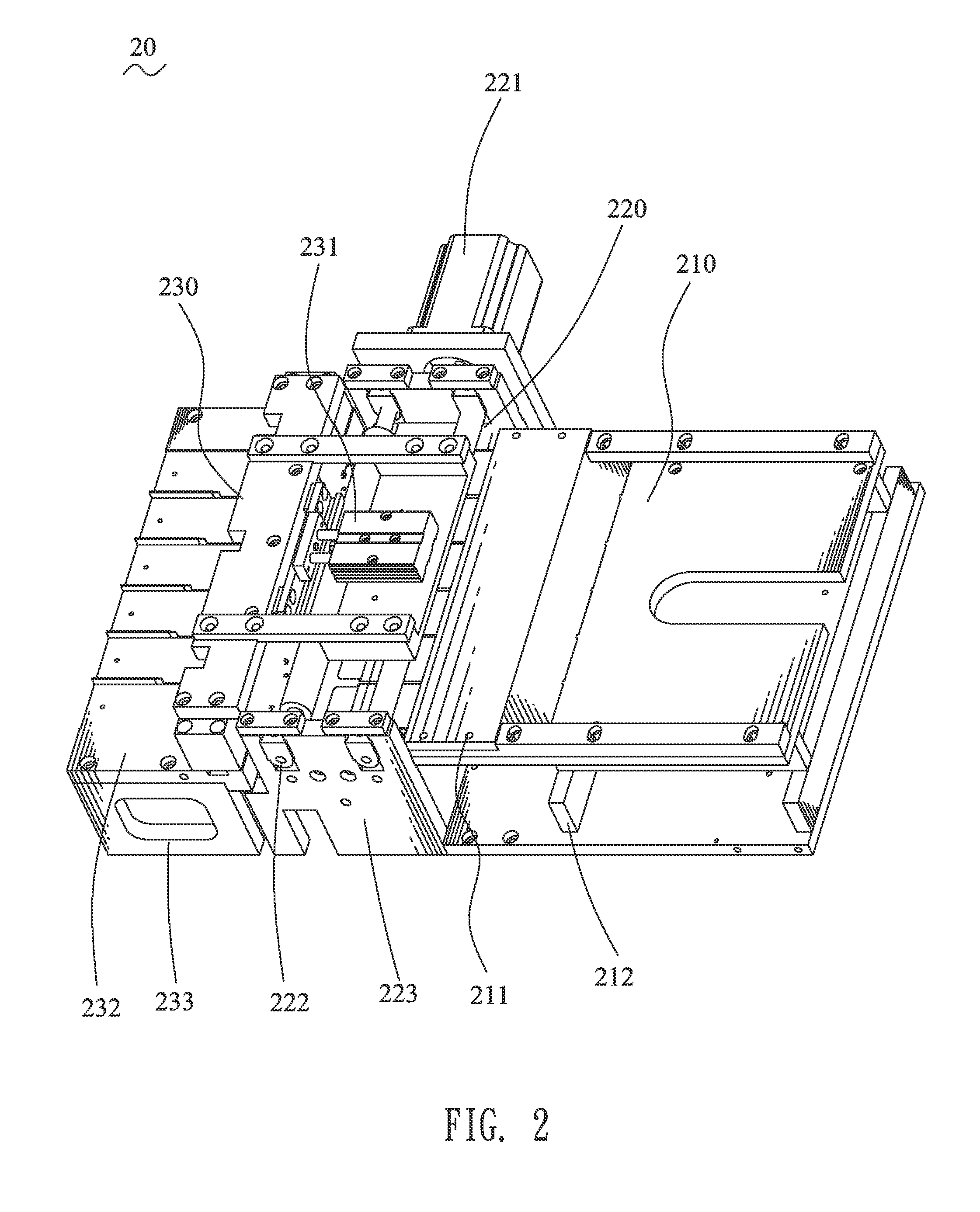

InactiveUS20130302461A1Operation efficiency can be improvedReduce operatorsFilament handlingAuxillary shaping apparatusEngineeringElectrical and Electronics engineering

An automatic circle forming apparatus adapted for automatically forming OPP (O-phenylphenol) plastic circles includes a lower equipment cabinet, a first base plate, a transmitting module, an automatic separating module, an automatic tearing film module, a sucking waste mechanism, a displacement module, an automatic forming module and an upper equipment cabinet. The upper equipment cabinet is positioned on the first base plate for installing the transmitting module, the automatic separating module, the automatic tearing film module, the sucking waste mechanism, the displacement module and the automatic forming module therein. The upper equipment cabinet is equipped with a man-machine control interface which connects with and controls the transmitting module, the automatic separating module, the automatic tearing film module, the sucking waste mechanism, the displacement module and the automatic forming module for automatically forming the OPP plastic circles so as to improve operation efficiency and save a human cost.

Owner:CHENG UEI PRECISION IND CO LTD

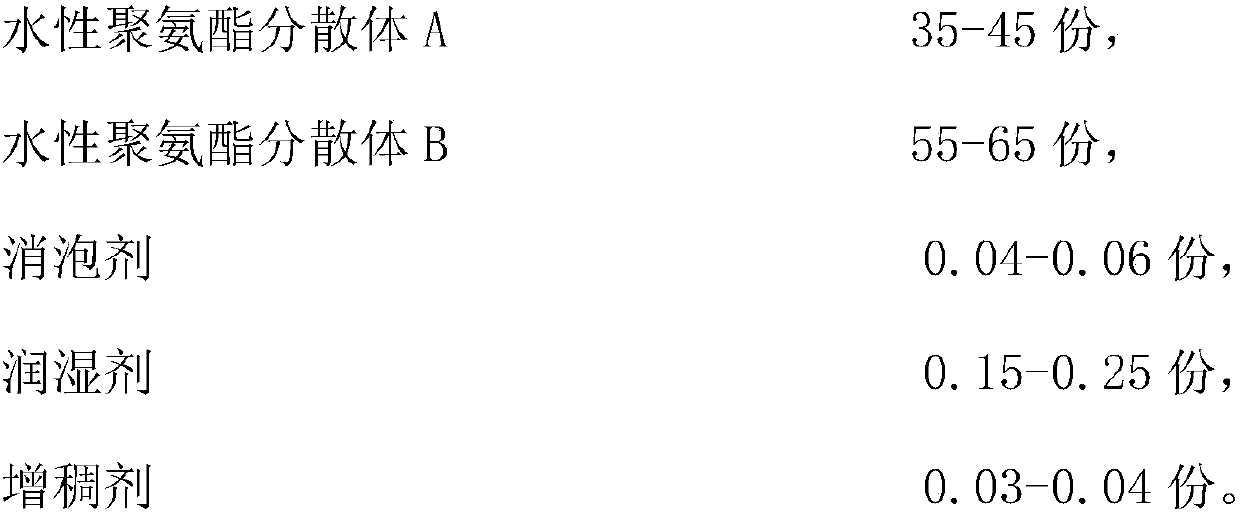

Water-based adhesive for automotive interior as well as preparation method and application of adhesive

ActiveCN109957370ALow costIncrease productivityPolyureas/polyurethane adhesivesPolyurethane dispersionWater based

The invention discloses a water-based adhesive for automotive interior and a preparation method of the adhesive. The adhesive comprises the following components, in parts by weight: 30-50 parts of a water-based polyurethane dispersion A, 50-70 parts of a water-based polyurethane dispersion B, 0.03-0.08 part of an antifoaming agent, 0.1-0.3 part of a wetting agent, and 0.02-0.05 part of a thickening agent; and the adhesive is obtained by mixing the above components. The adhesive provided by the invention can be used for bonding of plastic skeletons such as automotive interior door boards and instrument boards to surface layers, and can be used for a pre-coating process; and compared with a traditional two-component adhesive, the adhesive provided by the invention not only saves complicatedprocesses of mixing and spraying of two-component glue on a traditional process site, but also relieves limitation of use time of the two-component glue; and the method is easy to operate, and greatlyimproves production efficiency.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

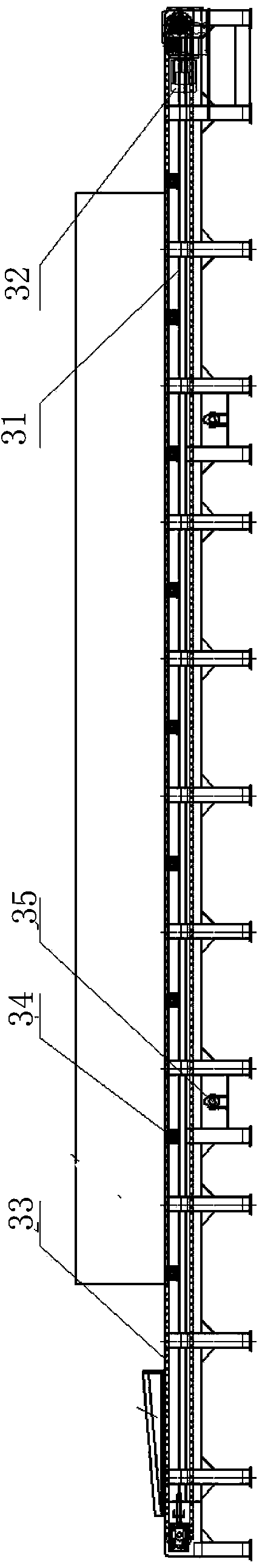

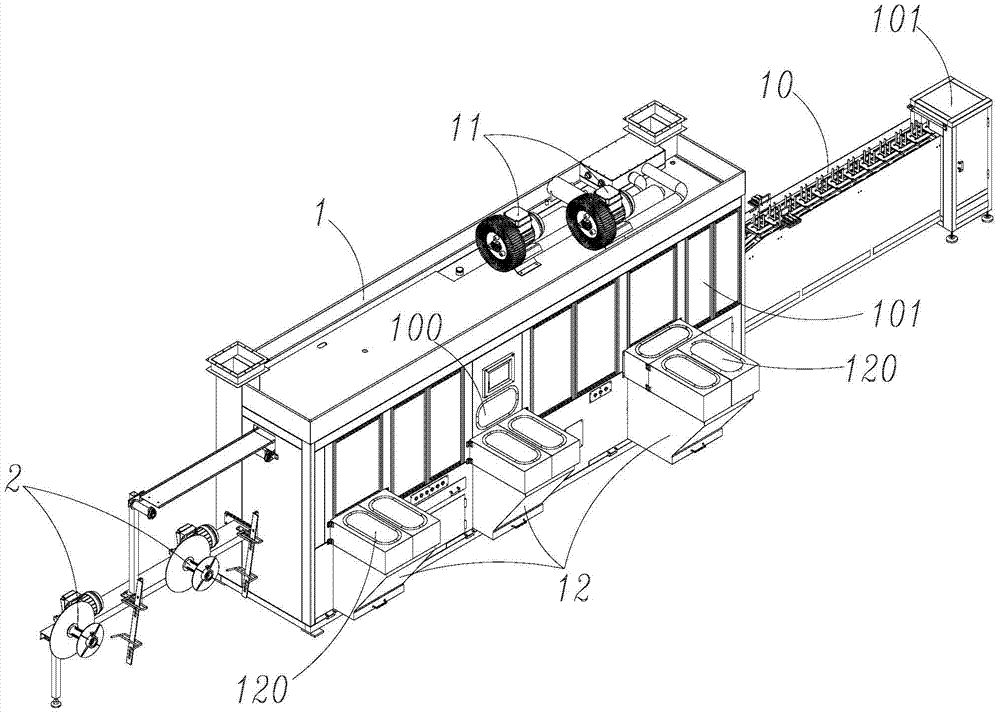

Medium-large-density battery piece wrapping machine

InactiveCN105070955AHigh precisionSmall quality errorFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a medium-large-density battery piece wrapping machine. The machine comprises a main frame mechanism, partition paper uncoiling mechanisms, a conveying mechanism, a feeding mechanism, a transmission mechanism, a paper feeding piece wrapping mechanism, a piece stacking mechanism, a collecting mechanism, an output mechanism and a negative pressure mechanism. The conveying mechanism is composed of a first conveying mechanism body and a second conveying mechanism body. The partition paper uncoiling mechanisms are installed on the left side of the main frame mechanism. Each partition paper uncoiling mechanism is connected with a motor. The first conveying mechanism body, the second conveying mechanism body, the piece stacking mechanism and the collecting mechanism are sequentially installed in the main frame mechanism from left to right. The paper feeding piece wrapping mechanism is located over the joint of the first conveying mechanism body and the second conveying mechanism body. The output mechanism is installed at the right end of the main frame mechanism. The medium-large-density battery piece wrapping machine is reasonable in structure. The medium-large-density battery piece wrapping machine is wholly arranged linearly, so that the space occupying coefficient is high. A mechanical linkage mode is adopted, so that piece wrapping efficiency is high. The piece wrapping efficiency and quality of batteries are improved while labor cost is reduced.

Owner:CHANGXING JINGSHENG HYDRAULIC MACHINERY

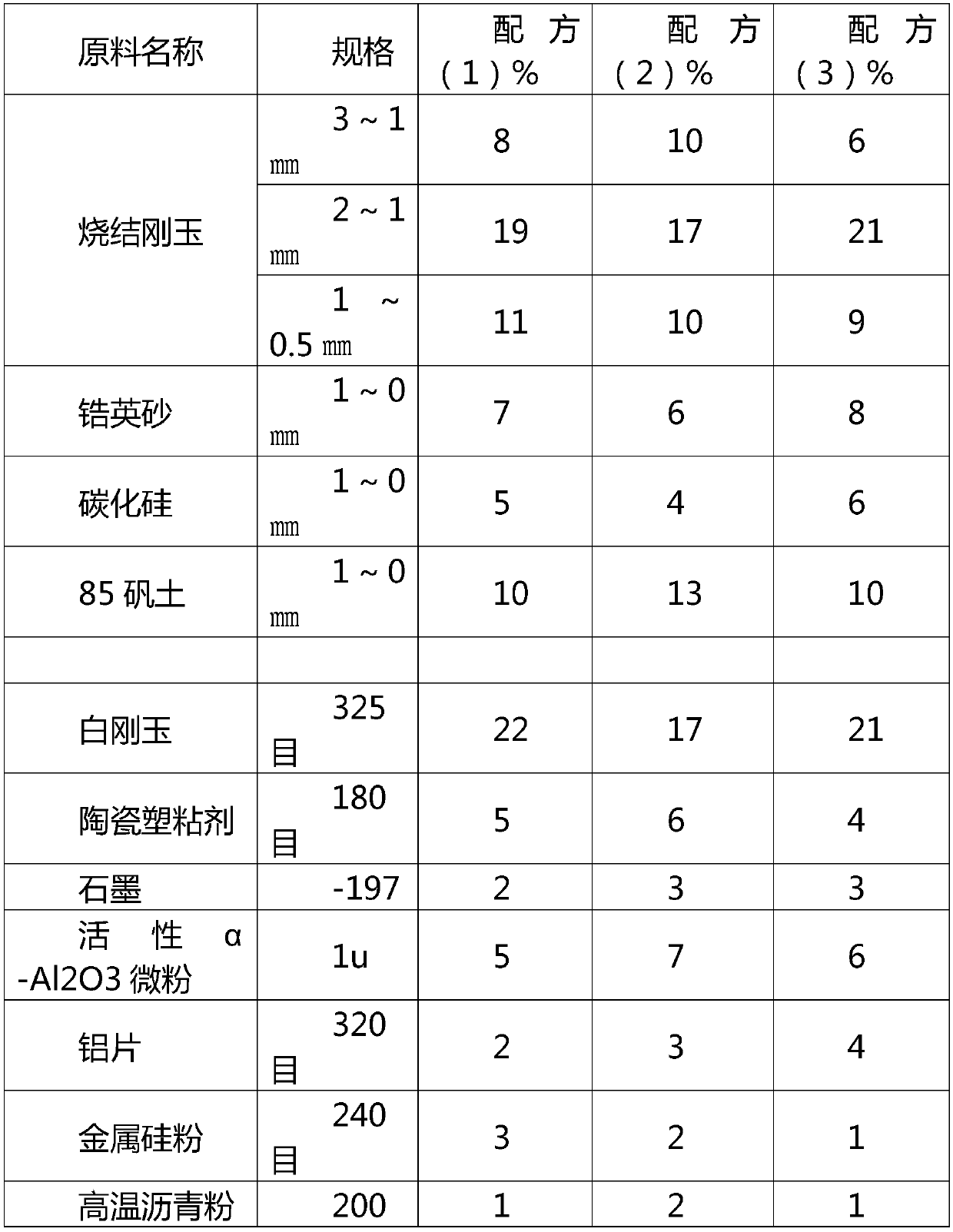

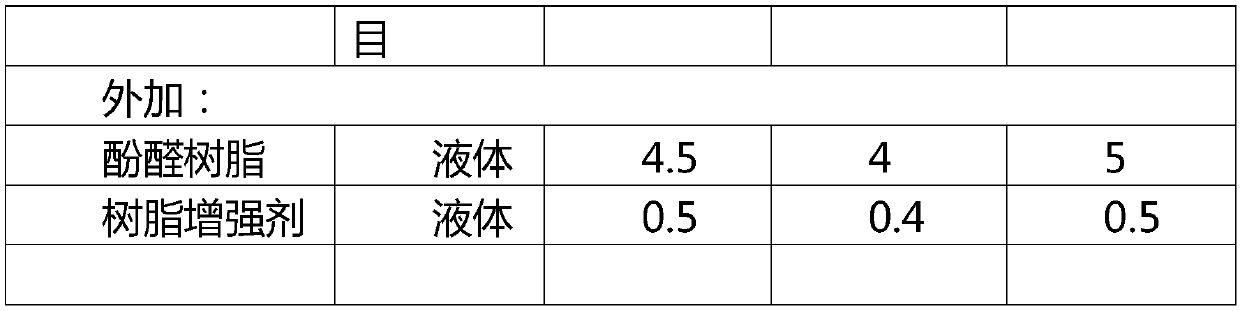

Impregnation-free sliding plate brick and preparation method thereof

The invention discloses an impregnation-free sliding plate brick which comprises, in weight percent, 36%-38% of sintered corundum, 6%-8% of zircon sand, 4%-6% of silicon carbide, 10%-13% of 85 alumina, 17%-21% of white corundum, 4%-6% of ceramic plastic adhesives, 2%-3% of graphite, 5%-7% of active alpha-Al2O3, 2%-4% of aluminum sheets, 1%-3% of silicon metal powder and 1%-2% of high-temperature asphalt powder. The total weight percent of all components in the formula is 100%. 4-5% of phenolic resin and 0.4-0.5% of resin reinforcing agents are added. The impregnation-free sliding plate brick is short in production cycle, environmentally friendly in production and use and good in erosion resistance and scouring resistance and saves a large amount of energy.

Owner:无锡市南方耐材有限公司

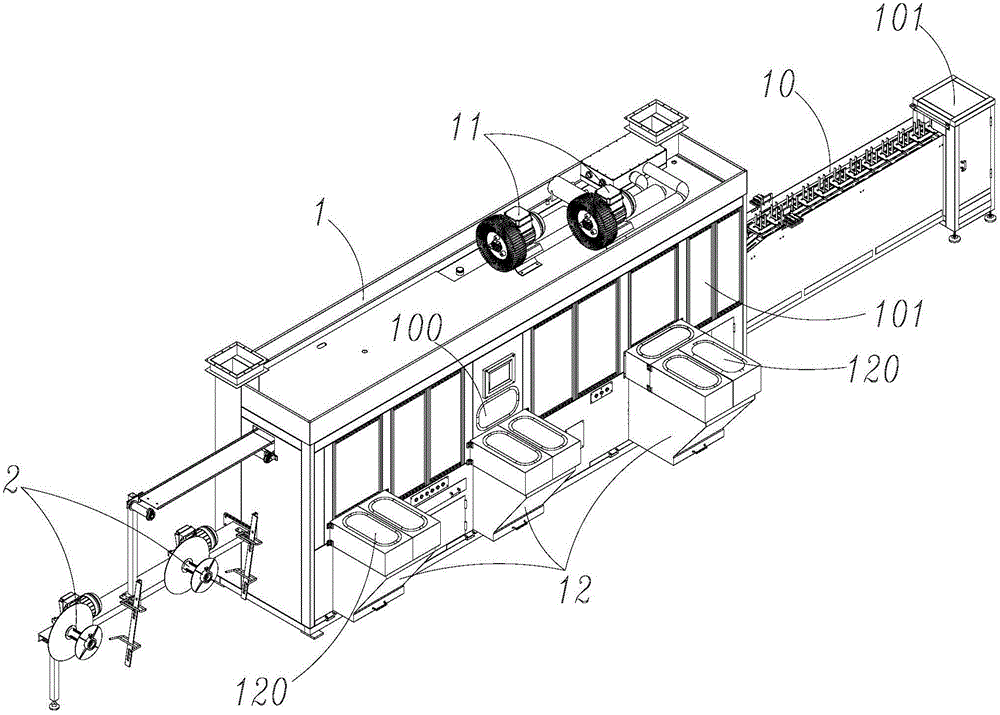

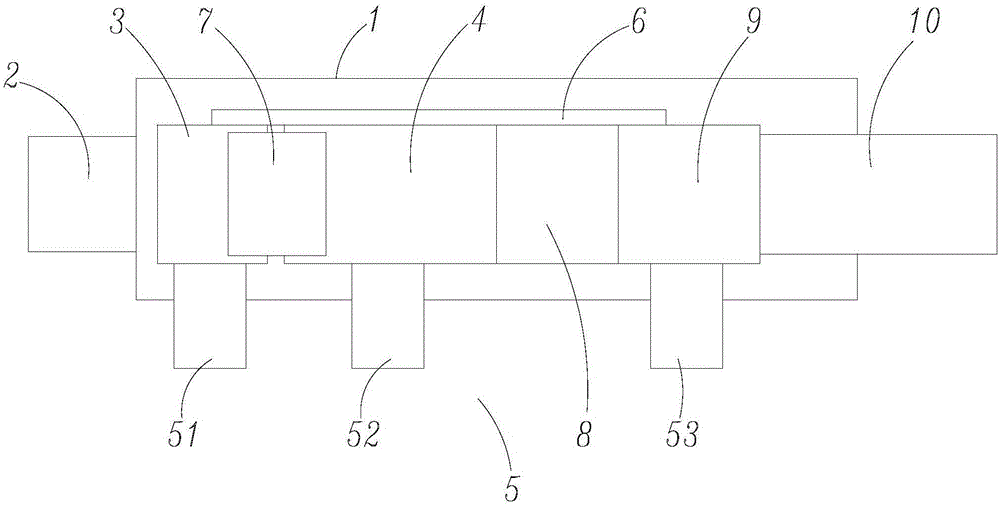

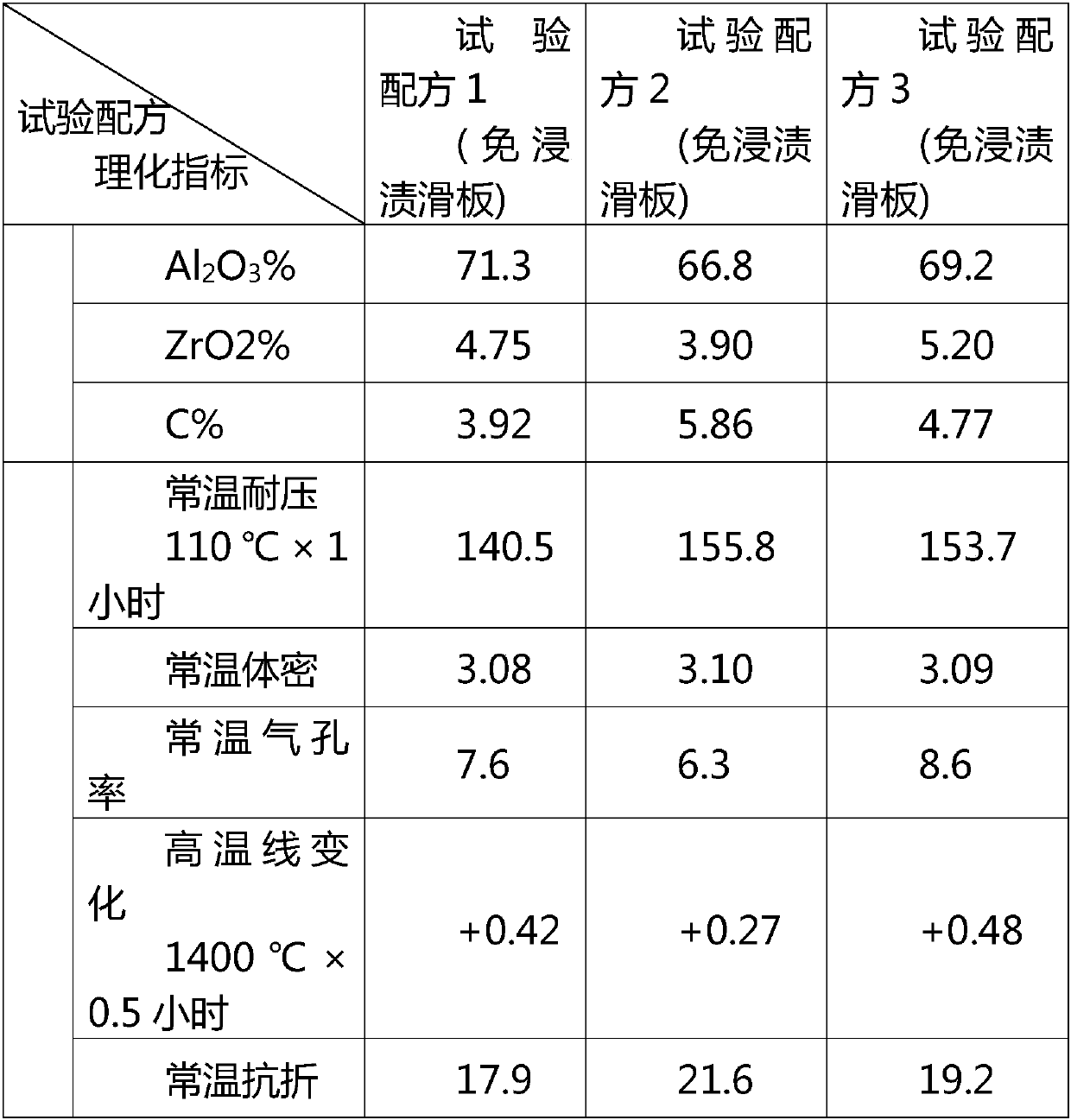

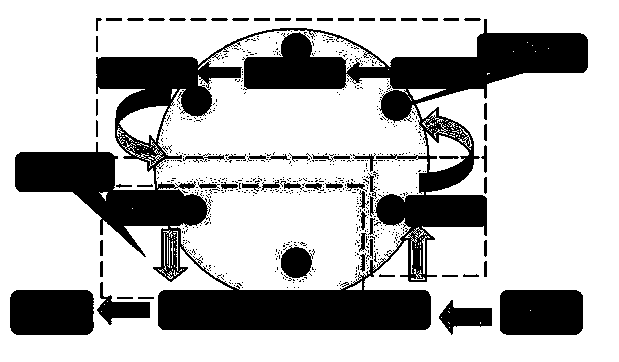

Automatic tank cover integrated production line and preparation technology of tank cover

PendingCN107497961AImprove transfer efficiencyReduce operatorsMetal-working feeding devicesMetal working apparatusProduction linePunching

The invention discloses an automatic tank cover integrated production line. According to the automatic tank cover integrated production line, the number of operators is reduced, the transfer efficiency is improved, and meanwhile, the effect that workpieces enter each process one by one in the correct posture is guaranteed. The automatic tank cover integrated production line particularly comprises a feeding machine, a cover punching machine, a trimming punching machine, a pre-bending punching machine, a hemming punching machine, a dotting machine and a PLC electric control system, wherein the output end of the feeding machine is in butt joint with an material cutting and punching position of the cover punching machine; the cover punching machine is in butt joint with the trimming punching machine through a first conveying unit; the trimming punching machine is in butt joint with the pre-bending punching machine through a second conveying unit; the pre-bending punching machine, the hemming punching machine and the dotting machine are arranged at intervals along the conveying direction of an intermittent conveyor and are in transmission connection with the intermittent conveyor; a first cover control mechanism used for controlling the tank covers to be conveyed to the trimming punching machine one by one is arranged on the first conveying unit; and a second cover control mechanism used for controlling the tank covers to be conveyed to the intermittent conveyor one by one is arranged on the second conveying unit. The invention further discloses a preparation technology of the tank cover.

Owner:晋江兴泰制罐有限公司

Raw material formula of tundish insulating board and preparation method for tundish insulating board

InactiveCN101544506BSmall bulk densityHigh strengthMelt-holding vesselsCeramic shaping apparatusBrickChloride

The invention discloses a raw material formula of a tundish insulating board. The raw materials (mass percentage) consist of 30 to 50 percent of olivine sand, 15 to 25 percent of magnesia, 25 to 40 percent of waste magnesite brick, 4 to 8 percent of magnesium chloride and 0.2 to 0.5 percent of hardening agent. The preparation method for the tundish insulating board by adopting the raw material formula of the tundish insulating board comprises the following steps: 1) configuring the raw materials, and mixing and stirring the raw materials; 2) adding water accounting for 5.5 to 7.5 percent of the total mass of the raw materials into the stirred raw materials, mixing and stirring the mixture for 3 to 5min, and then putting the mixture into a mould for vibratory compaction; 3) demoulding after 1 to 2 hours of the forming; and 4) baking the demoulded tundish insulating board at a temperature of between 120 and 150 DEG C for 6 to 8 hours in a drying room. The preparation method adopts the magnesium chloride as a bonding agent, has no smoke and penetrating odor in the baking and using processes, is suitable for smelting clean steel and extreme low carbon steel, simplifies production process and reduces operators and investment of production cost and equipment due to adoption of the mould for casting.

Owner:陈红良

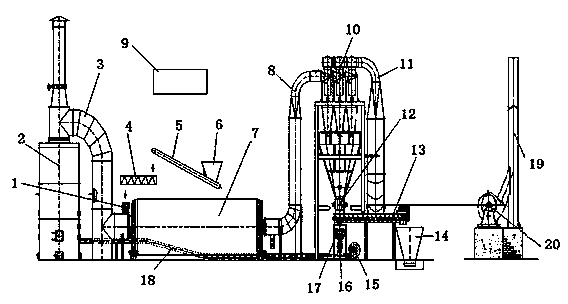

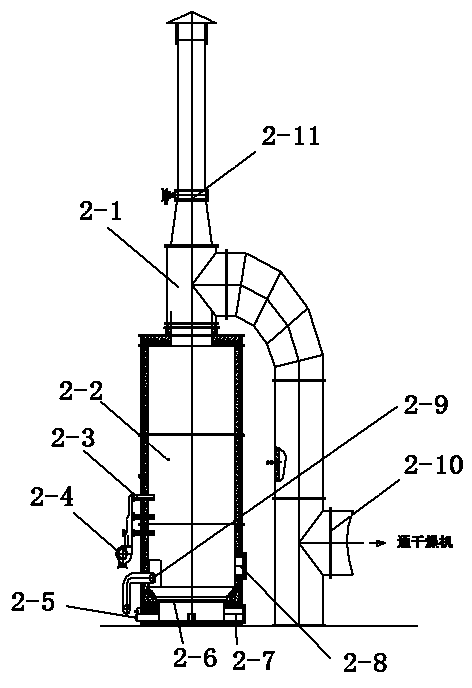

Dual-purpose hot blast heater system with automatic material returning system for burning wood bits through spraying and burning miscellaneous trees and use method of dual-purpose hot blast heater system

ActiveCN103808123ARealize automatic supplyReduce operatorsDrying gas arrangementsSolid fuel combustionAutomatic controlHot air oven

A dual-purpose hot blast heater system with an automatic material returning system for burning wood bits through spitting and burning miscellaneous trees is provided with a hot blast heater, a drying main machine, a feeding system, a multi-cylinder cyclone collecting device, the automatic material returning system, a main exhaust fan, temperature sensors and a fuzzy controller. An outlet of a drying machine, an inlet of the drying machine and an outlet of the hot blast heater are respectively provided with one temperature sensor, the corresponding temperatures are respectively calibrated through the fuzzy controller, a material returning spiral, an electric gate valve at the top of the hot blast heater and a variable-frequency variable-speed motor of a feeding conveyor are controlled respectively, the burning amount in the hot blast heater, the amount of air sucked into the drying machine and the amount of wet materials entering the drying machine are adjusted, it is guaranteed that the calibrated temperatures are reached respectively, and therefore automatic control over the whole system is achieved. In addition, the heater is dual in purpose and the burning efficiency is improved.

Owner:SHENYANG YUANDA TECH IND

Inverted-T-shaped hole table facet perforating device and application thereof

ActiveCN112024937AMeet the needs of precision drillingSimple and fast operationFeeding apparatusPositioning apparatusElectric machineryStructural engineering

The invention discloses an inverted-T-shaped hole table facet perforating device and application thereof.The inverted-T-shaped hole table facet perforating device comprises an operation table and a perforating machine.The perforating machine is movably hung above the operation table through a sliding rail. The perforating machine comprises an operating rod, a shell, a motor and a back bolt drill bit. An arc-shaped groove is formed in the operating rod.A supporting table, a pull rod, a swing base and a movable rod are arranged in the shell. One end of the pull rod is pivoted with the top of theperforating machine.The other end of the pull rod is arranged in the arc-shaped groove.The concave part of the arc-shaped groove faces towards the pull rod.The arc-shaped groove is composed of a first groove body and a second groove body, and the bending degree of the first groove body is smaller than the bending degree of the second groove body.The top of the swing base is pivoted with the supporting table.A chute is formed in the bottom of the swing base, and the movable rod is sleeved with the chute. The motor is arranged in the shell and used for driving the back bolt drill bit to rotate.The back bolt drill bit is arranged at the bottom of the shell and connected with the movable rod, and the back bolt drill bit is in an inverted-7 shape. The perforating method of the inverted-T-shaped hole table facet perforating device and application thereof is simple, convenient, rapid, time-saving and labor-saving.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

Wire cutting device for screw energy conserving lamp assembling production

ActiveCN101219488ARealize continuous cuttingContinuous cuttingShearing machinesProduction lineInsertion stent

The invention discloses a lead cutting device used for assembly production of edison screw energy saving lamps, which is characterized in that the invention comprises at least one cutting mechanism arranged on a work station platform. The cutting mechanism comprises a first vertical stent and a first horizontal stent that are coupled. One end of the first horizontal stent is connected with a first cylinder pull rod and the other end is provided with cutter rests which are connected with a second cylinder pull rod. An elastic recovery device is positioned between the first horizontal stent and the cutter rests. The invention has the advantages that: the second cylinder pull rod is applied to pull the rotary cutter rest open and the recovery spring ensures the cutter on the rotary cutter rest and the cutter on a fixed cutter rest mutually cut to cut the lead, which is convenient to operate; the first vertical stent and the first horizontal stent are coupled, and therefore control of the first cylinder pull rod can uplift or drop the cutter rest, thereby realizing continuous cutting of lead on the edison screw energy saving lamps. The invention is applicable for production line.

Owner:浙江阳光城市照明工程有限公司

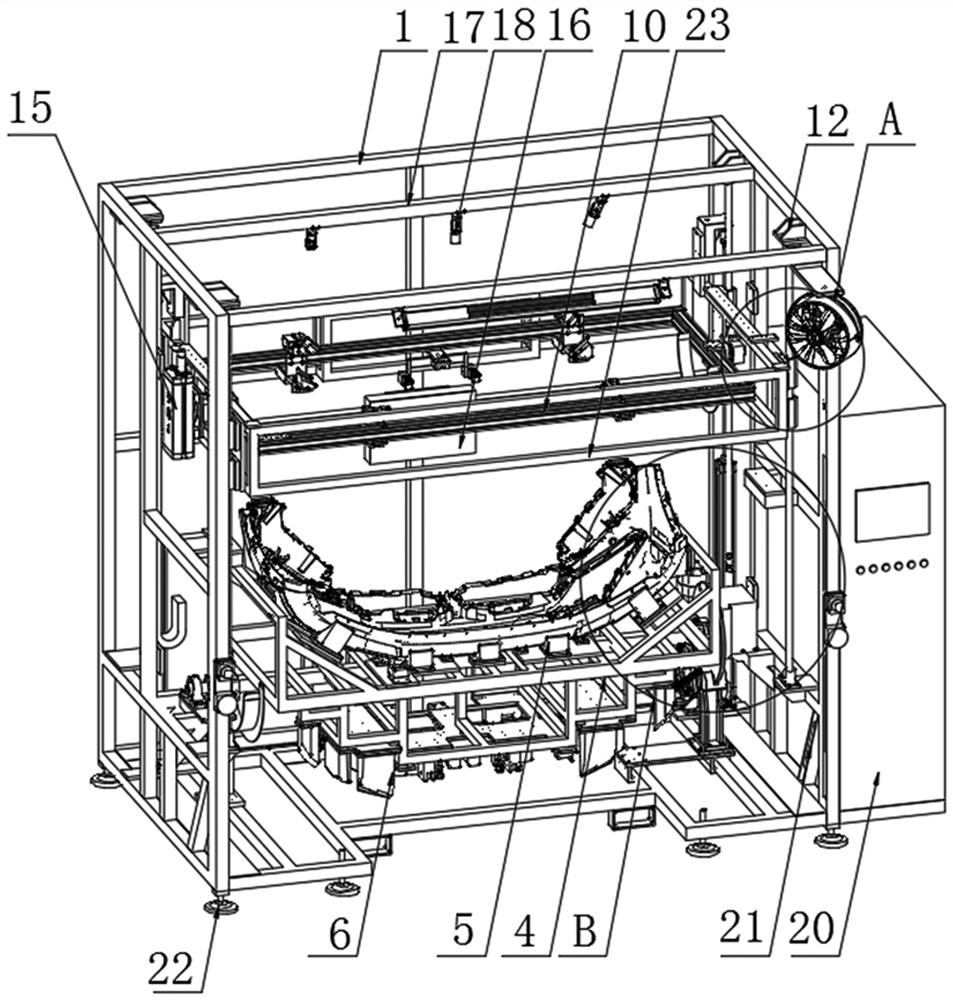

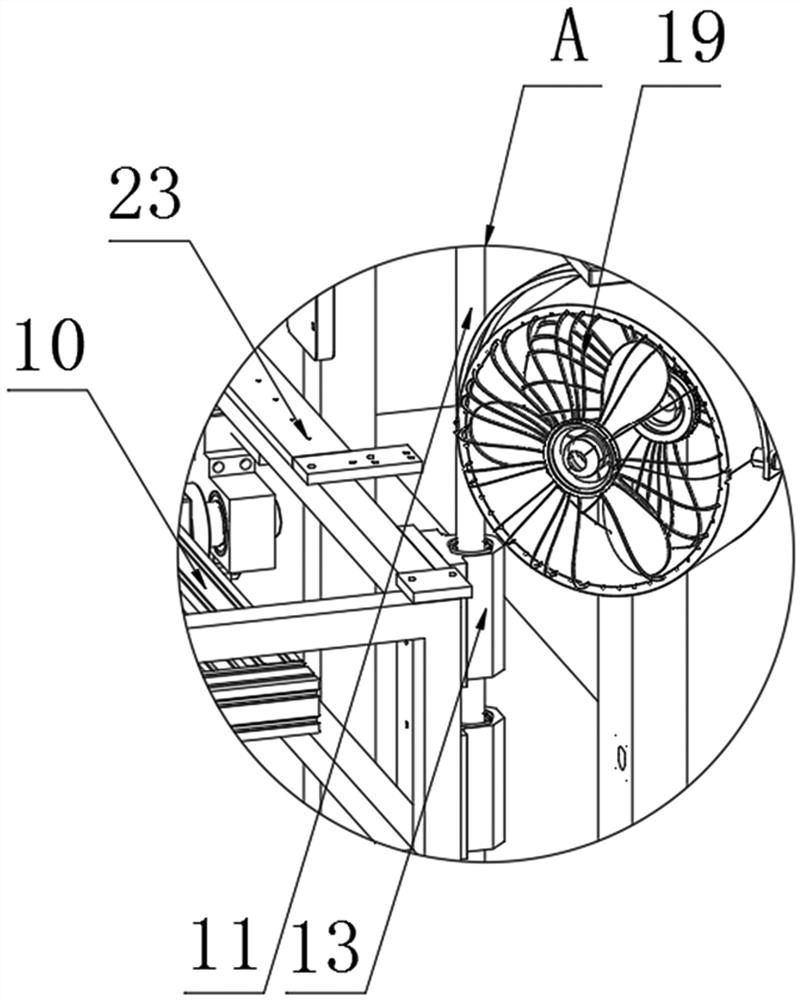

Integrated assembling equipment for front bumper of passenger car

The invention relates to integrated assembly equipment for a front bumper of a passenger car, in particular to the technical field of bumper assembly.The integrated assembly equipment comprises a frame body, a turnover shaft is arranged in the frame body, the two ends of the turnover shaft are each sleeved with two mounting supports, and the outer walls of the two ends of the turnover shaft are movably connected with the two mounting supports through bearings correspondingly; the installation support is connected with the frame body through bolts, and the overturning shaft is sleeved with an overturning frame. The two chain wheels connected through the chain are driven by the overturning motor to rotate, so that the overturning shaft drives the overturning frame to rotate, the positions of the A-face tire mold and the B-face tire mold on the overturning frame can be adjusted, through overturning switching of the B-face tire mold and the A-face tire mold, development of one assembly tool and product occupation of the tool can be reduced, and the production efficiency is improved. And meanwhile, one operator is reduced, the occupied area and the working hours of workers are saved, and the effect of saving labor and space is achieved.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

An automatic tab-bending device for battery side plates

ActiveCN104475503BImprove efficiencySolve quality problems such as sheddingCell component detailsClassical mechanicsStructural engineering

The invention discloses an automatic tab-bending device for a battery side plate, which is characterized in that it mainly includes an L-shaped mounting seat, a lifting cylinder, a cylinder pad, a T-shaped support plate, a cylinder, a fixing seat, a connecting rod, a sleeve clip, and a screw , upper plate, lower plate, side plate, through hole, sliding cylinder, mounting plate, slider, guide rail, B mounting plate, air finger, pressure plate, bump, waist hole, shaft rod, swing top piece, the L The spacer is installed horizontally on the mounting base, the lifting cylinder is installed on the spacer, the T-shaped support plate is installed on the side of the L-shaped mounting seat, and the upper and lower plates, the cylinder, and the shaft are arranged successively above the T-shaped support plate. A mounting plate is installed behind the upper and lower plates, and guide rails and air fingers are arranged on the mounting plate. The pole group is arranged in the middle of the lifting cylinder and the pressing plate. The strength and angle of the tabs are consistent, ensuring that the side plates of each pole group are not damaged, which improves the quality and production efficiency of battery products.

Owner:ZHUZHOU YINGDING AUTOMATION EQUIP TECH

A device for opening holes on countertops with inverted t-holes and its application

ActiveCN112024937BMeet the needs of precision drillingSimple and fast operationFeeding apparatusPositioning apparatusPunchingClassical mechanics

The invention discloses a hole opening device for an inverted T-hole table surface and its application, which includes an operation table and a punching machine, and the hole punching machine is movably suspended above the operation table through slide rails; the hole punching machine includes an operating rod, Shell, motor and back bolt drill bit; an arc groove is set on the operating rod; a support platform, a pull rod, a swing seat and a movable rod are arranged in the casing; one end of the pull rod is pivotally connected with the top of the punching machine, and the other end is set In the arc-shaped groove, the recess of the arc-shaped groove body faces the pull rod; the arc-shaped groove is composed of the first groove body and the second groove body, and the bending degree of the first groove body is smaller than that of the second groove body; the top of the swing seat and the support The table is pivotally connected, the bottom of the swing seat is provided with a chute, and the movable rod is sleeved in the chute; the motor is arranged in the casing to drive the backbolt drill to rotate; the backbolt drill is arranged at the bottom of the casing and connected with the movable The rod is connected, and the drill bit of the back bolt is an inverted "7" shape. Utilizing the opening method of the device of the present invention is simple and quick, saves time and effort.

Owner:เซี่ยเหมิน โกลเด้นโฮม โค

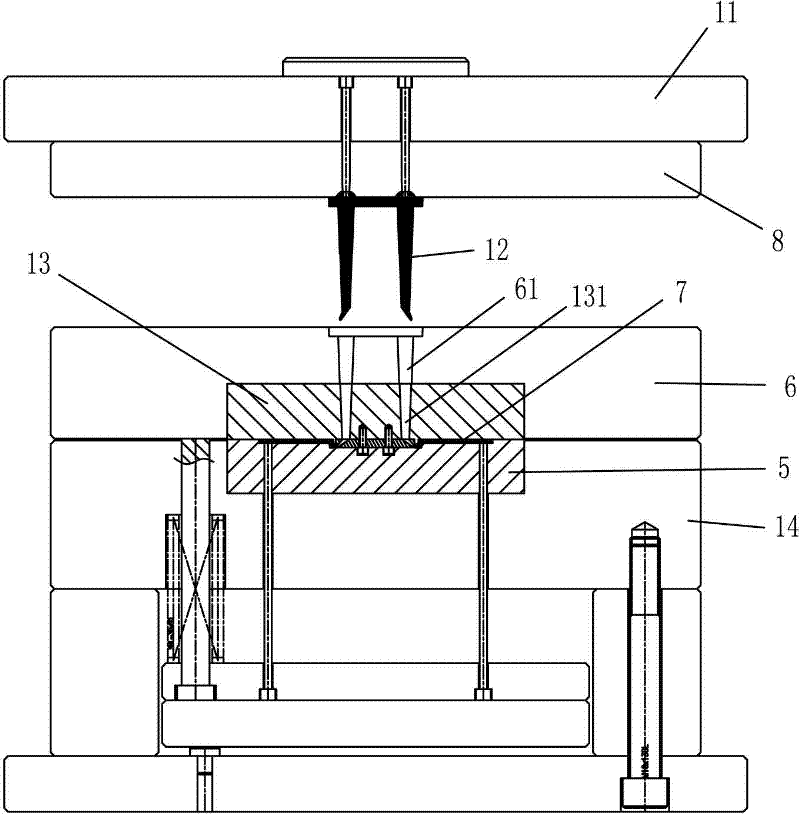

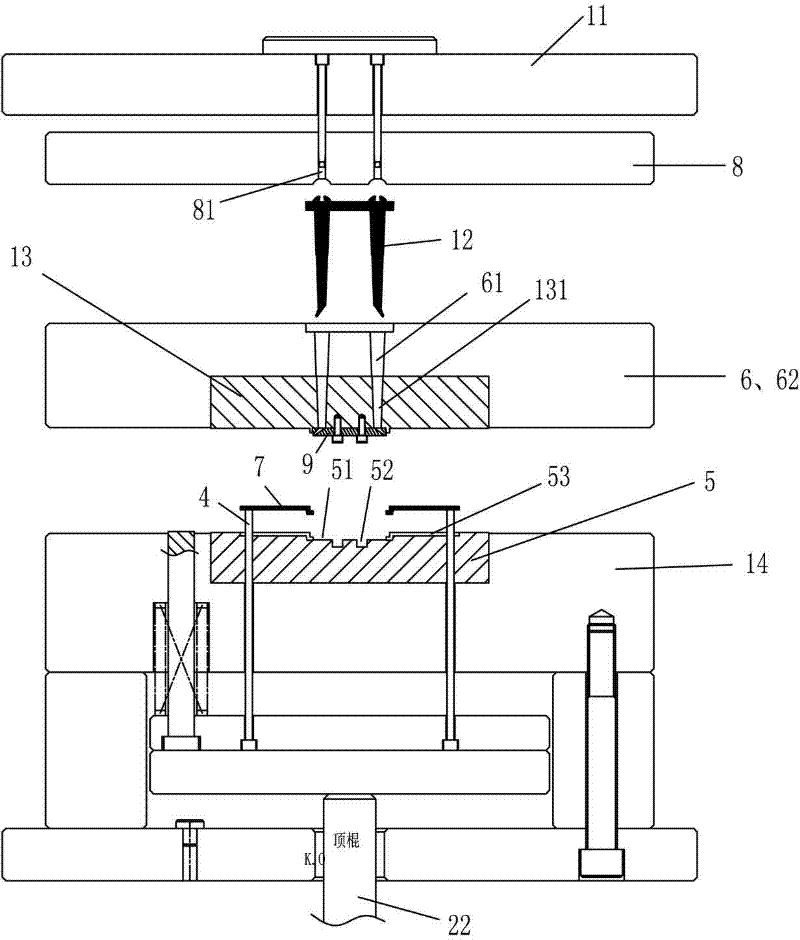

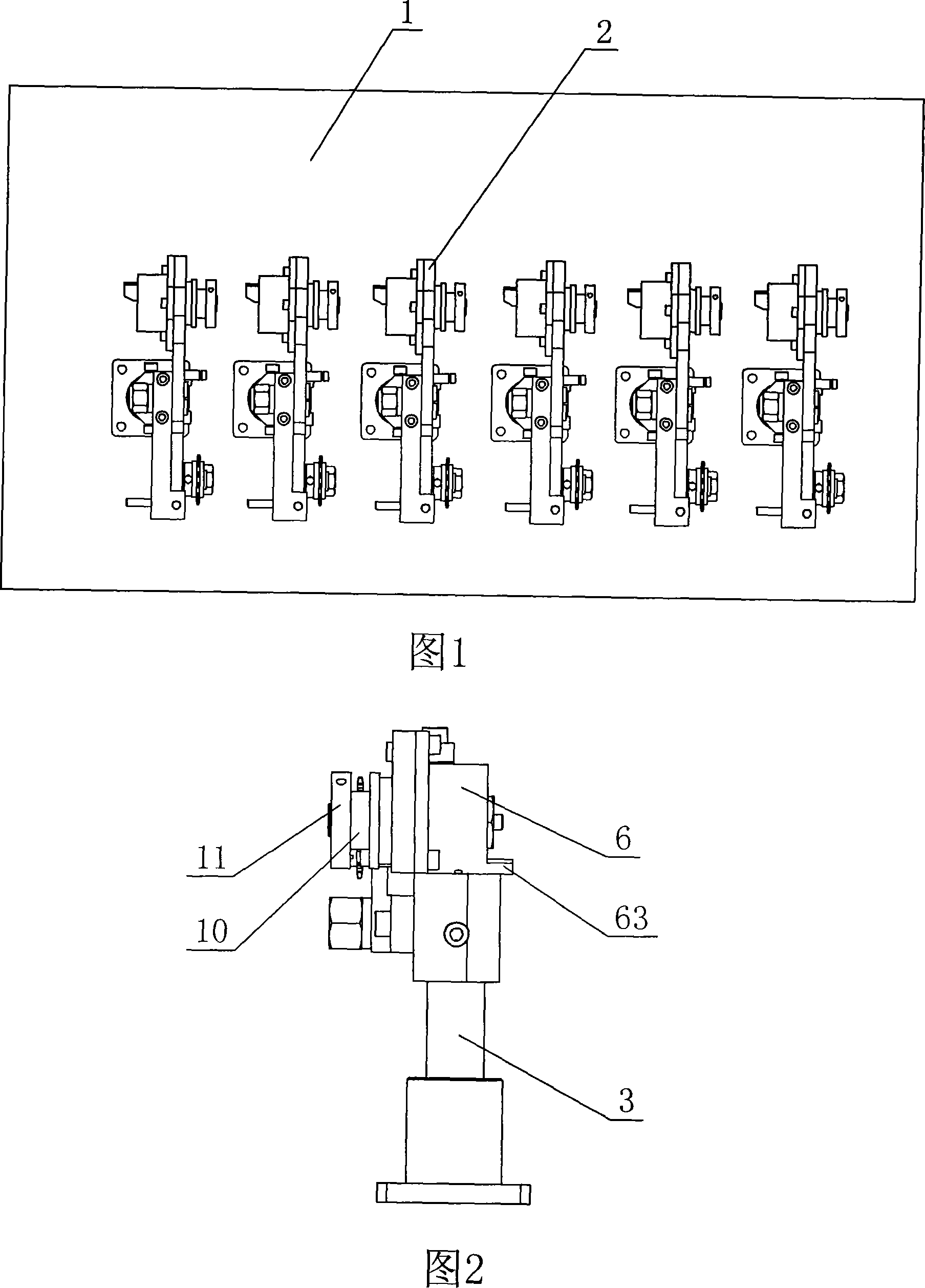

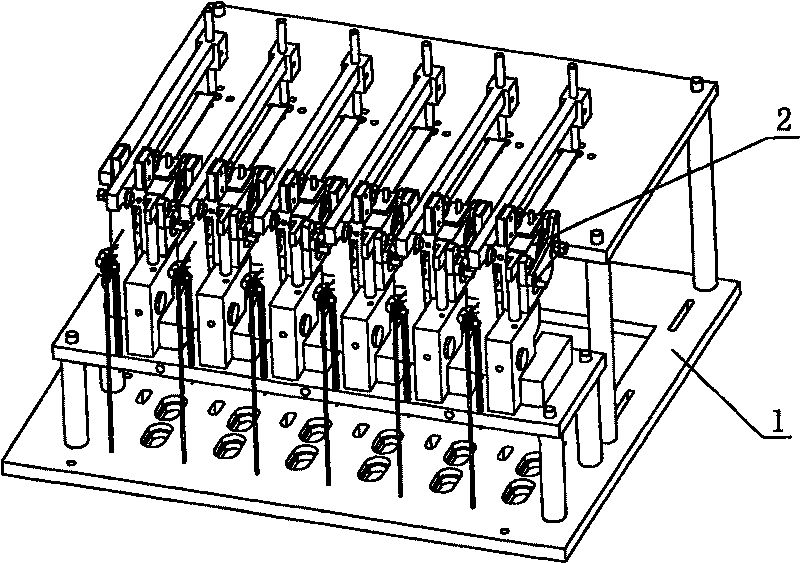

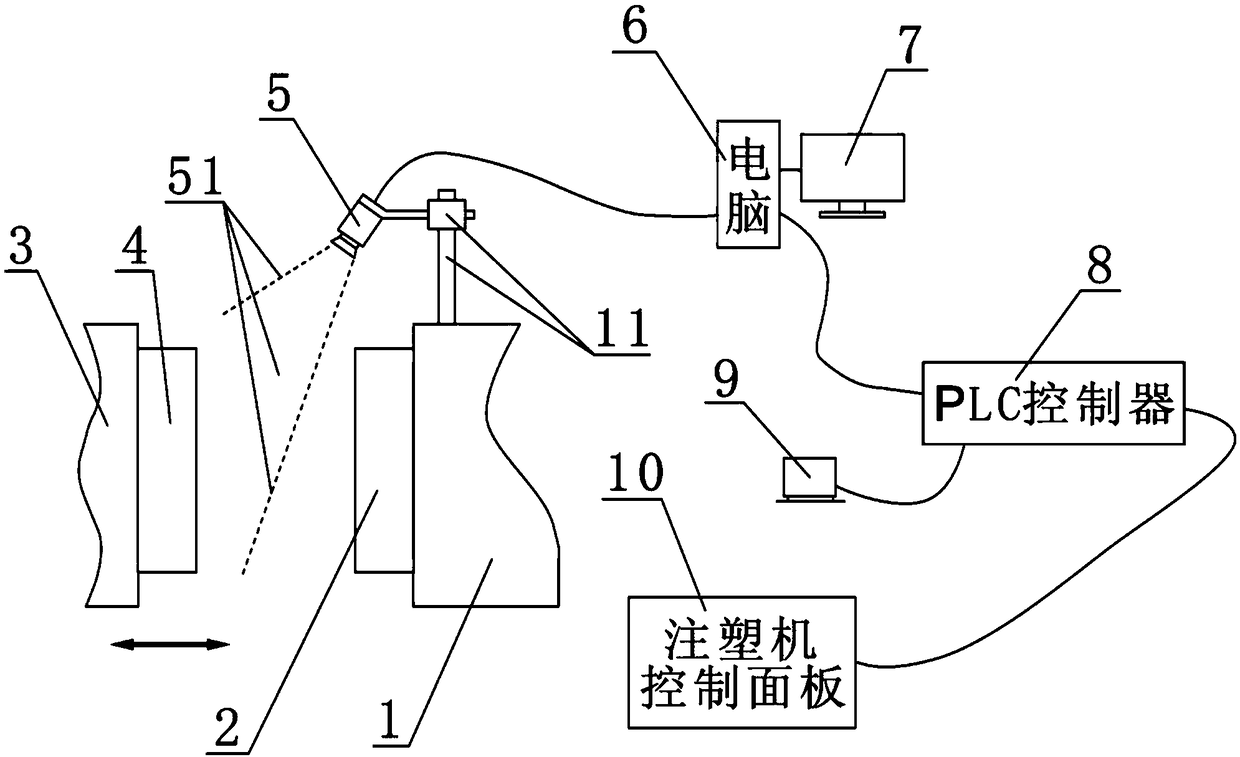

A device with multiple inserts placed into the mold at one time

ActiveCN103737789BShorten injection molding cycleReduce operatorsCoatingsEngineeringMechanical engineering

The invention relates to a device capable of placing multiple inserts into a mold once. The device comprises a movable elastic top thread, a thimble, a linear bearing, a linear guide track, a reset spring, a pipe position workpiece, a positioning and fixing plate, a pushing and pulling rotary grab handle, a phenolic resin handle and the like, the inserts can be positioned with high precision, the inserts can be pushed into the mold very flexibly, and the linear guide track, the elastic movable top thread and a combined workpiece are used for positioning. According to the device provided by the invention, a clamp is used for mounting the inserts outside the mold, the whole injection molding period and the time for mounting the inserts outside the mold are the same, and the multiple inserts can be mounted on the clamp once and pushed into a mold cavity together, so that the whole injection molding period is reduced by one half, operators are simultaneously reduced, the injection molding period is relatively stable, and the product quality is upgraded.

Owner:NINGBO TIANLONG ELECTRONICS

Wire lead solder device for screw energy conserving lamp assembling production

InactiveCN101219496BNo wasteHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesEdison screwOxidation resistant

The invention discloses a lead solder device applied to assembly production of edison screw energy saving lamps, which is characterized in that the invention comprises at least one soldering tin mechanism arranged on a work station platform. The soldering tin mechanism comprises a base and a first cylinder ejector pin. The base is coupled with a rocker arm; one end of the rocker arm is coupled with a second cylinder ejector pin and the other end with a cantilever. The end of the cantilever is vertically arranged with a welding head, the first cylinder ejector pin goes through the base and is apically grafted at the lower part of the cantilever and the base is provided with a solder wire delivery mechanism. The invention has the advantages that the welding head is made of oxidation-resistant and corrosion resistant pontil which does not need replacing frequently, the work station platform can be provided with a plurality of soldering tin mechanism parallel to meet different production demand, the structure of the whole device is simple, the working efficiency can be improved at least one time and operators can be reduced at least by half.

Owner:ANHUI SUNSHINE LIGHTING APPLIANCE CO LTD

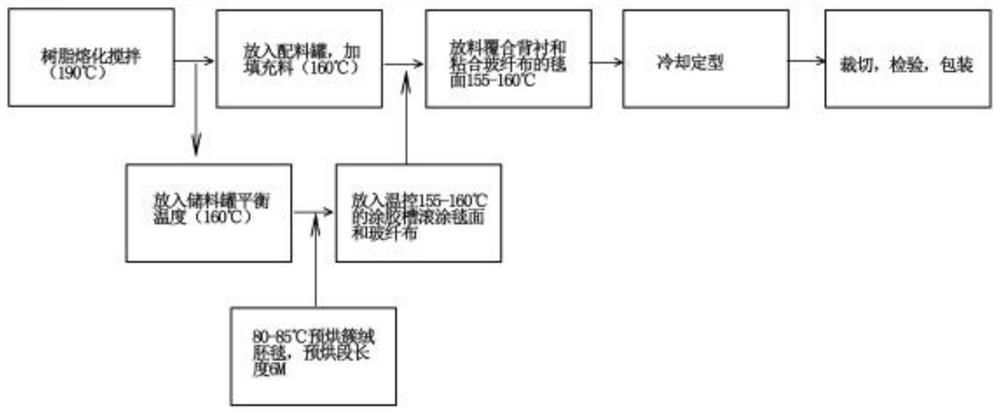

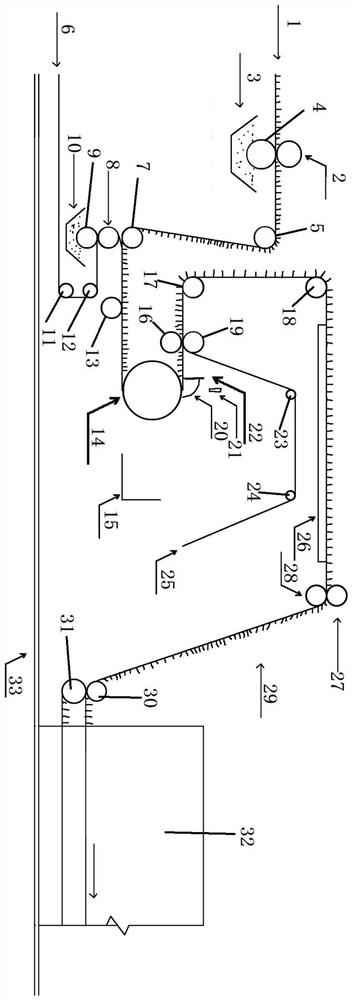

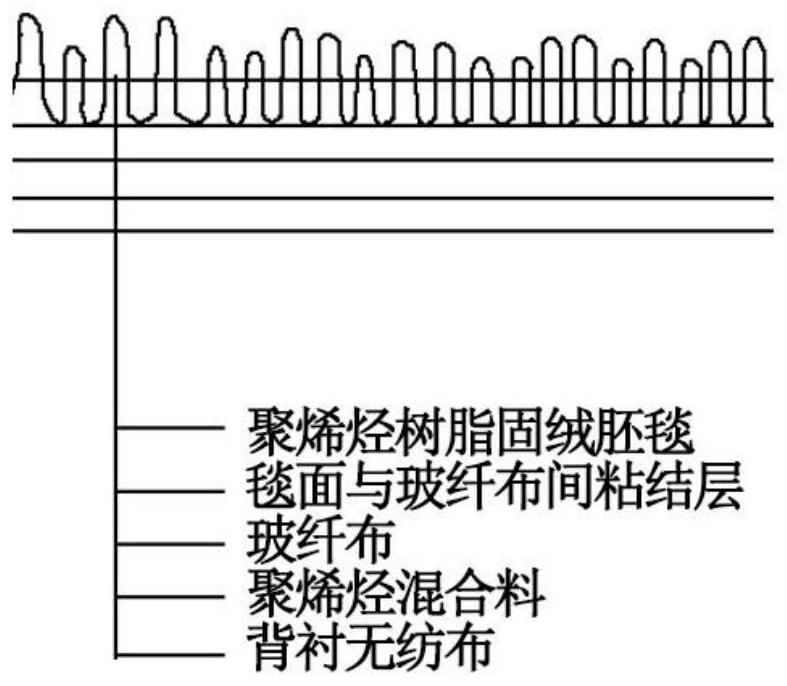

Preparation method and device of polyolefin bottom-back spliced carpet

PendingCN114474932AHigh bonding strengthGood dimensional stabilitySynthetic resin layered productsLaminationGlass fiberPolymer science

The invention relates to the technical field of spliced carpets, in particular to a preparation method and device of a polyolefin bottom-back spliced carpet. The preparation method comprises the following steps: roller-coating a first allyl resin adhesive on the back surface of a tufted blank carpet to obtain a glued blank carpet; roller-coating a second layer of propenyl resin adhesive on the surface of the glass fiber cloth to obtain cloth adhesive glass fiber cloth; carrying out first rolling on the glued blank carpet and the glued surface of the glued glass fiber cloth to obtain a composite blank carpet; the glass fiber cloth surface of the composite blank carpet is coated with a third layer of propenyl resin bonding material in a blade coating mode, a bonding layer is formed, the cloth-glue composite blank carpet is obtained, and the propenyl resin bonding material comprises filler and propenyl resin glue; rolling a bottom back non-woven fabric layer on the surface of the bonding layer for the second time to obtain a semi-finished product; and cooling and shaping the semi-finished product to obtain the propylene-based back spliced carpet. The propylene-based back-spliced carpet obtained by the preparation method provided by the invention is high in dimensional stability, firm and durable.

Owner:山东优尼科斯科技股份有限公司

An automatic pole-bending device

ActiveCN104362282BImprove efficiencySolve quality problems such as sheddingCell component detailsEngineeringMechanical engineering

Owner:ZHUZHOU YINGDING AUTOMATION EQUIP TECH

Rotary streamline production method of junction boxes

InactiveCN104253176AReduce operatorsIncrease productivityFinal product manufactureSemiconductor devicesAdhesiveWorkstation

The invention relates to a rotary streamline production method of junction boxes. The rotary continuous production method includes steps of taking unwelded raw materials and placing into the raw materials into a clamp; rotating a streamline turnplate, sending the raw materials to the next workstation, and welding the junction boxes ultrasonically; dispensing adhesives and detecting the junction boxes; if the junction boxes are unqualified, repeating detection three times, and halting if the junction boxes are still unqualified; if the junction boxes are qualified, rotating the streamline turnplate, sending the raw materials into the next workstation, and taking the welded finished products from the turnplate manually. By the rotary streamline production method, operators can be reduced, and production efficiency is improved.

Owner:JIANGSU TONGLIN ELECTRIC

Polyurethane direct buried insulation pipe digital two-step filling operation line

The invention relates to the technical field of medical auxiliary devices, in particular to a digitalized two-step method filling operation assembly line for directly-buried polyurethane thermal insulation pipes. The digitalized two-step method filling operation assembly line comprises a steel pipe transmission unit, a rust and dust removal system, a medium frequency heating device, a pipe penetrating machine, a lifting moving V-shaped box, an upper blocking machine, a preheating device before foaming and a polyurethane foaming unit, wherein the steel pipe transmission unit, the rust and dust removal system, the medium frequency heating device, the pipe penetrating machine, the lifting moving V-shaped box, the upper blocking machine, the preheating device before foaming and the polyurethane foaming unit are connected in sequence. By means of the digitalized two-step method filling operation assembly line for the directly-buried polyurethane thermal insulation pipes, potential safety hazards in production are reduced; through a continuous operation mode, namely, after the pipes (including steel pipes and PE pipes) enter a production line, the bottoms of the pipes never leave the production line, and the pipes move from one position to a next position through a series of actions such as hydraulic transmission and chain transmission till finished pipes move out of the production line; a hoisting tool is used in none of the steps, so that hidden dangers are reduced.

Owner:天津裕实工程技术有限公司

A medium and large density battery packing machine

InactiveCN105070955BHigh precisionSmall quality errorFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a medium and large-density battery wrapping machine, which comprises a main frame mechanism, a partition paper unwinding mechanism, a conveying mechanism, a material feeding mechanism, a transmission mechanism, a paper feeding and wrapping mechanism, a stacking mechanism, a material receiving mechanism, an output mechanism and negative pressure mechanism, the conveying mechanism is composed of a first conveying mechanism and a second conveying mechanism, a number of separator paper unwinding mechanisms are installed on the left side of the main frame mechanism, and each separator paper unwinding mechanism is connected with a motor Connected, the inside of the main frame mechanism is sequentially installed with a first conveying mechanism, a second conveying mechanism, a stacking mechanism and a receiving mechanism from left to right, and the paper feeding and wrapping mechanism is located between the first conveying mechanism and the second conveying mechanism. Directly above the mechanism junction, the output mechanism is installed on the right end of the main frame mechanism. The invention discloses a medium-to-large-density battery wrapping machine, which has a reasonable structure, an overall linear layout, a high space occupation factor, adopts a mechanical linkage method, has high wrapping accuracy, reduces labor costs, and improves battery wrapping efficiency and quality.

Owner:CHANGXING JINGSHENG HYDRAULIC MACHINERY

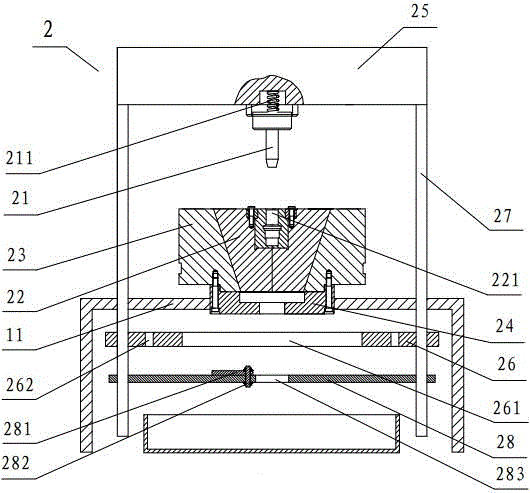

Automatic imaging monitoring system and method for mold clamping and injection molding operations

Owner:HEILONGJIANG KELUN PHARMA

An automatic demoulding punch

ActiveCN104985081BRealize automatic homingAvoid deformationShaping toolsMetal-working feeding devicesPunch pressEngineering

An automatic demolding punching machine comprises a punching machine frame, a mold frame and a programming controller, wherein the mold frame is provided with a male mold, a female mold, a mold frame upper plate, a mold frame lower plate, a suspender and a mold change ejection plate; a demolding mechanism, a receiving mechanism and a mold ejection mechanism are also arranged in the mold frame; the demolding mechanism comprises a demolding plate, demolding pull rods and demolding tension springs; the receiving mechanism comprises a hopper, a rotating arm, a middle shaft, oblique blocks and rotating tension springs; and the mold ejection mechanism comprises arrow plates, a mold ejection plate and an ejector rod. Automatic lubricating oil spray is realized under the control of program, automatic demolding is realized, and a punching finished product automatically enters a feed trough; the mold ejection mechanism enables the female mold to have a certain buffer space, so that the product is prevented from deforming; the mold ejection plate is improved so as to facilitate the mold change operation, the number of operators is reduced, the labor intensity and the energy consumption are reduced, the automatic production of the punching product is realized, and the product quality and the production efficiency are improved.

Owner:NINGBO JIEKELONG PRECISION MFG

Automatic circle forming apparatus

An automatic circle forming apparatus adapted for automatically forming OPP (O-phenylphenol) plastic circles includes a lower equipment cabinet, a first base plate, a transmitting module, an automatic separating module, an automatic tearing film module, a sucking waste mechanism, a displacement module, an automatic forming module and an upper equipment cabinet. The upper equipment cabinet is positioned on the first base plate for installing the transmitting module, the automatic separating module, the automatic tearing film module, the sucking waste mechanism, the displacement module and the automatic forming module therein. The upper equipment cabinet is equipped with a man-machine control interface which connects with and controls the transmitting module, the automatic separating module, the automatic tearing film module, the sucking waste mechanism, the displacement module and the automatic forming module for automatically forming the OPP plastic circles so as to improve operation efficiency and save a human cost.

Owner:CHENG UEI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com