Method for manufacturing thin film transistor based on anodic oxidation insulating layer

A technology for oxidizing insulating layers and thin-film transistors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of low conductivity and difficulty in meeting the needs of large-area preparation, and achieve low preparation temperature and suppression of hillocks. Good growth and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

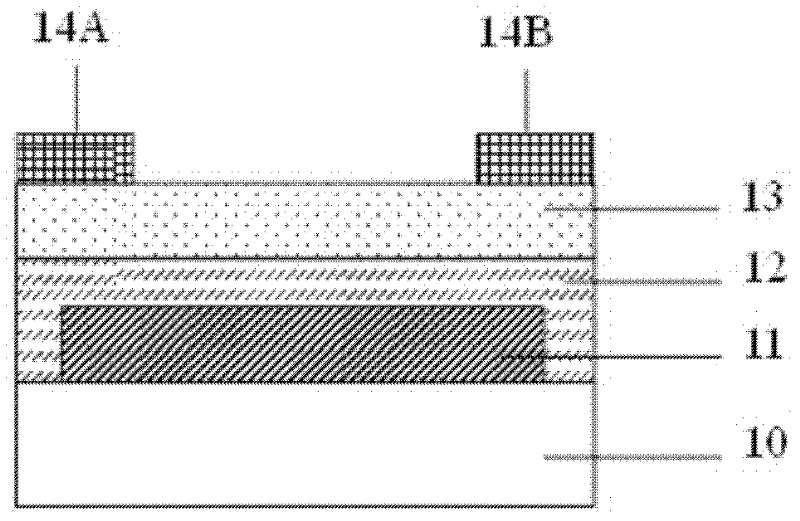

[0047] In this embodiment, a thin-film transistor (a schematic diagram of its structure is shown in Figure 1A shown).

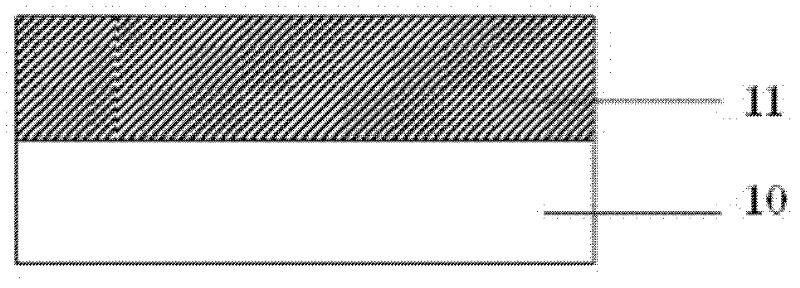

[0048] Wherein, the material of the glass substrate 10 is alkali-free glass with a thickness of 0.4 mm;

[0049] The material of the gate 11 is Al x Nd y (x=0.99, y=0.01), prepared by sputtering, the background vacuum of sputtering is better than 1×10 -3 Pa, argon gas pressure is 0.6Pa, power is 10W / cm 2 , with a thickness of 300nm, formed by photolithography;

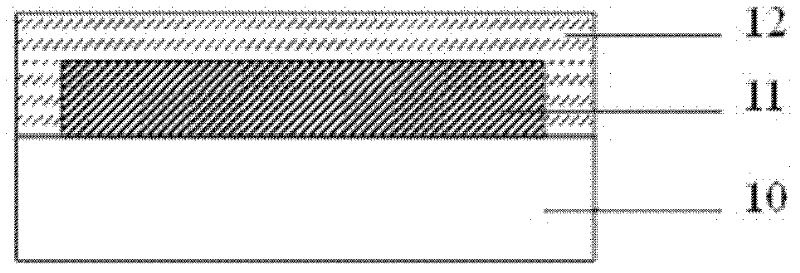

[0050] The single oxidized insulating layer 12 is prepared by anodic oxidation. The electrolyte solution used in the anodic oxidation can be a mixture of ammonium tartrate and ethylene glycol. Put the prepared grid 11 substrate and stainless steel plate into the electrolyte solution as the anode respectively. and cathode, first apply a constant current of 0.1mA / cm between the anode and the cathode 2 , the voltage between the anode and the cathode will increase linearly with time, when the voltag...

Embodiment 2

[0055] In this embodiment, a thin-film transistor (a schematic diagram of its structure is shown in Figure 1A shown).

[0056] Wherein, the material of the glass substrate 10 is alkali-free glass with a thickness of 0.4mm;

[0057] The material of the gate 11 is Al x Nd y (x=0.97, y=0.03), prepared by sputtering, the background vacuum of sputtering is better than 1×10 -3 Pa, argon gas pressure is 0.6Pa, power is 10W / cm 2 , with a thickness of 300nm, formed by photolithography;

[0058] The single oxidized insulating layer 12 is prepared by anodic oxidation. The electrolyte solution used in the anodic oxidation can be a mixture of ammonium tartrate and ethylene glycol. Put the prepared grid 11 substrate and stainless steel plate into the electrolyte solution as the anode respectively. and cathode, first apply a constant current of 0.1mA / cm between the anode and the cathode 2 , the voltage between the anode and the cathode will increase linearly with time, when the voltage...

Embodiment 3

[0063] In this embodiment, a thin-film transistor (a schematic diagram of its structure is shown in Figure 1A shown).

[0064]Wherein, the material of the glass substrate 10 is alkali-free glass with a thickness of 0.4mm;

[0065] The material of the gate 11 is Al x Nd y (x=0.9, y=0.1), prepared by sputtering, the background vacuum of sputtering is better than 1×10 -3 Pa, argon gas pressure is 0.6Pa, power is 10W / cm 2 , with a thickness of 300nm, formed by photolithography;

[0066] The single oxidized insulating layer 12 is prepared by anodic oxidation. The electrolyte solution used in the anodic oxidation can be a mixture of ammonium tartrate and ethylene glycol. Put the prepared grid 11 substrate and stainless steel plate into the electrolyte solution as the anode respectively. and cathode, first apply a constant current of 0.1mA / cm between the anode and the cathode 2 , the voltage between the anode and the cathode will increase linearly with time, when the voltage re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com