Carbon paper continuous production method capable of automatically controlling impregnation amount

A technology of impregnation, carbon paper, applied in the direction of paper, paper, textile and paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

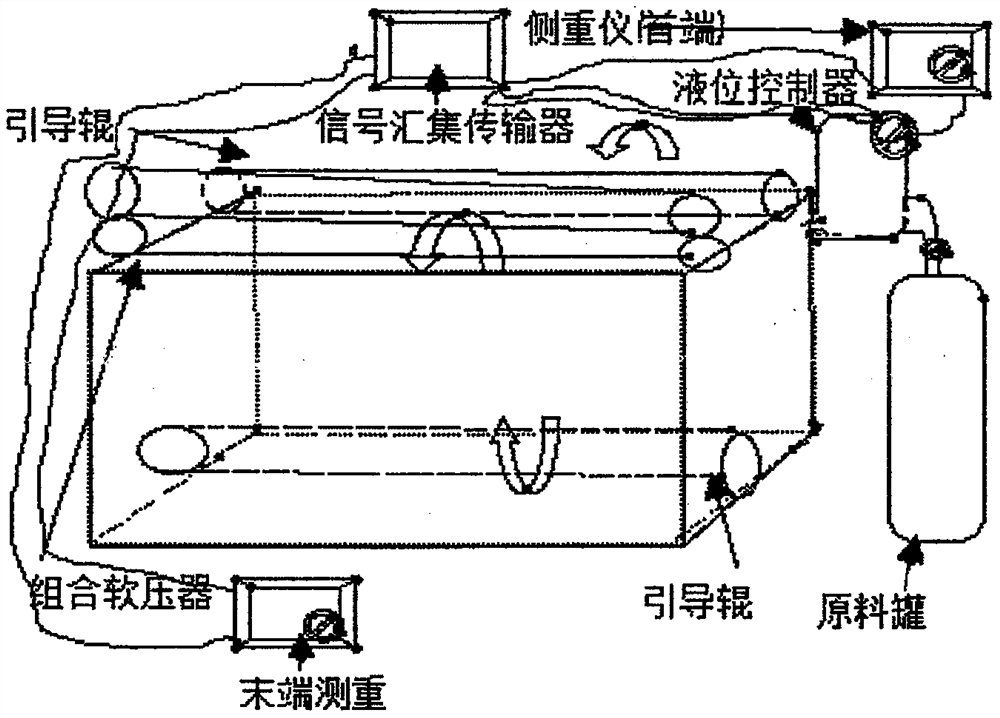

[0006] A carbon paper continuous production method for automatic control of impregnation. The method has a PTFE (polytetrafluoroethylene) impregnator, which is connected to the PTFE liquid level controller, and the liquid level controller is connected to the tank containing the impregnated raw material PTFE (polytetrafluoroethylene), and the first end automatic weight gauge. Preset Automatic Control Program (Signal Collection Output Processor - Abbreviation Signal Transmitter). Carbon-based paper production diameter setting: 80cm, keep the header focus on substantially consistent. The impregnator depth is 0.9 meters, which is 0.4 meters wide. The bottom is provided with a circular guide roller. There are two circular guiding rollers in the upper portion, and the carbon retained paper is entered by the upper leading roller, and the lower guide roller, and then the other The guide roller out of the impregnator is designed as a soft roller, and then a soft roller is added, and the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com