Method for producing hot stamping forming bulletproof piece

A technology of hot stamping forming and production method, which is applied in the technical field of bulletproof parts, and can solve the problems of increased weight, decreased anti-ballistic performance of welded seams, and high rejection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

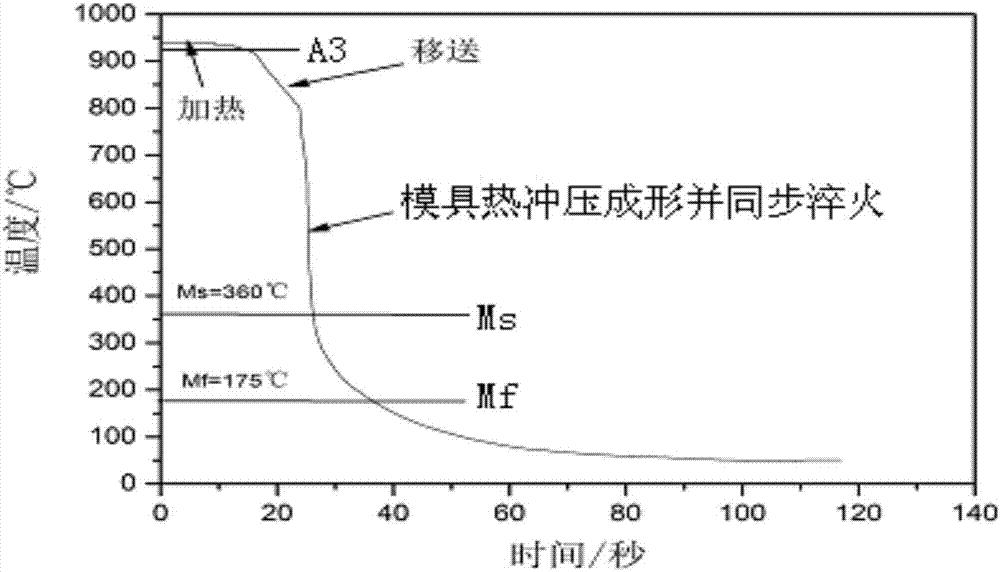

[0023] Embodiment 1: implement the product and the method of the production method of a kind of hot stamping bulletproof part of the present invention as follows: be the 30CrNiMo steel plate of 2.3mm to produce the bulletproof escape compartment top cover with thickness, after laser blanking, steel plate is in box-type electric furnace The quenching heating temperature is 880-920°C, the holding time is plate thickness × (2-3) min / mm, it is transferred to the mold within 10s for stamping, the holding pressure is 400 tons, cooling water is passed through the mold, and the parts are stamped during the stamping process. The average cooling rate is 53°C / s (cooling curve such as figure 1 shown), the holding time is 30s, and then tempered at 200 °C, and the holding time is plate thickness × 3min / mm. The detected hardness and tensile test data are shown in Table 1. The target test results prove that this part can protect the penetration of Type 51B pistol bullets fired by Type 79 sub...

Embodiment 2

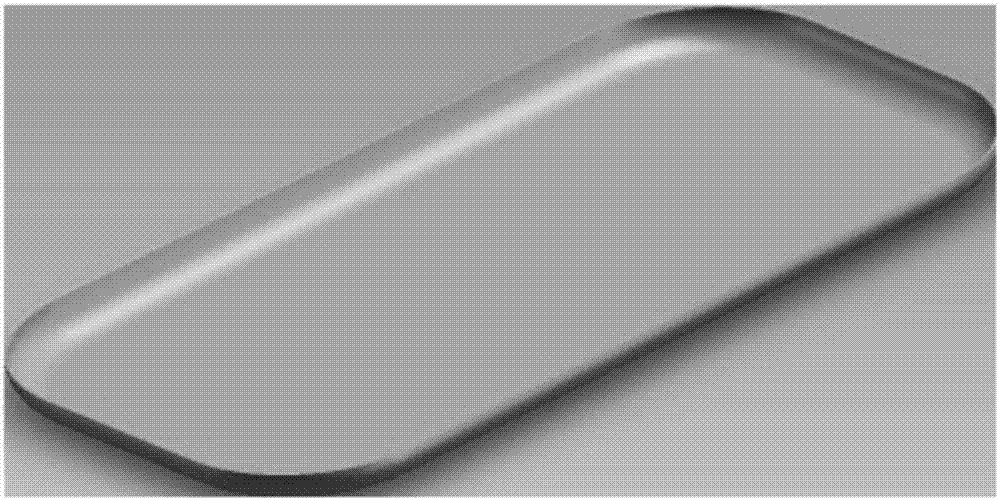

[0026] Embodiment 2: implement the product and the method of the production method of a kind of hot stamping forming bullet-proof part of the present invention as follows: be that the 40CrNiMo steel plate of thickness 6.2mm is used to produce bullet-proof clothing insert plate, after steel plate is blanked, heat at 900 ℃, holding time Thickness × (2 ~ 3) min / mm, it has been sent to the mold for stamping within 5s, cooling water is passed through the mold, the cooling rate is 40°C / s, the holding pressure is 400 tons, and the holding time is 30s. Then temper at 200°C, and the holding time is plate thickness × 3min / mm. The detected hardness and tensile test data are shown in Table 2. The target test results prove that the part can protect against the penetration of the 7.62mm NATO bullet fired by the M14 rifle according to the UL752-8 standard. Photos of parts such as Figure 4 As shown, compared with the production mode of traditional first cold forming before heat treatment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com