Patents

Literature

62results about How to "Ensure product quality consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for preparing epoxy natural rubber

The invention discloses a technique for preparing epoxy natural rubber, related to a technique for preparing the epoxy natural rubber through epoxidation reaction. The technique comprises the following steps: stabilizing concentrated natural rubber by using a stabilizing agent; then, keeping stirring and sequentially adding methanoic acid, peroxide, lipase Novozym 435 and deionized wate; uniformlystirring and reacting for 12-24 hours under the temperature of 25 DEG C-50 DEG C; after the reaction is completed, using ammonia water to regulate the pH value of rubber latex to be 7; leading in steam to heat the rubber latex until the rubber latex is solidified, and then dehydrating, rinsing, granulating and drying the rubber latex. The invention effectively reduces the temperature of preparation reaction so that the preparation reaction of the epoxy natural rubber is carried out under a more moderate condition and the content of ring-opening products is controlled to be lower than 3 percent.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

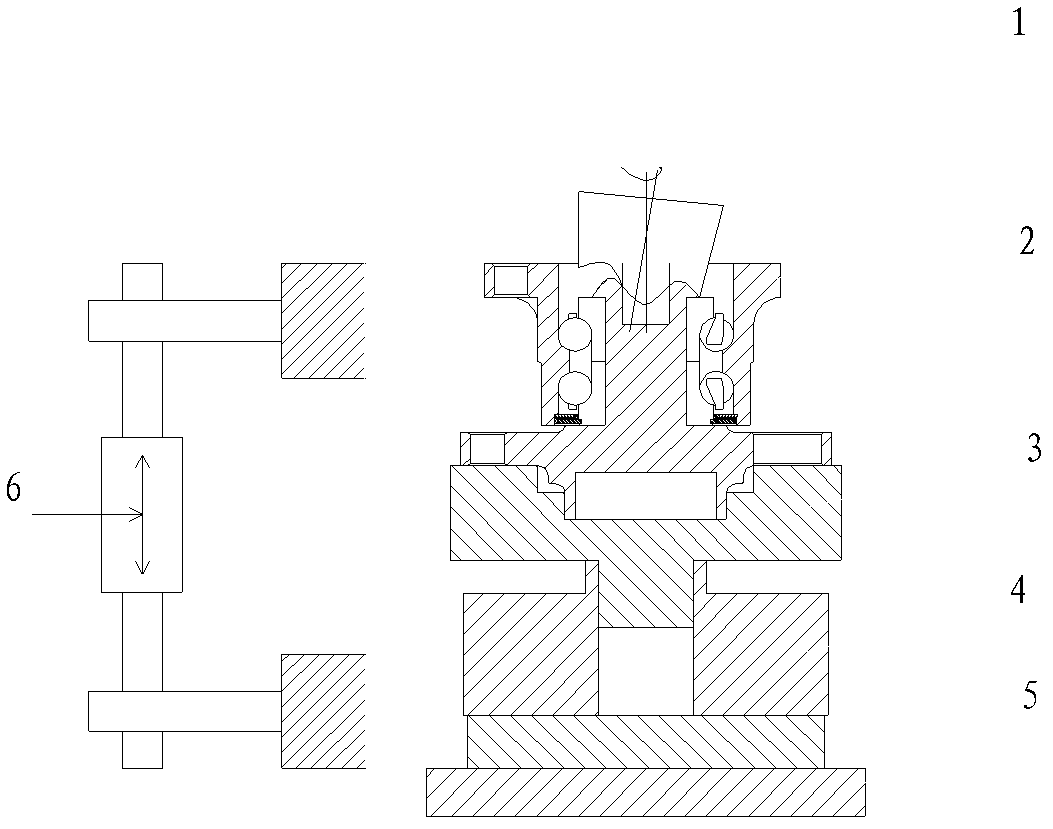

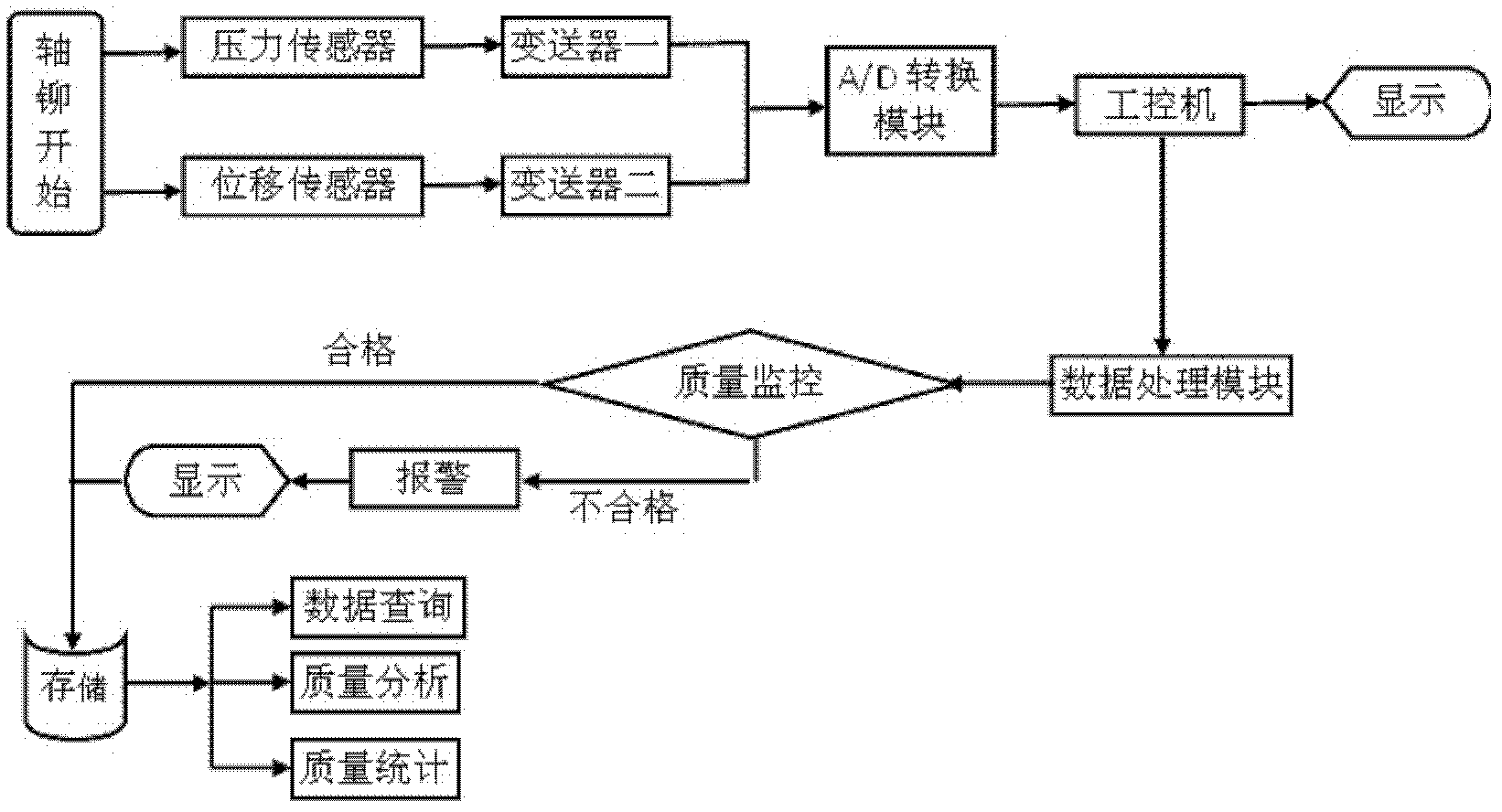

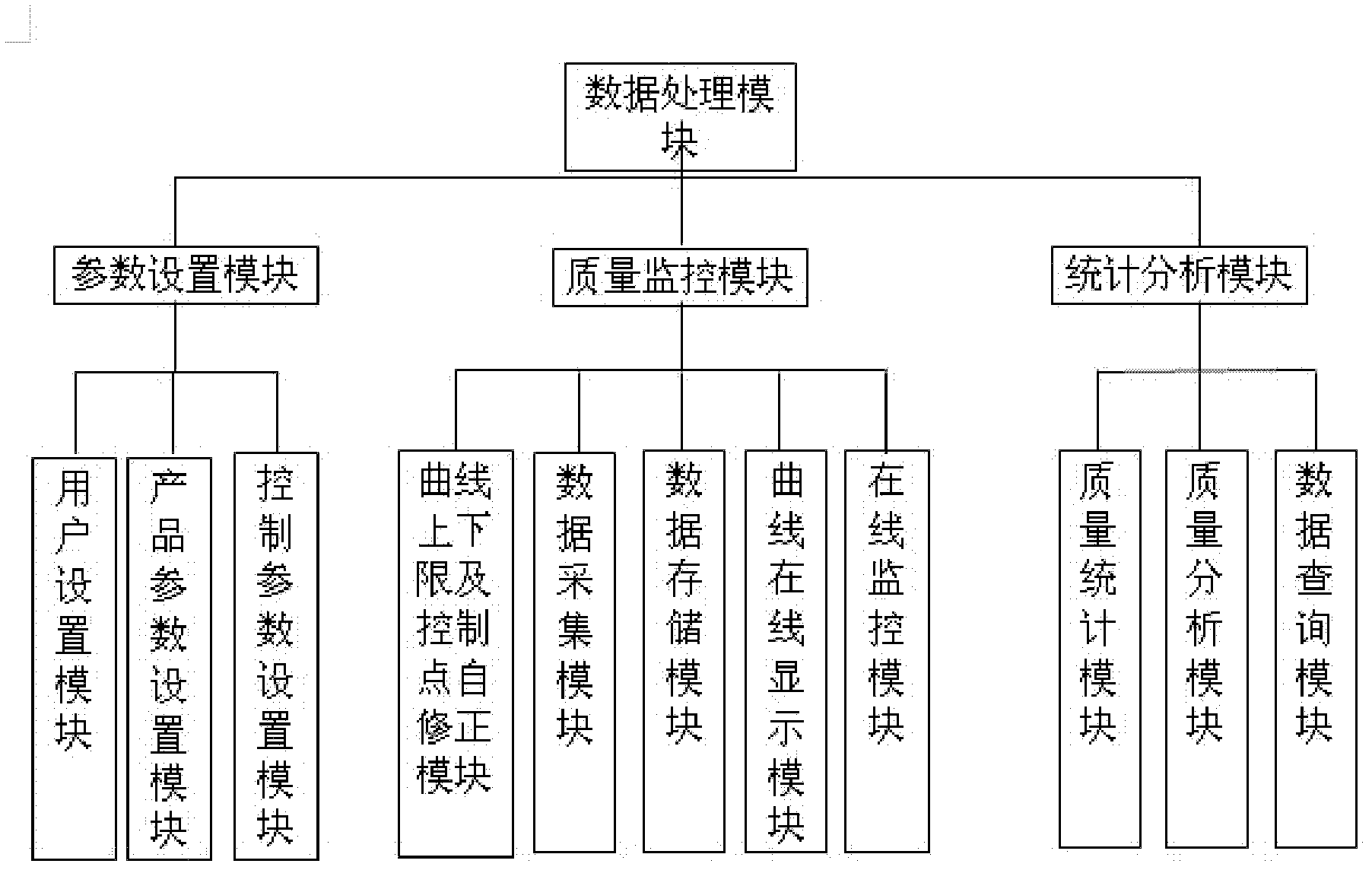

Shaft pivoted hub bearing unit monitoring system for axial pivoting force and displacement and method

InactiveCN102323059ASimple technical meansEnsure product quality consistencyMachine bearings testingForce measurementEngineeringData processing

The invention discloses a shaft pivoted hub bearing unit monitoring system for axial pivoting force and displacement and a method. The system comprises a pressure sensor, a transducer I, a displacement sensor, a transducer II, an A / D (Analog to Digital) conversion module, an industrial computer and a data processing module, wherein the pressure sensor and the transducer I are connected in sequence; the displacement sensor and the transducer II are connected in sequence; the transducer I and the transducer II are connected with the A / D conversion module respectively; and the A / D conversion module, the industrial computer and the data processing module are connected in sequence. By adopting the system, pivoting force-displacement data measured in each pivoting process can be recorded, the qualification of a shaft pivoting process can be judged automatically according to a measured pivoting force-displacement curve, possible causes leading to defective goods can be given automatically, and data can be counted and analyzed or called automatically. The system has an easy, convenient and practical technical means and positive and beneficial technical effects.

Owner:SOUTH CHINA UNIV OF TECH +1

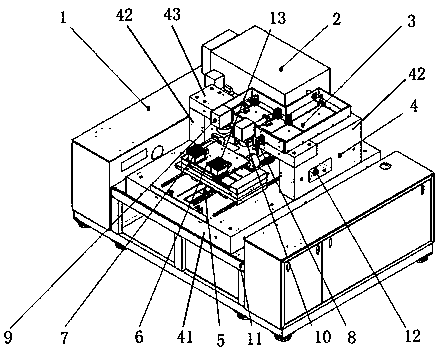

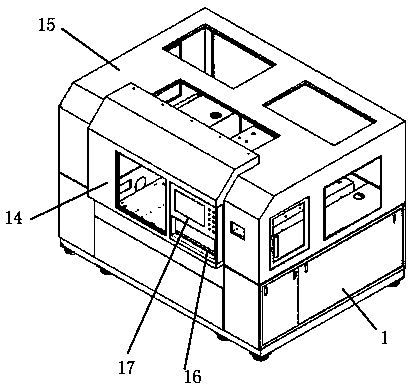

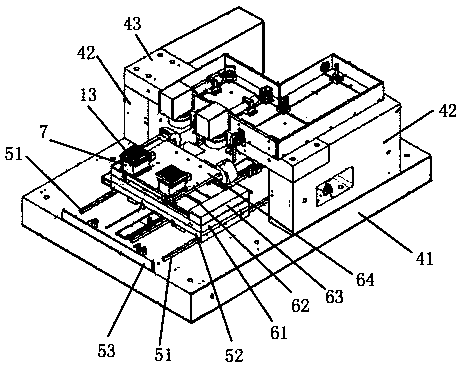

Appearance detection system and apparatus for automobile component

InactiveCN110108714AQuick checkImprove qualityOptically investigating flaws/contaminationUsing optical meansPattern recognitionEngineering

The invention discloses an appearance detection system for an automobile component. The appearance detection system comprises a human-computer interaction module, a user management module, an interaction module, an image acquisition module, an algorithm tool module, a data management module, an operation module and a visual recognition module. The human-computer interaction module is used for realizing interaction between a workpiece and the image acquisition module. The image acquisition module is used for collecting an appearance image of the workpiece and transmitting the image to the algorithm tool module. The algorithm tool module receives the workpiece appearance image, carries out real-time processing on the image to generate a pre-processed image and sends the processed image to the visual recognition module. The operation module is used for selecting an algorithm tool in the algorithm tool module. The visual recognition module receives the preprocessed image, identifies a defect on the outer surface of the workpiece, and generates result data. The user management module is used for managing the operation module. Therefore, rapid switching of detection of various products is realized; multi-direction detection of the appearance of a component is operated rapidly; the labor force is saved; the product quality consistency is ensured; and the factory quality and managementlevel are improved.

Owner:浙江博拉自动化科技有限公司

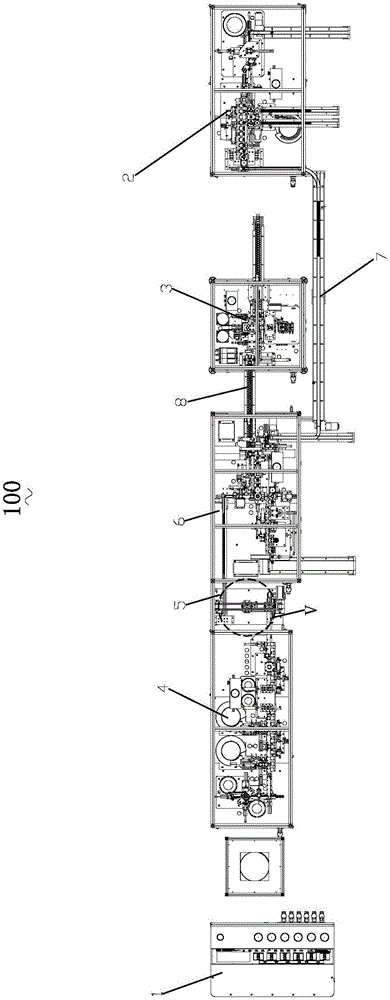

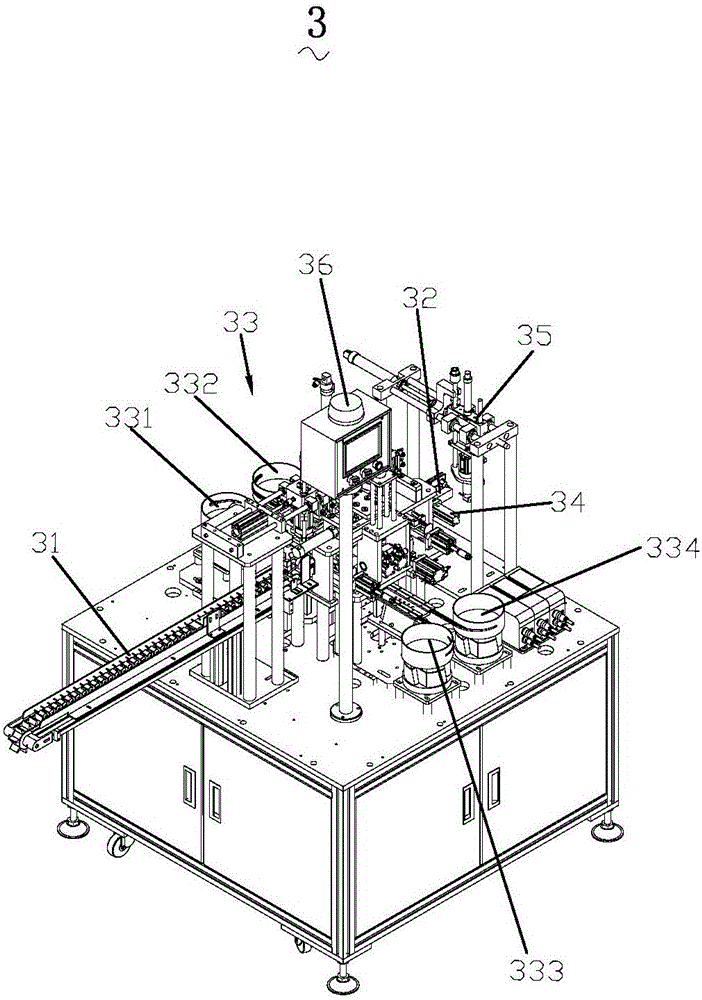

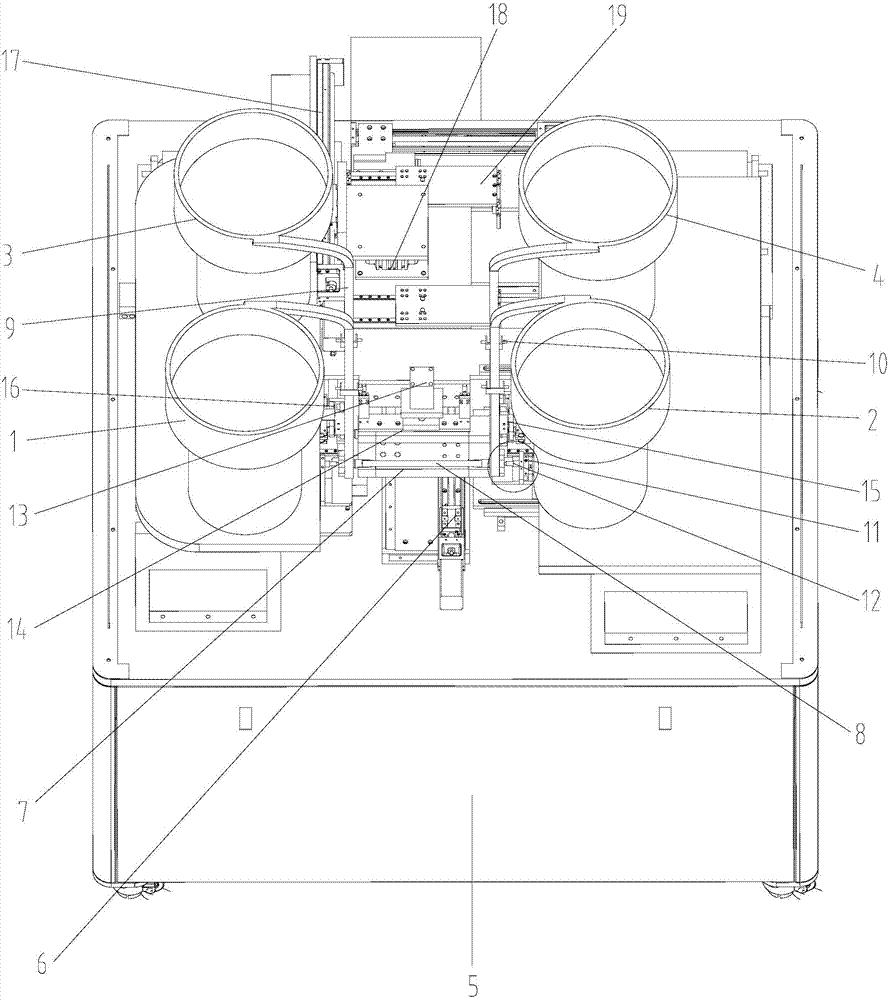

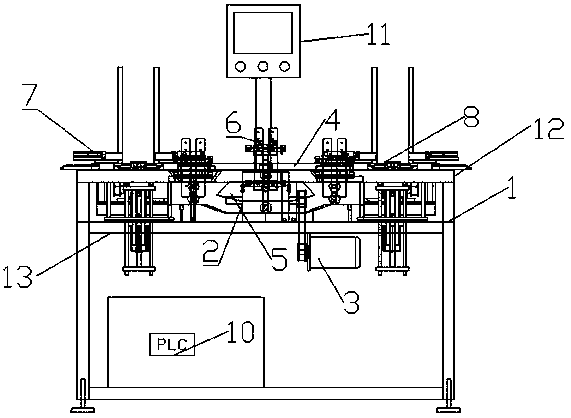

Cylindrical micro-motor automatic assembly line

ActiveCN106059210AImprove assembly productivityReduce manual assemblyManufacturing stator/rotor bodiesProduction lineAssembly line

The present invention provides a cylindrical micro-motor automatic assembly production line. The cylindrical micro-motor automatic assembly production line comprises a PLC general control device, and a stator assembly integral device, a meson assembly integral device, an end cap assembly integral device, an end cap on-line assembly and a three-piece assembly device that are electrically connected with the PLC general control device. The stator assembly integral device communicates with the three-piece assembly device via a stator transfer track; the meson assembly integral device communicates with the three-piece assembly device via a rotor transfer track, and the end cap assembly integral device communicates with the three piece assembly device via the end cap on-line assembly. The present invention provides a cylindrical micro-motor automatic assembly production line, so that assembly production efficiency can be improved, manual assembly can be reduced, and the product quality consistency can be ensured.

Owner:SHENZHEN KECHI AUTOMATION EQUIP

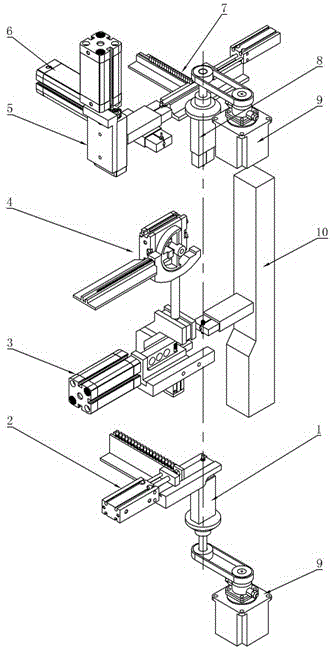

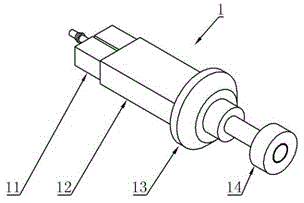

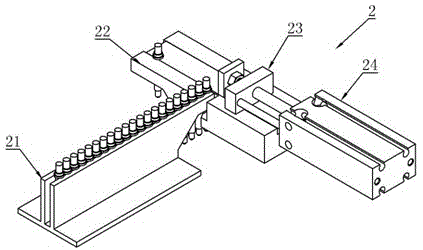

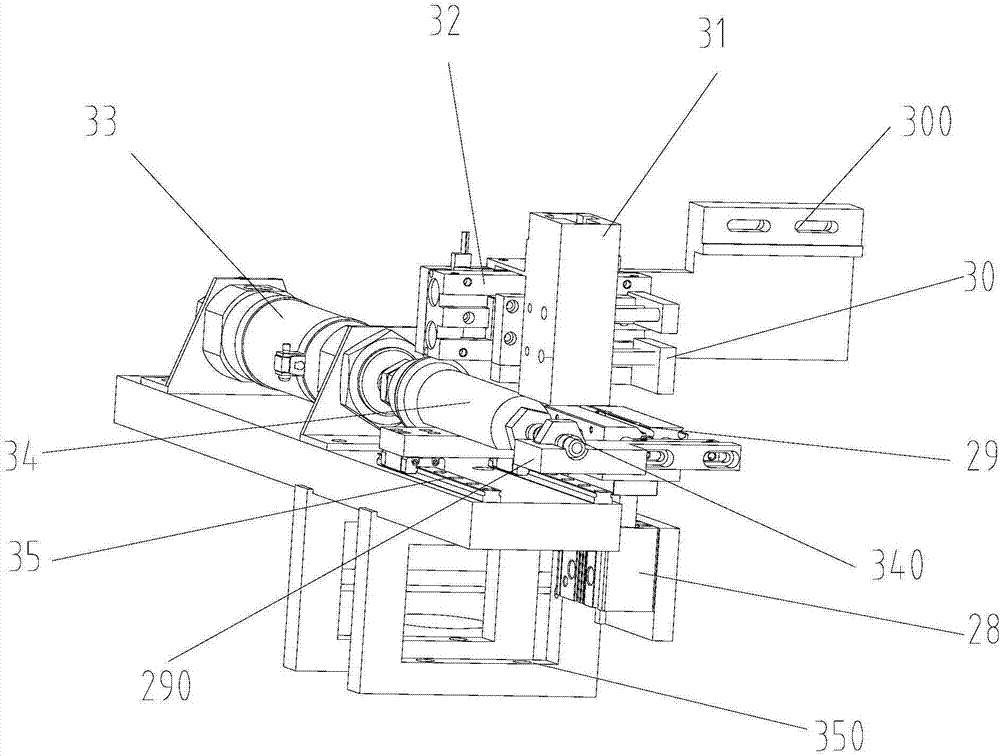

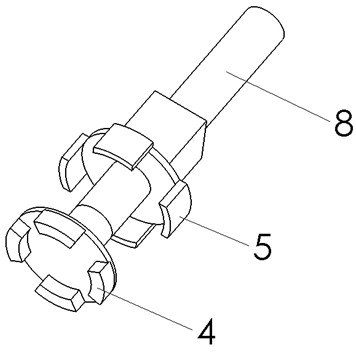

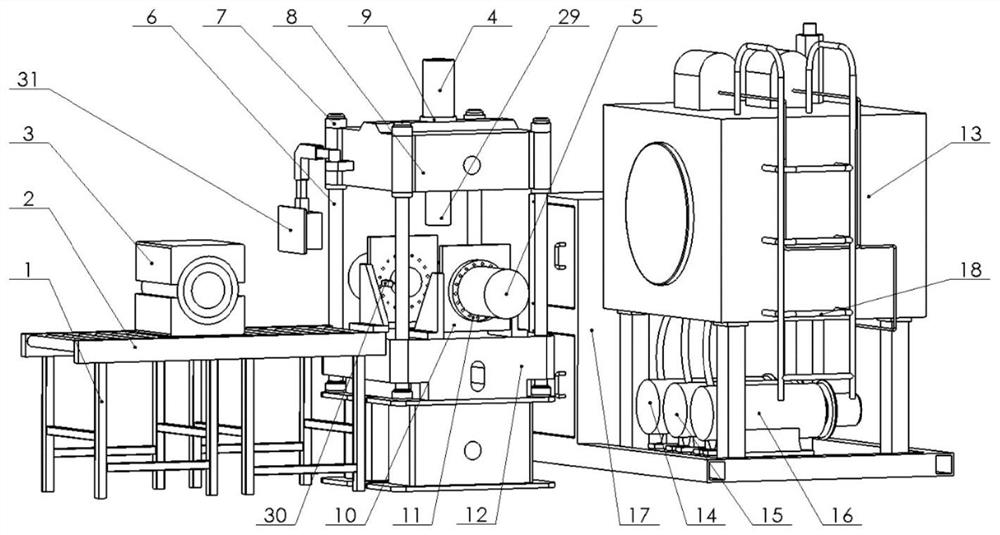

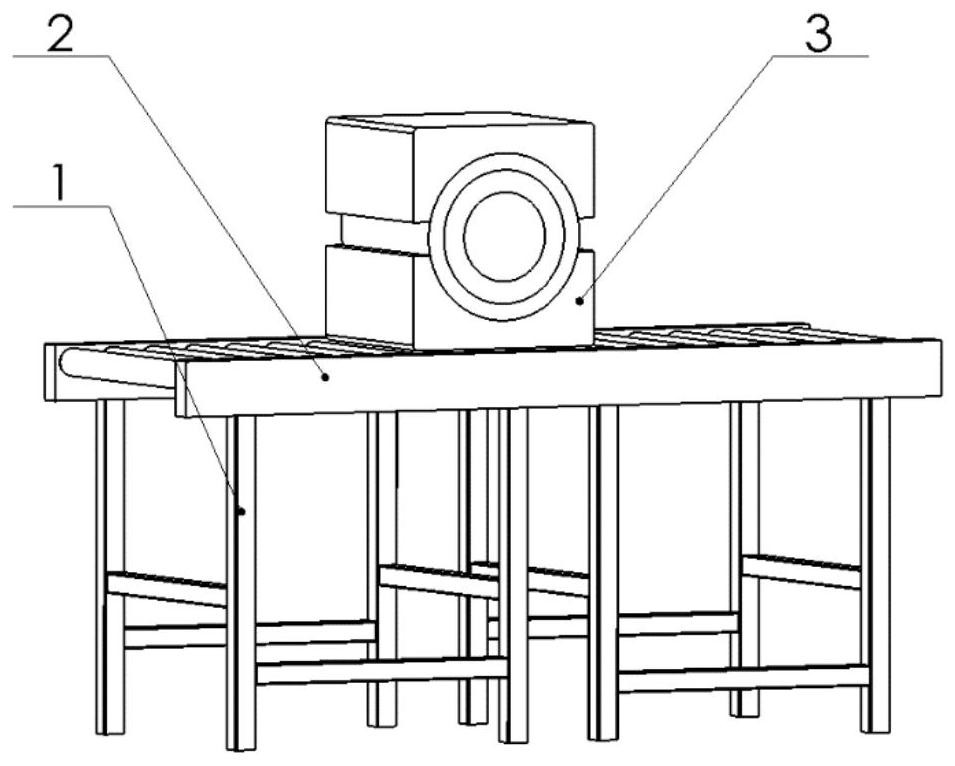

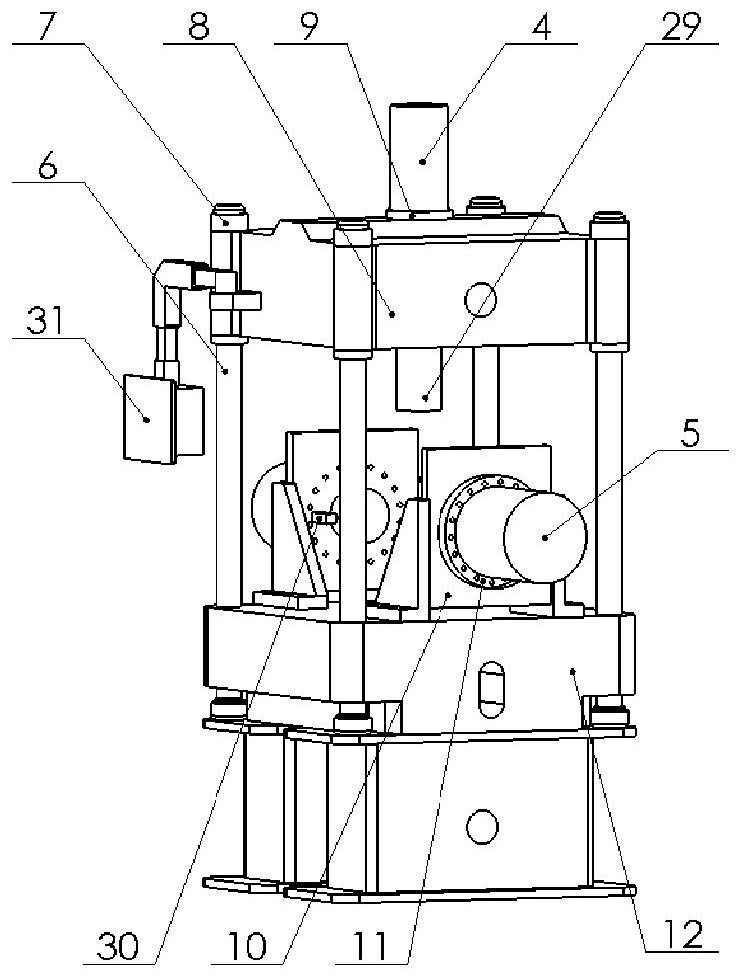

Automatic assembling device for flexible shaft

ActiveCN105414956AAvoid causingHigh degree of automationAssembly machinesMetal working apparatusElectric machineryControl theory

The invention discloses an automatic assembling device for a flexible shaft. The flexible shaft is formed by assembling connectors at the two ends of a spring. The automatic assembling device for the flexible shaft comprises an automatic spring supply mechanism, a spring positioning, clamping and feeding mechanism, two automatic connector supply mechanisms, two connector positioning and clamping rotating shaft mechanisms and two rotating torque control mechanisms. According to the automatic assembling device for the flexible shaft, positioning and screwing of the spring and the connectors of the flexible shaft are achieved through the automatic mechanical devices such as the automatic spring supply mechanism, and the automatic degree is high; torque clutches are adopted in the rotating torque control mechanisms; when torque is increased to a certain extent, driving force is lost between the torque clutches and rotating shafts of servo motors of the control mechanisms; scrapped products caused when the torque is excessively large and the spring and the connectors are screwed excessively are avoided, and the production cost is lowered; and the clutch torque can be adjusted by adjusting adjustment screw rods and nuts, and the requirement for assembling different flexible shafts is met.

Owner:宁波韵声机芯制造有限公司 +1

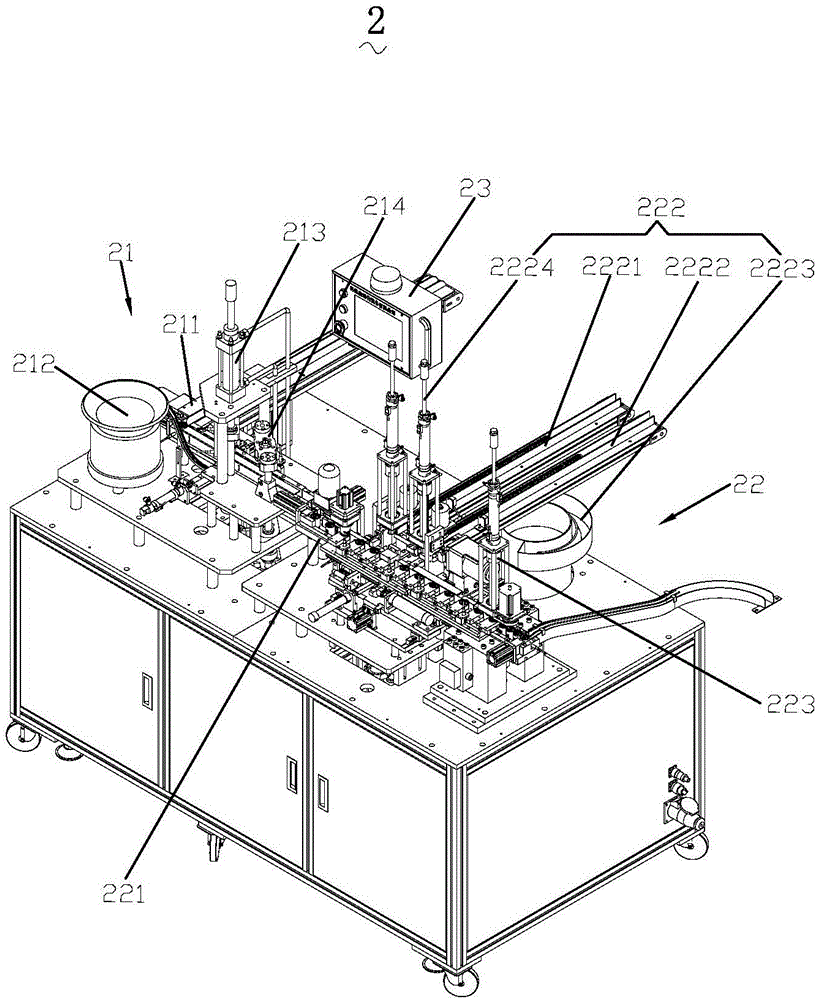

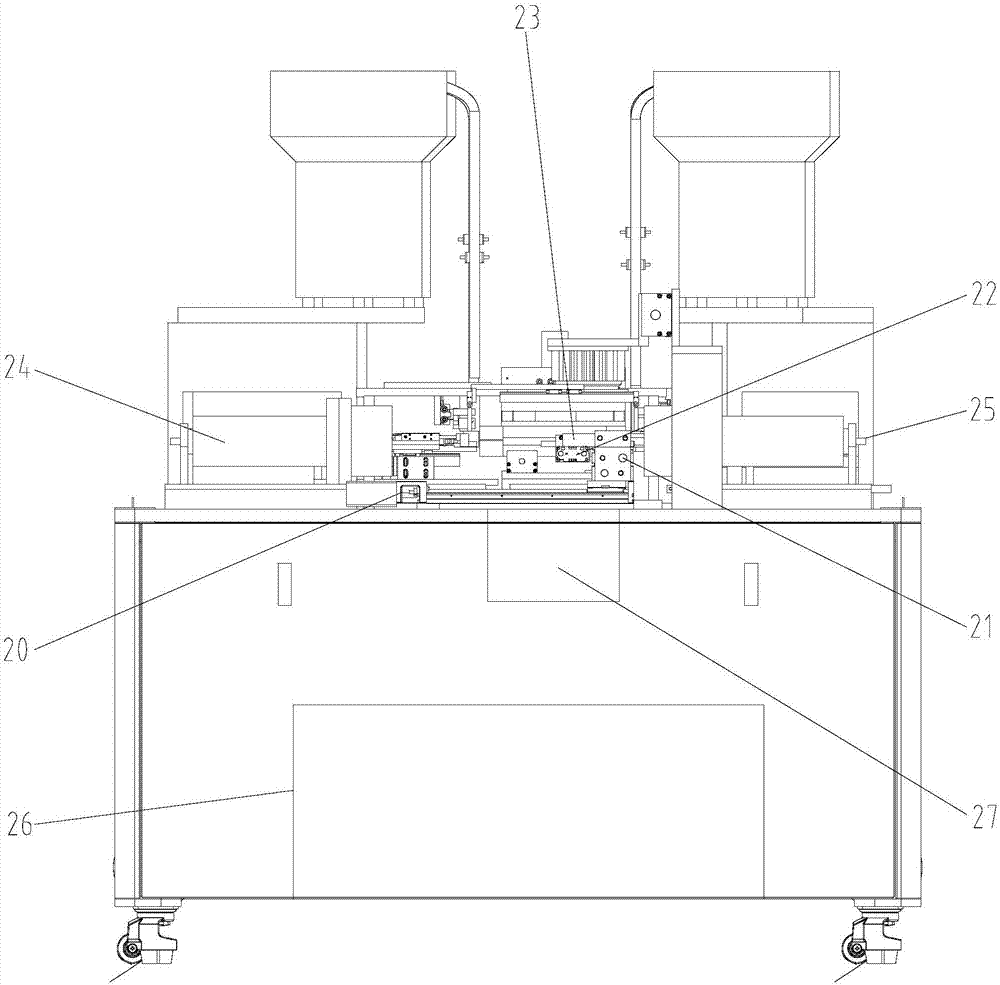

Automatic assembling equipment and assembling method for fire extinguisher hose

The invention provides automatic assembling equipment for a fire extinguisher hose. The automatic assembling equipment comprises a vibrating disc discharging mechanism, an automatic feeding pushing and jacking mechanism, a first-segment part assembling station, a paw grabbing and placing mechanism, a second-segment aluminum cap buckling station, an oil pressure buckling mechanism and a rack; the vibrating disc discharging mechanism is located on the two sides above the rack; the automatic feeding pushing and jacking mechanism comprises an aluminum cap feeding pushing and jacking mechanism, a plastic spray nozzle feeding pushing and jacking mechanism and a metal head feeding pushing and jacking mechanism, wherein the aluminum cap feeding pushing and jacking mechanism, the plastic spray nozzle feeding pushing and jacking mechanism and the metal head feeding pushing and jacking mechanism are located below the vibrating disc discharging mechanism containing aluminum caps, plastic spray nozzles and metal heads correspondingly; the first-segment part assembling station is located in front of the center of the rack, and the paw grabbing and placing mechanism is located above a hose placement table; and the second-segment aluminum cap buckling station is located at the tail of a machine. By means of the automatic assembling equipment, automatic discharging and assembling of the fire extinguisher hose is achieved, automatic material outputting is achieved, the structure is simple, space is saved, manpower is replaced, product quality and production efficiency are improved at the same time, the labor cost is lowered, and the blank of the automatic hose assembling equipment is made up for.

Owner:宁波智畅机器人系统有限公司

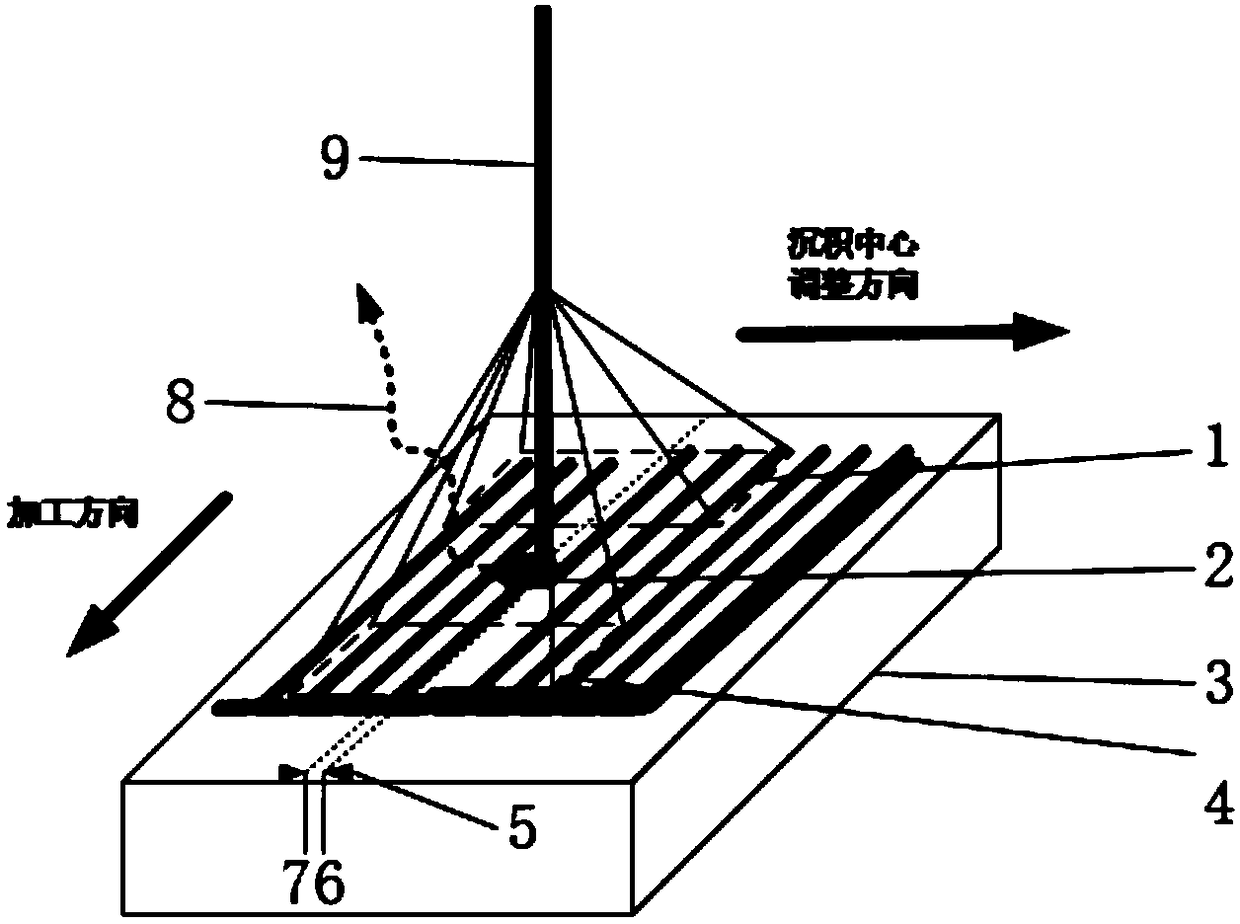

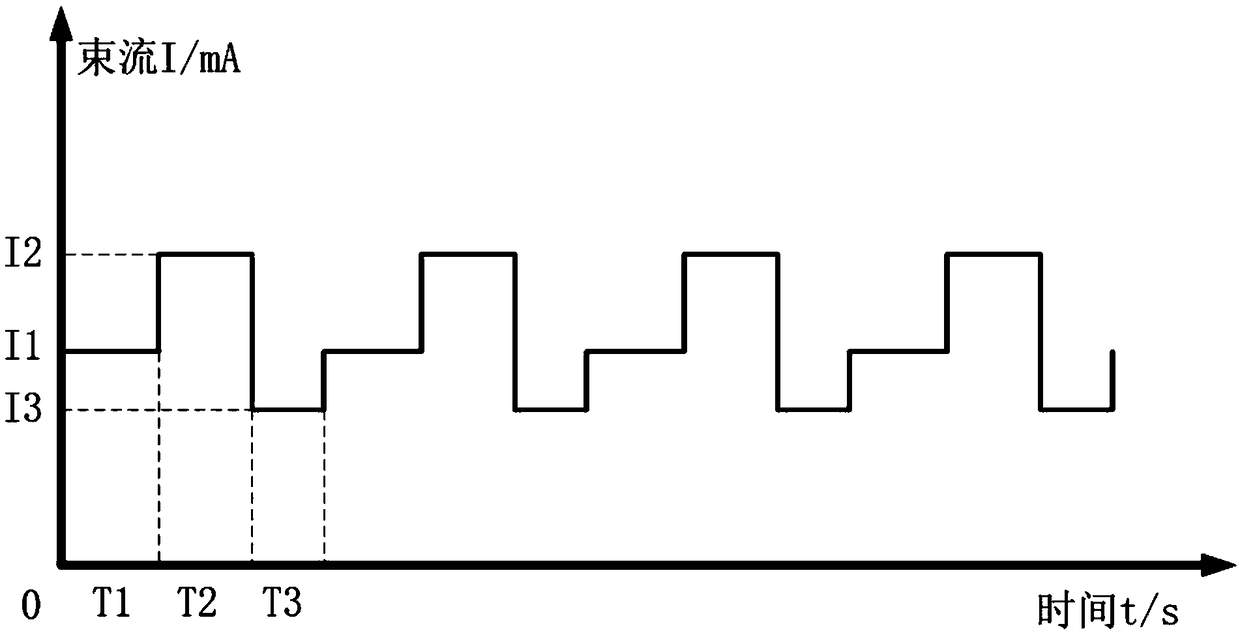

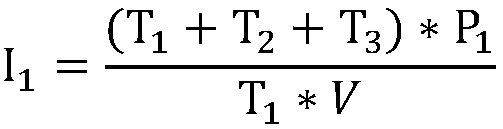

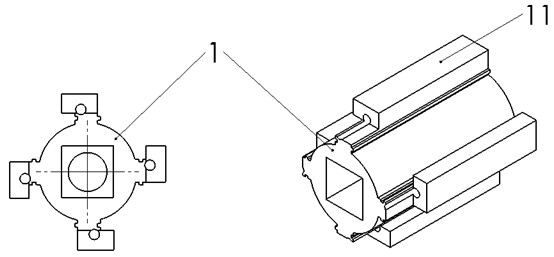

Real-time monitoring method in electron beam fuse deposition additive manufacturing

ActiveCN109465530AReduce sizeFully formedAdditive manufacturing apparatusElectron beam welding apparatusClosed loopTime-sharing

The invention relates to a real-time monitoring method in electron beam fuse deposition additive manufacturing, belonging to the technical field of monitoring in electron beam forming manufacturing. The monitoring method realizes preheating and accompanying heat treatment of a workpiece while carrying out an electron beam fuse deposition process through a time-sharing multiplexing mode. The backscattered electronic signals of a preheating area, a molten pool area and an accompanying heat treatment area are collected in real time, the generated preheating area image is used for the path planning of the deposition process, the molten pool area image is used for the closed-loop control of the heat input of a molten pool, and the accompanying heat treatment area image is used for the defect detection of molded parts. The monitoring method provides three electron beam current control modes, and the power magnitudes of preheating, processing and heat treatment can be conveniently adjusted according to needs. The monitoring method is based on the backscattering electron imaging principle and can be adapted to the environment of large beam current and high metal vapor. Real-time imaging can be achieved without off-line scanning, which improves the production efficiency.

Owner:TSINGHUA UNIV

Preparation method of carbon-ceramic composite material based on unidirectional belt process

ActiveCN108892523AShorten the manufacturing cycleReduce manufacturing costCarbon fibersCeramic composite

The invention relates to a preparation method of a carbon-ceramic composite material based on a unidirectional belt process. The preparation method comprises the steps of compositing a carbon fiber asa reinforcement with slurry prepared from high-carbon residue resin, so as to prepare a carbon fiber unidirectional belt, spreading the unidirectional belt as a layer, carrying out mold pressing andhot-pressure tank formation so as to prepare a preform, and carrying out carbonization and infiltration, so as to prepare a carbon fiber enhanced ceramic-base composite material. The preparation method has the beneficial effects that an interface layer does not need to be prepared on the surface of the carbon fiber, the uniform distribution of the fiber in a matrix can be realized by virtue of a unidirectional belt process, the continuous production can be realized, and the performance degradation caused due to twists formed during the weaving of traditional fibers is avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Automatic assembling work head device of curved-surface magnet of voice coil motor

InactiveCN102497062AImplement automatic assemblyReduce dependenceManufacturing dynamo-electric machinesMagnetic tension forceDevice form

The invention discloses an automatic assembling work head device of a curved-surface magnet of a voice coil motor. The device comprises: an automatic feed warehouse, an outbound warehouse positioning device formed by a rotation adsorption magnet and a built-in baffle plate, a push-rod blanking mechanism and a non-magnetic shell. The feed warehouse is uniformly embedded around the shell. The push-rod blanking mechanism is fixed at a position which has an interval of a specific angle with the feed warehouse. The outbound warehouse positioning device is located under the shell and a rotating shaft passes through a central section of the shell and is connected with the external motor. Batch magnets are loaded into the automatic feed warehouse before magnetization and after the magnetization, the magnets mutually generate an expulsive force. A rotation adsorption magnet drives the magnet to be assembled on an exit on a lower part of the feed warehouse to be separated from the warehouse and be positioned. The residual magnets automatically feed under common effects of a gravity and a magnetic force. The push-rod blanking mechanism pushes the positioned magnets into the voice coil motor shell so as to complete the assembling. According to the invention, batch magnetization of the voice coil motor magnets and continuously automatic assembling can be realized. Production efficiency of the voice coil motor can be increased. Artificial cost can be reduced and product quality can be guaranteed.

Owner:ZHEJIANG UNIV

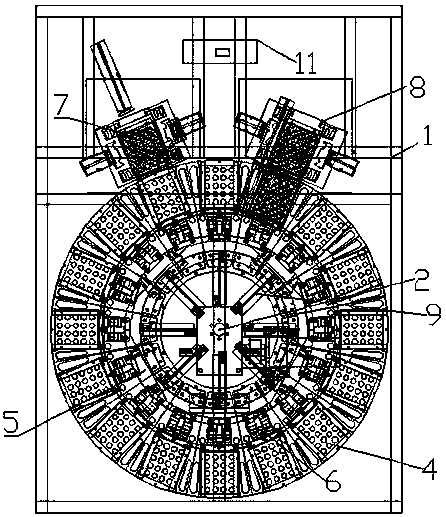

Rotating disc type automatic voltage reduction device for lithium-manganese button cells

PendingCN108155395AEnsure stable qualityHigh degree of automationPrimary cell manufactureAssembling battery machinesLithiumButton battery

The invention relates to a rotating disc type automatic voltage reduction device for lithium-manganese button cells. The rotating disc type automatic voltage reduction device comprises a frame, an upper flat plate and a lower flat plate are arranged on the frame, a feeding mechanism, a discharging mechanism and a touch screen are arranged on the upper flat plate, and a speed regulating motor and acam indexer are arranged on the lower flat plate. A cam mechanism is arranged on the upper flat plate and comprises a cam and a rolling wheel, and an output end of the speed regulating motor is connected with the cam. The rotating disc type automatic voltage reduction device has advantages that accuracy in positioning of the lithium-manganese button cells is achieved, automatic feeding and discharging can be realized, and quality stability and uniformity of products subjected to voltage reduction are guaranteed; the rotating disc type automatic voltage reduction device comprises sixteen stations, voltage reduction of sixteen units of cells can be realized in each rotating lap of a rotating disc, production efficiency is remarkably improved and production cost is reduced as compared with those of manual voltage reduction, manual operations are replaced by the rotating disc type automatic voltage reduction device, automation of enterprises is improved, labor intensity of operators is relieved, and labor cost is reduced.

Owner:山东信湖新能源科技有限公司

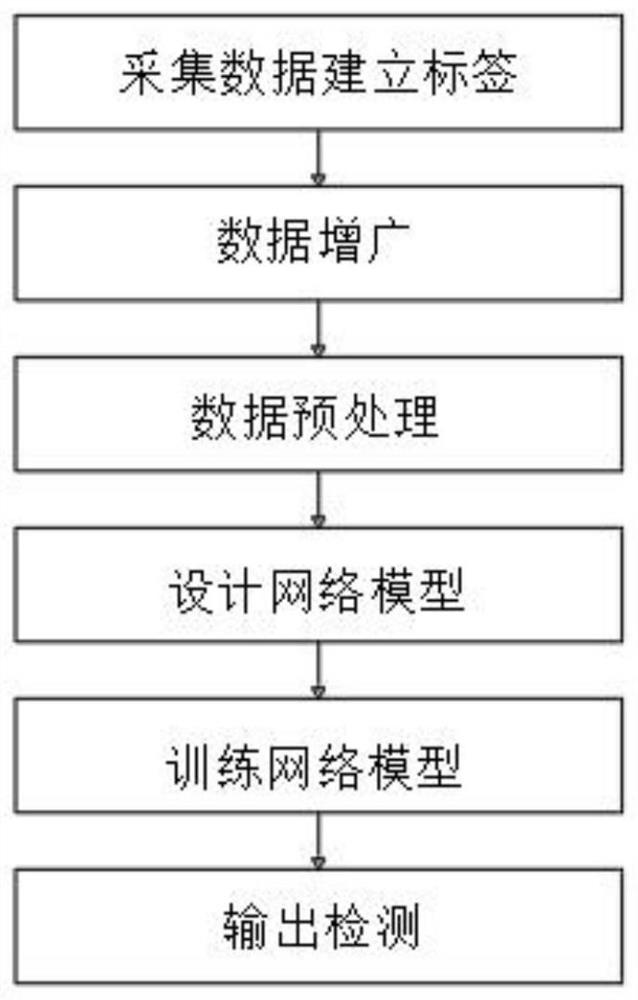

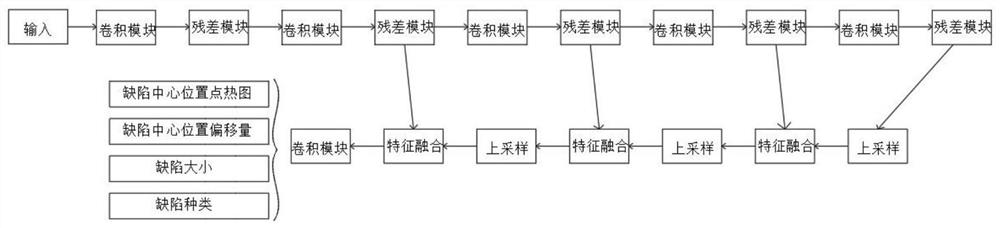

Cloth defect detection method based on deep learning multi-layer feature fusion

PendingCN111862059AAchieve differentiabilityEnsure product quality consistencyImage enhancementImage analysisNetwork structureEngineering

The invention discloses a cloth defect detection method based on deep learning multilayer feature fusion, and the method comprises the following steps: S01, building cloth detection image libraries and label libraries of different defect types, and importing defect type pictures; S02, expanding data in the cloth detection image library by utilizing the data augmentation technology; S03, dividing the expanded cloth detection image library data into a training set and a test set, and processing the data; S04, designing a target detection network model with multi-layer feature fusion; S05, training the designed network model by adopting the training set; S06, deploying the trained network model to an upper computer, and applying the network model to an automatic cloth detection production line to detect the cloth. According to the invention, the defect detection method integrates a network structure with multi-layer features, can accurately detect the position and type of the defect, doesnot need to preset a preset frame, also achieves the end-to-end microscopicity of the model, does not need to be observed by naked eyes, and unifies the detection standard.

Owner:苏州臻识信息科技有限公司

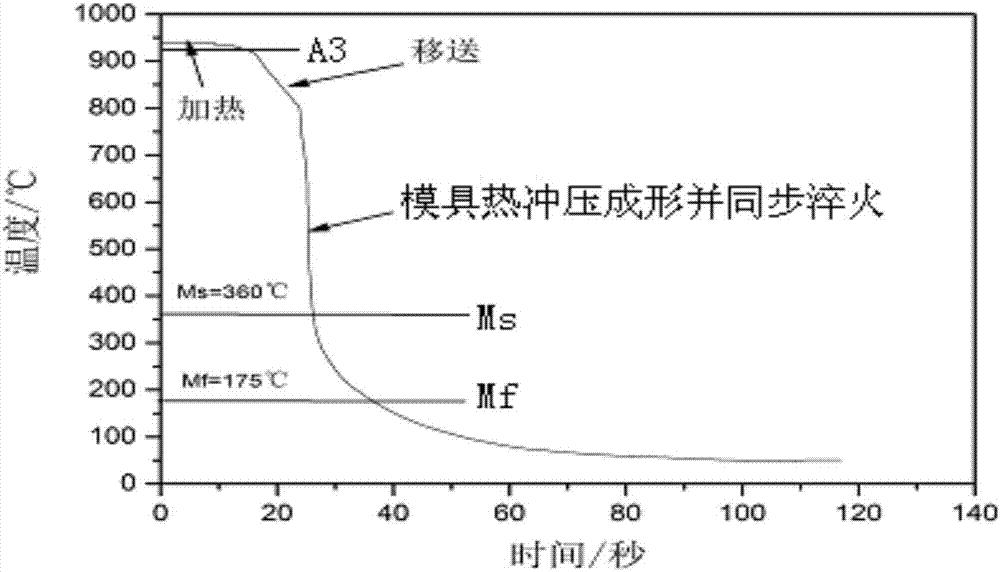

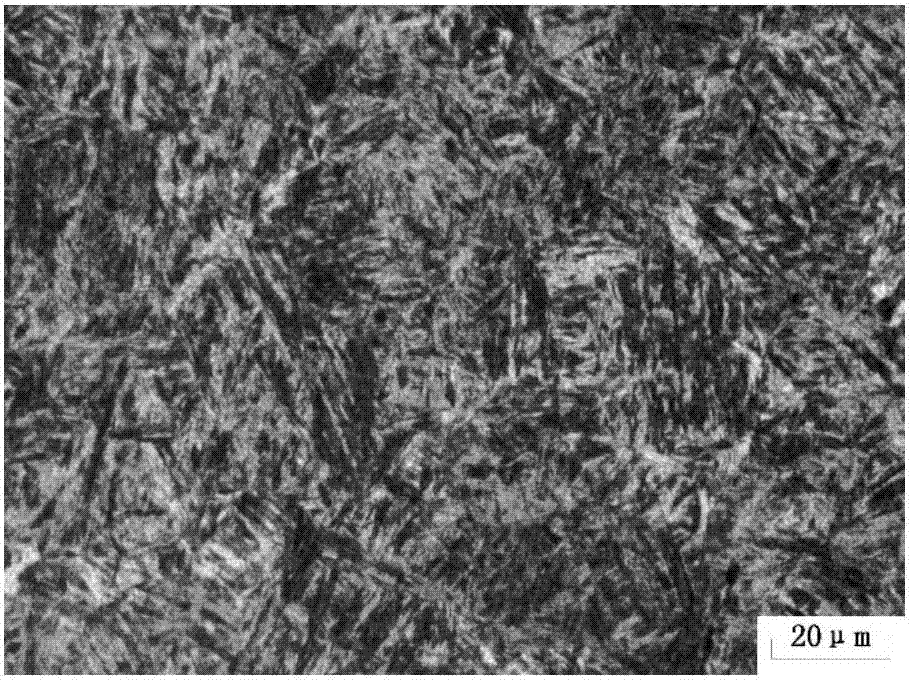

Method for producing hot stamping forming bulletproof piece

ActiveCN107083475AEnsure product consistencyEnsure product quality consistencyHot stampingMartensite transformation

The invention discloses a method for producing a hot stamping forming bulletproof piece. According to the hot stamping forming bulletproof piece, a bulletproof steel plate with the thickness being larger than 1.8mm is heated to a fully-austenitic area at first and then is stamped to be in a certain shape; and meanwhile, quenching is achieved by means of rapid cooling in the forming process so that the bulletproof piece can achieve a super-strength mechanical property, for example, the tensile strength is not lower than 1550MPa, and the capacity of resisting bullet shooting or breaking is achieved. The method is characterized by including the following steps that the bulletproof steel plate with the thickness being larger than 1.8mm is heated to be fully austenitic and then is subjected to mold hot stamping forming so that the bulletproof piece can be formed, austenite is synchronously quenched into martensite in a mold, the mold is provided with a quenching device used for cooling the bulletproof piece, flowing cooling media are contained in the quenching device, and the bulletproof piece is cooled below the martensite transformation finishing temperature Mf through the cooling media to be turned into a martensite bulletproof piece.

Owner:CENT IRON & STEEL RES INST +1

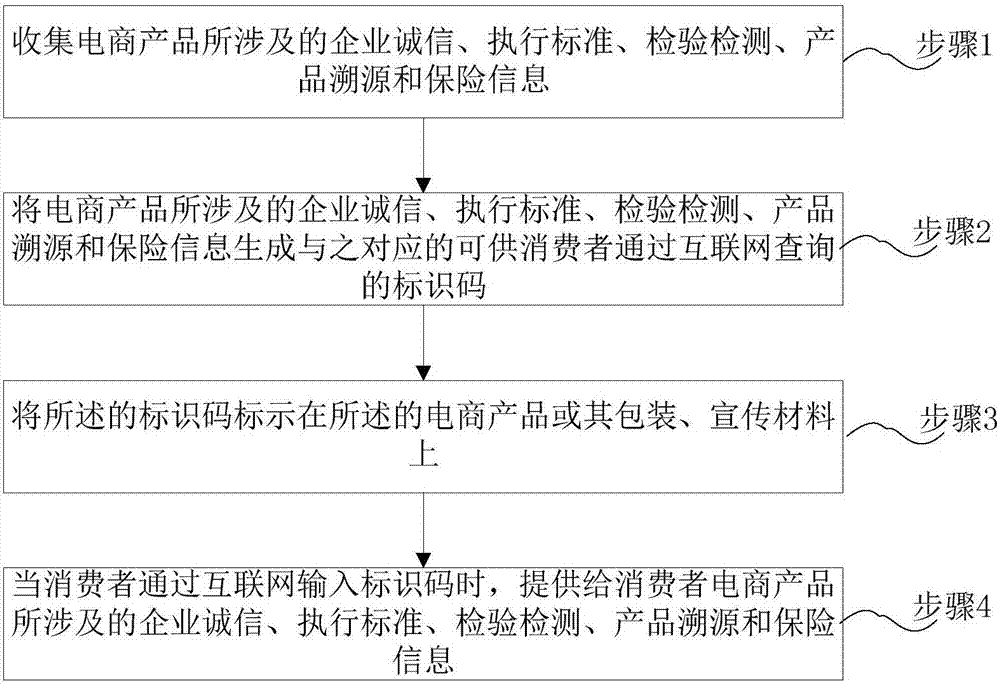

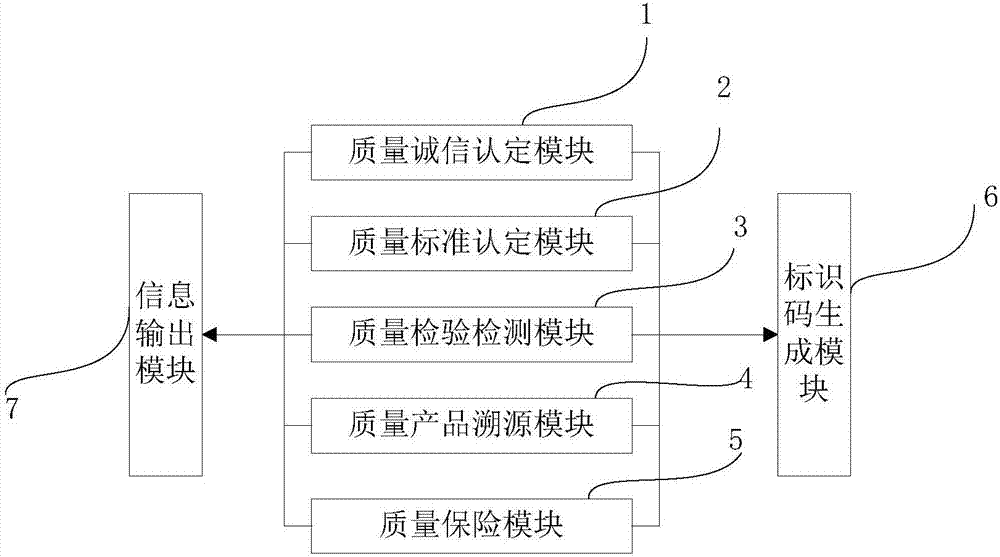

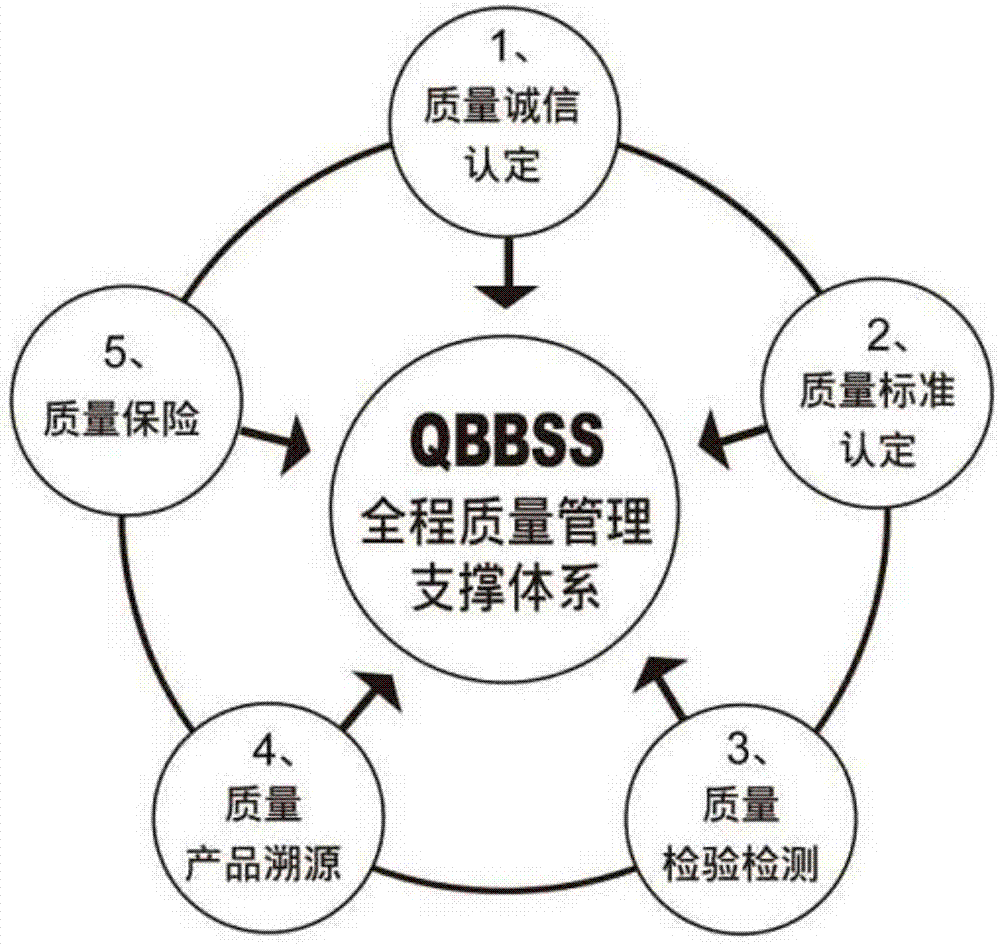

Internet-based e-commerce quality management platform and method

InactiveCN107392626AImprove product quality levelEnsure product quality consistencyBuying/selling/leasing transactionsProcess qualityManagement support systems

The present invention discloses an Internet-based e-commerce quality management method. The method comprises the following steps that: step 1, enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in e-commerce products are collected; step 2, identification codes which are corresponding to the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products and can be inquired by consumers through the Internet are generated based on the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products; step 3, the identification codes are marked on the e-commerce products or the packages and promotional materials of the e-commerce products; and step 4, when the consumers enter the identification codes through the Internet, the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products are provided for the consumers. With the Internet-based e-commerce quality management platform and method of the invention adopted, a five-in-one full-process quality management support system concerning quality credit certification, quality standard certification, quality inspection and testing, quality product traceability and quality assurance can be realized.

Owner:赵茜茜

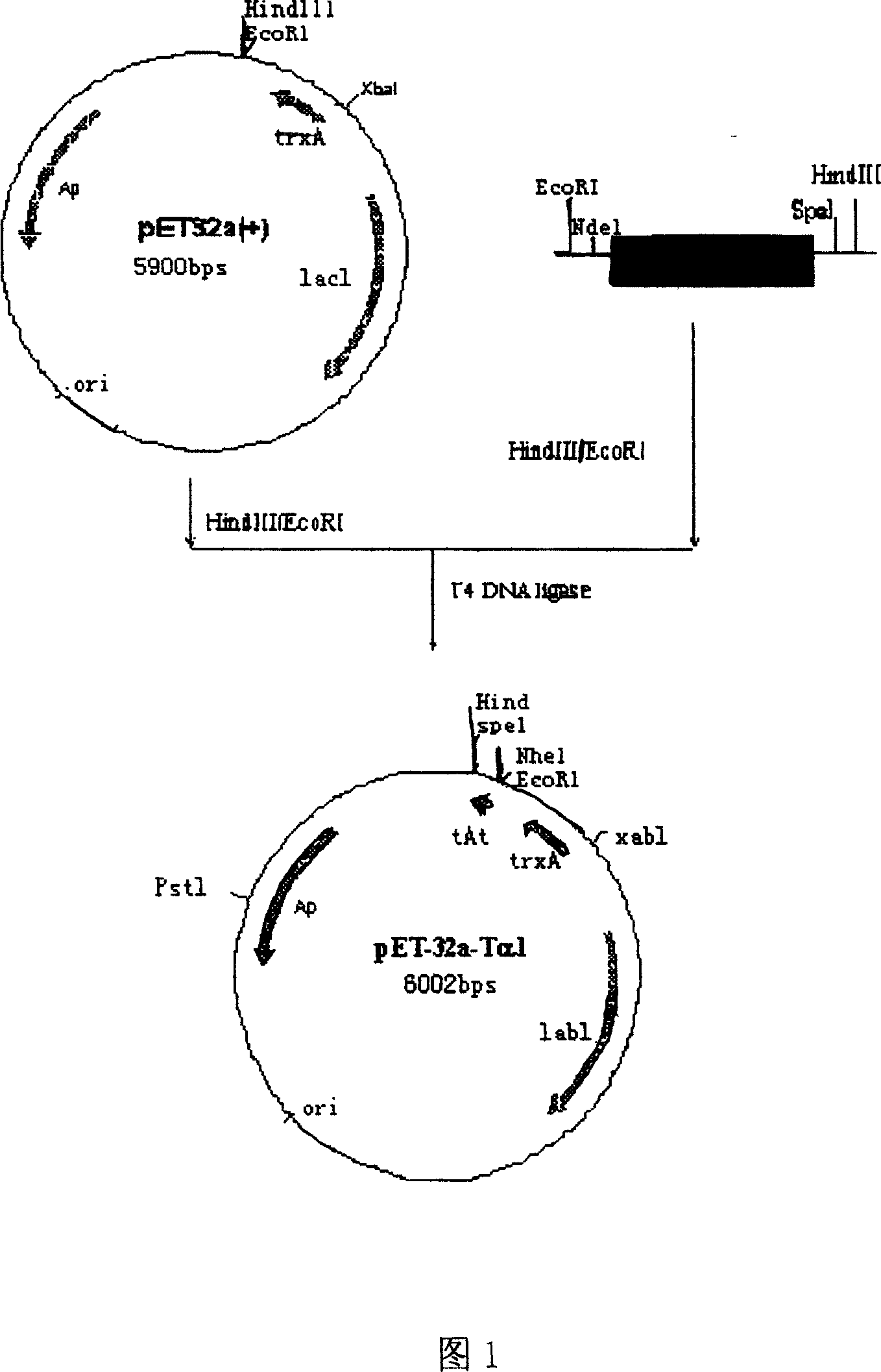

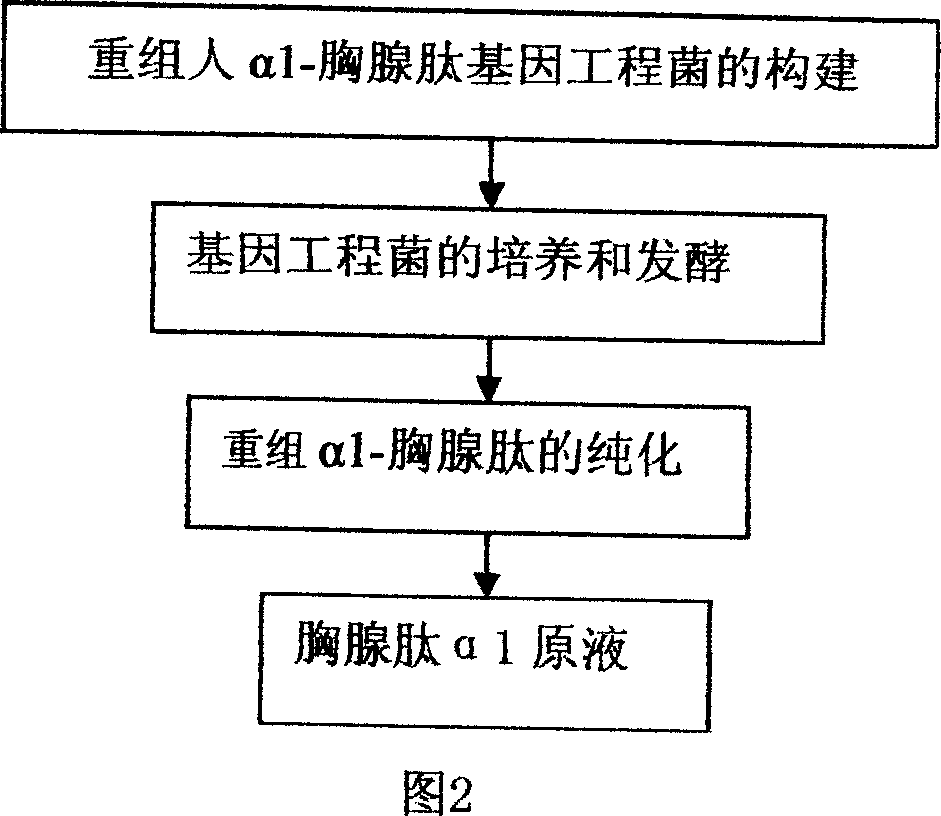

Production method of recombined human alpha1-thymus peptide and preparation thereof

InactiveCN1990862AEnsure product quality consistencyLow costPowder deliveryBacteriaDiseaseGene engineering

The invention discloses a method for preparing human alpha 1- thymosin and the human alpha 1- thymosin agent produced with said method. The method comprises: constructing gene engineering bacteria for human alpha 1- thymosin, liquid culturing gene engineering bacteria and fermentating, and puring the recombined human alpha 1- thymosin. The method is characterized by no limit to raw material source, low cost, feasibility for large- scale production, and the product can be used as injection agent for preventing and curing and assistant curing for disease caused by low immune function.

Owner:SHANGHAI HUAXIN HIGH BIOTECH

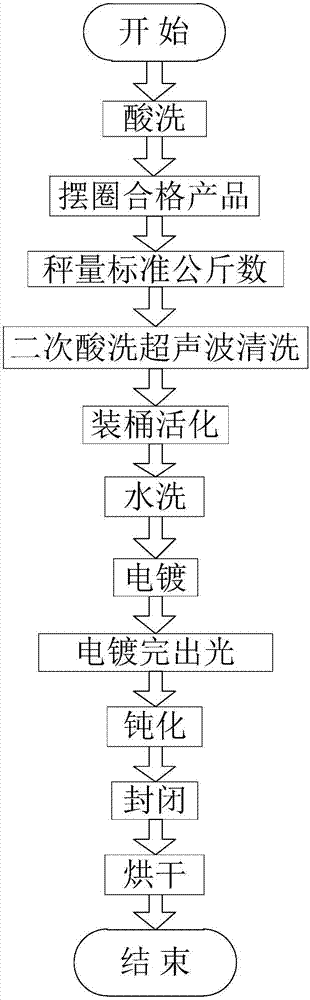

Manufacturing method for automatic galvanizing

InactiveCN106884200AAvoid mutual contaminationEnsure product quality consistencyCellsMagnetic materialsPower flowElectroplating

The invention discloses an automatic galvanizing production method. The automatic galvanizing production method includes the following steps: pickling, swinging qualified products, weighing standard kilograms, secondary pickling ultrasonic cleaning, barrel activation, water washing, electroplating, light emission after electroplating, passivation, sealing, and initial drying and out of the barrel for secondary drying; among them, the current control of the galvanizing production process, the pH detection and adjustment of the plating solution and passivation solution, the addition of supplementary solution, the replacement of the light-emitting solution, the control of electroplating and passivation time, and the passivation Quantity control is controlled by computer automation. Multiple control points of the automatic galvanizing production method are automatically controlled to ensure the consistency of product quality; the operator is reduced accordingly, and the labor cost is reduced; the mutual pollution of the solution in the operation process is solved, and the production process goes smoothly; the work site is neat and orderly .

Owner:SINO MAGNETICS TECH

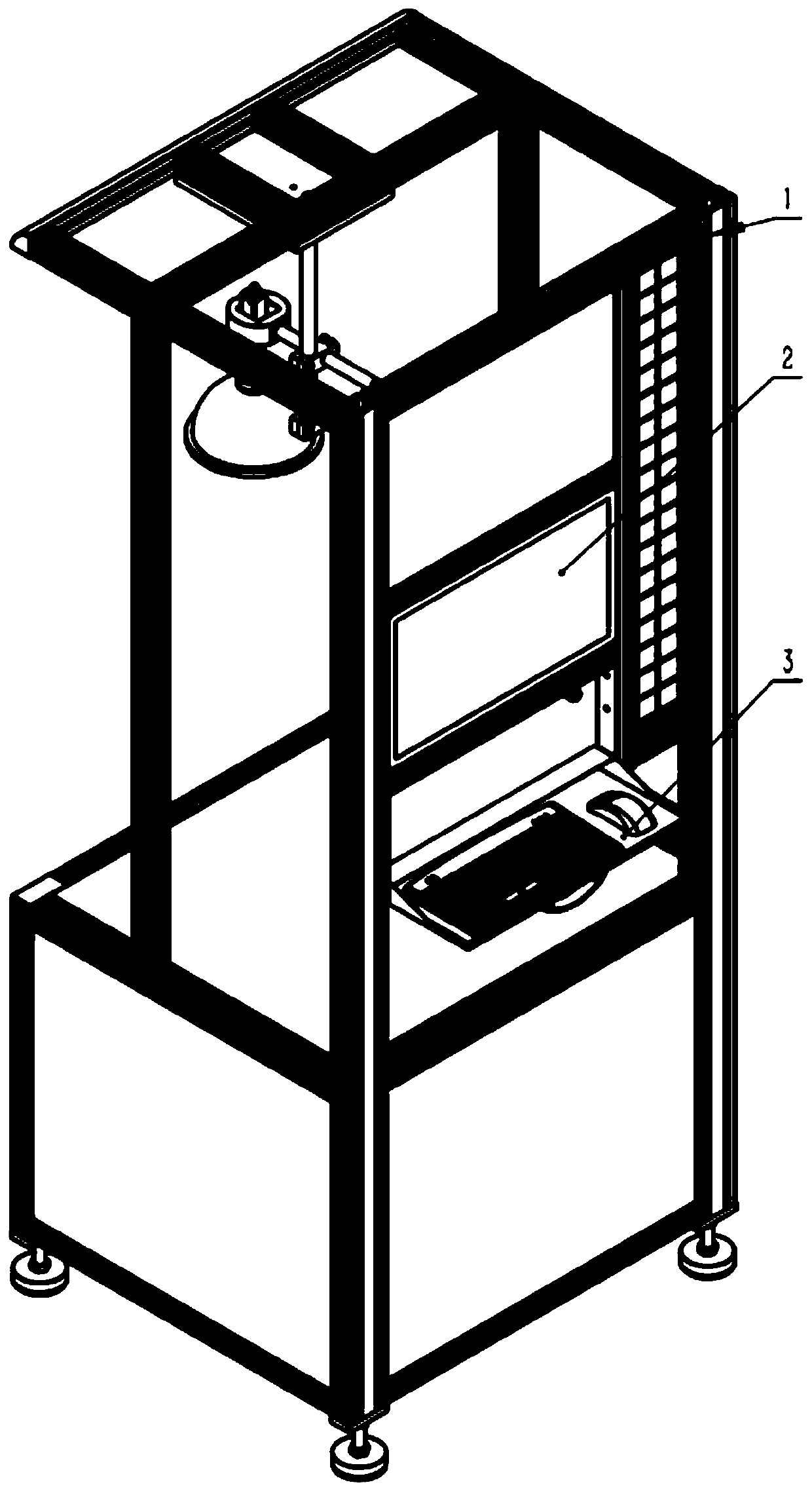

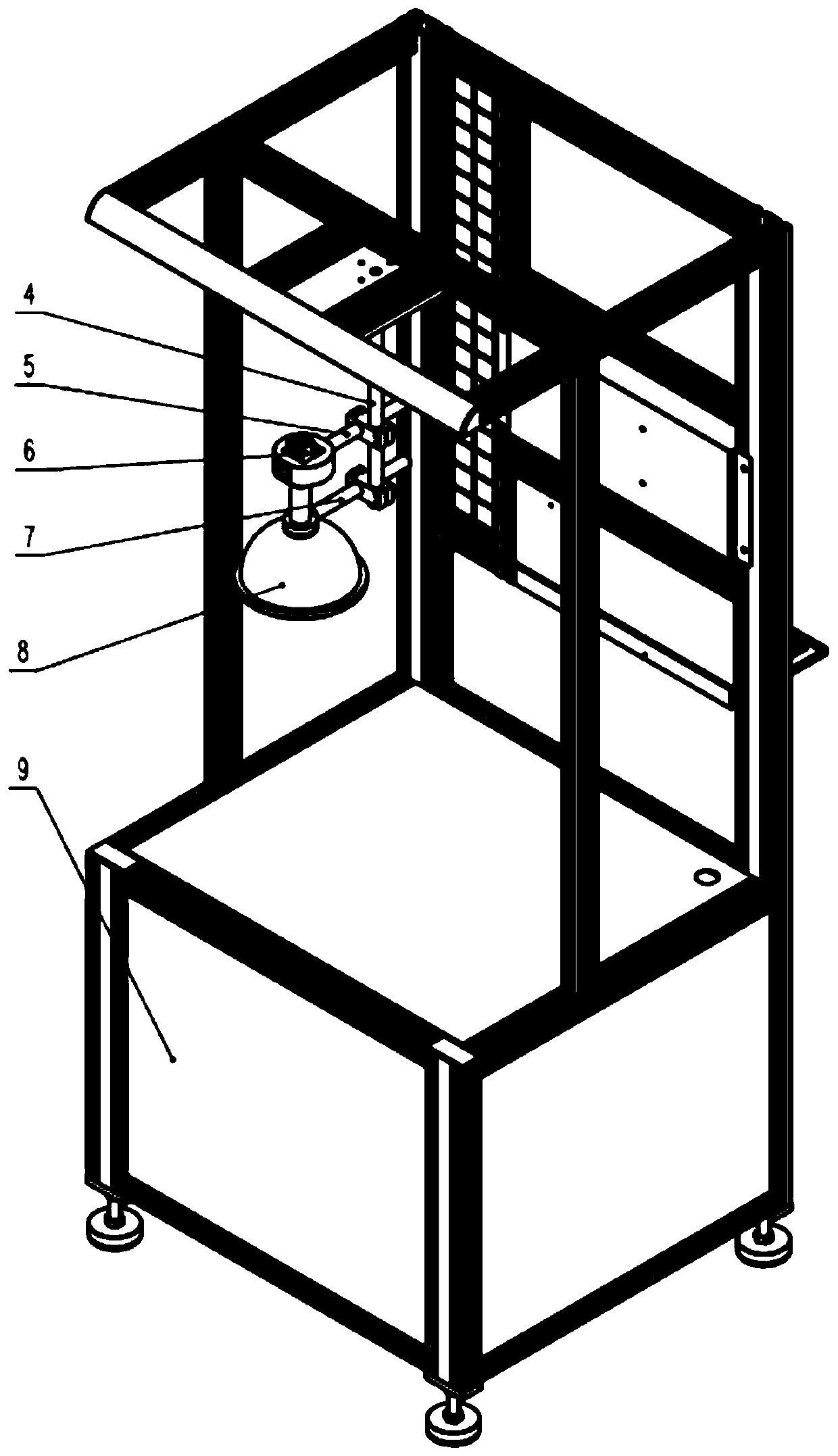

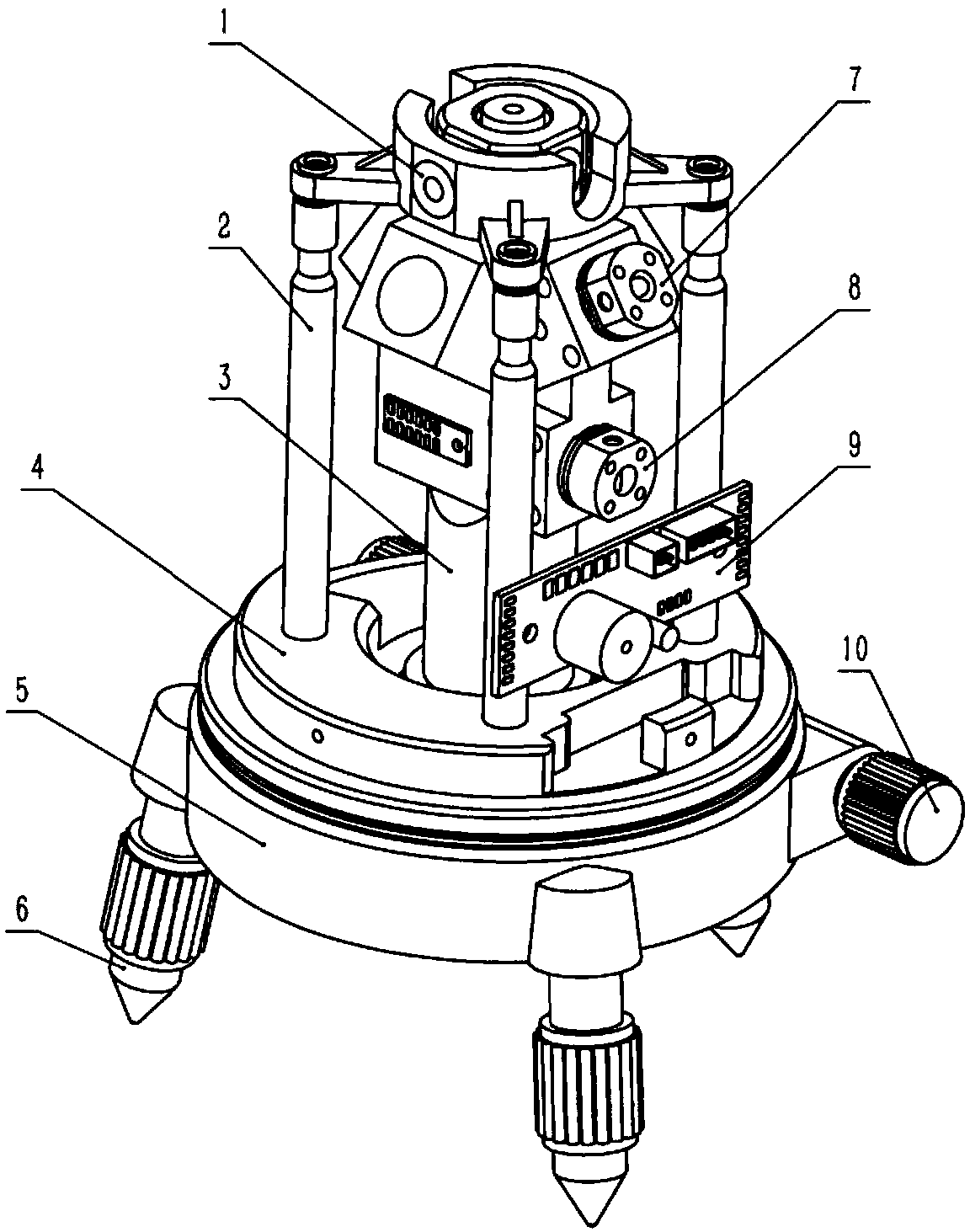

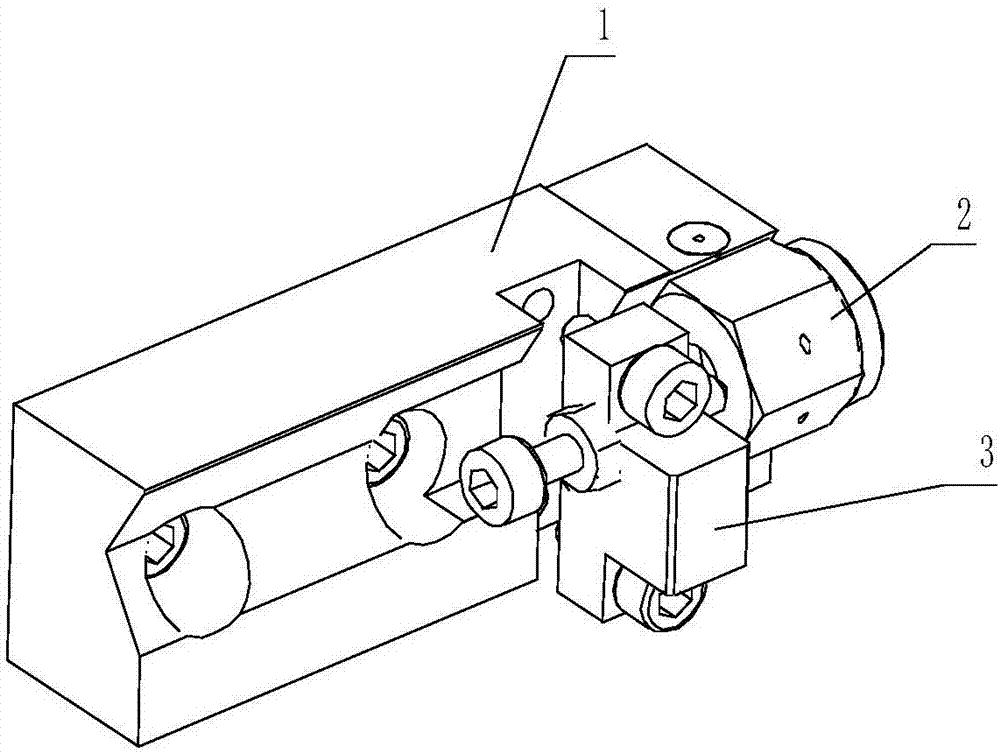

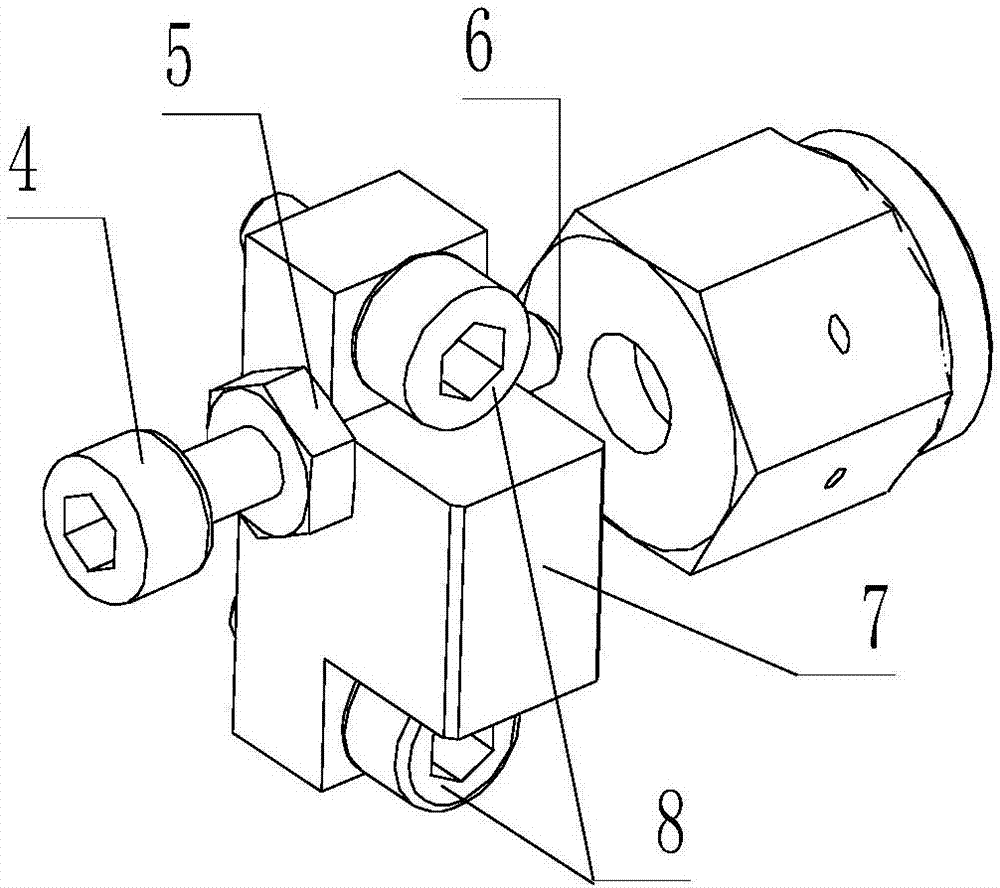

Inspection and adjustment device for cross-shaped laser measuring instruments

InactiveCN108871380AReduce labor costsReduce labor intensityMeasurement devicesProduction rateMeasuring instrument

The invention discloses an inspection and adjustment device for cross-shaped laser measuring instruments. The inspection and adjustment device comprises a calibration screen, CCD cameras, a conveyingline, a workbench and a robot device; high-precision ruler are arranged at the four peripheral edges of the calibration screen; the CCD cameras are arranged at different positions in front of the calibration screen; the conveying line is used for conveying the to-be-detected and detected cross-shaped laser measuring instruments; the workbench is arranged beside the conveying line; a positioning and clamping device is arranged on the workbench; the CCD cameras identify laser line position coordinates projected on the calibration screen, obtain the deviation and feed the deviation back to an industrial personal computer; and the industrial personal computer calculates the parameters comprising the torque and the rotation turns according to the deviation value so as to drive a screwdriver toperform adjustment until the deviation value meets the precision requirement. According to the inspection and adjustment device, automatic inspection and adjustment are realized; manual judgment and adjustment errors are eliminated, the assembling and adjusting precision can be improved, and the product quality consistency can be ensured; and automatic assembly line detection is adopted, and the productivity is remarkably improved.

Owner:CHANGZHOU INST OF TECH

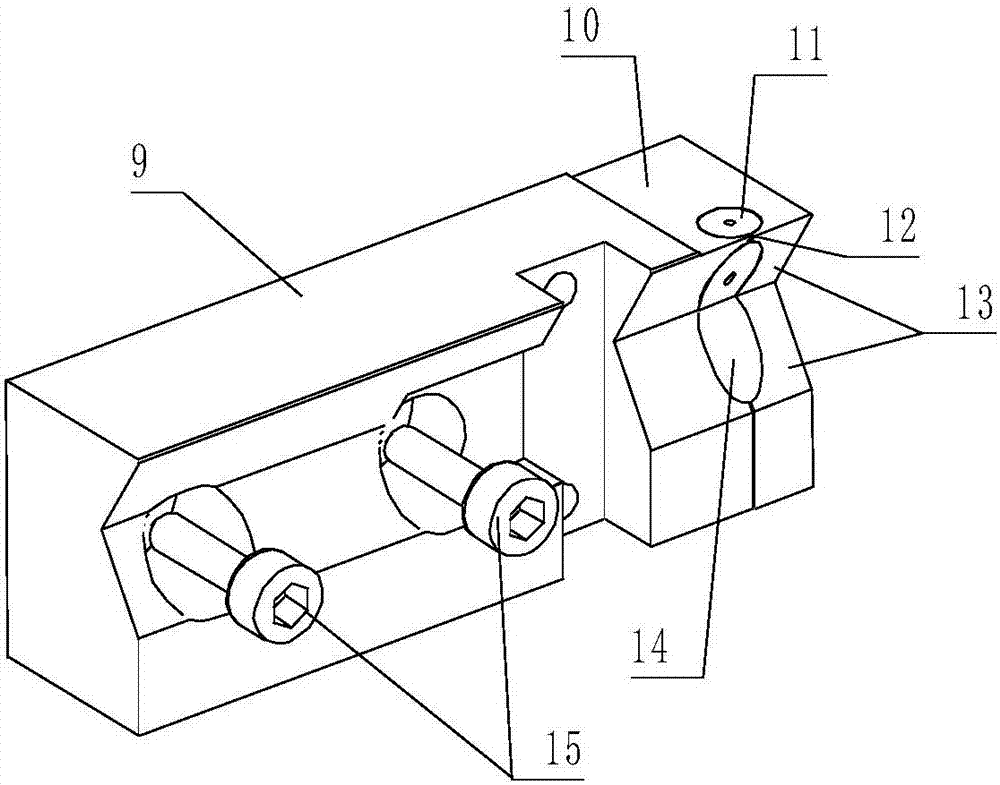

Jaw vice based simple drilling mould for hexagonal nut fuse wire hole and processing method for jaw vice based simple drilling mould

ActiveCN107081454AEnsure clamping positioning accuracyImprove processing efficiencyPositioning apparatusDrill jigsAviationEngineering

The invention belongs to the technical field of aviation manufacturing engineering and aircraft part processing assembly, and discloses a jaw vice based simple drilling mould for a hexagonal nut fuse wire hole and a processing method for the jaw vice based simple drilling mould, and the jaw vice based simple drilling mould is used for positioning, processing and manufacturing the hexagonal nut fuse wire hole of an aircraft pipeline part. The jaw vice based simple drilling mould comprises an adjustable type positioning device, a hexagonal nut and a V-shaped positioning pedestal. The adjustable type positioning device is used for realizing one-time clamping and positioning of products; the V-shaped positioning pedestal is a mechanism for realizing mechanical connection of the adjustable type positioning device and a jaw vice; and the hexagonal nut is positioned through a positioning section of the V-shaped positioning pedestal fixedly arranged on the jaw vice and a positioning section of a positioning bolt, and is clamped through the jaw vice. According to the jaw vice based simple drilling mould disclosed by the invention, the positioning structure is optimized, processing efficiency is improved, and stability and consistency of processing quality of the hexagonal nut fuse wire hole can be guaranteed; and the jaw vice based simple drilling mould further can be suitable for small-batch multi-specification need characteristics of military aircraft parts of China.

Owner:SHENYANG AIRCRAFT CORP

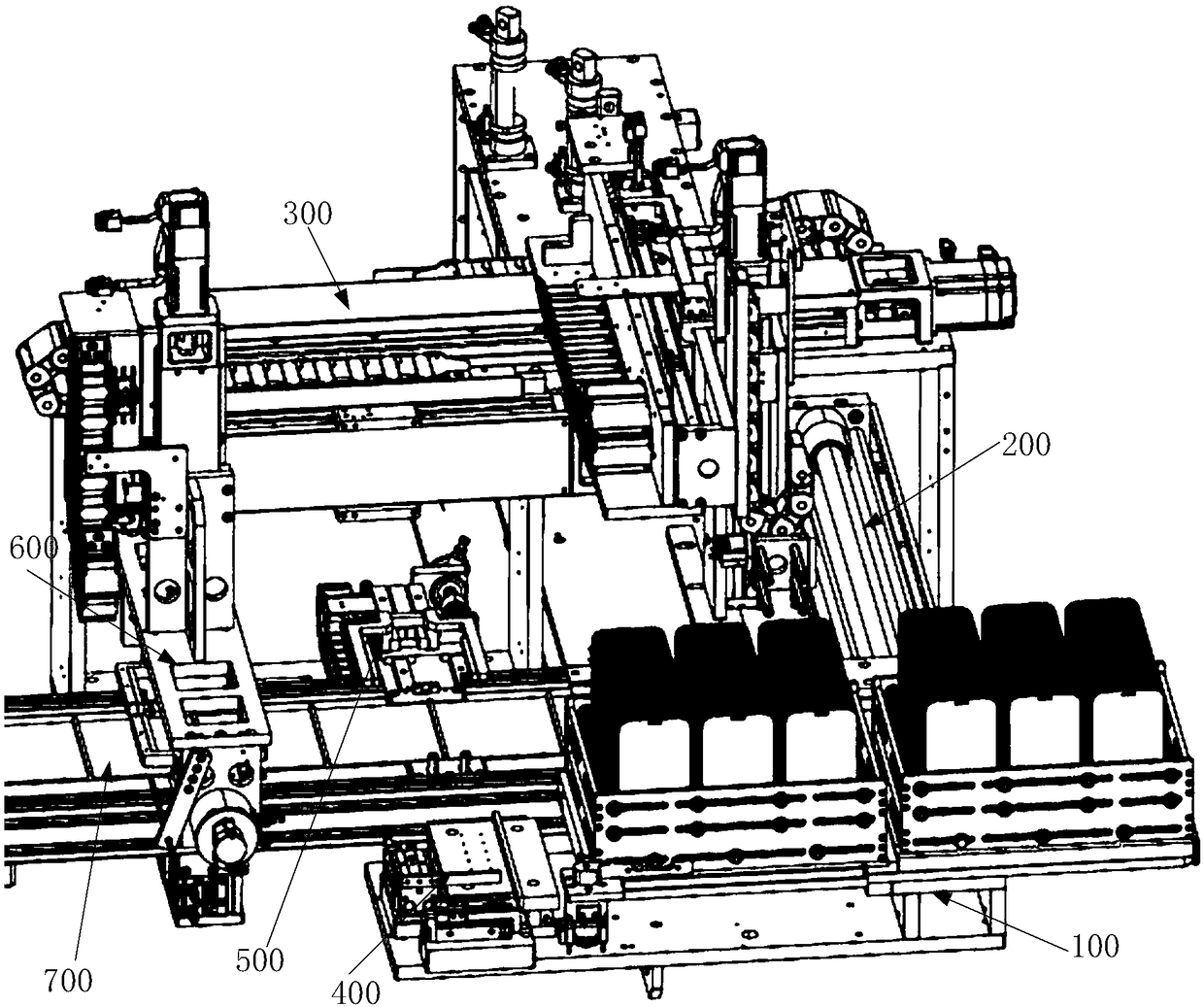

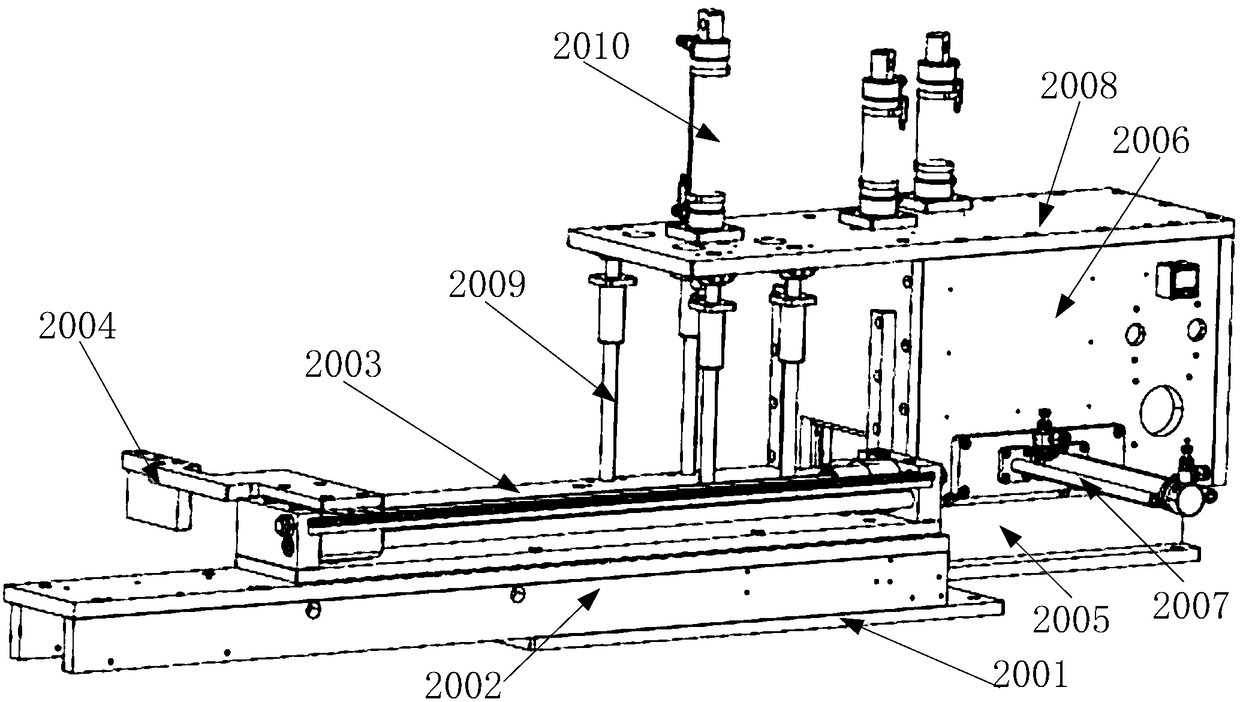

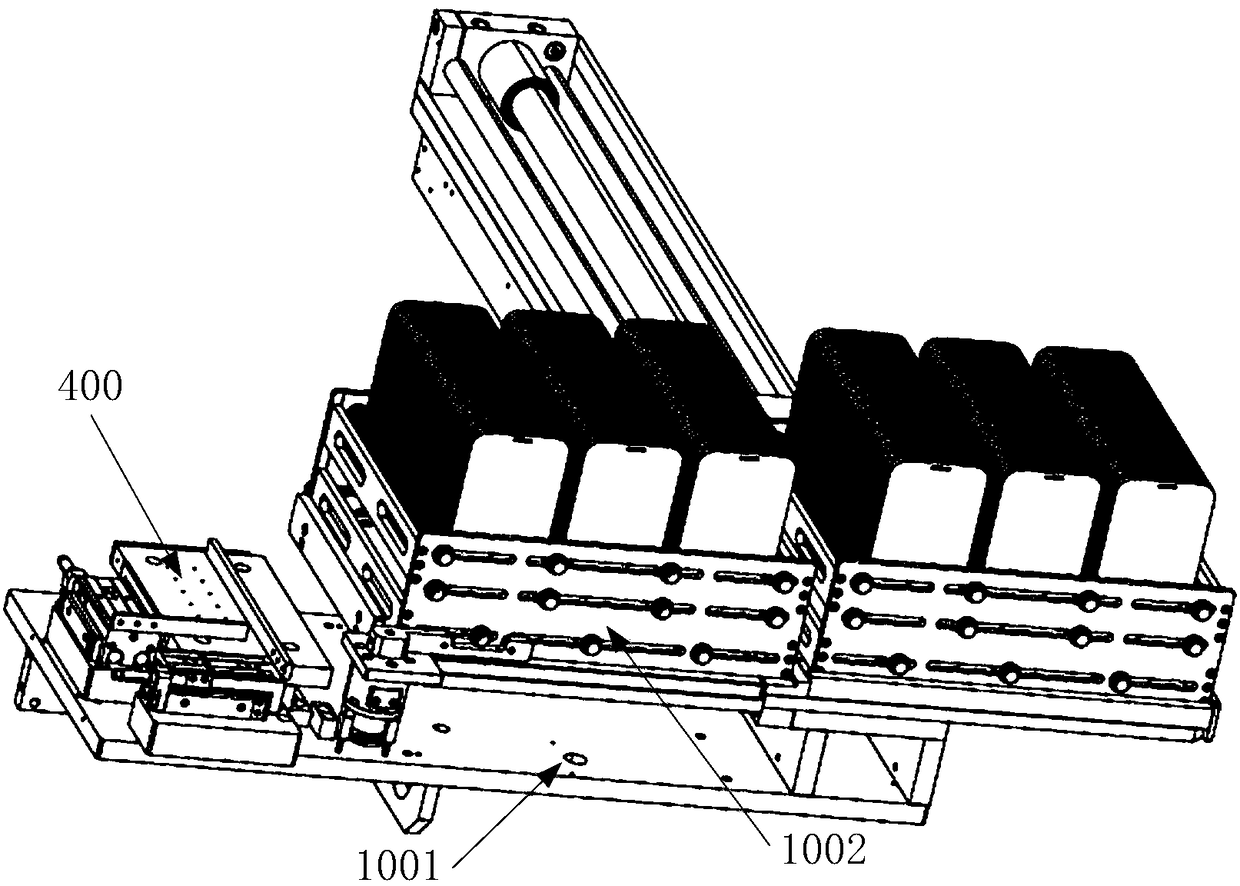

Automatic feeding mechanism of 3D hot bending machine

PendingCN108585453AEnd repetitive boring labor intensityIncrease productivityGlass reforming apparatusGlass productionFrame basedEngineering

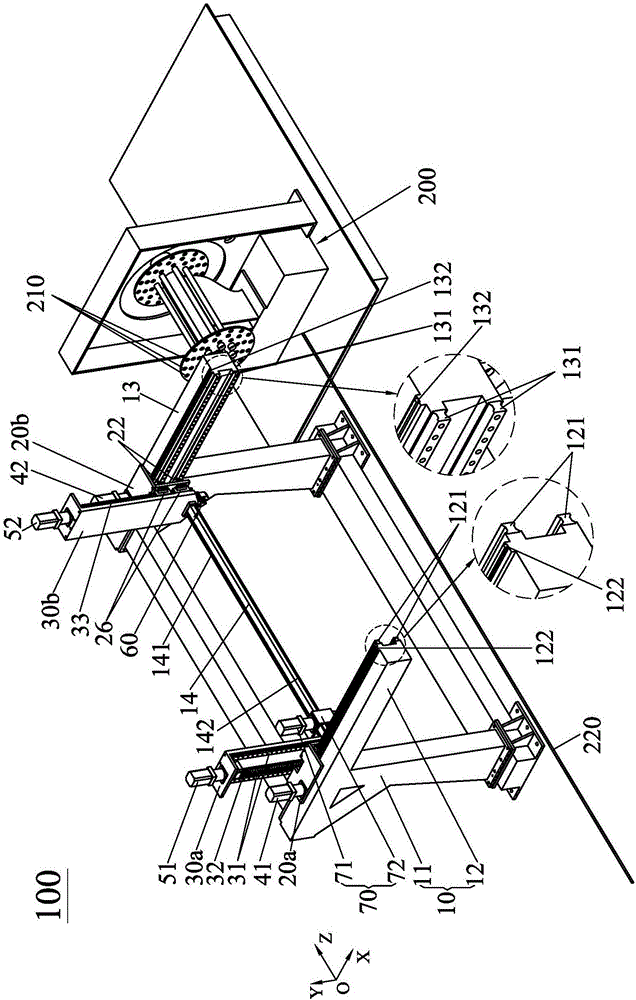

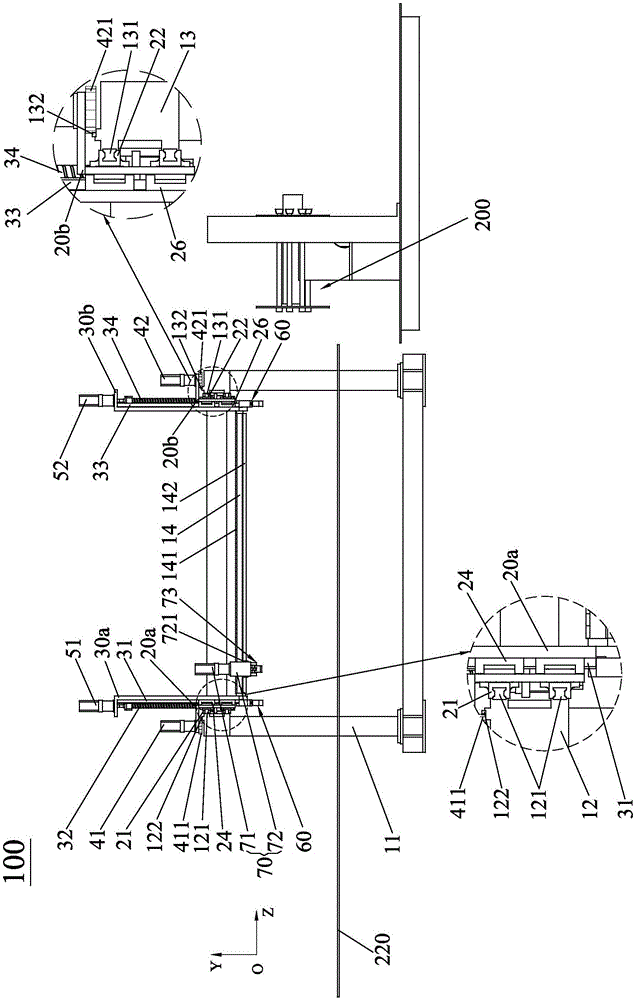

The invention applies to the field of modifications of glass techniques and provides an automatic feeding mechanism of a 3D hot bending machine. The automatic feeding mechanism comprises a glass traycomponent, a feeding stirring component, a picking manipulator component, a glass secondary positioning component, a lower die positioning component, an upper die positioning and picking-placing component, a die conveyer belt line component and an equipment frame base plate. The glass tray component, the feeding stirring component, the picking manipulator component and the die conveyer belt line component are arranged separately on the equipment frame base plate; the lower die positioning component and the upper die positioning and picking-placing component are arranged separately on the picking manipulator component; the glass secondary positioning component is arranged on the glass tray component. The idea of automatic feeding is achieved herein; the repeated tedious labor of manual feeding is ended; production efficiency is improved. In addition, the influence of human factors upon product quality is avoided, and uniformity of product quality is effectively ensured.

Owner:SHENZHEN COLIBRI TECH

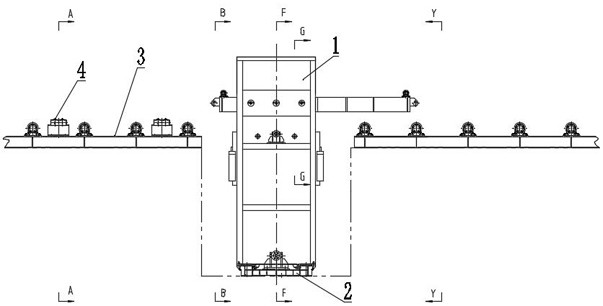

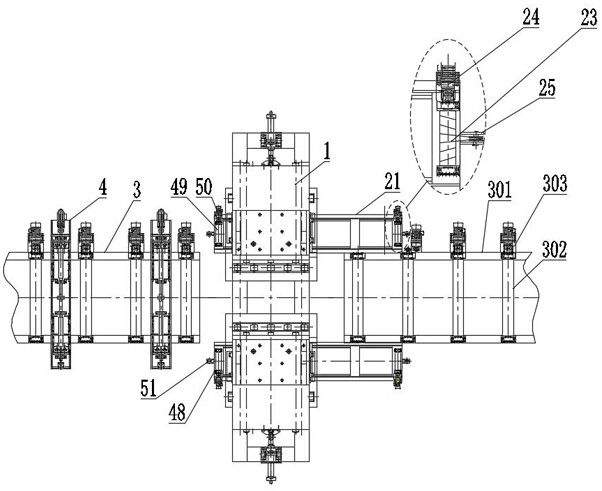

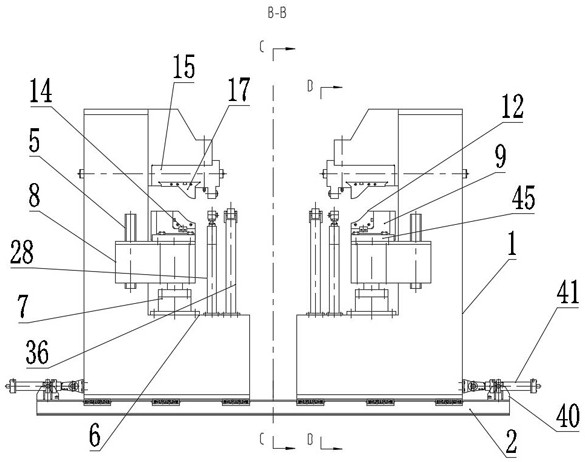

Bidirectional synchronous loading hydraulic forming equipment for aero-engine sealing ring

ActiveCN112246951AEnsure consistent qualityEnsure quality stabilityMetal working apparatusNumerical controlLoop controlControl manner

The invention discloses bidirectional synchronous loading hydraulic forming equipment for an aero-engine sealing ring. The bidirectional synchronous loading hydraulic forming equipment comprises an automatic die filling system, a main machine system, an ultrahigh pressure system and a numerical control system, wherein the main machine system comprises two servo hydraulic cylinders of which the displacement synchronous control precision can reach + / -0.02 mm, and a die locking hydraulic cylinder; the ultrahigh pressure system not only drives the hydraulic cylinder, but also provides a bulging pressure of 100MPa at most; the pressure can be dynamically adjusted along with feeding displacement of the servo hydraulic cylinders, so that the requirement for bidirectional synchronous loading hydraulic forming of special-shaped section members made of difficult-to-deform materials such as high-temperature alloy is met; and the numerical control system is based on a control mode of an upper computer and a lower computer and has intelligent functions such as database and parameter analysis. According to the bidirectional synchronous loading hydraulic forming equipment, closed-loop control isadopted, and the functions of precise load application, servo drive / hydraulic constant-load composite control, load / pressure real-time detection, forming error intelligent compensation and the like are integrated, so that integration and automation of the bidirectional loading bulging process are achieved, and product quality consistency and stability are guaranteed.

Owner:BEIHANG UNIV +1

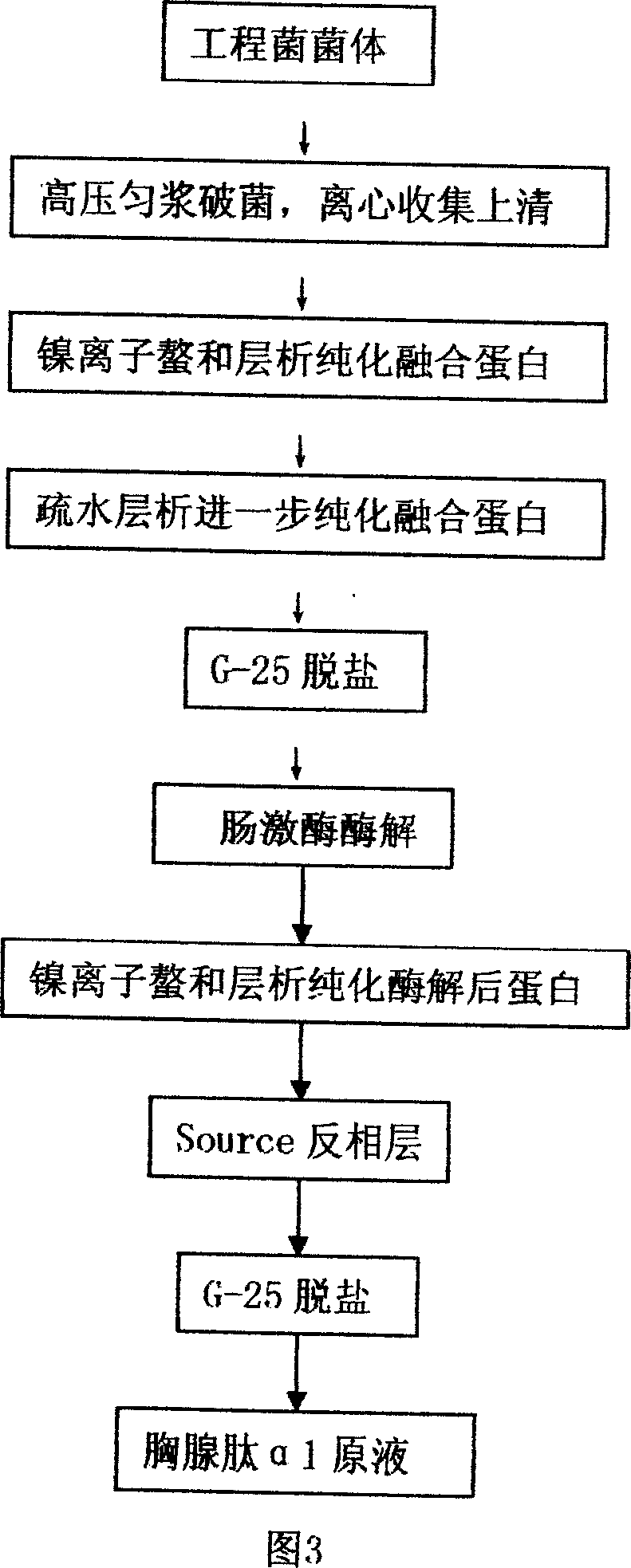

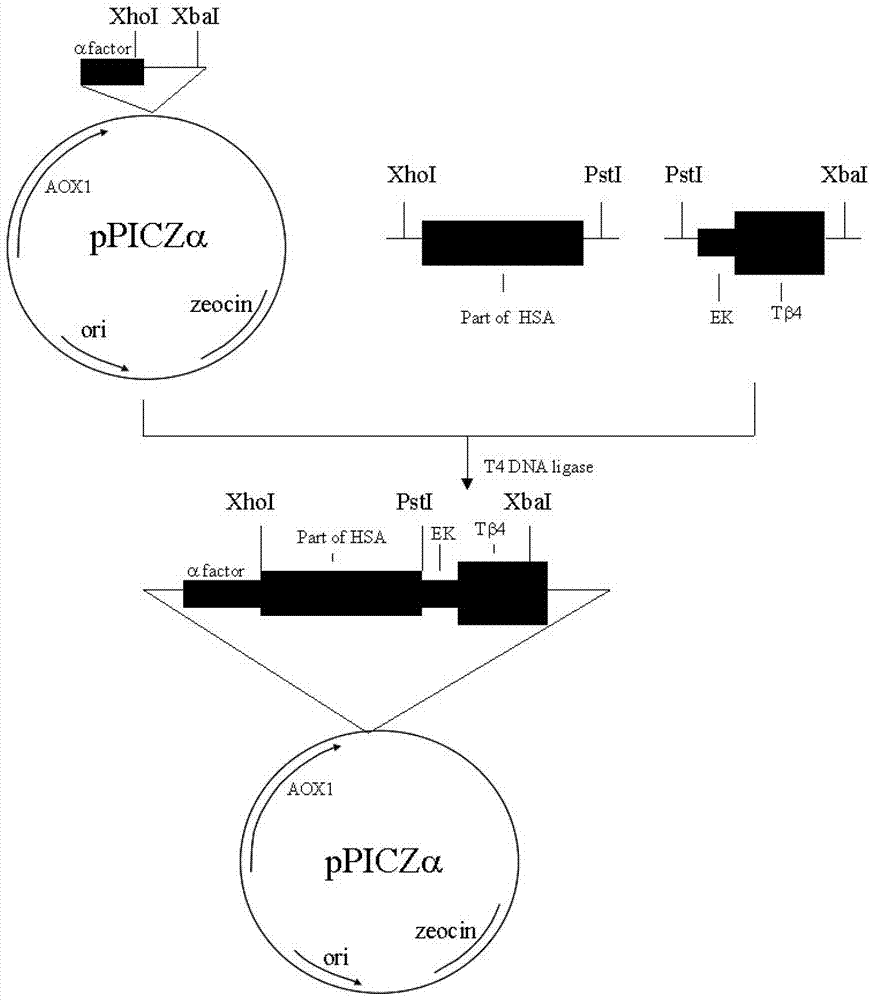

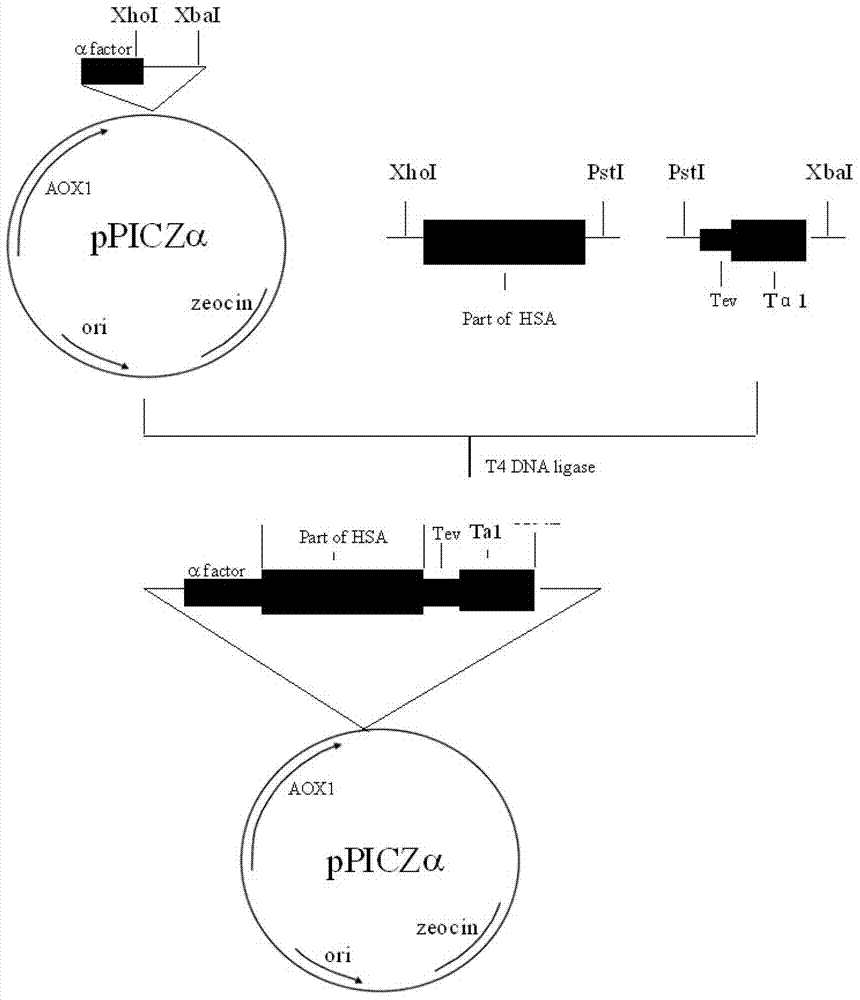

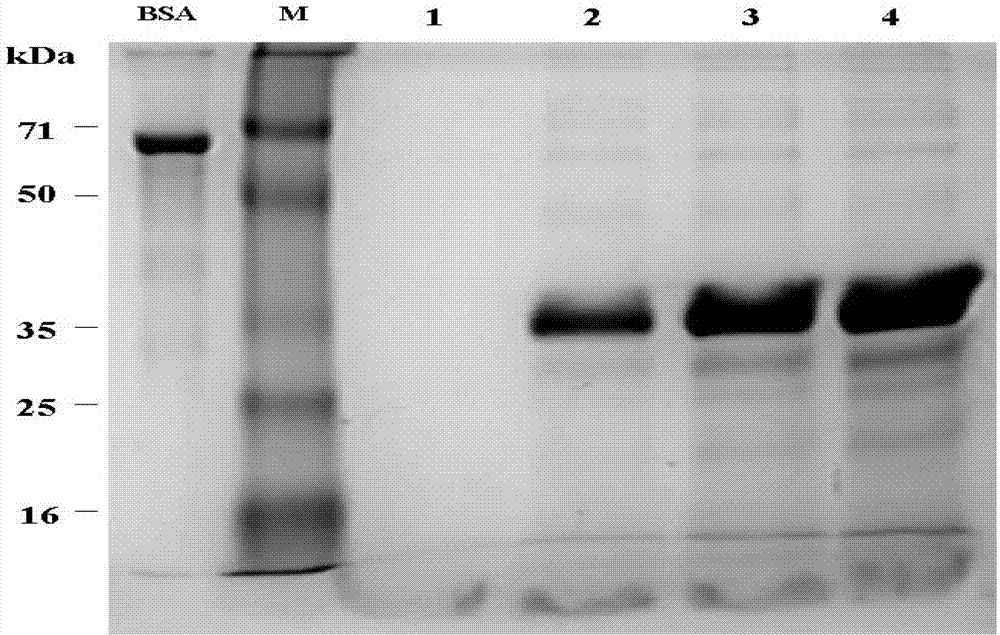

Method for recombining, expressing and producing human thymosin in yeast

ActiveCN102925470AEnsure product quality consistencyLow costHybrid peptidesVector-based foreign material introductionNicotiana tabacumRestriction enzyme digestion

The invention provides a method for massively producing human thymosin with low cost. The method is used for implementing restriction enzyme digestion to obtain a fusion gene sequence with a structure as follows: A-X-C, wherein A is a nucleotide sequence of site (1-150)-(1-372) amino acids at the N- end of coded mature human serum albumin; X is the nucleotide sequence of connecting peptide with enterokinase or tobacco etch virus (TEV) protease cutting site contained in a code; and C is a human thymosin gene. The method comprises steps as follows: connecting the fusion gene sequence to an expression carrier; transforming and introducing the expression carrier into saccharomycetes; carrying out induction expression to obtain soluble human serum albumin-thymosin fusion protein; then adding the TEV protease for cutting; and separating and purifying to obtain the recombined human thymosin. The human thymosin production method provided by the invention has the advantages that consistency of quality of products can be ensured, no limitation is generated from sources of raw materials, cost is low, an expression index is high, and mass production can be achieved and the like.

Owner:冯鹏波

High-voltage planar switch structure based on flexible manufacturing process and preparation method of structure

ActiveCN106783391AEnsure product quality consistencyEasy to prepare in large batchesExplosion switches closingElectricityEngineering

The invention discloses a high-voltage planar switch structure based on a flexible manufacturing process and a preparation method of the structure. The high-voltage planar switch structure comprises a positive electrode plate, a negative electrode plate and a signal input electrode plate. The positive electrode plate comprises a positive electrode plate insulating substrate and a positive electrode. The negative electrode plate comprises a negative electrode plate insulating substrate and a negative electrode. The signal input electrode plate comprises an exploding foil insulating substrate, an exploding foil positive electrode and an exploding foil negative electrode, wherein the exploding foil positive electrode corresponds to the exploding foil negative electrode. The negative electrode plate, the signal input electrode plate and the positive electrode plate are vertically laminated to form the high-voltage planar switch structure, the positive electrodes and the negative electrodes are spatially intersected, the positive electrode plate is separated from the negative electrode plate by the insulating substrates, and a connecting line between the exploding foil positive electrode and the exploding foil negative electrode passes the intersection. A high-voltage planar switch is prepared by a flexible printed circuit board process, the size of the high-voltage planar switch structure is reduced, the structure and other devices are integrated, and response of the switch is rapider as plasma generated by electric explosion breaks down an insulating medium.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

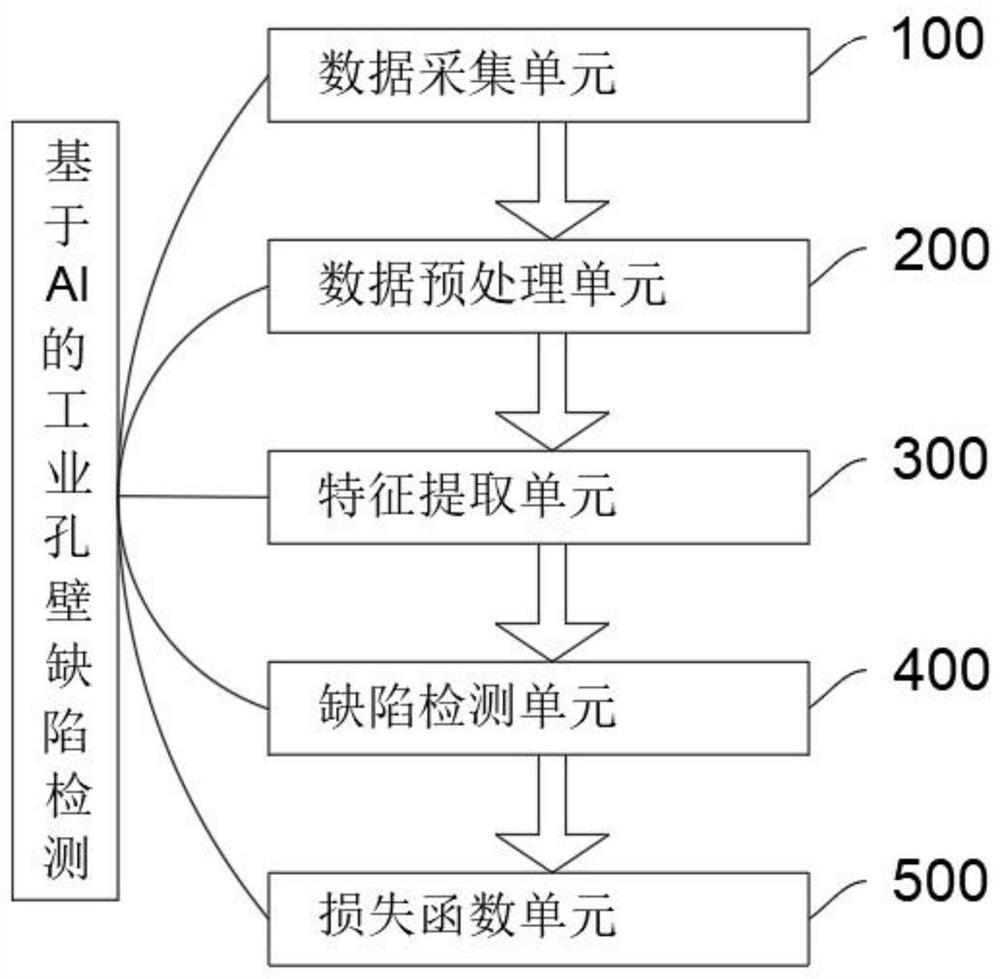

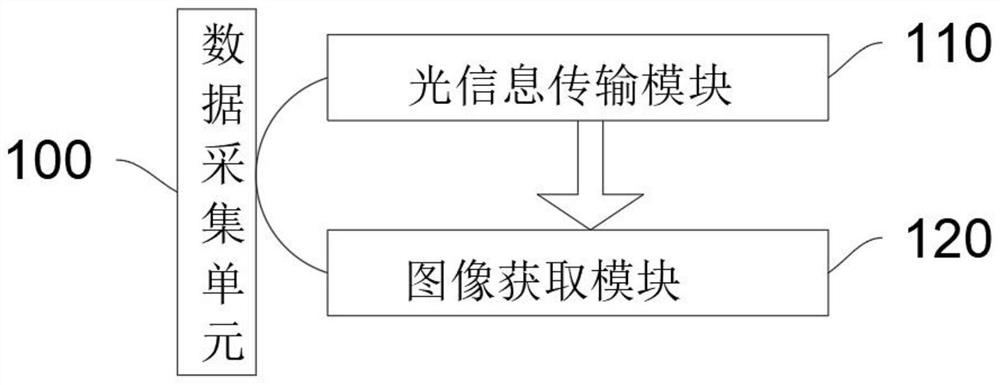

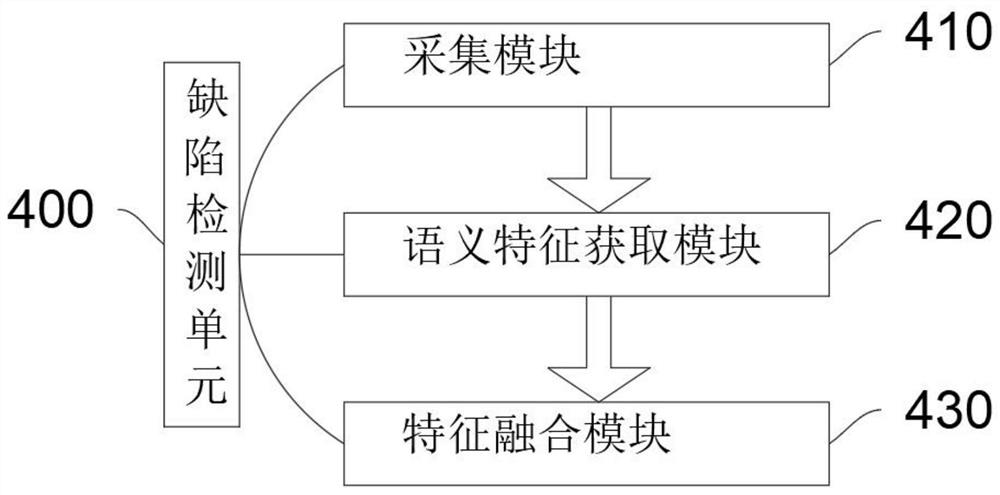

Industrial hole wall defect detection system based on AI and identification algorithm

ActiveCN112903692AImprove defect detection speedEnsure product quality consistencyImage analysisOptically investigating flaws/contaminationFeature extractionAlgorithm

The invention relates to the technical field of defect detection, and in particular relates to an industrial hole wall defect detection system based on AI and an identification algorithm. The system comprises a data acquisition unit, a data preprocessing unit, a feature extraction unit, a defect detection unit and a loss function unit; the data acquisition unit is used for converting a shot target into an image signal, the data preprocessing unit is used for carrying out data augmentation on the image signal acquired by the data acquisition unit and subtracting a mean value from images in a training set and a test set, and the feature extraction unit is used for optimizing a weight coefficient and offset of each node by the images; the defect detection unit is used for determining a central point of a defect detection position according to the image features in the feature extraction unit. According to the invention, the position and the type of the defect can be obtained only by converting the picture into the image signal, naked eye observation is liberated, the detection standard is unified, the product quality consistency is ensured, and the detection speed is improved, so that the detection speed of the inner wall defect of an industrial product is improved.

Owner:无锡金元启信息技术科技有限公司

Picosecond laser galvanometer equipment with same light source and double galvanometers

PendingCN110052723ASmall heightCompact and reasonable structureWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond laserPunching

The invention discloses picosecond laser galvanometer equipment with a same light source and double galvanometers. The equipment comprises a rack, a marble base, a power distribution cabinet, a control system, a display system, a door control mechanism, an outer cover assembly, a vacuum generator, a vacuum adsorption system, an XYZ axis moving system, a laser device, an optical path integration, the galvanometers and a telecentric variable focusing lens. The marble base is composed of a base, a vertical base and a top base, and sequentially provided with a Y-axis moving system, an X-axis moving system, two Z-axis moving systems and a vacuum adsorption system, the telecentric variable focusing lens and the galvanometers are coaxially mounted, the distances between the axes are consistent, and the laser device is the picosecond grade laser generation device. Product quality consistency is ensured by adopting the same light source, the marble base is of an integrated structure, high-precision curve cutting, punching, grooving and edging are realized by matching the galvanometers with the telecentric variable focusing lens, processing precision, product quality and production efficiency are improved, the process adaptability is good, and the practical effect is remarkable.

Owner:WUHAN GSTAR TECH CO LTD

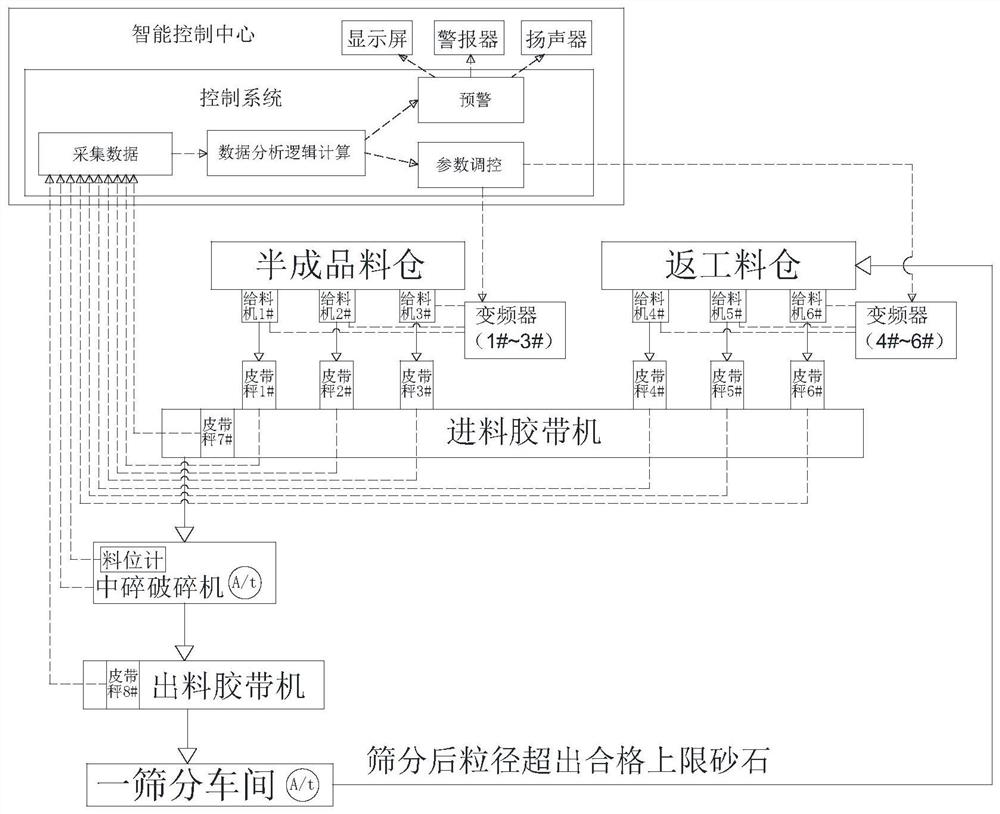

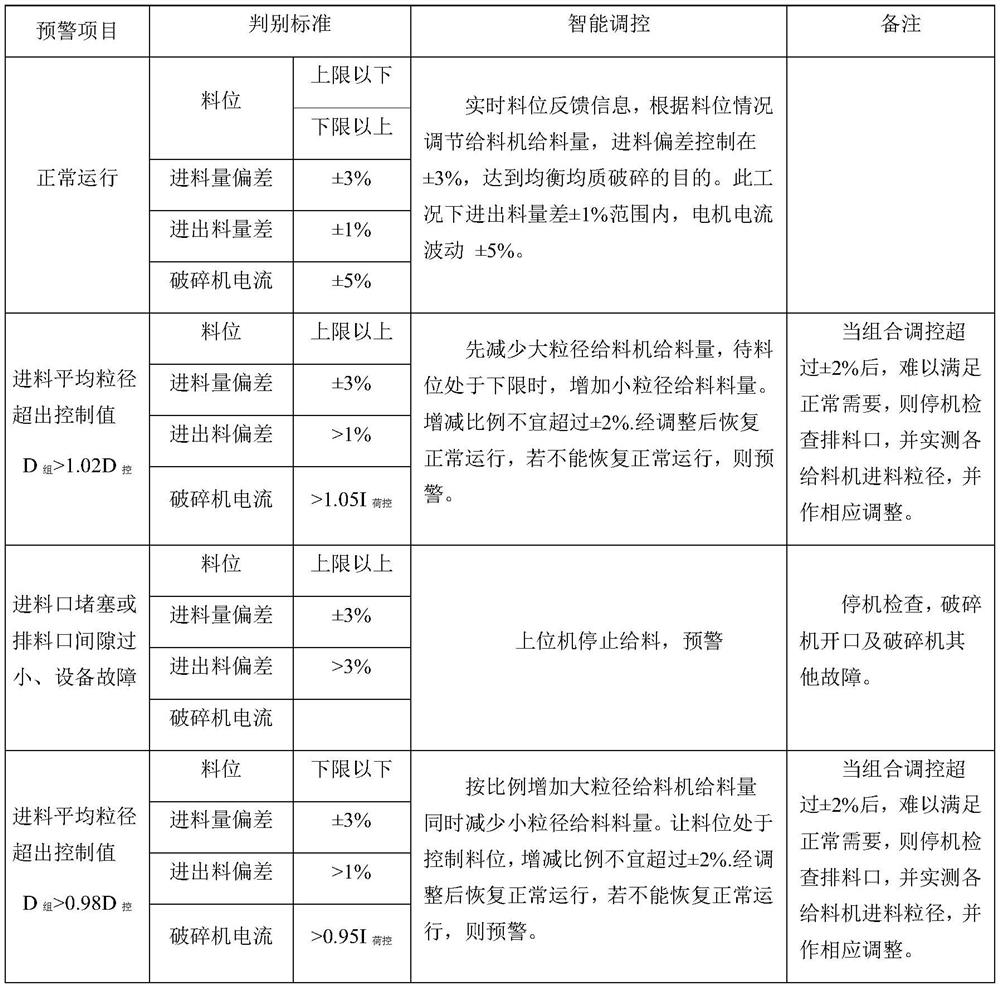

Intelligent control method for balanced crushing of fine crushing workshop in machine-made gravel

ActiveCN113262871AEliminate fractional segregationLarge particle sizeGrain treatmentsControl systemControl engineering

The invention provides an intelligent control method for balanced crushing of a fine crushing workshop in machine-made gravel. An intelligent control judgment table is preset in a control system of an intelligent control center, data of a level gage are acquired in real time, the data are compared with a set control range, and the conveying capacity of a feeding adhesive tape machine is adjusted when deviation occurs, so that the ore filling amount in a crusher is within the control range of the level gage; and meanwhile, the feeding relation and the conveying amount of each batching point of the feeding adhesive tape machine, the discharging conveying amount and the working current of the crusher are monitored in real time, a control deviation range is set for each parameter, and when the parameters exceed the deviation ranges, the frequency parameter of a feeding machine is adjusted according to the judgment standard of the intelligent control judgment table, so that each parameter is maintained within the allowable deviation range. Through intelligent monitoring and regulation of process parameters, balanced operation of the system can be effectively ensured, so that the process target of green, efficient and low-consumption shaping and crushing is achieved, intelligent regulation of each device is realized, the labor cost is reduced, the product quality consistency of medium and fine crushing procedures is ensured, and a foundation is laid for high-quality sandstone processing.

Owner:SINOHYDRO BUREAU 9

Automatic rib-penetrating device

ActiveCN106624318AReduce labor intensityLow technical requirementsWelding with roller electrodesDrive motorEngineering

The invention discloses an automatic rib-penetrating device which comprises a frame, a slide base, a slide frame, a first direction driving motor, a second direction driving motor, a clamping jaw and a penetrating driving component, wherein the slide base slides on the frame along a first direction; the slide frame slides on the slide base along a second direction; X, Y and Z axis directions of a three-dimensional coordinate system are formed by the first direction, the second direction and a penetrating direction; the first direction driving motor is arranged on the slide base or the frame and is used for driving the slide base to slide; the second direction driving motor is arranged on the slide base or the slide frame and is used for driving the slide frame to slide; the clamping jaw is arranged on the slide frame and is used for capturing ribs; the penetrating driving component is used for driving the ribs captured by the clamping jaw to slide relative to a model base; in the process of inserting the ribs into different rib-penetrating holes of the model base, under the cooperative effect of the first direction driving motor and the second direction driving motor, the clamping jaw is capable of capturing the ribs and conveying the ribs to the positions aligned with the rib-penetrating holes of the model base and the penetrating driving component is capable of inserting the ribs on the clamping jaw into the aligned rib-penetrating holes, so that the automatic rib-penetrating purpose can be achieved.

Owner:DONGGUAN JIANYUAN ELECTROMECHANICAL

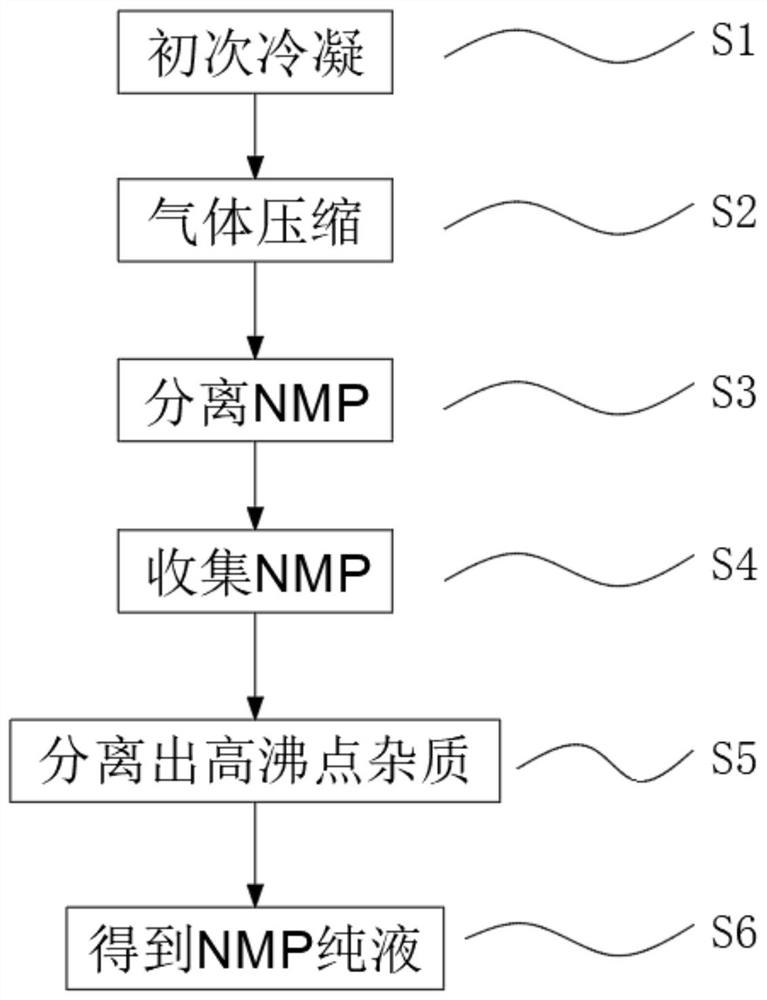

Method and system for purifying NMP in coating process of lithium ion battery

ActiveCN113788776ARealize online recyclingReduce energy consumptionOrganic chemistryDispersed particle separationThermodynamicsLiquid storage tank

The invention discloses a method and a system for purifying NMP in coating process of a lithium ion battery, and belongs to the field of NMP purification. The NMP purification method comprises the following steps: S1, primary condensation, S2, gas compression, S3, NMP separation, S4, NMP collection, S5, high boiling point impurity separation, and S6, NMP pure liquid obtaining. The NMP purification system comprises a pre-cooling surface air cooler, a first NMP liquid storage tank, a compressor, a separation assembly, a pressure buffer assembly, a negative pressure flash tank, a vacuum pump, a vacuum condenser and an NMP pure liquid tank, the pre-cooling surface air cooler is connected with the compressor and the first NMP liquid storage tank, the compressor is connected with the separation assembly, the separation assembly is connected with the pressure buffer assembly, the pressure buffer assembly is connected with the negative pressure flash tank, the negative pressure flash tank is connected with the vacuum pump, and the vacuum condenser is connected between the vacuum pump and the negative pressure flash tank. According to the invention, the system structure can be simplified, recovery and purification are facilitated, then butt joint with production is facilitated, effective recycling of NMP is realized, and the cost is reduced.

Owner:深圳市德尼环境技术有限公司

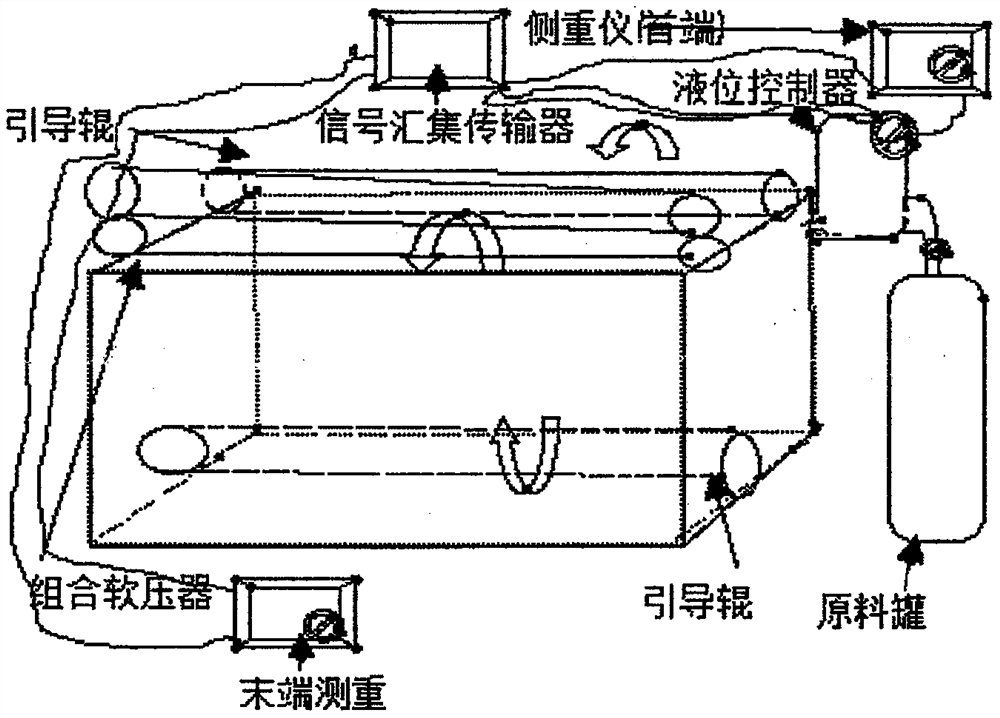

Carbon paper continuous production method capable of automatically controlling impregnation amount

PendingCN112941957AAvoid foamingHigh speedCell electrodesPaper/cardboardAutomatic controlControl signal

The invention relates to the technical field of hydrogen fuel cells, and concretely relates to a carbon paper continuous production method capable of automatically controlling the impregnation amount. According to the method, a PTFE (polytetrafluoroethylene) impregnator and a PTFE liquid level controller connected with the PTFE impregnator are adopted, the liquid level controller is connected with a tank filled with an impregnation raw material PTFE (polytetrafluoroethylene), and automatic weighing instruments are arranged at the head end and the tail end. An automatic control program (a signal collecting and outputting processor-a signal collecting and transmitting device for short) is preset. The production diameter of the carbon body paper is set to be 80 cm, and the head end emphasizes are kept basically consistent. The concentration of a dipping raw material PTFE water-phase dispersion is 60%. The dipping speed cannot exceed 2 m / min, so that air bubbling caused by too high speed is prevented. And the equipment always keeps working at a set liquid level according to the control signal.

Owner:郭金武

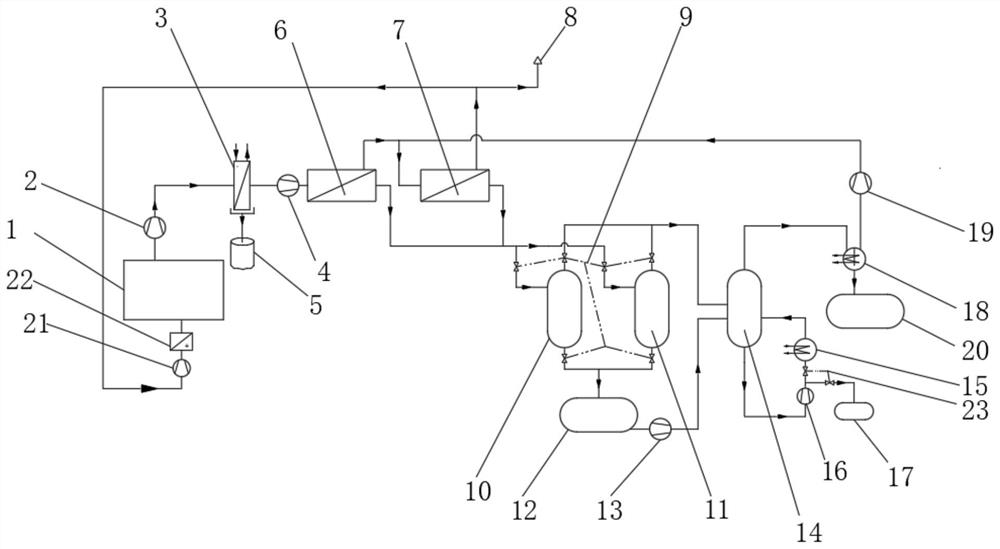

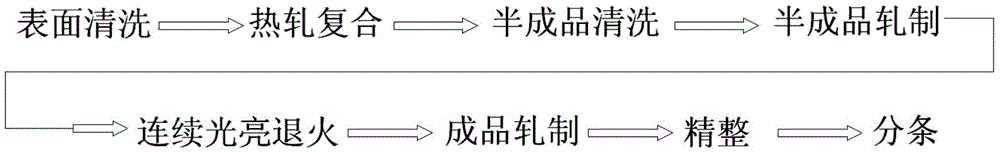

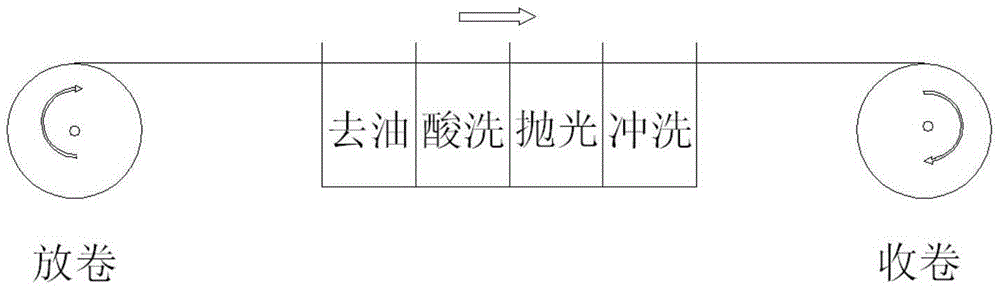

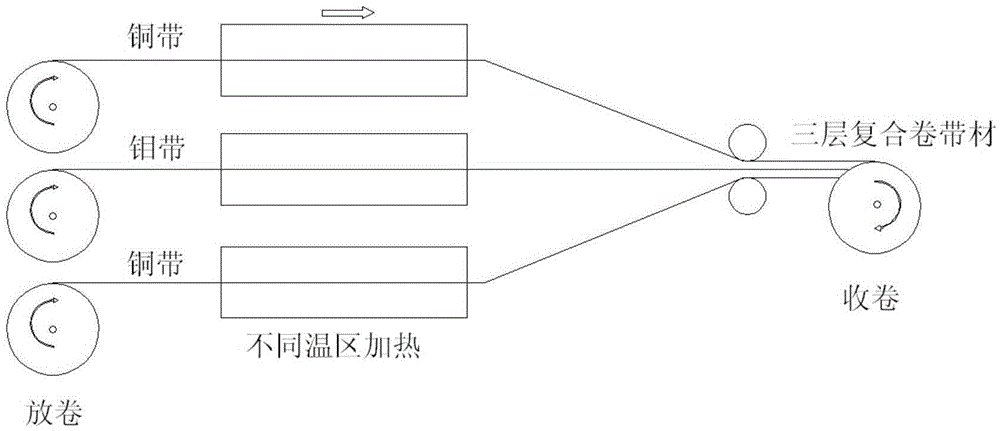

Cu/Mo/Cu laminated metal coiled strip and continuous machining method

ActiveCN105619931AIncrease productivityReduce manufacturing costMetal layered productsSurface cleaningWork in process

The invention discloses a Cu / Mo / Cu laminated metal coiled strip and a continuous machining method. The method comprises the steps of surface cleaning, hot-rolling compositing, semi-finished product surface cleaning, semi-finished product rolling, continuous bright annealing, finished product rolling, finishing and striping. The length of the finished Cu / Mo / Cu laminated metal coiled strip manufactured by the adoption of the method can reach dozens of meters and even hundreds of meters, production efficiency can be improved, production cost can be lowered, uniformity of product quality is ensured, and the Cu / Mo / Cu laminated metal coiled strip is suitable for large-scale continuous production and has high production and application value.

Owner:重庆金荣金属有限公司

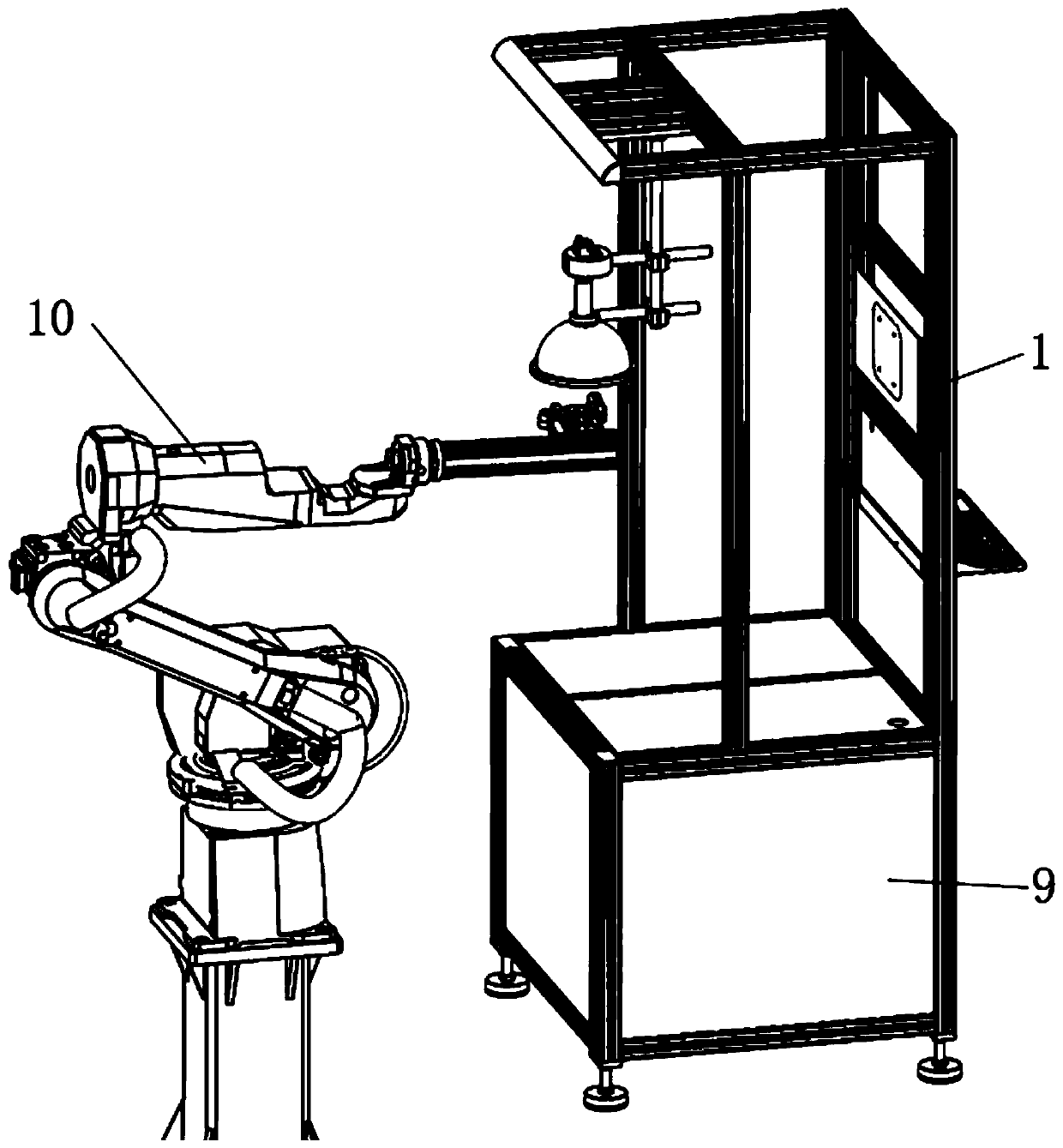

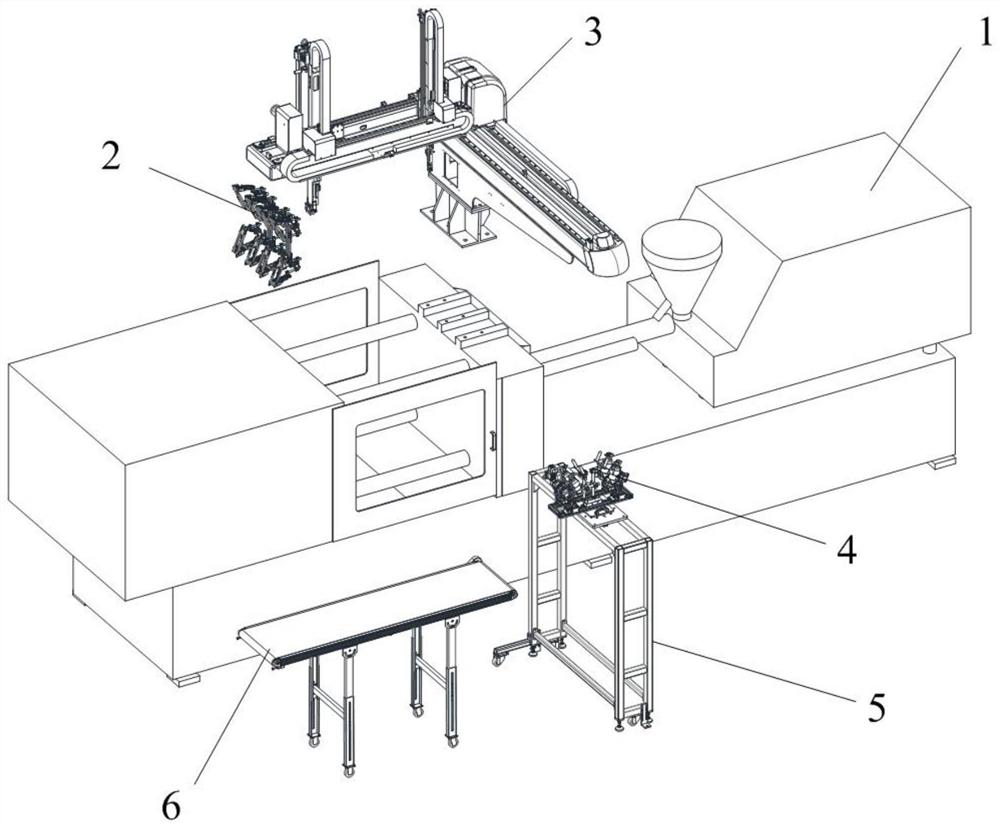

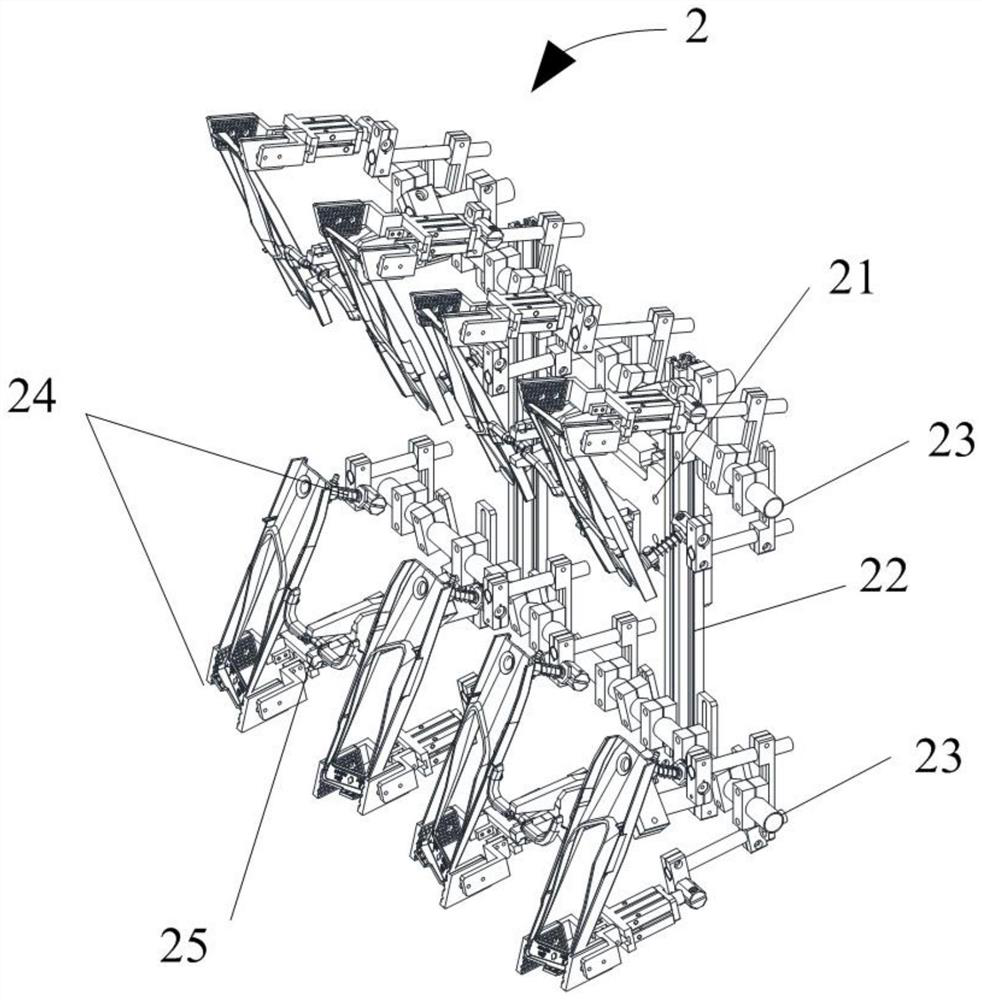

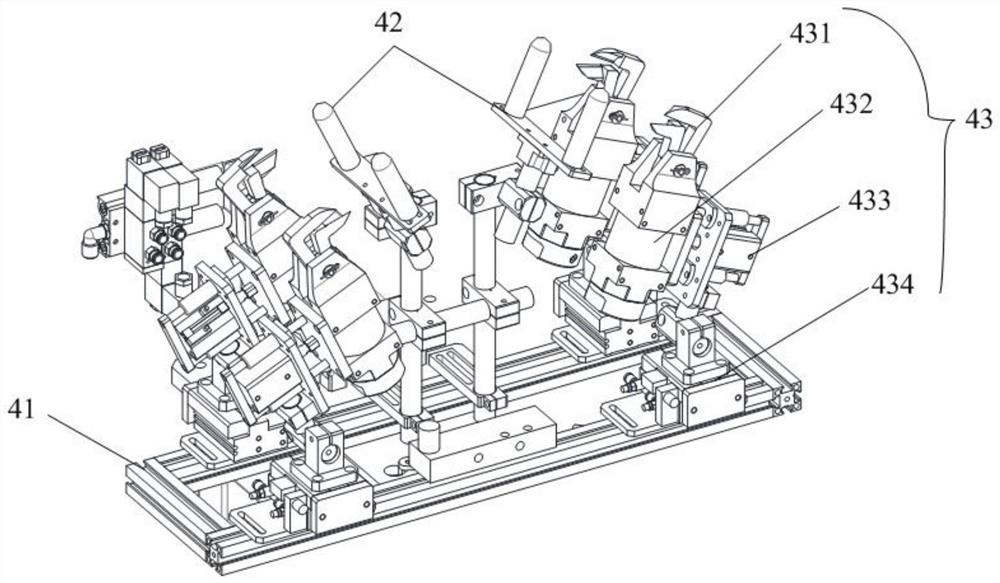

A system and method for automatic shearing of nozzles of injection molded parts

The present invention proposes an automatic nozzle shearing system for injection molded parts, which is used to cooperate with the injection molding machine to complete the automatic shearing of the nozzle of injection molded parts. The clamp is arranged at the end of the manipulator, the manipulator is fixed on the injection molding machine body, the shearing jig is arranged on the jig bracket, and the jig bracket is set on one side of the injection molding machine body. The product conveying line is set at one end of the jig support. The invention also proposes an automatic cutting method for nozzles of injection molded parts. The system and method for automatic shearing of injection molded nozzles in the present invention can ensure the accuracy of shearing and high efficiency by using manipulators to operate flexibly in space, high-precision positioning, accurate signal detection, and fast response. After the shearing is completed, the injection molded parts are directly cut Through the product conveying line, the quality inspection and packing are carried out, which realizes the automatic operation of the whole process.

Owner:深圳市鼎星精密科技有限公司

Full-hydraulic plate-edge pre-bending device and method for thick-wall metal longitudinal welded pipes

ActiveCN113732148AReduce positioning errorsPrevent thinningShaping toolsMetal-working feeding devicesClassical mechanicsEngineering

The invention relates to the technical field of pre-bending devices for welded pipes, in particular to a full-hydraulic plate-edge pre-bending device and method for thick-wall metal longitudinal welded pipes. The full-hydraulic plate-edge pre-bending device for the thick-wall metal longitudinal welded pipes comprises rack main bodies which are symmetrically arranged left and right, wherein the rack main bodies are installed on a lower bottom plate, carrier roller mechanisms are arranged on the inlet side and the outlet side of the rack main bodies and used for conveying plates, at least two sets of alignment mechanisms are arranged on the inlet side of the rack main bodies, and the alignment mechanisms are installed on carrier roller frames and used for straightening the plates. A full-hydraulic working structure is adopted, high efficiency and precision control in the machining process are guaranteed, and it is guaranteed that the position error is smaller than 0.1 mm when all key structure parts operate; and meanwhile, by arranging mounting tables, first hydraulic motors, first rollers and the like, replacement of a lower mold and an upper mold is facilitated, and the efficiency is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com