Jaw vice based simple drilling mould for hexagonal nut fuse wire hole and processing method for jaw vice based simple drilling mould

A hexagonal nut and fuse technology, which is applied to drill dies for workpieces, metal processing equipment, metal processing machinery parts, etc. problems, to achieve the effect of simplifying product processing operations, ensuring product quality consistency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

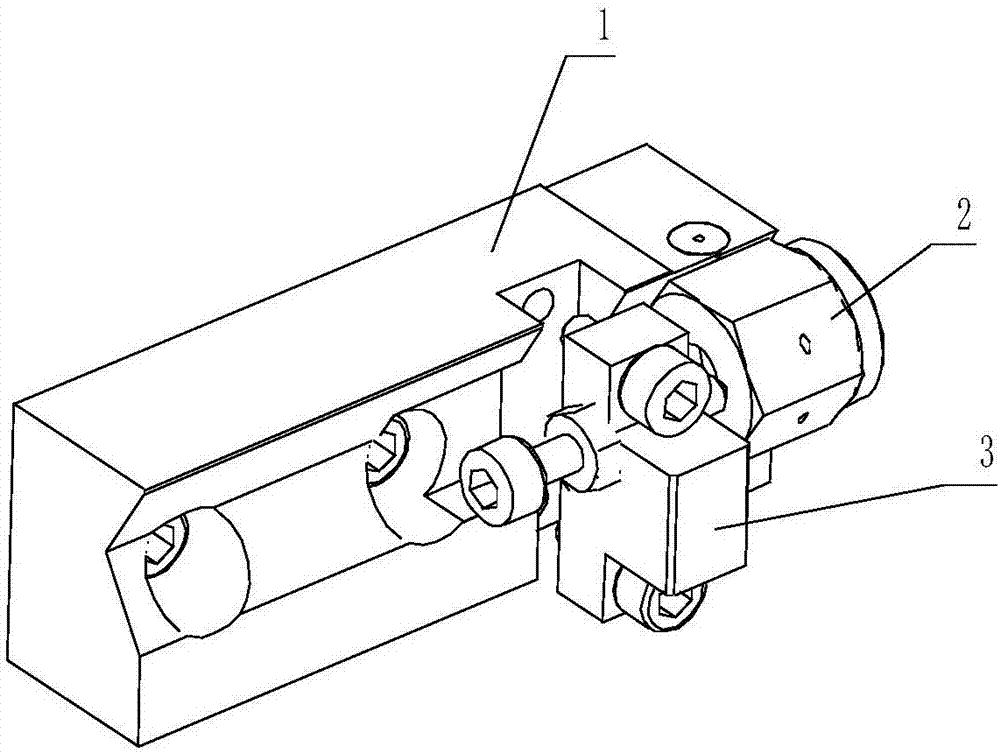

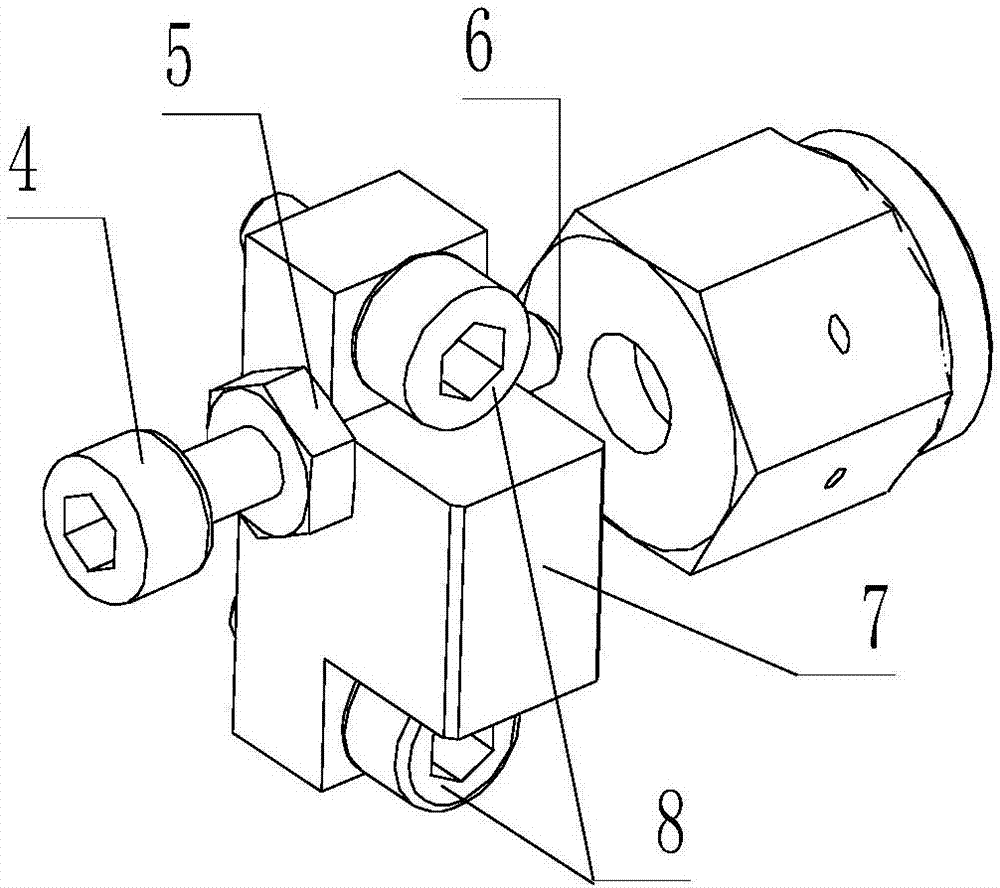

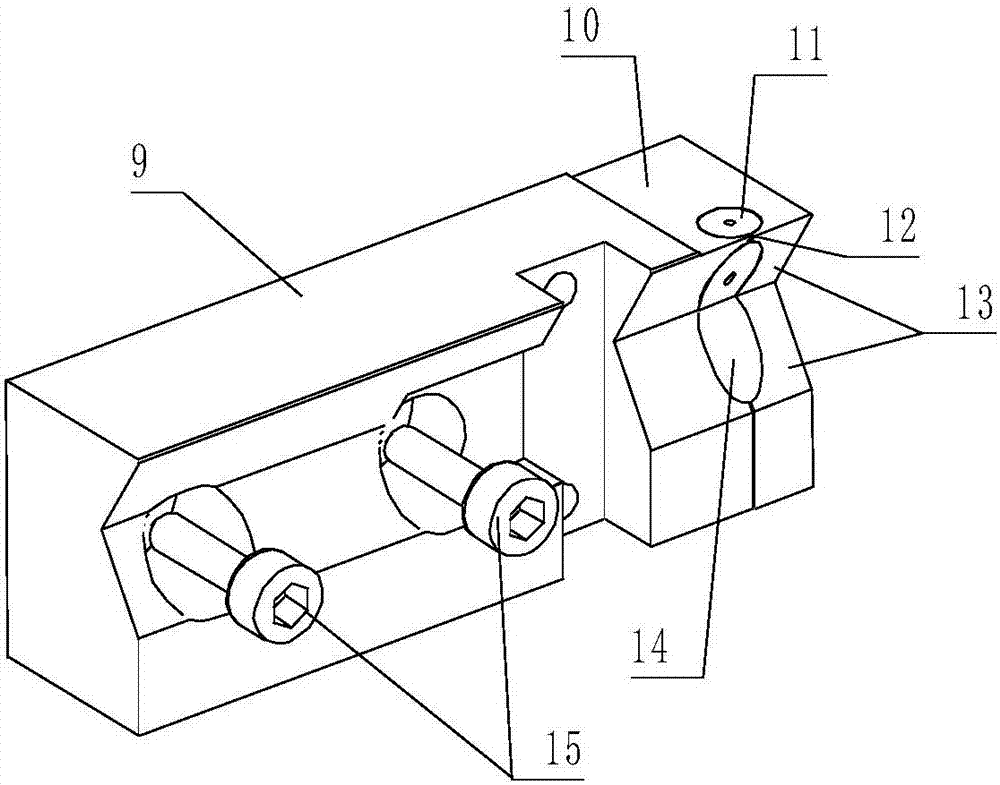

[0030] The invention relates to a vise-based simple drilling mold for fuse holes of hexagon nuts, which is used for positioning and processing the fuse holes of hexagon nuts of aircraft pipeline components. The invention mainly consists of an adjustable positioning device and a V-shaped positioning base. The adjustable positioning device is used to realize one-time clamping and positioning of the product; the V-shaped positioning base is a mechanism to realize the mechanical connection between the adjustable positioning device and the vise (the vise can be fixed on the table top of the bench drilling machine). The vise-based hex nut fuse hole is machined as follows:

[0031] 1, the simple and easy drilling template of hex nut fuse hole based on vise of the present invention comprises adjustable positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com