Process for treating ammonia nitrogen wastewater by gas-state membrane

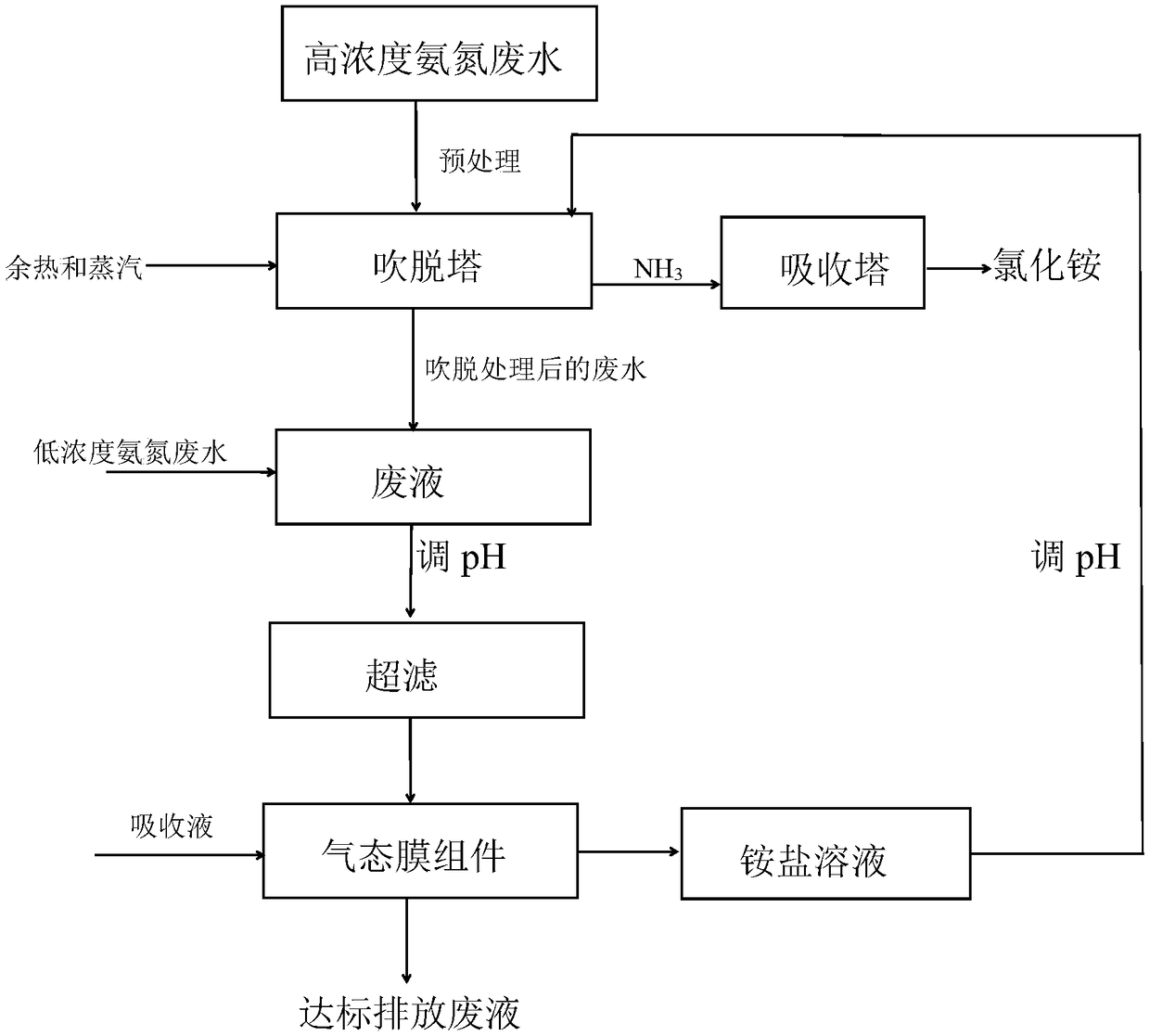

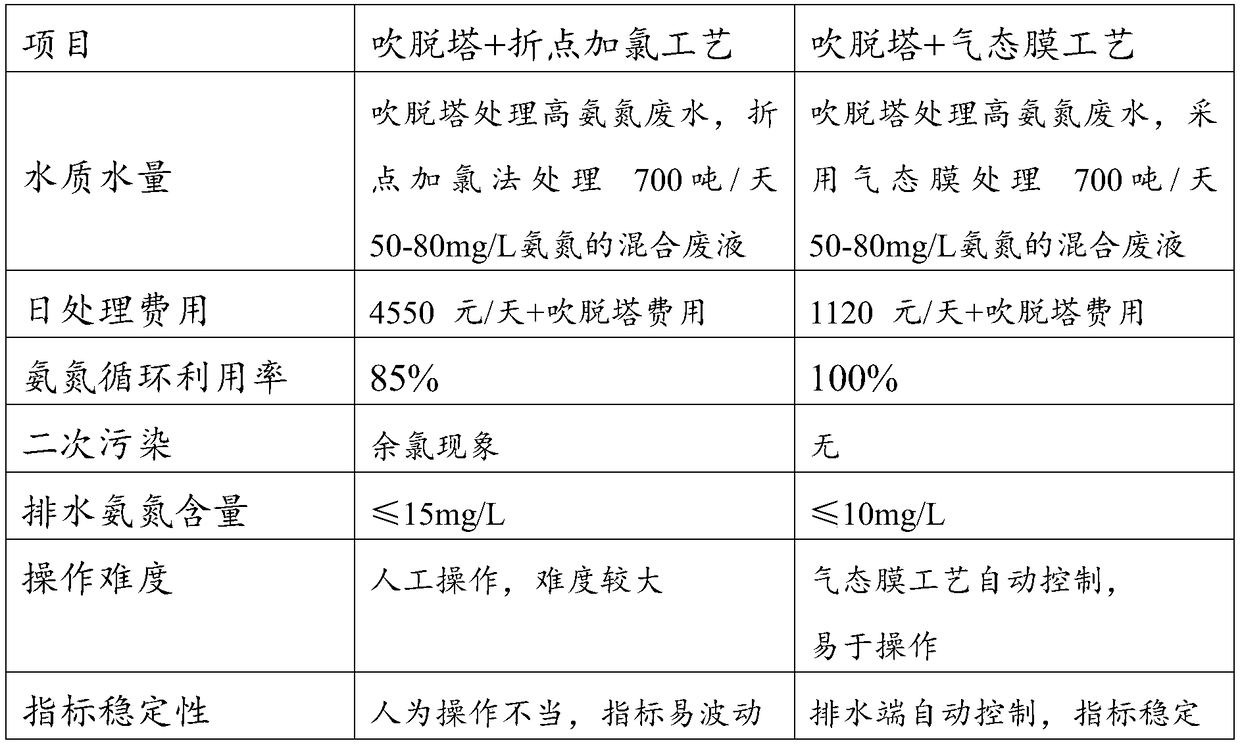

A technology for ammonia nitrogen wastewater and gaseous membranes, applied in degassed water/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Shorten service life and other problems, to avoid permeation distillation, improve stripping efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The type of waste water is condensed concentrated ammonia water with an ammonia nitrogen content of 10000mg / L, and a compound decolorizing agent is added according to the ratio of g / mL to 10:10000. The compound decolorizing agent is composed of calcium hydroxide, sodium hydroxide, activated carbon and fly ash according to the weight It is obtained by mixing 3:2:3:1. Then add the heavy metal scavenger HMC-M1 according to the solid-liquid ratio g / mL of 2:10000, stir at a speed of 200r / min for 40min, and then filter and ultrafilter in sequence. The pH of the pretreated wastewater is 11, and it is sent to the stripping tower. The waste heat and steam in the production are used to heat the air blown by the blower. The hot air is continuously blown into the wastewater, and the ammonia nitrogen in it is stripped into ammonia gas. Through the hydrochloric acid absorption tower, it is converted into ammonium chloride. The concentration of ammonia nitrogen in the waste water aft...

Embodiment 2

[0051] The type of wastewater is cleaning APT wastewater with an ammonia nitrogen content of 5000mg / L. According to the ratio of solid to liquid g / mL of 15:10000, a composite decolorizing agent is added. The composite decolorizing agent is composed of calcium hydroxide, sodium hydroxide, activated carbon and fly ash according to the weight It is obtained by mixing 3:2:3:2. Then add the heavy metal scavenger according to the solid-liquid ratio g / mL of 3:10000, stir at a speed of 300r / min for 35min, and then filter and ultrafilter in sequence. The pH of the pretreated wastewater is 12, and it is sent to the stripping tower. The waste heat and steam in the production are used to heat the air blown by the blower. The hot air is continuously blown into the wastewater, and the ammonia nitrogen in it is stripped into ammonia gas. Through the hydrochloric acid absorption tower, it is converted into ammonium chloride. The concentration of ammonia nitrogen in the stripped wastewater wa...

Embodiment 3

[0054] The type of waste water is condensed concentrated ammonia water with an ammonia nitrogen content of 20000mg / L, and a compound decolorizing agent is added according to the solid-liquid ratio g / mL of 20:10000. The compound decolorizing agent is composed of calcium hydroxide, sodium hydroxide, activated carbon and fly ash according to the weight It is obtained by mixing 4:2:3:1. Then add the heavy metal scavenger according to the solid-liquid ratio g / mL of 2.5:10000, stir at a speed of 500r / min for 30min, and then filter and ultrafilter in sequence. The pH of the pretreated wastewater is 11, and it is sent to the stripping tower. The waste heat and steam in the production are used to heat the air blown by the blower. The hot air is continuously blown into the wastewater, and the ammonia nitrogen in it is stripped into ammonia gas. Through the hydrochloric acid absorption tower, it is converted into ammonium chloride. The concentration of ammonia nitrogen in the stripped w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com