Inspection and adjustment device for cross-shaped laser measuring instruments

A technology of cross laser and adjustment device, applied in the direction of measuring device, instrument, etc., can solve the problems of low efficiency, low precision and high labor intensity, and achieve the effect of improving productivity, improving assembly and adjustment accuracy, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

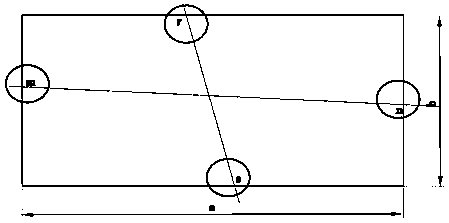

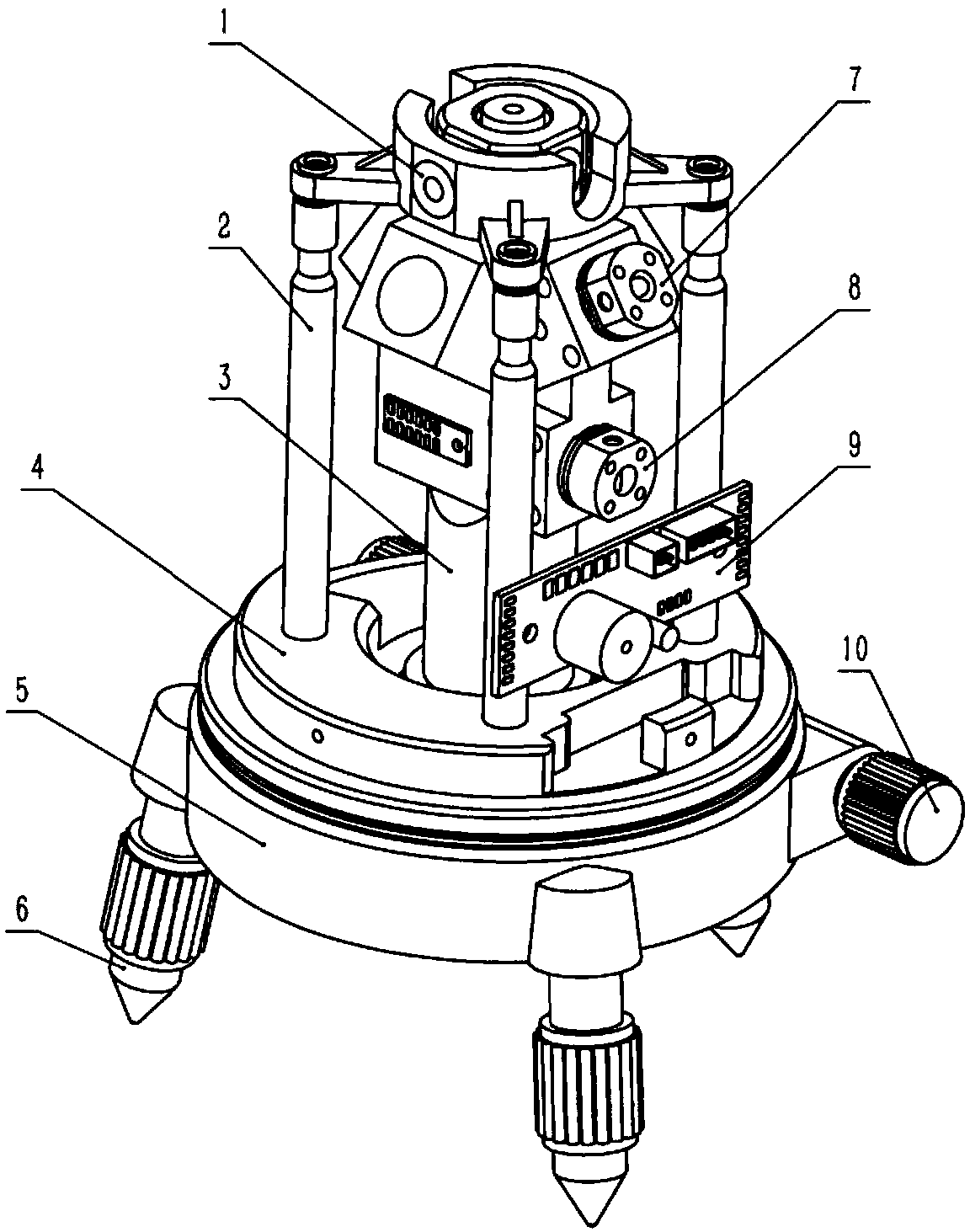

[0051] Figure 5 It is an automatic inspection and adjustment device for a cross laser measuring instrument based on a dual-arm robot (robot). The device mainly includes a calibration screen 11 and four CCD cameras (including the first CCD camera 12 and the second CCD camera 13) for identifying the position of the light scale. , the third CCD camera 14, the fourth CCD camera 15), conveying line 16, workbench 17, positioning and clamping assembly 18, product to be inspected 19, double-arm robot 20 (installed on the robot base 27, including the left arm 24 and right arm 25), inspected product 21, screwdriver mounting ring 22 (for installing electric servo screwdriver 26), and robot left arm positioning clamping module 23. Wherein, the surroundings of the calibration screen 11 are standard scale lines. When the laser measuring instrument emits light, the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com