Rotating disc type automatic voltage reduction device for lithium-manganese button cells

A button-type battery and step-down device technology is applied in primary batteries, equipment for manufacturing primary batteries, and battery assembling machines. The effect of stability and consistency, labor intensity reduction, labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

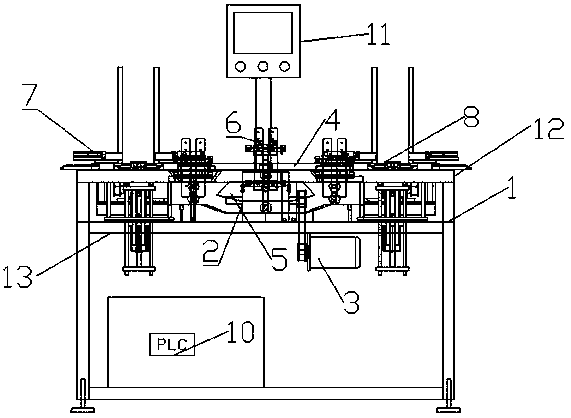

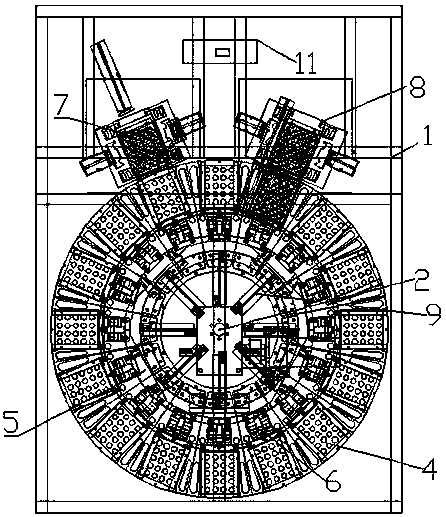

[0017] Such as Figure 1-2 As shown, the present invention provides a lithium-manganese button battery turntable automatic decompression device, including a frame 1, an upper plate 12 and a lower plate 13 are arranged on the frame 1, and an upper plate 12 is provided on the upper plate 12. Material mechanism 7, discharging mechanism 8 and touch screen 11, described lower plate 13 is provided with speed regulating motor 3 and cam divider 2, and described upper plate 12 is also provided with cam mechanism 5, and described cam mechanism 5 comprises cam With the scroll wheel, the output end of the speed regulating motor 3 is connected to the cam, one side of the cam is in contact with the scroll wheel, the top of the cam divider 2 is connected with a step-down turntable 4, and the other side of the cam Connected with the cam divider 2, a step-down mechanism 6 is provided above the step-down turntable 4, a step-down electrical cabinet 9 is provided on one side of the step-down mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com