An automatic demoulding punch

A technology of automatic demolding and punching, which is applied to storage devices, metal processing equipment, stripping devices, etc., to facilitate mold change, save operators, and reduce labor intensity and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

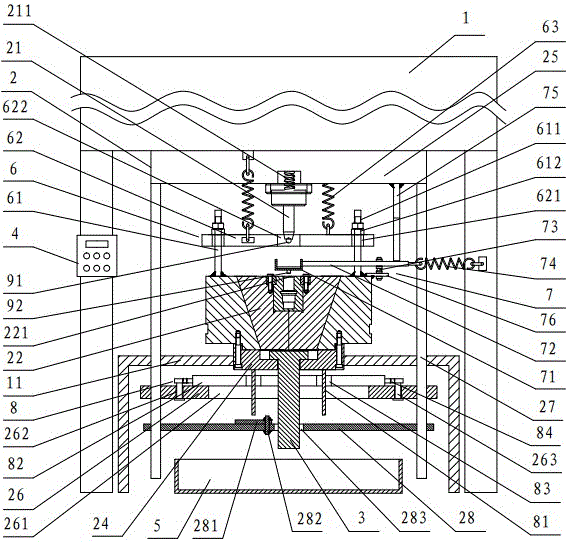

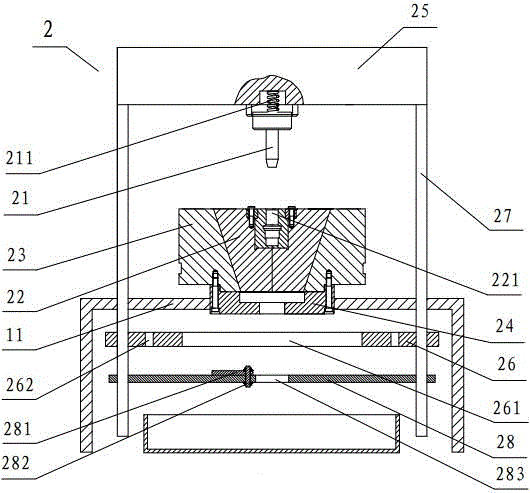

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

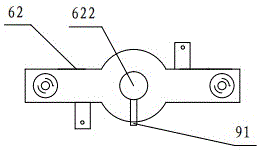

[0023] see figure 1 with figure 2 As shown, the automatic demoulding punching machine includes a punch frame 1, a mold frame 2, a top mold rod 3, a program controller 4 and a trough 5, and the mold frame 2 is provided with a demoulding mechanism 6, a material receiving mechanism 7, and a top mold mechanism 8 and fuel injection pipe 9. Described punch frame 1 is provided with workbench 11, and described die frame 2 is provided with punch 21, die 22, is arranged on die cylinder 23 outside die 22, is affixed to die base 24 below die 22, Die frame upper plate 25 and mold frame lower plate 26, the suspender 27 that connects mold frame upper plate 25 and lower plate 26, and the mold changing top plate 28 that two ends connect the lower end of suspender. The punch 21 is provided with a punch spring 211 and is fixedly connected to the upper plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com