Method and system for purifying NMP in coating process of lithium ion battery

A technology of lithium-ion batteries and purification methods, which is applied in the field of NMP purification methods and systems in the coating process of lithium-ion batteries, can solve the problems of ineffective recycling, inconvenient production docking, and increased costs, so as to ensure product quality consistency, The effect of reducing procurement costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with specific examples, further illustrate the present invention, the examples are implemented under the premise of the technical solutions of the present invention, it should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

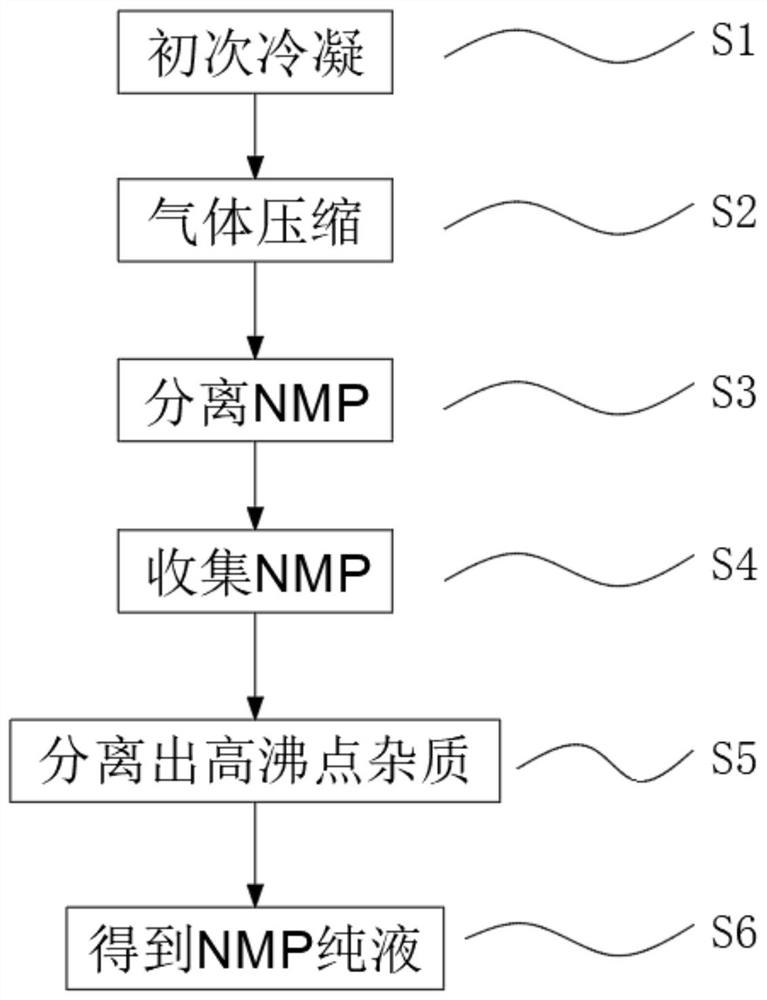

[0057] see figure 1 , in an embodiment of the present invention, a lithium-ion battery coating process NMP purification method, comprising the following steps:

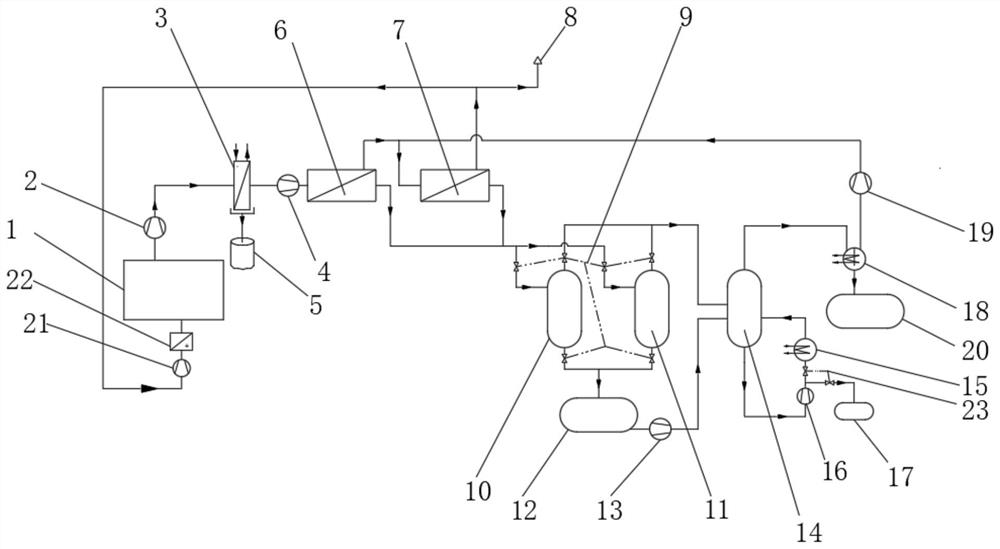

[0058] S1: initial condensation, that is, the high-temperature exhaust gas containing NMP is condensed through the pre-cooling surface cooler 3, and a small amount of NMP liquid is condensed and sent to the first NMP liquid storage tank 5;

[0059] S2: gas compression, that is, the exhaust gas after the initial condensation is compressed by the compressor 4;

[0060] S3: Separating NMP, that is, separating the exhaust gas compressed by the compressor 4 through the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com