Manufacturing method for automatic galvanizing

A production method, automatic galvanizing technology, applied in the direction of magnetic materials, program control, comprehensive factory control, etc., can solve the problems of large randomness of operators, difficult management, and many operators, so as to ensure product quality consistency, The work site is neat and orderly, and the effect of mutual pollution is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0012] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

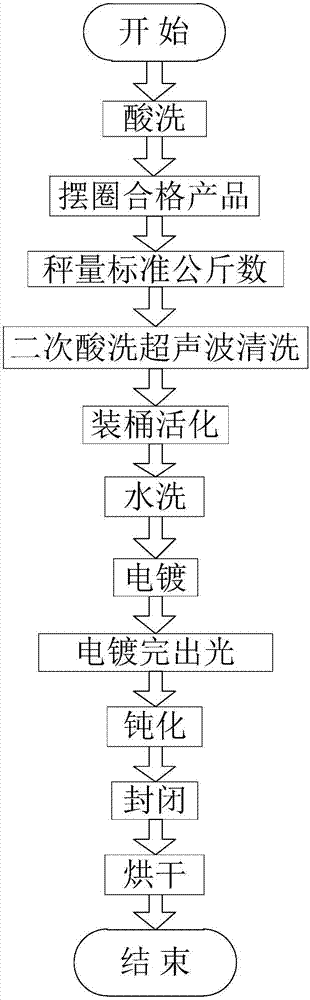

[0013] Such as figure 1 As shown, the automatic galvanizing production method according to the specific embodiment of the present invention includes the following processes: pickling, swinging ring qualified products, weighing standard kilograms, secondary pickling ultrasonic cleaning, barrel activation, water washing, electroplating, and electroplating. , passivation, sealing, initial drying and secondary drying out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com