Friction-wear testing machine capable of realizing variable gravity orientation and testing method

A friction and wear test, gravity technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of high cost, cumbersome operation, long time, etc., and achieve simple and easy technical means, good space environment, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

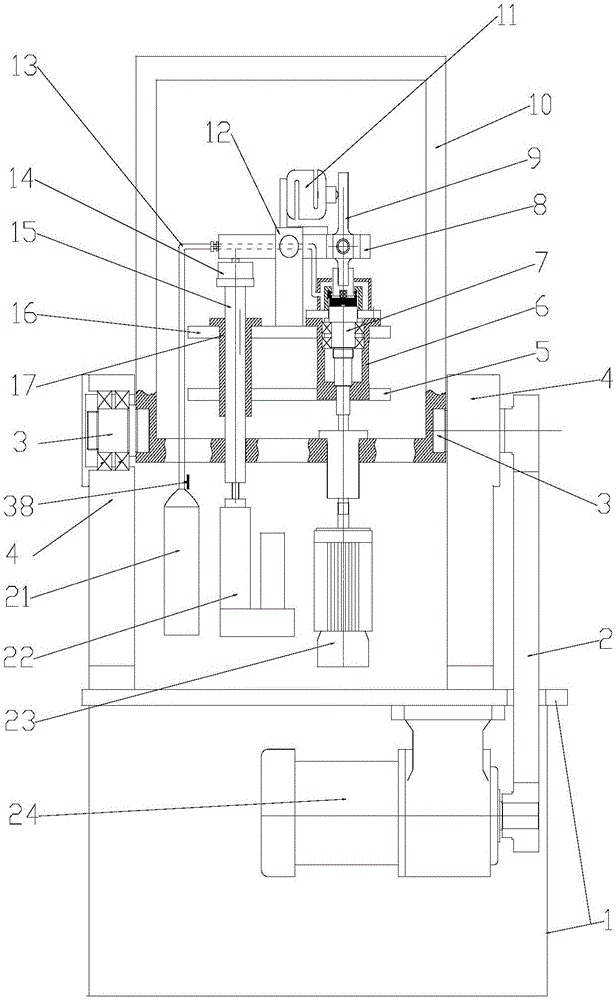

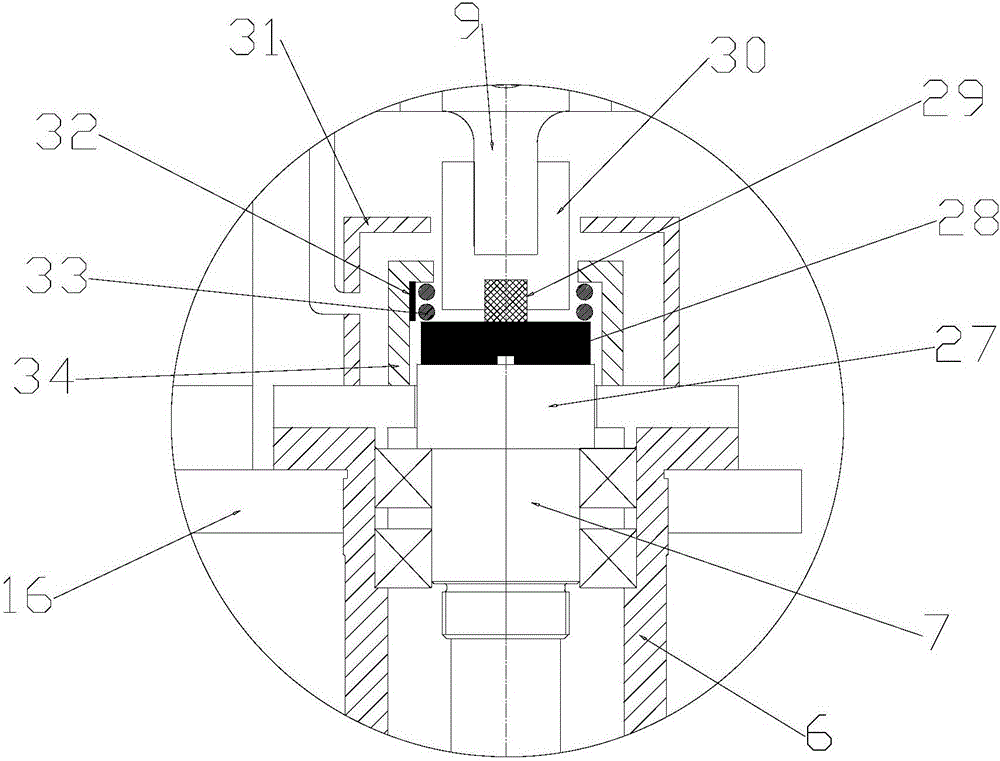

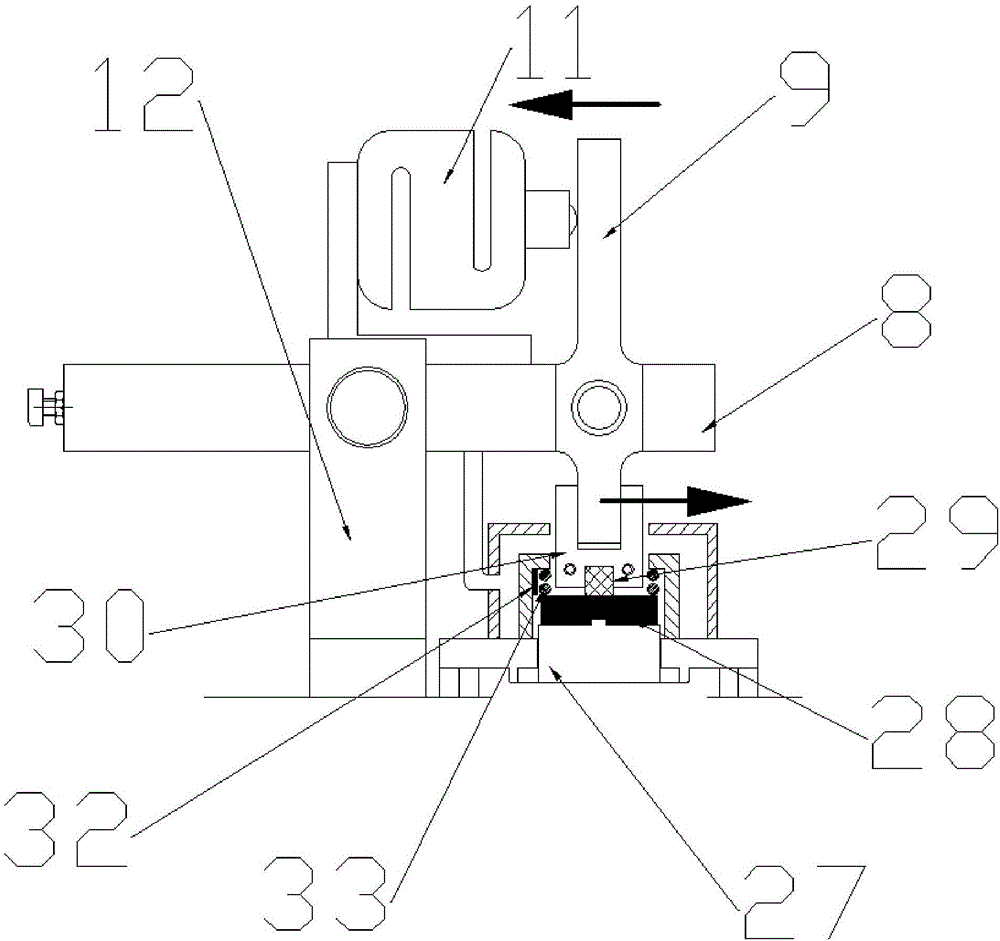

[0042] like Figures 1 to 5 shown. The invention discloses a friction and wear testing machine with variable gravity orientation, comprising a main frame 1 and a rotating shaft 3; the rotating shaft 3 is supported above the main frame 1 by support columns 4 installed on both sides of the main frame The drive mechanism installed under the mainframe bracket 1 drives it to rotate;

[0043] A vacuum box 10 is fixedly installed on the rotating shaft 3; a support frame 5 is arranged in the vacuum box 10, and a lever mechanism and a rotating mechanism are installed side by side on the support frame 5; the lever mechanism and the rotating mechanism are placed from top to bottom. The upper sample 29 and the lower sample 28; the lever mechanism provides the downward pressure to the upper sample 29 during the test, and the rotating mechanism provides the rotation torque to the lower sample 28 during the test;

[0044] When the driving mechanism drives the rotating shaft 3 to rotate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com