Shaft pivoted hub bearing unit monitoring system for axial pivoting force and displacement and method

A wheel bearing and riveting force technology, which is applied in the direction of mechanical bearing testing, force measurement, and measuring devices, can solve problems such as poor product quality consistency, and achieve the effect of simple and easy technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

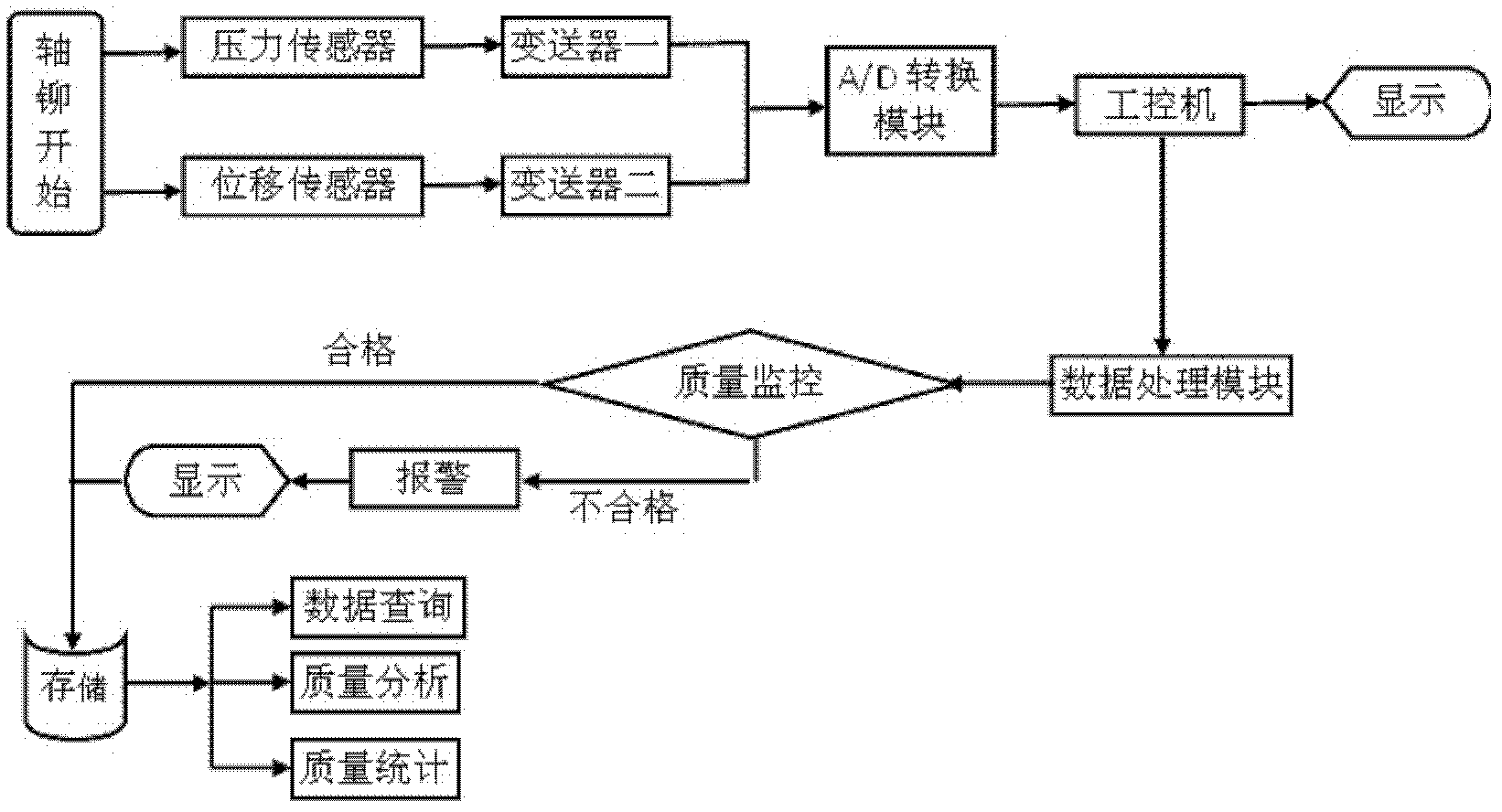

[0029] In order to make the shaft riveted hub bearing unit have good performance, it is necessary to monitor the axial riveting force-displacement curve in real time during assembly to ensure that the shaft riveted hub bearing unit has a high service life and low working clearance Difference.

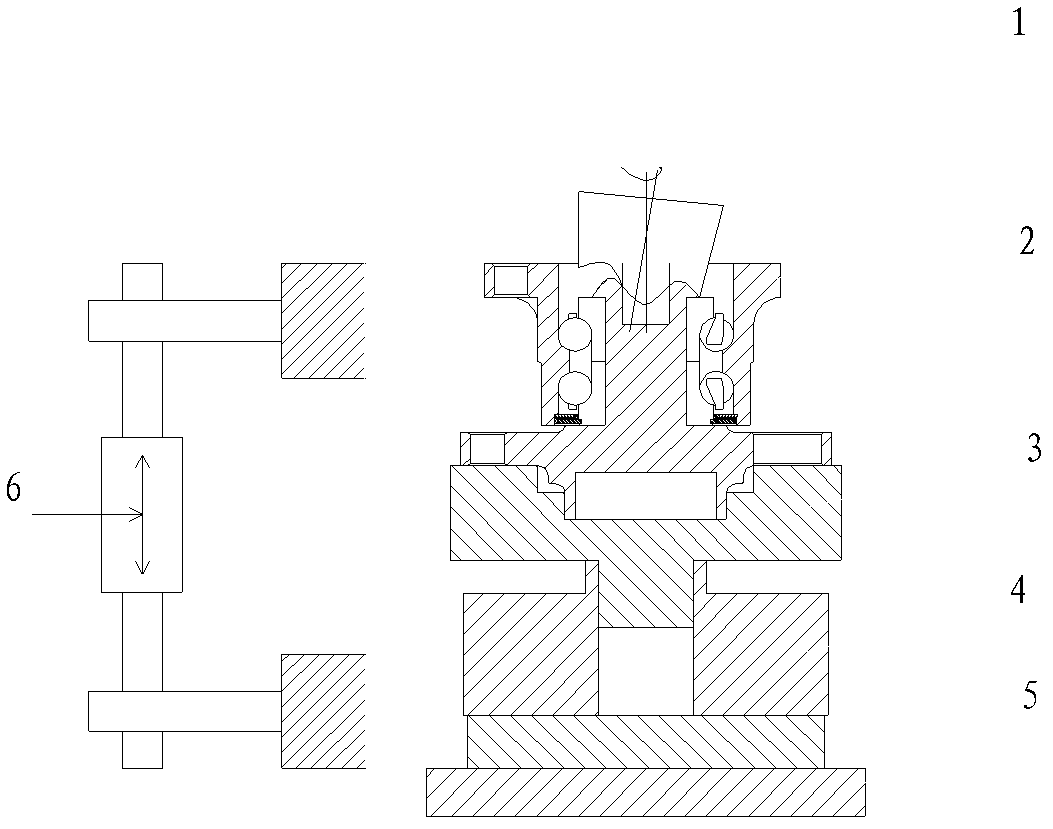

[0030] Such as figure 1 shown. The hub bearing unit 2 is assembled on the riveting machine 1, and the hub bearing unit 2 to be assembled is placed in the transition sleeve 3 of the pressure sensor 4 for positioning, and the pressure sensor 4 is fixed on the workbench of the riveting machine through the transition sleeve 3 5 on. When the main shaft of the riveting machine goes down, the force exerted by the riveting head on the hub bearing unit is transmitted to the pressure sensor 3 through the lower die. The pressure signal generated on the pressure sensor 3 is sent to the data acquisition card (not shown in the figure) after being amplified by the transmitter, and then input to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com