Full automatic heat pipe degassing and sealing device

A fully automatic and heat pipe technology, applied in the field of automatic heat pipe degassing and sealing devices, can solve the problems of inconvenient popularization and promotion, and difficulty in ensuring the sealing quality of heat pipes, achieve positive technical effects and popularization and application value, and the technical means are simple and easy to implement. The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

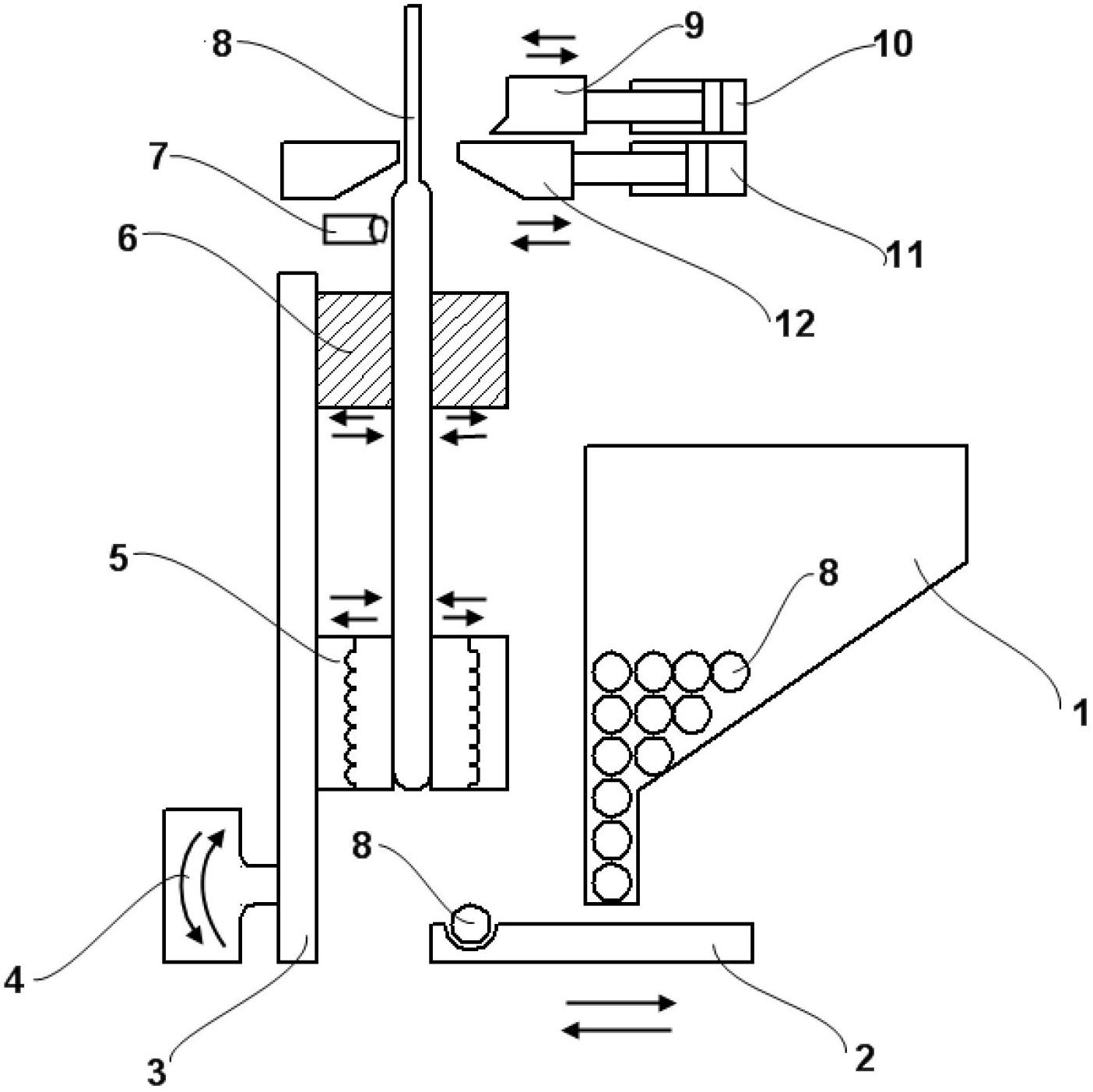

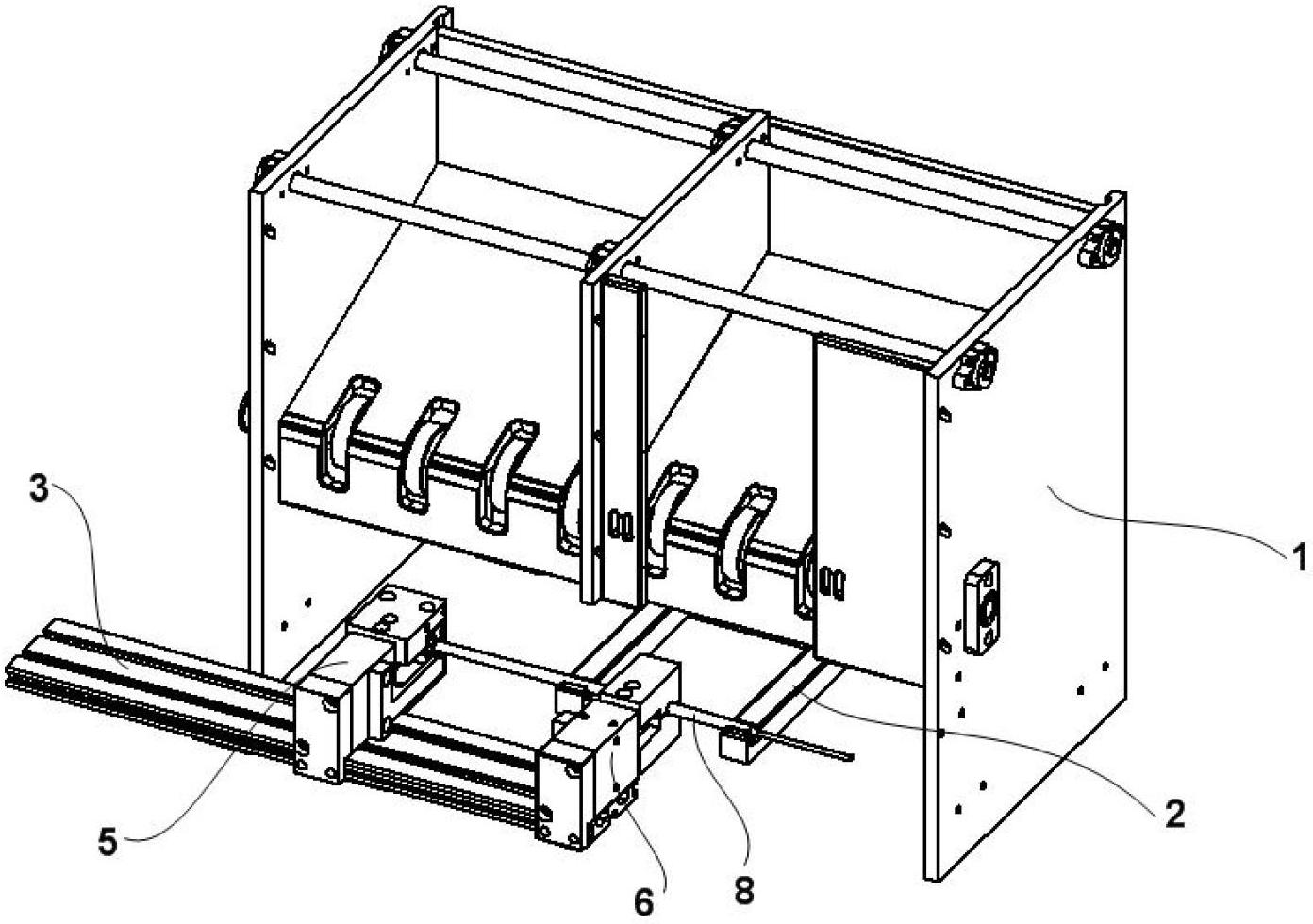

[0021] Such as figure 2 , image 3 , Figure 4 , Figure 5 shown. The full-automatic heat pipe degassing and sealing device of the present invention includes a feeding mechanism connected to a control system, a transmission mechanism, and a molding mechanism. The feeding mechanism includes a collecting hopper 1 and a feeding arm 2, and the feeding arm 2 is correspondingly arranged and the lower end of the collecting hopper 1;

[0022] The transmission mechanism includes a rotating arm 3, a rotating cylinder 4, and an air claw 5 with a heating rod. The rotating cylinder 4 is arranged at the lower end of the rotating arm 3, and the lower end of the rotating arm 3 is placed on one side of the feeding arm 2. , the air gripper 5 with a heating rod is arranged in the middle of the rotating arm 3;

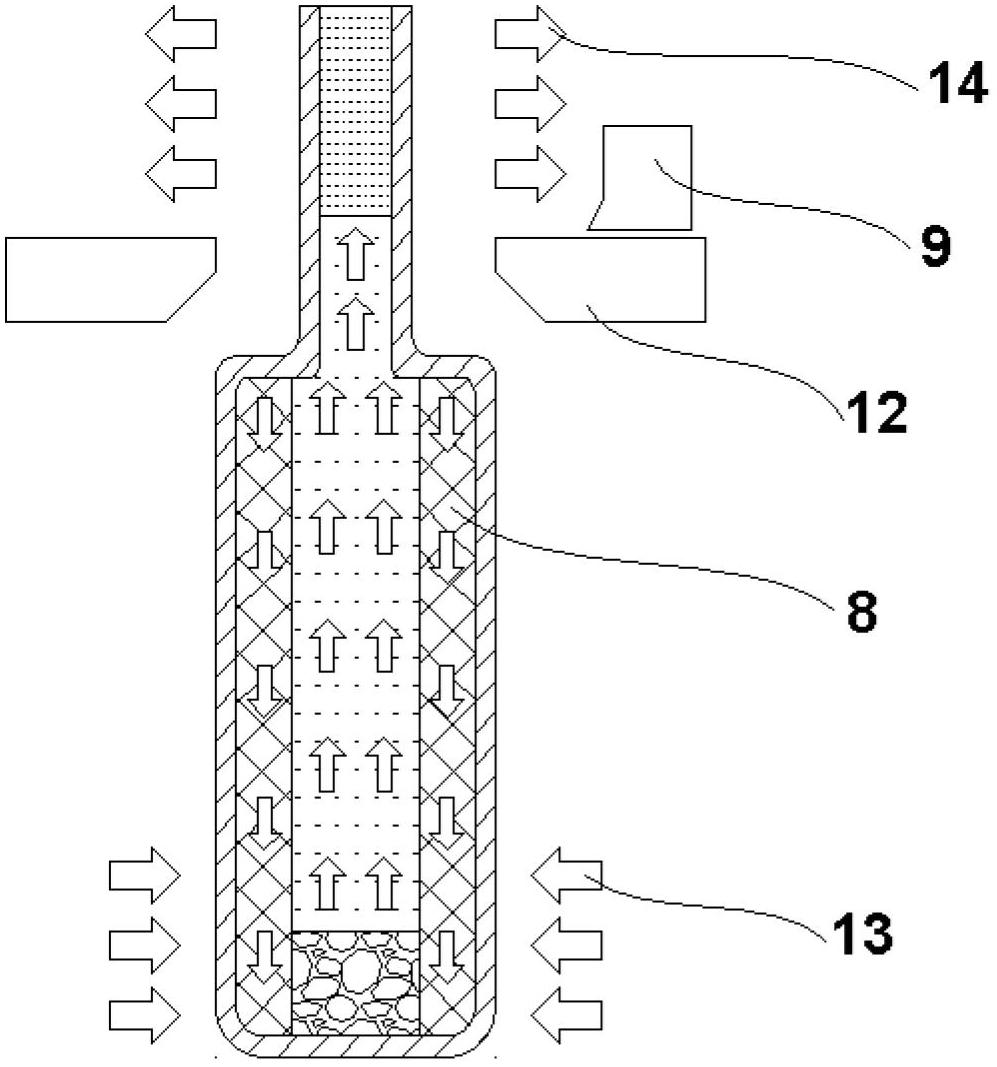

[0023] The molding mechanism includes a clamping air claw 6, a thermocouple 7, a shearing knife 9, a shearing cylinder 10, a flattening cylinder 11, and a flattening mold 12. The cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com