Full-hydraulic plate-edge pre-bending device and method for thick-wall metal longitudinal welded pipes

A straight seam welded pipe, full hydraulic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems affecting product quality, low production efficiency, affecting the consistency of pipe thickness, etc., to ensure product quality consistency, High efficiency and precision control, effect of avoiding thinning phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

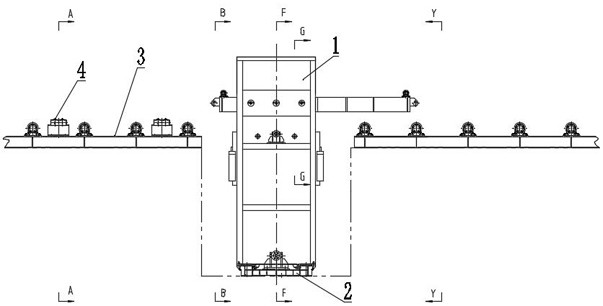

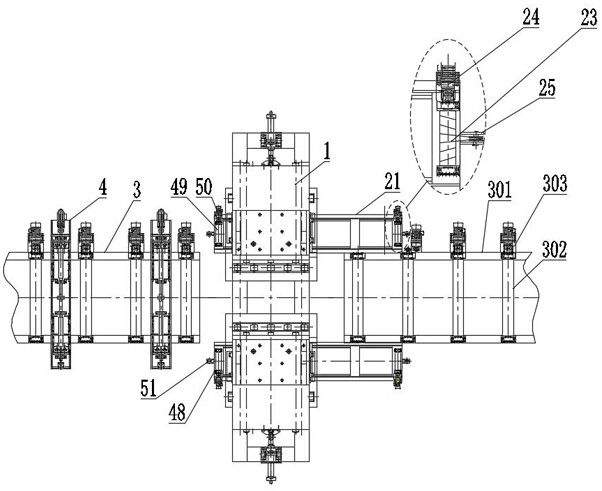

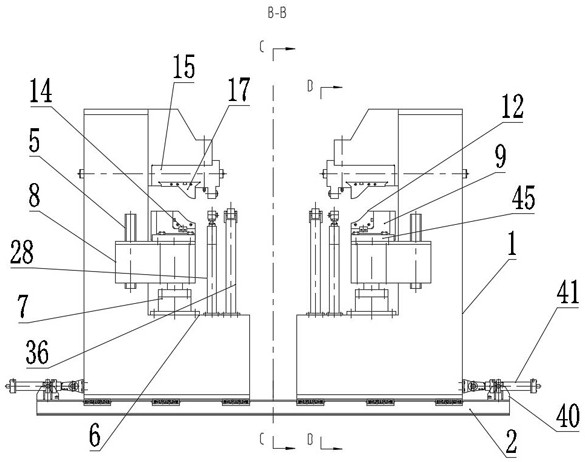

[0032] Such as Figure 1 to Figure 14 As shown, a full-hydraulic pre-bending device for thick-walled metal straight seam welded pipe plates includes a frame body 1 arranged symmetrically on the left and right, and the frame body 1 is installed on the lower bottom plate 2, and the Frame slide rail 38, the frame main body 1 is slidably arranged on the frame slide rail 38, and the lower ends of the left and right sides of the frame main body 1 are all provided with limit blocks 39, so that the frame main body 1 and the lower base plate 2 For the limit in the up and down direction, support blocks 40 are arranged on the left and right sides of the lower base plate 2, and a propulsion hydraulic cylinder 41 is arranged on the support block 40, and the piston rod of the propulsion hydraulic cylinder 41 is connected with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com