Automatic rib-penetrating device

A technology of automatic wear and equipment, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of high labor cost, heavy burden on operators, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

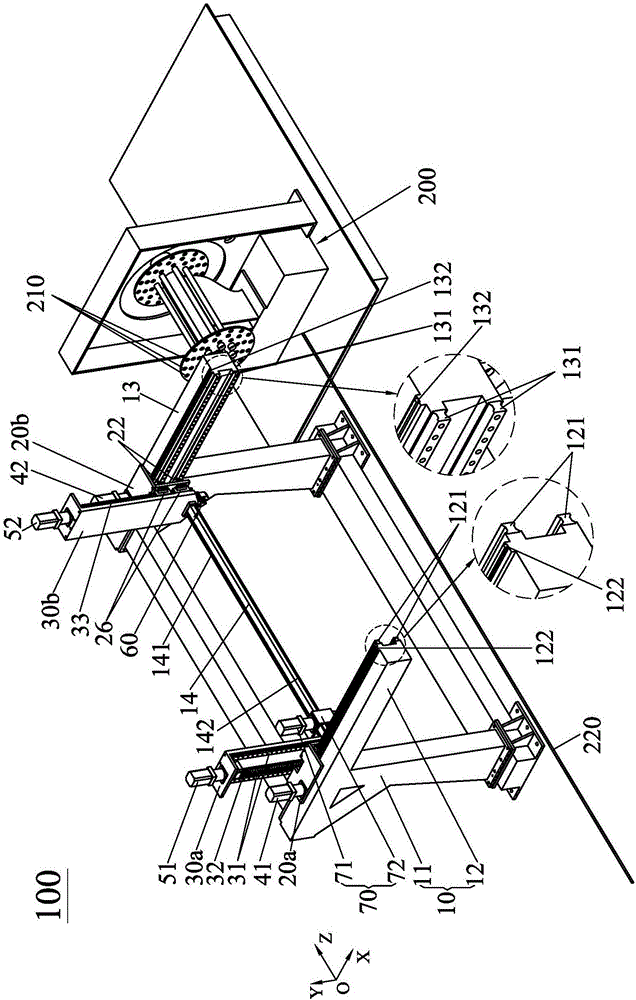

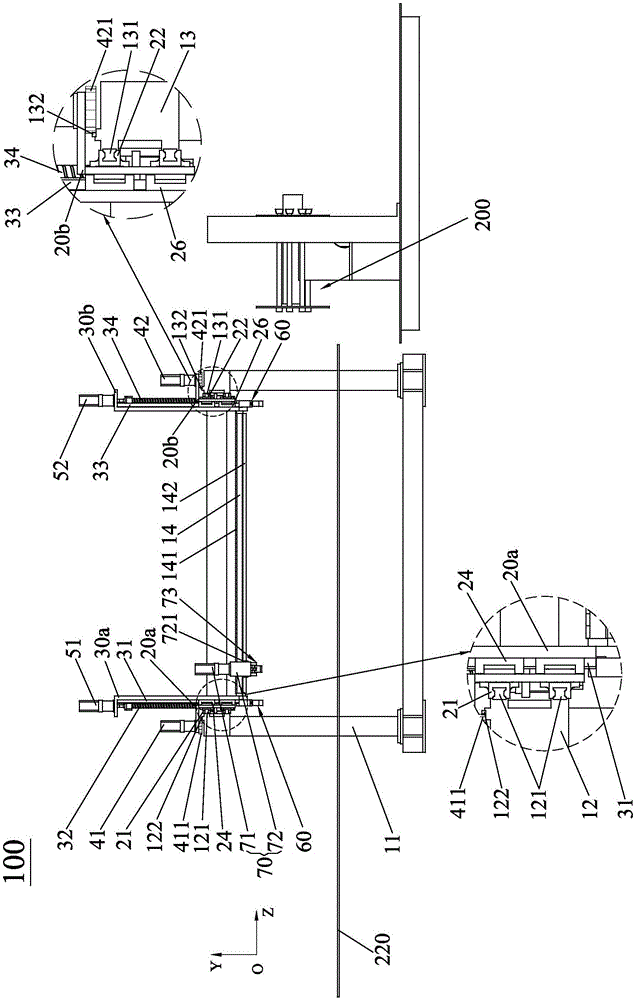

[0021] see figure 1 , the automatic tendon threading device 100 of the present invention is suitable for inserting strips of ribs 220 into different rib holes 210 of the model base 200; specifically, as figure 1 As shown, in this embodiment, the reinforcement holes 210 are arranged along the circumference of the model seat 200; for example, the reinforcement holes 210 are arranged in several circles in the model seat 200, for example figure 1 The three circles shown in , of course, can also be one circle, two circles or four circles, etc., and the center angles occupied by the rib holes 210 in the same circle are the same to ensure that the ribs 220 are arranged reasonably uniformly, but not This is the limit; preferably, the automatic tendon threading equipment 100 of the present invention is electrically connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com