Micro-torque and large-pressure nut

A high-pressure, micro-torque technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of affecting the positioning accuracy of the wheel, the rebound of the screw, and the large application, so as to reduce labor intensity and ensure clamping Effect of positioning accuracy and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

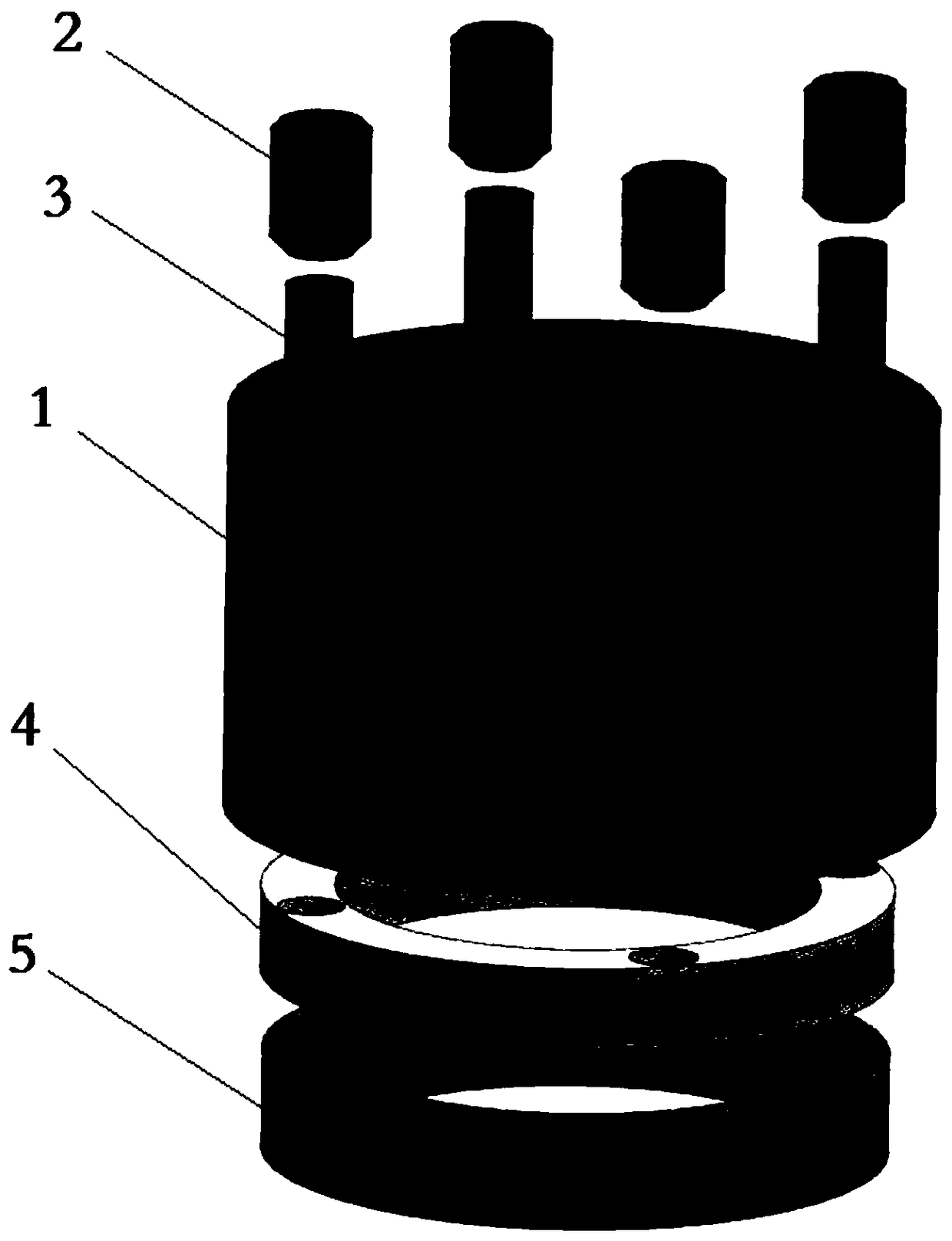

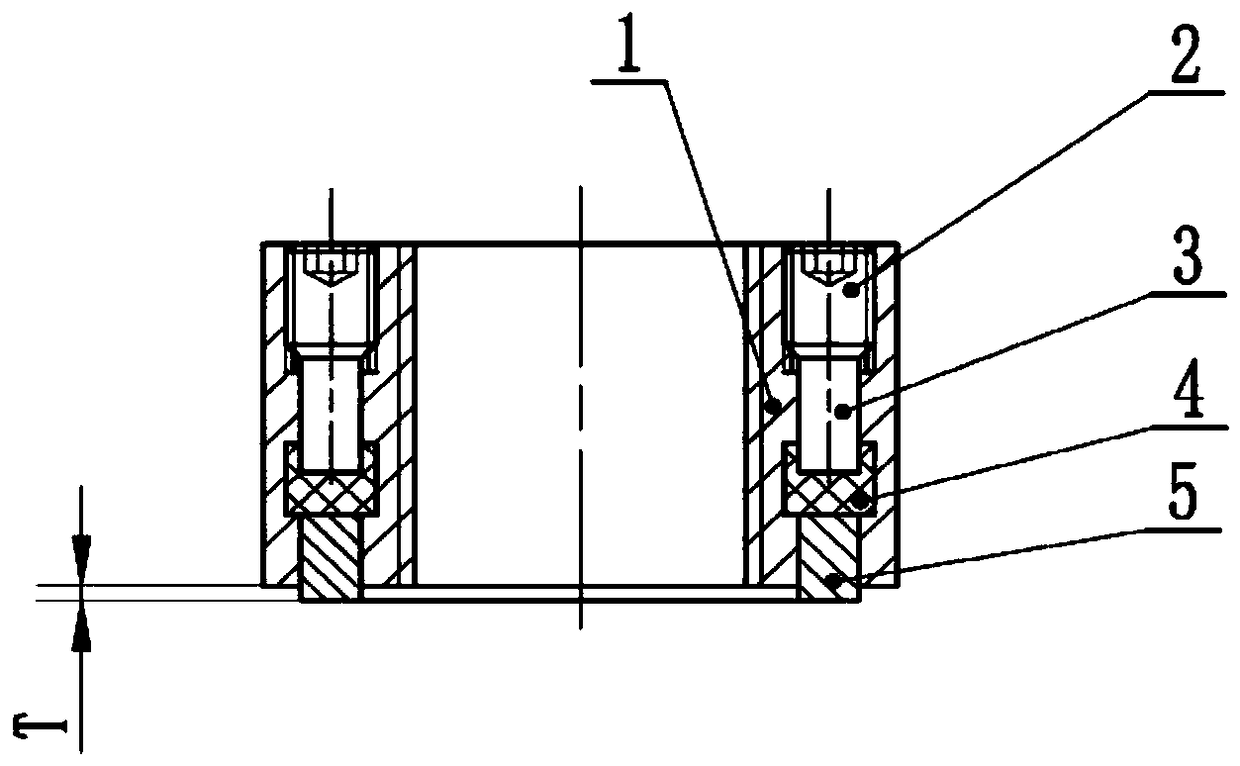

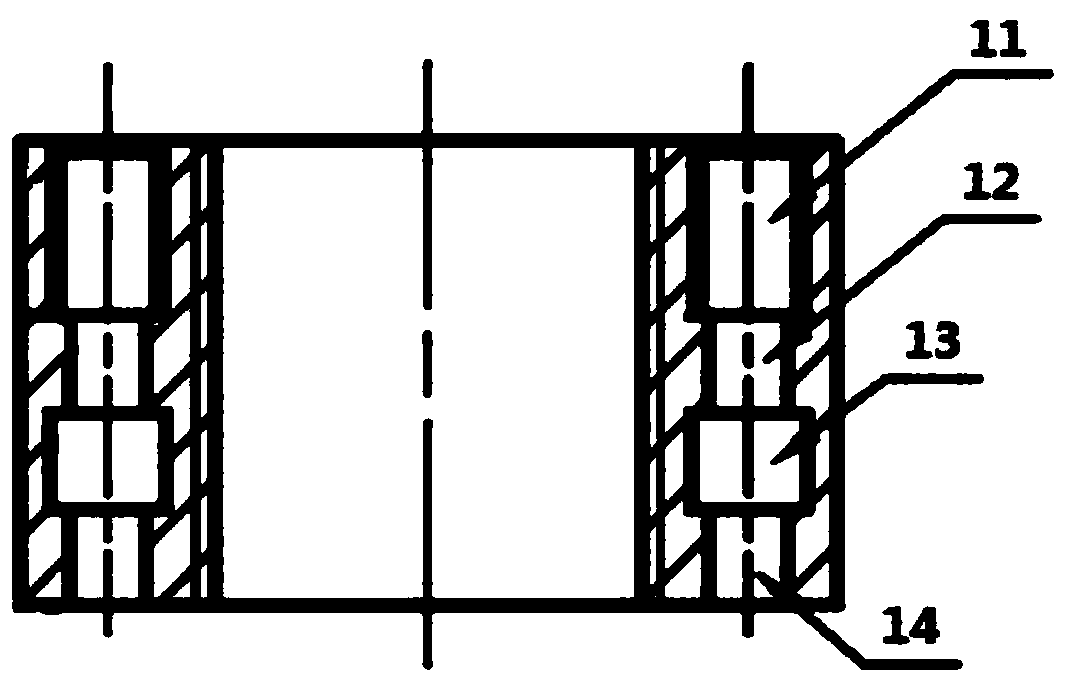

[0021] Such as Figure 1-3 As shown, a micro-torque high-pressure nut includes a nut shell 1, a set screw 2, a sliding column 3 and a compression ring 5, wherein the lower end surface of the nut shell 1 is provided with a circle of pressure ring groove 14, along which the pressure ring groove 14 is provided with a circle of plastic ring grooves 13 upwards, and along the plastic ring grooves 13, there are a plurality of spool holes 12 parallel to the axis of the nut. It communicates with the upper end surface of the nut shell 1; the set screw 2 is placed in the screw hole 11, the spool 3 is placed in the spool hole 12, the plastic ring groove 13 is filled with liquid plastic 4, and the compression ring 5 is placed in the Press ring groove 14.

[0022] Further, the plurality of spool holes 12 are evenly distributed on the nut housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com