High-voltage planar switch structure based on flexible manufacturing process and preparation method of structure

A planar switch, flexible manufacturing technology, applied in the direction of electric switch, closed switch, explosive switch, etc., can solve the problems of being easily affected by strong vibration and strong electromagnetic radiation environment, the limitation of actual use occasions, and the limitation of working voltage range, so as to achieve convenient Effects of high-volume manufacturing, fast response time, and fast switching response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

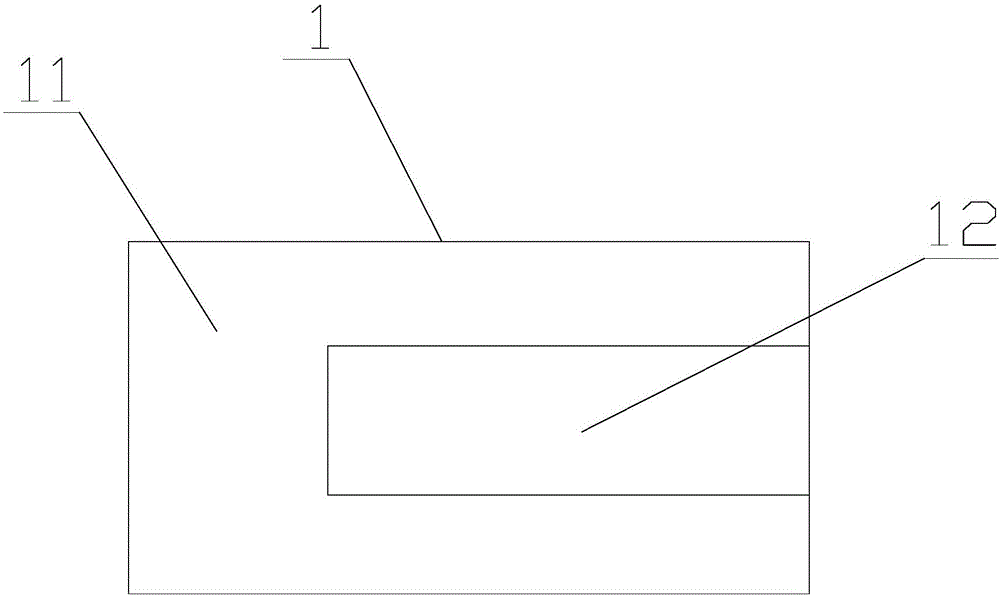

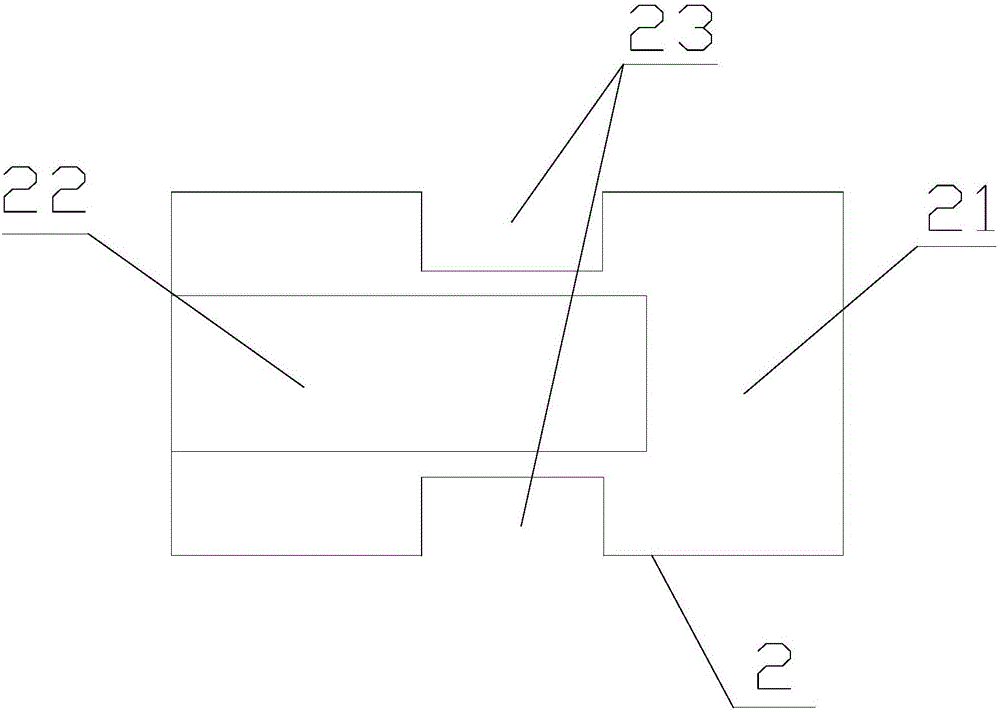

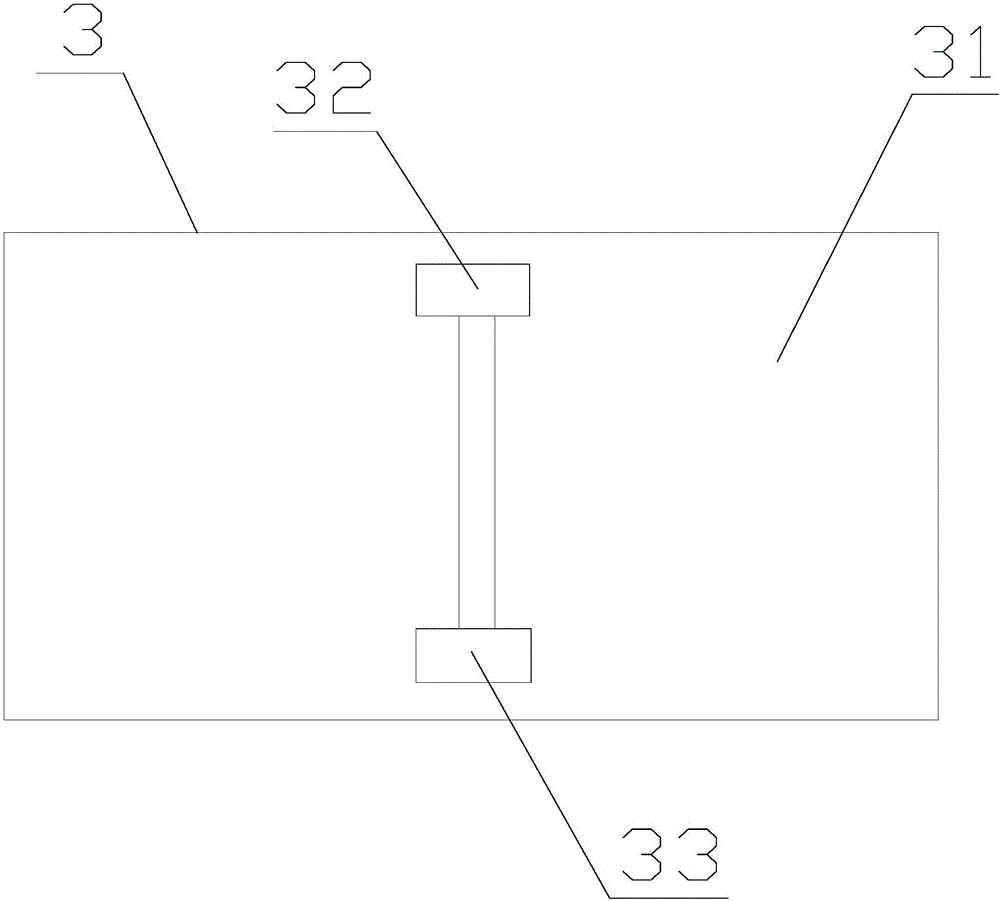

[0026] Such as Figure 1 ~ Figure 4 As shown, a high-voltage planar switch structure based on a flexible manufacturing process includes a positive electrode plate 1, a negative electrode plate 2 and a signal input plate 3, and the positive electrode plate 1 includes a positive plate insulating substrate 11 and an insulating liner arranged on the positive plate The positive electrode 12 on the bottom 11 has a thickness of several microns; the positive electrode plate 1 has a rectangular shape as a whole, and the positive electrode 12 has a rectangular shape as a whole. Negative electrode plate 2 comprises negative electrode plate insulating substrate 21 and the negative electrode 22 that is arranged on the negative electrode plate insulating substrate 21, and negative electrode 22 thickness is several microns; Negative electrode plate 2 is the rectangular shape corresponding to positive electrode plate 1, The negative electrode 22 has a rectangular shape as a whole. The signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com